Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6921

Research Article(ISSN: 2641-6921)

Pull-Off Method for Different Adhesives in A Light Floor Heating System Volume 4 - Issue 1

Jacek Karpiesiuk*

- Expert in Construction and Building Specialties, Bialystok University of Technology, Poland

Received: March 01, 2021; Published: March 18, 2021

*Corresponding author: Jacek Karpiesiuk, Bialystok University of Technology, Government Building Expert in Construction and Building Specialties, Member of the Polish Chamber of Civil Engineers, Wiejska str. 45A, 15-351, Poland

DOI: 10.32474/MAMS.2021.04.000176

Abstract

The light surface heating/cooling system (LSH/CS) creates a structure in which the surface of the thermal insulation is very often covered with metal heat diffusers. These are steel sheets, aluminum sheets, or aluminum foils with various thicknesses. Different types of floors are glued directly to them, no required screeds. For this purpose, you can use various types of adhesives dedicated by manufacturers to glue the thermal insulation layer with aluminum foil or metal heat diffusers with the floor. The most important parameter of the glued layers is their strength perpendicular to the face. It may depend on the influence of the temperature. To check this, various types of adhesives were tested by being put between thermal insulation and a layer of aluminum foil, between tiles and foil heat diffusers, as well as tiles and XPS boards without this foil, using the pull-off method at a temperature of 20-40 ˚C. This allowed us to determine the adhesion values of selected adhesives at the temperature level occurring in the LSH/CS system or light floor system (LFS). Ultimately, adhesives that met the conditions of high adhesion and easy application were selected. The research results may be useful for manufacturers and scientists dealing with the subject of structural or functional bonding of composites.

Keywords: Light floor system, Pull-off method, Aluminum heat diffusers, Thermal tests

Introduction

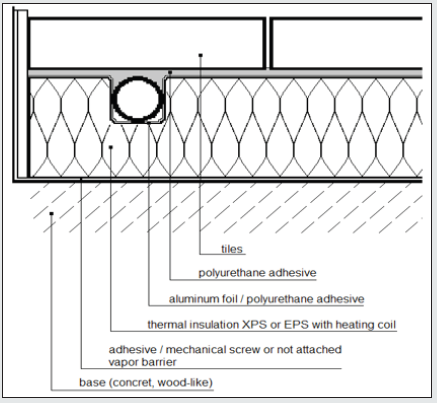

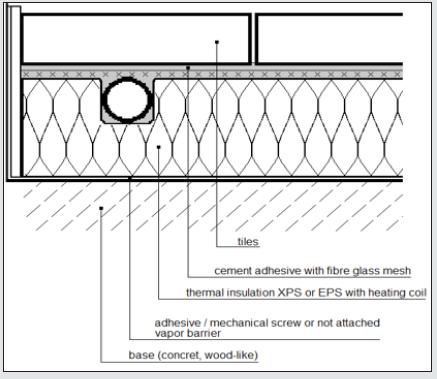

In the LFS system horizontally (on the floor), the metal sheet is usually laid loosely without sticking. Mounting the system on a wall would require attaching it. On the other hand, aluminum foils in SLP are always attached to thermal insulation both horizontally and vertically. This article describes the experimental pull-off tests on a lightweight floor system (SLP) without screeds. The results of previous experiments in which the detachment of C2S1 and C2S2 class cement adhesives and some polyurethane adhesives [1-3] were tested, allowed to determine their strength at a laboratory temperature of 20˚C . There, adhesive cement mortars were connected to the substrate of extruded polystyrene (XPS) or expanded EPS with terracotta, and two polyurethanes glued to the XPS/EPS layers with aluminum foil or aluminum heat diffuser with terracotta. In this study, a greater number of different types of adhesives, connecting tiles with XPS or aluminum foil and aluminum heat diffuser with XPS/EPS substrate were tested, at the temperature of 20 - 40˚C. An example of a vertical cross-section of a lightweight floor system with and without aluminum foil is shown in (Figures 1 & 2).

Research Methodology

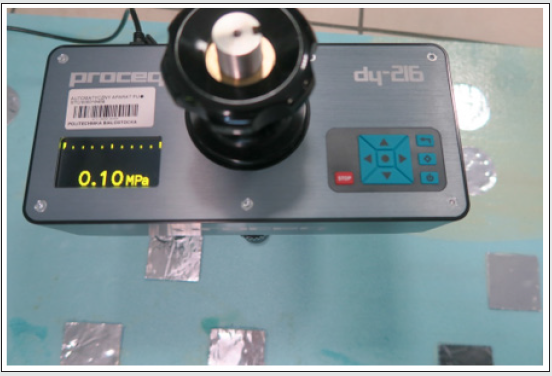

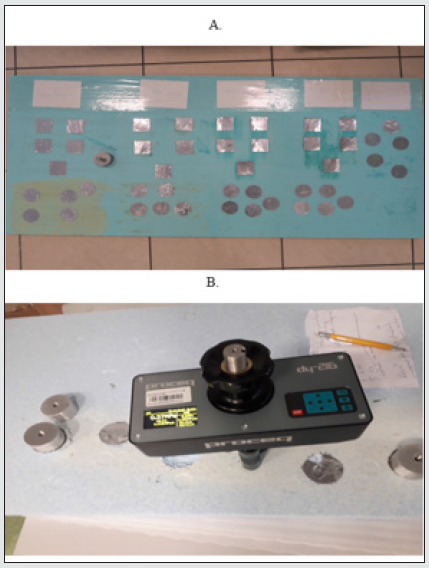

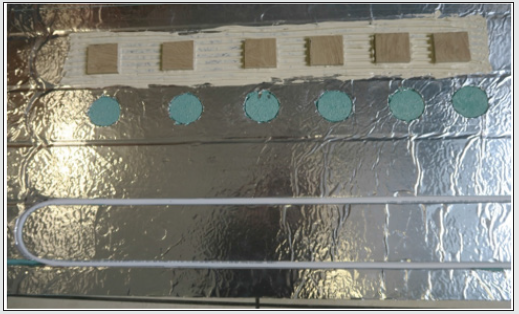

The pull-off test was performed in accordance with the standard [4], using the Proceq dy-216 FAMILY machine (Figure 3). The research focused on a light floor system, where the underlay material was XPS 300 thermal insulation with a rough surface and EPS 200, to which an aluminum foil with a thickness of 0.06 mm was glued. The samples of aluminum foil mounted on the XPS are shown in (Figure 4), and the tiles glued to the aluminum foil are shown in (Figure 5).

The following industrial adhesives were used to glue the aluminum foil with XPS/EPS insulation:

- universal SPRAY-KON S2O2, 4Technic Company

- contact Spray Glue EXTRA STRONG 60022, Tesa Company

- universal 3M Super 77 aerosol, 3M Company

- polyurethane, two-component SikaForce-7710 L100, Sika Company

- polyurethane, one-component SikaBondT8, Sika Company

- Euroterm hot-melt ET 6S

- double-sided adhesive tape 396008 with a PET Rollfix, carrier based on acrylic adhesive

- Loctite UK 8103+ 5400 (Henkel)

- Loctite UR 7225 (Henkel)

The following adhesives were used to glue the layer of tiles with aluminum foil on XPS base or directly with XPS:

- PCI Nanolight (Basf cement)

- Loctite UK 8103+ 5400 (Henkel)

- Loctite UR 7225 (Henkel)

- SikaBond T8

- SikaCeram255

- SikaForce 7710

Figure 4: The pull-off research stands for adhesion tests, A: on XPS insulation, B: on EPS insulation.

Figure 5: The pull-off research stands to check adhesion of ET 6S adhesive on XPS insulation board and tiles, glued by BondT8 adhesive to aluminum foil..

The temperature load was obtained using an Elektra UltraTec 10/90 heating cable with a capacity of 10 W/m. It was inserted into the inside of the Herz-FH-Rohr PE-RT / AL / PE-RT 16 x 2.0 heating pipe. The temperature was measured using the Elektra OCD2 1999 electronic thermostat with a floor sensor with an accuracy of 0.5 ˚C.

Results of Research

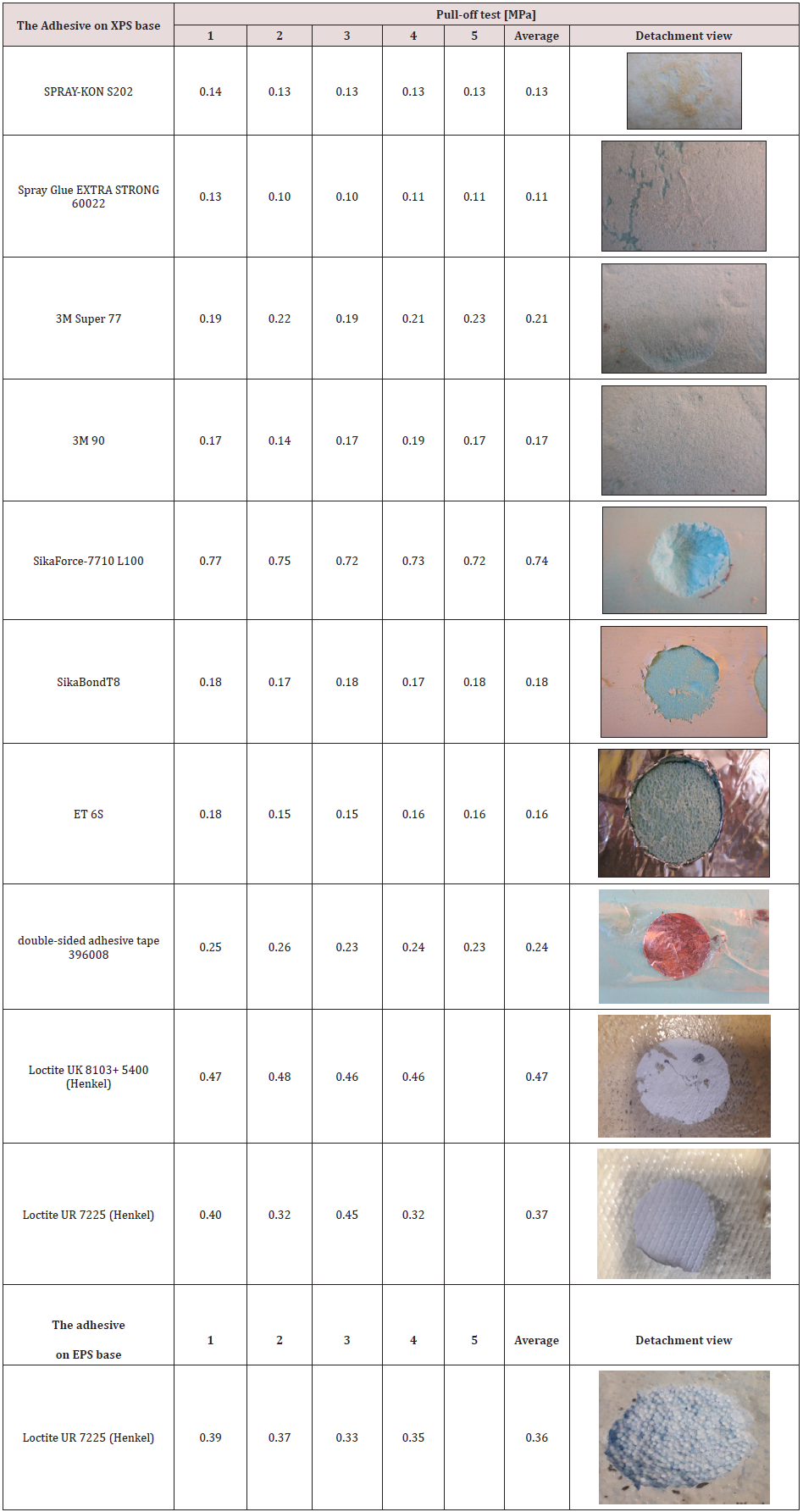

Table 1: The results of the pull-off method in various types of adhesives, located between the aluminum foil and the XPS 300 or EPS 200 thermal insulation.

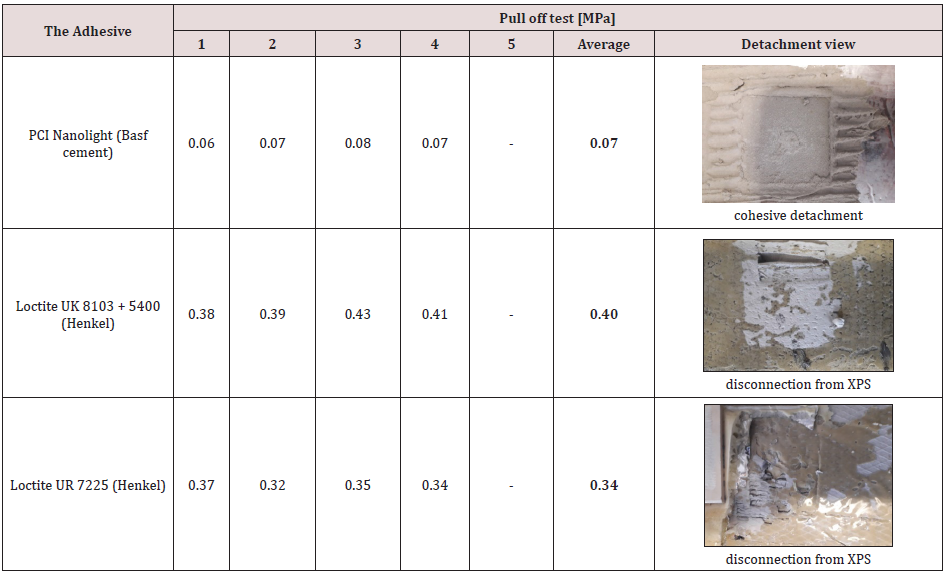

Table 2: The results of the pull-off method on various types of adhesives, located between the tile and aluminum foil on the XPS 300 base, at 20 ˚C.

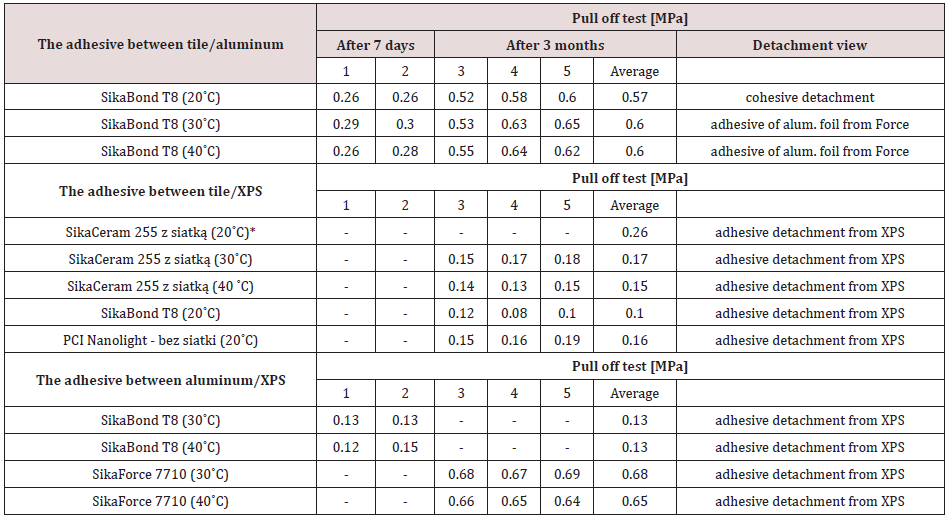

Table 3: The results of the pull-off method in the light floor system, with or without heat diffusors, at the 20-40˚C.

The adhesion results of various adhesives between the rough XPS 300 or EPS 200 insulation and the aluminum foil with a thickness of 0.06 mm were performed on 4-5 samples each at a temperature of 20 ˚C and are presented in (Table 1). The results of the adhesion of tiles to aluminum foil on the XPS board are shown in (Table 2, Table 3) presents the results of the pull-off method in the light heated floor system both with and without heat diffuser, using the temperature from 20 to 40 ˚C, where the following layers were joined:

- tile attached to aluminum by Sika Bond T8 adhesive

- tile attached to the XPS 300 thermal insulation by Sika Ceram 255 cement-based adhesive mortar, reinforced with 320 g/m2 mesh, and Sika Bond T8 or PCI Nano light (only at 20 ˚C)

- aluminum foil attached to the XPS 300 insulation by Sika Bond T8 or Sika Force 7710

- It is worth supplementing the information provided in the above tables with that contained in the conclusions of the article [4], where it was found that after the tests of pull-off and shear strength, the optimal structure of a lightweight floor in terms of economy and strength, which meets the criteria of more durable dispersion adhesives according to [5], is composed of:

- rough XPS thermal insulation

- C2S1 cement adhesive mortar

- terracotta tile

Conclusion

When the tiles were joined to the XPS300 insulation base during the performed pull-off tests, they showed the following average C2S1 adhesive strength in dry conditions and temperatures up to 40 ˚C:

- 0.26 MPa for XPS in pull-off method, at 20 ˚C

- 0.17 MPa for XPS in pull-off method, at 30 ˚C

- 0.15 MPa for XPS in pull-off method, at 40 ˚C

SikaBondT8 and PCI Nanolight adhesives – with no reinforce by mesh at 20 ˚C have lower adhesion - (average up to 0.16 MPa), about 40% less than C2S1 adhesive. SikaBondT8 at 30 ˚C and 40 ˚C when joining aluminum and XPS shows five-times less adhesion than SikaForce 7710 and its use on such a substrate should be subject to numerical calculations. On the other hand, it maintains a stable pull-off strength at these temperatures, when tiles and aluminum are combined by it.

Loctite UR 7225 polyurethane adhesive on both XPS and EPS200 hydro substrates, similarly to SikaForce-7710 L100 and Loctite UK 8103+ 5400 adhesives on XPS substrate, meet the minimum values of adhesion adopted in the Waterpanel XL and EL Declaration of Performance equal 300 kPa [8, 9]. In the final selection of the use of adhesives, in addition to pull-off strength, the easiness of use should also be considered. In this case, preference should be given to the one-component polyurethane adhesive Loctite UR 7225, due to faster and easier application when compared to the two-component materials in the LFS system with heat diffusers.

Acknowledgment

The authors of this article would like to thank Ceramika Paradyz Poland, Sika Poland, Loctite - Henkel Poland, Euroterm and 3M Poland for providing material to research as well as Mrs. Anna Zakowicz, from the Bialystok University of Technology for technical cooperation. The research was performer as part of author’s own work from the Bialystok University of Technology No. WI/WBIIL/ 7/2020, financed from the subsidy provided by the Ministry of Science and Higher Education.

References

- Karpiesiuk J, Chyzy T (2017) The results of selected interface strength of lightweight radiant heater with dissipating elements. Civil and Environmental Engineering. TCEIA 8(3): 123-132.

- Karpiesiuk J, Chyzy T (2017) The results of selected strength tests of the adhesive layer of radiant heater with lightweight construction. Civil and Environmental Engineering. Degruyter 8(4): 165-171.

- Karpiesiuk J, Chyzy T (2018) The interface strength tests of lightweight floor with heating coil. Building Materials 12: 68-70.

- (2017) Adhesives for ceramic tiles - Part 2: Test methods: PN-EN 12004-2: 03.

- Karpiesiuk J (2019) Analysis of Tensile and Shear Strength Research Results of a Deformable Adhesive in a Lightweight Floor System. Mod App Matrl Sci 1(5): 140-145.

- Karpiesiuk J, Chyzy T (2020) The effects of various parameters on the strengths of adhesives layer in a lightweight floor system. Open Engineering 10: 443-453.

- (2012) PN-EN 12004+A1: Adhesives for tiles-Requirements, evaluation of conformity, classification, and designation.

- Declaration of Performance Elektra Kardo, DoP Number PL-3.2020. Unique identification code of the product-type Kardo WATERPANEL XL. 01.12.2020.

- Declaration of Performance Elektra Kardo, DoP Number PL-4.2020. Unique identification code of the product-type Kardo WATERPANEL EL. 01.12.2020

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...