Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-6652

Review Article(ISSN: 2637-6652)

Natural Gas Pipelines Leakage, Toxicity and its Safety Measures Volume 1 - Issue 2

Papiya Mandal*, Rashmi Misra and Poonam Kumari

- CSIR-National Environmental Engineering Research Institute, India

Received: March 09, 2018; Published: March 14, 2018

Corresponding author: Papiya Mandal, Delhi Zonal Centre, CSIR-National Environmental Engineering Research Institute, Delhi, India

DOI: 10.32474/MAOPS.2018.01.000110

Abstract

A fugitive emission of natural gas during the extraction of oil and gas and its transportation through the pipeline has potential threat to the environment. Natural gas (NG) is the mixture of hydrocarbon gases consisting primarily of methane and other varying hydrocarbons, a small fraction of carbon dioxide, hydrogen, nitrogen, hydrogen sulphide and rare trace gases like helium, neon, xenon etc. The colorless and odorless NG has a wide range of applications as a cleaner fuel. The rapid urbanization, industrialization and economic growth all over the world demand the increasing transportation capacity of NG. Though the transportation pipeline are laid with well-equipped sophisticated technology and leak detection sensors, however still there are risk factor associated for leakage of the gases and explosion. The impacts of man-made disaster are in terms of deaths, injury, losses in economics, property and also having the adverse effect on ecology. The integrity of the NG pipeline system can be achieved by adopting continuous sophisticated up gradation technology. It also requires operation and maintenance of the pipeline at regular interval.

Abbrevations: NG: Natural Gas; CNG: Compressed Natural Gas; PNGRB: Petroleum and Natural Gas Regulatory Board

Introduction

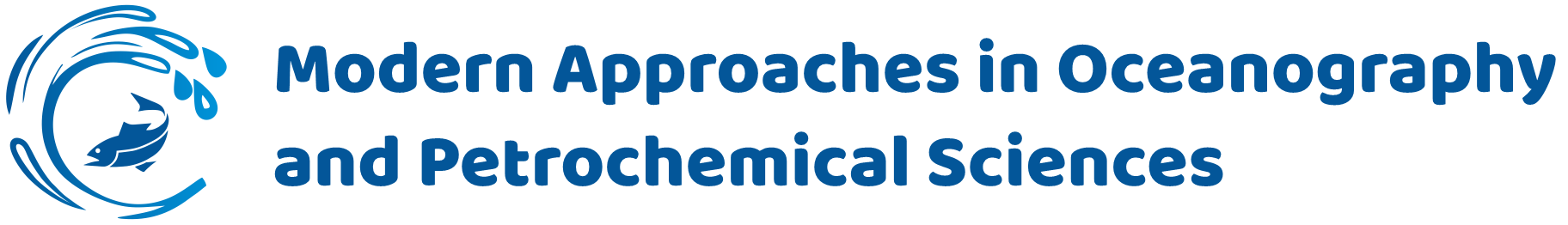

Figure 1: The composition of natural gas and its composition in percentage

Urbanization, industrialization and economic growth of India are exerting the tremendous pressure on the natural resources.This increases the frequency and intensity of disaster, especially man-made disaster in the developing country like India due to large population density, borderline economic status of the vulnerable population and inadequate adjustment of capacity building.Sometimes, a natural disaster may not be averted; however man-made disasters can definitely be controlled by taking adequate preventive actions and preparedness. The leakage of NG through pipeline is man-made disaster, which is most common and has major problem in industrial, commercial and residential sectors in India. NG has wide application as cleaner fuel in power driven vehicles like CNG (compressed natural gas) buses, cars, etc. The chemical formula of NG is CnH2n+2, (n=1, 2.. etc.). The components, structure and its percentage in NG is shown in (Figure 1). NG mainly consists of a high percentage of CH4 gas (60-90%). Odorless, invisible CH4 gas is highly combustible and clean burning in nature, and highly explosive under pressure. NG easily cannot mix-up and disperses in the atmosphere, which may lead to suffocation as well as fire explosion. Though NG is highly useful but their leakages have serious toxicological impacts on environment and human health. So it is essential to control the leakage of NG to protect people, ecology and environment.

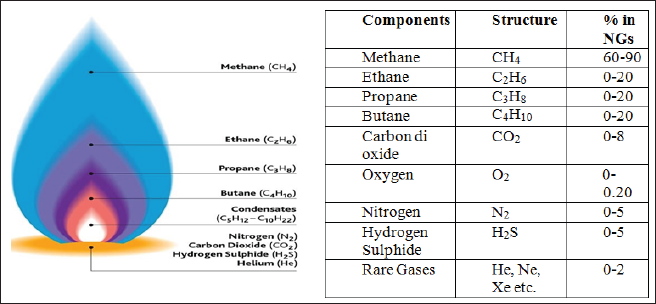

Natural Gas -Production, Transmission & Distribution (Sector-Wise Demand and Production of Natural Gas)

India has limited reserves of NG. The production of NG in India in the month of January, 2017 was 2,738 million standard cubic meter (mmscm) which was higher by 11.9% as compared to January, 2016 (2,447 mmscm) [1]. Sector wise demand, production, transmission and distribution process of NG in India is shown in (Figure 2). The increasing demands for uses of NG at various sectors include electricity generation, fertilizer production, commercial, small, medium and large scale industries and residential sector. The extraction of NG, treatment and transportation through pipelines are tedious and costly phenomena. NG is extracted through gas wells in raw form and oil and water portions are separated. Oil components are treated in a gas processing plant in which nonhydrocarbon gases are removed.

Figure 2: Sector wise demand, production, transmission and distribution process of NG in India

NG is colorless, odorless and flammable gas, which are compressed to liquid at very low temperature. Odorant like ethyl mercaptan are mixed with gases so that leakage can easily detect through pungent smell installing a gas leakage detection system in a critical zone or sector is another alternative to identify the leakage of NG from storage and pipelines.

Intricacies of NG Pipeline Network System

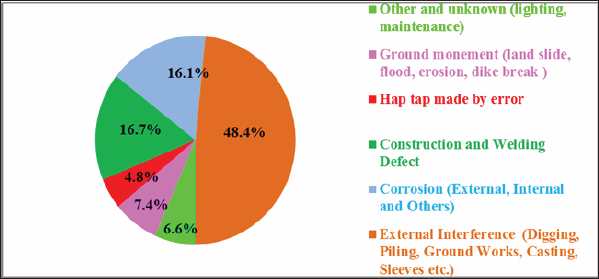

The pipelines of NG are mostly laid in the combination of underground and overhead network system. It consists of compressor stations, isolation valves, relief valves, leak detection system, receivers, control system and sometimes casting sleeves under road and rail crossing. NG pipeline network system are damaged due to external interference, corrosion, construction defect/ material failure, hot tap made by error, ground movement etc [2]. Transportation of NG requires provision for protection of hazardous properties of NG, quantity of NG to be released and its effects and periodical maintenance of pipeline- accessories. The intensity of damage due to leakage of NG would lead to fire hazard. Fire hazard causes burning of gas/oil, which produces heat, light and often smokes (mixture of soot particle, toxic gases, water vapor etc.) and flames. This type of critical situation arises when NG is mixed with appropriate concentration of air or oxygen in the presence of ignited source in atmospheric environment. The primary failure cause distribution in percentage is shown in (Figure 3). Fire and explosion causes accidents mostly in refineries, petrochemical, gas processing, terminal, and offshore facilities which are attributed due to mechanical issues, process upset, and operational error. Flammable material releases in the form of a fireball, pool fire, flash fire, flare or jet fire, and an unconfined vapor cloud explosion [3]. The similar types of anthropogenic disaster effect in term of the injury, loss of life, damage of property, ecology and environment. Few major disasters occurred till date since 1984 due to gas/oil leakage and fire hazards in India is presented in (Table 1).

Figure 3: Primary failure cause distribution in percentage.

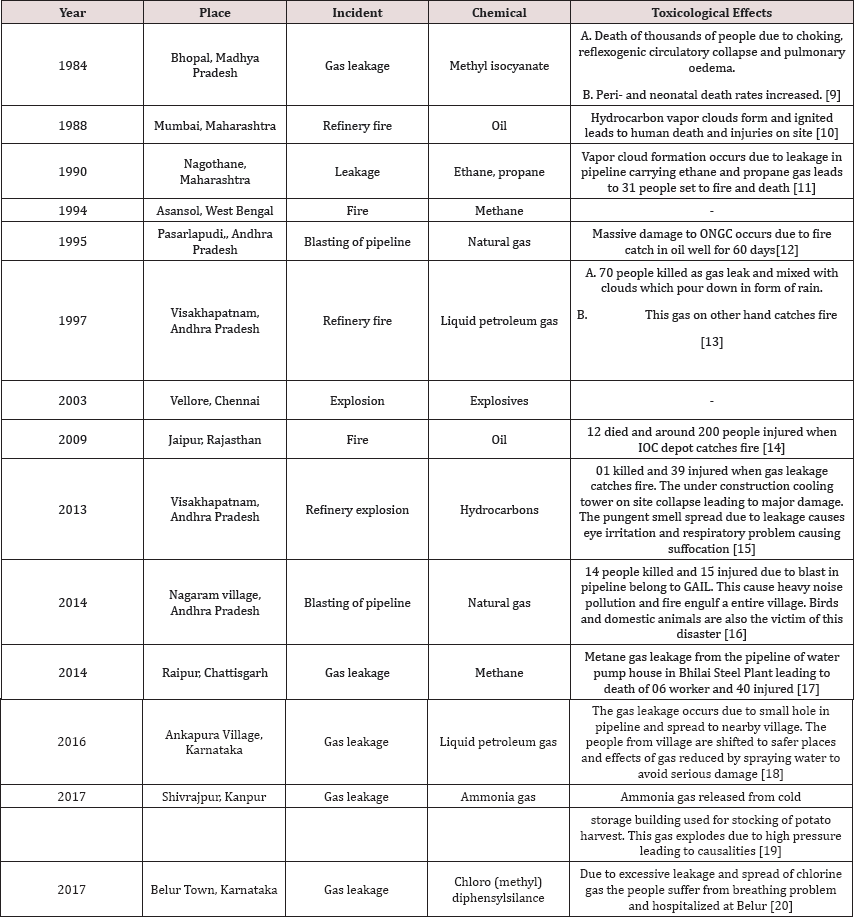

Table 1: Few Major Disaster Due Gas/Oil Leakage and Fire in India

Remedial Measures for the Safety of Ng Pipelines

The statuary compliances are already established by Govt. of India for safety of NG pipelines in terms of construction, operation and maintenance, which has to be followed strictly by every oil and gas company [4, 5]. The statuary compliances are as below

a) Petroleum and Natural Gas Regulatory Board (PNGRB) Act 2006

b) Guidelines for Environmental clearance specially of new projects - 1981

c) The Environment (Protection) Act 198

d) Water (Prevention & Control of Pollution) Act 1974

e) Air (Prevention & Control of Pollution) Act 1981

f) The Petroleum and Mineral Pipelines (Acquisition of Right of Users in Land) Act 1962

g) Manufacture, Storage & Import of Hazardous Chemical Rules - 1989

h) National Highway Act 1956

i) Railways Act 1989

j) OISD (Standard 226 - Natural Gas Transmission Pipeline and City Gas Distribution Network)

k) ASME 31.8 (Gas Transmission and Distribution Piping System)

Safety for Leakage of NG Pipelines

Safety from leakage of NG pipelines is the most essential requirements. Safety can be maintained by taking following precautions in India.

a) Pipeline is having three layers of polyethylene external coating. Every pipeline is properly marked which provides information about the transported materials and emergency phone number?

b) Liquid pools, discolored of pipe materials, bubbling in wet or flooded area, or fire coming from the ground or pipe is a indicator of a pipeline leakage. Immediate identification of pin holes, leakage from valves, cracking of pipes is to be made for safe transportation of NG.

c) Sometimes sound of leaking of gas from pipelines can make possible by listening or hearing a quiet hissing of loud roar. It also depends on the volume of gas leaking from the pipelines.

d) An unusual smell, petroleum odor, or gaseous odor will sometimes serve as a indicator to detect pipeline leakage. Mercaptans due to its odorant properties added in NG for detection of leakage.

e) Installation of casing pipes at all the crossing and highway crossing as per International Standards.

f) Automatic fire detection and suitable fire extinguisher installed at the critical sections.

g) Provision for cathodic protection system for pipeline against corrosion.

h) Corrosion sensing probes for monitoring external corrosion rate.

Various Phases to Minimize Process Leakage and Fire

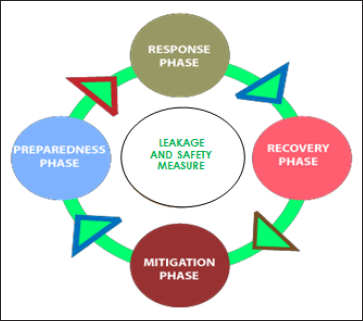

Figure 4: The various phases of leakage and safety measures

The leakage of NG and fire hazard are preventable but it requires routine checkup and maintenance of the NG processing and its transportation system. Various phases viz preparedness phase, response phase, recovery phase and mitigation phase to minimize process leakage and fire safety measures are shown in (Figure 4).

Toxicological Impacts of Natural Gas Leakage

NG is an asphyxiant that reduce oxygen in air causing suffocation. The varying toxicological adverse effects on environment and human health of NG are as follows

Environmental Effects: NG leak and explode to produce large water vapor leading to humid atmosphere. This is a favorable condition for growth of multiple viruses and bacteria. It also produces toxic chemicals fumes and greenhouses gases may cause serious damage to various environmental entities [6].

Human Health Effects: NG is an asphyxiant it may cause unconsciousness, brain injuries and even death due to oxygen depletion. The combination of various chemicals may lead to various diseases. These gases have both short term and long term effects on human health which directly correlates with the nature of leakage, combination of gases contaminants, dispersion area of gas, concentration etc. The following are few common human health impacts of NG leakage.

Short Term Health Effects: Respiratory Tract Disorders (shortness of breath, coughing, wheezing, runny nose, respiratory irritation, asthma, bronchitis, pneumonia), Cardiovascular System Disorders (heart disease), Gastrointestinal System Disorders (diarrhea), Immune System Disorders (immune suppression), Dermal Disorders (eye irritation, skin rashes, chemical sensitivity), Psychiatric Disorders (depression, memory loss), Nervous System Disorders (fatigue, headache) and Other (weight loss) [7-20].

Long Term Health Effects: Cancer (lung and bronchus, skin, prostate, bladder, esophagus and stomach, pancreas, intestinal, leukemia, multiple mycelia, secondary cancers), genotoxicity, teratogenecity, the multiple organ disorders such as respiratory tract, gastrointestinal, dermal, musculo-skeletal, psychiatric, nervous, endocrine/nutritional/ metabolic, haematopoetic, genitourinary systems.

Conclusion

Natural Gas (NG) pipeline distribution system needs to be more skillful in India. The occurrence of anthropogenic disaster due to leakage and explosion of gas pipelines are recurrent in country. The integrity of NG pipeline distribution system may be achieved through continuous up gradation from initial stage of site selection, design of pipelines, commissioning, operation and maintenance as per the guidelines of Government of India. Technological up gradation, staff training for standard operating procedure, inspection, maintenance, fire safety and emergency preparedness enhances the safety of pipeline distribution system which may improve overall safety of the pipelines networking system to great extent. Toxicological effects of natural gas leakage and emission may be avoided by eliminating uses of these gases for general purposes.

References

- Economics Times Report (2017) India.

- EGIG Report (2015).

- OH&S Report (2010).

- S. P. Garg (2012) Safety of Natural Gas Pipelines. Gail Report.

- United Nations Report (2014).

- Harmful Effects of Natural Gas in Your Home.

- Erkekoglu P, Giray BK (2010) The Toxicological Outcomes of Oil Spills and Oil Fires. Fabad J Pharm Sci 35:45-58.

- Health Problems Related to Natural Gas Leaks.

- Eckerman Ingrid (2005) The Bhopal Saga-Causes and Consequences of the World's Largest Industrial Disaster. India: Universities Press 113(5): A344.

- R K Saha, S Ray, B R Maity, S Ganguly, D Bhattacharya, et al. (2012) Petroleum refining and petrochemical based industries in eastern India, Allied Publishers Limited.

- D Bradley G Makhviladze, P Sunderland, FTamanini, V Molkov(2013) Fireand Explosion Hazards

- GAIL pipeline blast: CoastalAndhra people seekproper safety measures

- MS Shanker (1997) It Rains Liquid Petroleum.

- 12 dead, over 200 injured in Indian Oil depot fire in Jaipur.

- One dead, 39 injured in Vizag refinery blast.

- 14 killed, 15 injured in gas pipeline blast in Andhra Pradesh.

- Gas leak in Chhattisgarh's Bhilai steel plant, 6 killed, 40 injured.

- Gas pipeline leak in Hassan village.

- Kanpur: Ammonia gas leak causes explosion in cold storage; five killed, several still trapped.

- Chlorine gas leak on Belur outskirts.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...