Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6921

Review Article(ISSN: 2641-6921)

Analysis of Tensile and Shear Strength Research Results of a Deformable Adhesive in a Lightweight Floor System Volume 1 - Issue 5

Jacek Karpiesiuk*

- Department of Building Expert in construction and building, Bialystok University of Technology, Poland

Received:June 26, 2019; Published: July 05, 2019

*Corresponding author:Jacek Karpiesiuk, Department of Building Expert in construction and building, Bialystok University of Technology, Poland

DOI: 10.32474/MAMS.2019.01.000122

Abstract

The article statistically analyzes experimental tests on a light floor system (LFS) without screeds. The results of over two years of experiments in which the strength of C2S1 and C2S2 cement deformable adhesive for tensile and shearing were tested allow to determine the confidence interval for the expected value of these strengths along with determining the relative precision of the estimation. In the article, only the C2S1 adhesive was analyzed because it meets two important criteria. It has relatively high mechanical strength and is more economically advantageous (purchase price 2-3 times lower than C2S2). The obtained data also allowed to verify the hypothesis regarding the minimum strength of the C2S1 adhesive during the pull-off test and shear strength.

Keywords: Deformable adhesive C2S; Statistical analysis; Lightweight floor system; Experimental research

Introduction

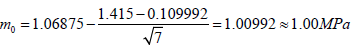

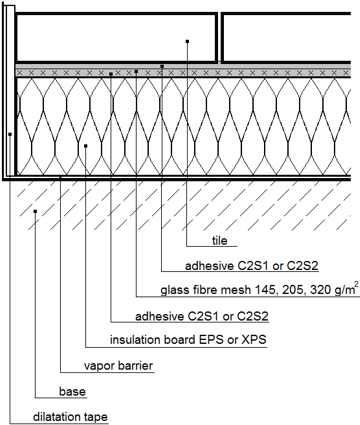

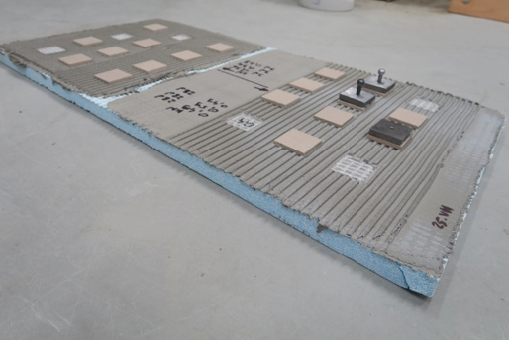

Tests of tensile and shear strength of mortars adhesive, after the preparation of samples, took place from July 2016 to October 2018. Tensile strength tests of adhesives perpendicular to the frontal surfaces (tensile strength) were carried out in dry conditions and water absorption in accordance with the standard [1]. The shear strength of adhesives was made by using PressoMess according to the manufacturer’s instructions. These tests were described in [2-4], and concerned a lightweight floor system, where the underlaying material was EPS 200 hydro or XPS 300 thermal insulation with a rough or waffle surface. The floor made from tiles was directly attached to the insulating underlay using deformable mortars adhesive of the C2S1 or C2S2 class, reinforced with a glass fiber mesh of various weights from 145-320g/m2. The test results indicate their insignificant dependence on the weight of the mesh embedded in the adhesive, as described in [4]. An exemplary vertical section of a light floor system is shown in Figure 1, and photographs of test stands in (Figures 2-4). The results of all tests are given in tables 1 and 2. In the conclusions of the article [4], it was found that after the tests of tensile and shear strength optimal construction of a lightweight floor in terms of economic and strength, meeting even the criteria for stronger dispersion adhesives acc. [5] is composed of:

Table 1: The results of pull-off and shear strength tests of the C2S1 adhesive in the entire population with EPS and XPS insulating substrate with various humidity conditions.

Table 2: The results of pull-off and shear strength tests of the C2S2 adhesive in the entire population with EPS and XPS insulating substrate with various humidity conditions.

Figure 1: Cross-section of a lightweight floor system with XPS or EPS thermal insulation.

Figure 2: An example of a research stand, for adhesion measurements, using the pull-off method.

Figure 3: An example of a research stand, for adhesion measurements of C2S1 and C2S2, using the pull-off method and shear strength tests.

Figure 4: PressoMess for shear strength testing.

a) XPS rough thermal insulation

b) Cement adhesive type C2S1

c) Tiles

For this reason, the article deals with the analysis of the light floor system (LFS) with the adhesive layer of the C2S1 class on various substrates to:

I. Determine the confidence interval for the value of the expected tensile and shear strength of the C2S1 adhesive together with the determination of the relative precision of the estimation.

II. Verify the hypothesis regarding the minimum strength of the C2S1 adhesive for the pull-off method and shear strength tests.

Results of Calculation

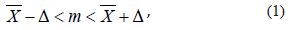

Determination of the confidence interval for the value of the expected tensile and shear strength of the C2S1 adhesive together with the determination of the relative precision of the estimation, according to [6]. Table 3 lists the test results from the sample, after rejecting the selected extreme stress values given in Table 1, considered as errors in sample preparation. Based on these data, the necessary calculations were made according to designs (1), (2) and they were placed at the bottom of Table 3. The calculation assumes a 90% confidence level due to the fact that assuming a 95% confidence level, the relative precision of estimation in some of the test samples was greater than 10%. The calculation was based on the formula for the range of interval estimation of the expected tensile and shear strength value for the C2S1 adhesive mortar (1) and the formula for the relative precision of estimation δ (2).

Table 3: The results of pull-off and shear strength tests for the C2S1 adhesive from the sample together with the relative δ data and the absolute precision estimation Δ .

Where:

δ – relative precision of estimation

mo – assumed expected value

m – expected value

X – the arithmetic mean of the random sample

Δ – absolute precision of estimation

t𝛼,s – reading from Student’s t-charts (for α=0,1)

Sx – standard deviation from the sample

n – random sample size

a. pull-off (dry) with EPS: 0.1955 < m < 0.2260 MPa

b. pull-off (wet) with EPS: 01850 < m < 0.2198 MPa

c. shear with EPS: 0.5174 < m < 0.6160 MPa

d. pull-off (dry) with XPS: 0.2530 < m < 0.2888 MPa

e. pull-off (wet) with XPS: 0.2028 < m < 0.2420 MPa

f. shear with XPS: 0.9900 < m < 1.1475 MPa

The designated intervals are one of those that can be treated with 90% certainty to cover the expected strength value for C2S1 in individual research models. Comparing the obtained results, it can be claimed that C2S1 characterizes by the greater shear and tensile strength is characterized C2S1 with the XPS insulation than the EPS insulation in dry conditions. It confirms the assumption contained in the article [4].

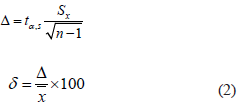

Verification of hypotheses regarding minimum C2S1 adhesive strength according to [7], using the pull-off method in dry conditions with EPS insulation.

Based on the obtained results, we can hypothesize that the expected value of the C2S1 strength adhesive with EPS isolation using the pull-off method (dry conditions) is higher than 0, 1955 MPa.

H0: m = 0.1955 H1: m > 0.1955

Using the t-test to verify the null hypothesis we get:

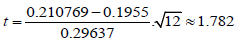

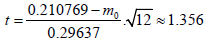

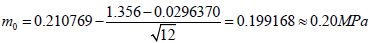

Comparing the obtained result with the critical value t2𝛼,s = t0.2; 12 = 1.356 read from the Student’s t-charts [6] at the righthanded alternative hypothesis, we can conclude that the test result is higher than the critical value (located in the critical area), which authorizes the rejection of the null hypothesis in favor of the alternative hypothesis. This means that for 90% certainty, the expected strength value of the C2S1 adhesive in EPS isolation using the pull-off method (dry conditions) is higher than 0.1955 MPa. In order to estimate the minimum strength of the C2S1 adhesive with EPS isolation using the pull-off method (dry conditions), with the results obtained from the carried-out samples, for α = 0.10 we can make calculations using the formula for the t-test:

Hence

The obtained result can be treated with 90% certainty as the minimum strength of the C2S1 adhesive with EPS insulation for pull-off method with dry conditions.

Using the above procedure, the data from Table 3 and the formulas were determined the minimum strength of the C2S1 adhesive in other performed tests. They are:

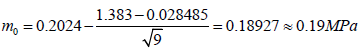

a) in the pull-off method (wet conditions) with EPS insulation

The obtained result can be treated with 90% certainty as the minimum strength of the C2S1 adhesive with EPS insulation for shear strength. Critical value krytyczna t2𝛼,s = t0.2 ; 8 = 1.397 read from the Student’s t-charts at the right-handed alternative hypothesis.

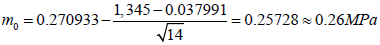

c) in pull-off method (dry conditions) with XPS insulation

The obtained result can be treated with 90% certainty as the minimum strength of the C2S1 adhesive with XPS insulation for pull-off method (dry conditions). Critical value t2𝛼,s = t0.2 ; 14 = 1.345 read from the Student’s t-charts at the right-handed alternative hypothesis.

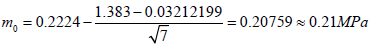

d) in pull off method (wet conditions) with XPS insulation

The obtained result can be treated with 90% certainty as the minimum strength of the C2S1 adhesive with XPS insulation for pull-off method (wet conditions). Critical value t2𝛼,s = t0.2 ; 9 = 1.383 read from the Student’s t-charts at the right-handed alternative hypothesis.

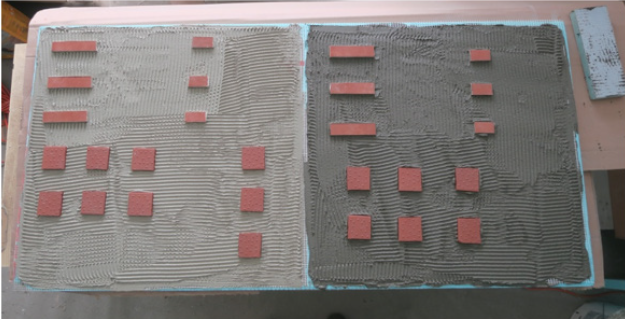

e) in shear strength with XPS insulation

The obtained result can be treated with 90% certainty as the minimum strength of the C2S1 adhesive with XPS insulation for shear strength. Critical value krytyczna t2𝛼,s = t0,2 ; 7 = 1,415 read from the Student’s t-charts at the right-handed alternative hypothesis.

Conclusion

The statistical analysis of the C2S1 type adhesive strength for pull-off method in dry and wet conditions and shear strength in dry conditions, which combines the tiles of two types of EPS 200 or XPS 300 insulation substrate, showed that:

a) A higher minimum shear and tensile strength was demonstrated using an XPS insulating substrate relative to EPS

b) Minimum strengths of the C2S1 adhesive, which can be treated with 90% certainty

1. depending on the insulating base:

a. 0.20MPa with EPS insulation for pull-off method in dry condition

b. 0.19MPa with EPS insulation for pull-off method in wet condition

c. 0.26MPa with XPS insulation for pull-off method in dry condition

d. 0.21MPa with XPS insulation for pull-off method in wet condition

e. 0.53MPa with EPS insulation for shear strength

f. 1.00MPa with XPS insulation for shear strength

Acknowledgement

The author of the article would like to thank Mrs. Elzbieta Golabeska from the Bialystok University of Technology for providing statistical literature. The research was carried out as part of my own work from Bialystok University of Technology No. W/WBIIŚ/15/2019, financed from the subsidy provided by the Ministry of Science and Higher Education.

References

- (2017) Adhesives for ceramic tiles - Part 2: Test methods: PN-EN 12004-2: 03.

- Karpiesiuk J, Chyzy T (2017) The results of selected strength tests of the adhesive layer of radiant heater with lightweight construction. Civil and Environmental Engineering 8(4): 165-171.

- Karpiesiuk J, Chyzy T (2018) The interface strength tests of lightweight floor with heating coil. Building Materials 12: 68-70.

- Karpiesiuk J, Chyży T Effects of testing the strength parameters of the adhesive layer in a light floor system. Open Engineering (to be published).

- (2012) PN-EN 12004+A1:Adhesives for tiles–Requirements, evaluation of conformity, classification and designation.

- Luszniewicz A, Słaby T (2008) Statystyka z pakietem komputerowym STATISTICA PL, wydanie trzecie, zmienione. Wydawnictwo CH Beck, Warszawa, Poland.

- Gołabeska E (2006) Jednowymiarowe analizy porównawcze struktur w: Statystyka w zarządzaniu. pod red A Luszniewicza, wydanie drugie poprawione. Wydawnictwo WSFiZ Białystok, Poland.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...