Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2638-6070

Research Article(ISSN: 2638-6070)

Fortification of Rice with Iron and Zinc-A Tool to Improve Nutritional Profile of Rice for Intended Consumers

Volume 3 - Issue 3Syed Junaid-ur-Rahman1*, Imran Pasha2 and Muhammad Farhan Jahangir Chughtai1

- 1Khwaja Fareed University of Engineering and Information Technology, Pakistan

- 2Faculty of Food Nutrition and Home Sciences, University of Agriculture Faisalabad, Pakistan

Received: August 27, 2020; Published: September 09, 2020

*Corresponding author: Syed Junaid-ur-Rahman, Khwaja Fareed University of Engineering and Information Technology, Rahim Yar Khan, Pakistan

DOI: 10.32474/SJFN.2020.03.000162

Abstract

The present study was carried out on different fortification techniques and salt combinations to select optimum technique and fortificant salt for fortification. Three techniques namely parboiling, dusting and extrusion technology were employed with reference to comparison between them. Four salts namely FeSO4, ZnSO4, ZnO and NaFeEDTA sourcing iron and zinc at different levels were utilized to fortify rice. It was found that best level of fortification for iron and zinc salts is 350mg/kg is 300mg/kg respectively and best suitable salts for fortification of rice are FeSO4 and ZnO. The best technique for fortification is parboiling.

Keywords:Fortification; Rice; Parboiling; Malnutrition; Minerals

Introduction

Rice is important food crop and is consumed all over the world and for more than half of world’s population it is a staple food. More than 90% of rice produced is consumed in Asia pacific; where 60% of world population resides [1]. Due to its high consumption in developing countries it results in severe kind of micronutrient deficiency. Among micronutrients iron and zinc are more deficient in rice profile. Iron has acquires great importance for human health because of its significant role in different metabolic process. It also participates in a variety of functionalities for example oxygen transport to brain and other parts of body, substrate oxidation reactions, electron transfer, DNA replication, hormone synthesis, cell cycle control and repair of damaged cells [2]. Zinc also has a key role in different body functions because it is involved in stabilization of DNA. Zinc deficiency results in depressed immunity which makes susceptible to different infectious diseases [3]. To address this kind of non-functionalities; different fortification techniques are used which are parboiling, dusting and extrusion technology. Parboiling is a hydrothermal treatment which involves three steps; soaking, steaming and drying. On worldwide basis more than 15% of rice produce is parboiled. Parboiled rice is preferred all over the world because of its peculiar taste and aroma [4]. Ohtsubo et al. [5] showed that in dusting technology minerals blended with corn starch powder is sprinkled or coated over rice surface and subsequently which were dried. Extrusion technology use is most prevalent in developed countries. Extrusion technology is a most prevalent technology which has been being introduced in present era to eradicate the ailment of micronutrient deficiency. According to Liu et al. [6] present nutrient deficiency has become a maximum for existing researcher because it has no clinical signs or symptoms. In this technology rice are grinded into floor and micronutrients are mixed. Then, rice dough is passed through extruder which expels the dough through dye by applying high pressure [7].

Materials And Methods

De-husking and milling of rice

The paddy rice was taken from market and was de-husked by yielding brown rice and husk. Then brown rice was milled to remove aleurone layer to produce white rice. After this, rice was sifted to remove dust, dirt and other extraneous material [8].

Parboiling

Paddy rice was cleaned to remove straws, chaff, sand, metal particles and dust. The iron and zinc salts were dissolved in distilled water and paddy was soaked in that water solution for 24-36hrs at ambient temperature. When rice endosperm absorbs water then minerals were also absorbed [9]. After soaking, steaming of rice was performed which leads to gelatinization of starch granules. Then, steamed rice was dried under shade and hardening of gelatinized starch occurs. Therefore, parboiling results in texture’s hardening of rice [10].

Dusting

Brown (unpolished) rice was taken and cleaned properly to remove extraneous matter. The salts for iron and zinc were mixed with corn starch powder to facilitate equal distribution of minerals on rice surface. Then, paste of salts containing corn starch powder was made. After this, rice was soaked in water for about quarter an hour to soften rice surface. Soaking also resulted in easy sticking of corn starch paste on rice surface. At last cornstarch premix was applied on rice surface and rice was dried under shade [1].

Extrusion technology

Extrusion technology is being used all over the world. Rice was grinded into floor and micronutrient salts were mixed in it and dough was made. Then, dough was passed through the dye of extruder under pressure. The dye converts the dough into rice shaped kernels and they were dried to attain hard structure [5].

Determination of minerals

0.5g of sample was taken in digestion flask and 10ml of Nitric (HNO3) and Perchloric acid (HClO4) in ratio of (7:3) was added in it. The sample and acids mixture were heated at 180-200 0C until contents in flask become transparent. Then, the digested content was diluted to 100 ml with distilled water. Finally, the samples were run on Atomic Absorption Spectrophotometer (AAS) to determine increase in iron and zinc content of fortified rice [11].

Results and Discussion

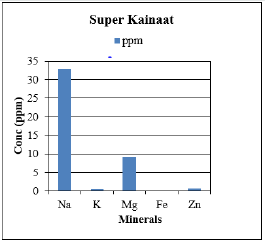

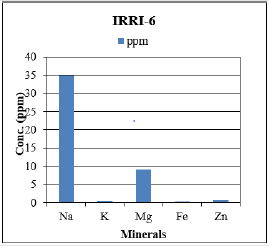

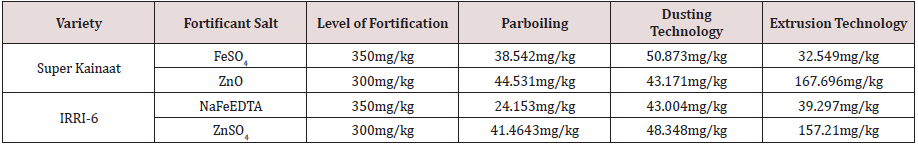

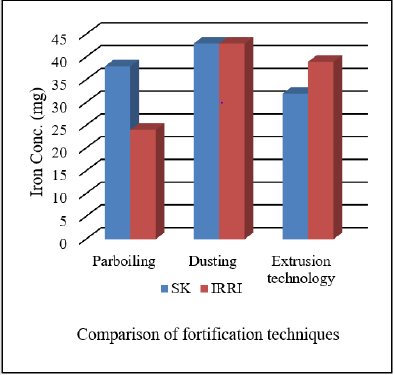

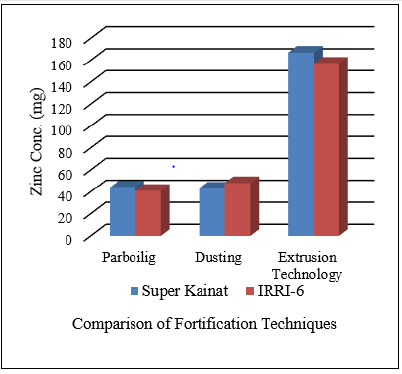

The present research was conducted to fortify rice with vital minerals especially iron and zinc to provide nation a valuable product with respect to nutrition. Two rice varieties i.e. Super Kainaat and IRRI-6 were subjected to three different fortification techniques namely, parboiling, dusting technology and extrusion technology. The initial mineral content of both these two varieties was determined as shown in Figures 1& 2. The mean value for sodium, potassium, magnesium, zinc and iron content of Super Kainaat was 348.63mg, 4.62mg, 91.34mg, 7.42mg and 2.15mg/100g of sample respectively. The mean value for sodium, potassium, magnesium, zinc and iron content of IRRI-6 was 327.59mg, 3.59mg, 91.76mg, 5.88mg and 2.18mg/100g of sample was respectively. After this these two rice varieties were subjected to fortification techniques using two salts combinations to fortify rice. The salts utilized for iron fortification were FeSO4 and NaFeEDTA and for zinc ZnSO4 and ZnO were used. For each salts four levels of applications were designed to fortify rice. In parboiling process there was considerable increase in zinc concentration; the maximum mean value was 44.531mg, 41.4643mg/kg at level of 350mg/kg respectively in Super Kainaat and IRRI-6 respectively. Similarly, iron uptake in parboiling process was maximum at level of 350mg/kg of FeSO4 with reading of 38.542mg and 24.153mg/100g for Super Kainaat and IRRI-6 respectively. In second technique dusting technology the amount of zinc uptake was 43.171mg and 48.348mg/100g at level of 350mg/kg of Super Kainaat and IRRI-6 respectively. In case of iron salts, maximum absorbance was observed at 350mg/kg of FeSO4 and values for iron absorption for Super Kainaat and IRRI-6 were 50.873mg and 43.004mg/kg respectively. In case of extrusion technology the zinc and iron uptake for Super Kainaat and IRRI-6 was 167.696mg, 157.21mg/100g and 32.549mg, 39.297mg/100g respectively. This maximum mineral absorption was observed at the level of 350mg/kg of FeSO4 and ZnO. So, it can be inferred from above mentioned results that optimum salts for iron and zinc fortification are FeSO4 and ZnO. The comparison of difference between two rice varieties is shown in Figures 3&4.

Figure 3: Mean values for Iron content by comparing two rice varieties and three fortification techniques.

Figure 4: Mean values for Zinc content by comparing two rice varieties and three fortification techniques.

Some of the physical properties of rice were significantly affected at higher level of salts concentration. In dusting technology color and aroma of rice at level of 450mg/kg of NaFeEDTA was badly affected and at this level rice become hygroscopic in nature, become moist and dull greenish color was observed. After two weeks at above mentioned level of salt concentration rice’s surface become rough and corrodible. In extrusion technology at higher level of NaFeEDTA foaming, fuzziness and slight green blackish color was observed. In parboiling process no significant alteration in physical properties of rice was under consideration. After application of zinc salts in dusting technology, light brownish color was developed at higher level of ZnSO4 application. Same trend was noted in extrusion technology but characteristics of parboiled rice remain unchanged. The NaFeEDTA and ZnSO4 were found non-significant in increasing mineral content of rice. The uptake of minerals was very high by rice as compared to FeSO4 and ZnO. The NaFeEDTA and ZnSO4 also badly affect colour, grain shape, aroma, taste and overall acceptability was affected badly. Sensory evaluation of iron and zinc fortified rice showed that there were significant differences in rice grain color, whiteness, grain shape and aroma. The rice fortified with iron and zinc was found acceptable at level of 300mg/kg of FeSO4 and ZnO. But higher doses of salts results in distortions of different physical properties of rice like color, aroma, taste, grain shape and grain length. Mean values for iron and zinc uptake is described under Table 1.

Conclusion

The physical and sensory properties of rice were affected at higher level of salt applications. It was observed that at higher concentrations of NaFeEDTA, the color and odour of rice was affected badly. Similarly, colour and aroma of rice was affected by ZnSO4 to lesser extent as compared to NaFeEDTA. The appearance, color, aroma and sensory properties were least affected at higher level of applications of FeSO4 and ZnO. The optimum level for fortification of Iron and Zinc was 350mg/kg and 300mg/kg respectively. The best suitable technique for iron and zinc fortification was parboiling because organoleptic properties of rice was not affected. At higher level of salt application sensory attributes of rice were badly affected. Iron salt NaFeEDTA at higher concentration of 450mg/kg results in dull greenish colour of rice and off odour. But, at lower level than 450mg/kg of NaFeEDTA application there was no significant difference in sensory attributes. Grain shape was also badly affected by NaFeEDTA at higher level and rice surface became rough. The zinc salt ZnSO4 resulted in light yellowish colour of rice at 300mg/kg of rice but grain length, aroma, shape and taste was not affected. So, it can be concluded that best suitable salt for iron and zinc fortification are FeSO4 and ZnO respectively.

Acknowledgement

I would like to thank my supervisor whose help has been a source of light for me. Moreover, authors also acknowledge this paper is not published or under consideration in any other journal.

Conflict of Interests

We authors of that research paper have no conflict of interest.

References

- Alavi S, Bugusu B, Cramer G, Dary O, Lee TC, et al. (2008) Rice fortification in developing countries: A critical review of technical and economic feasibility. Washington, USA.

- Saini RK, Nile SH, Keum YS (2016) Food science and technology for management of iron deficiency in humans: A review. Trends in Food Science & Technology 53: 13-22.

- Clemens S (2014) Zn and Fe biofortification: The right chemical environment for human bioavailability. Plant Science 255: 52-57.

- Bhattacharya K (2004) Parboiling of rice. Rice chemistry and technology Paul, Minnesota: American Association of Cereal Chemists 4: 329-394.

- Ohtsubo K, Suzuki K, Yasui Y, Kasumi T (2005) Bio-functional components in the processed pre-germinated brown rice by a twin- screw extruder. Journal of Food Composition and Analysis 18: 303-316.

- Liu C, Zhang Y, Liu W, Wan J, Wang W, et al. (2011) Preparation, physicochemical and texture properties of texturized rice produce by Improved. Extrusion Cooking Technology. Journal of Cereal Science 54: 473-480.

- Ray JG, Meier C, Vermeulen JM, Boss S, Wyatt PR, et al. (2002) Association of neural tube defects and folic acid food fortification in Canada. The Lancet 360(9350): 2047-2048.

- Sareepuang K, Siriamornpun S, Wiset L, Meeso N (2008) Effect of Soaking Temperature on Physical, Chemical and Cooking Properties of Parboiled Fragrant Rice. World Journal of Agricultural Sciences 4(4): 409-415.

- Kam K, Murray JM, Arcot J, Ward R (2012) Fortification of parboiled rice with folic acid: Consumer acceptance and sensory evaluation. Food Research International 49: 354-363.

- Joachim S (2011) Parboiling in Thailand and the world. Kasetsart University Thailand.

- Prom u thai C, Rerkasem B, Cakmak I, Haung L (2010) Zinc fortification of whole rice grain through parboiling process. Food Chemistry 120: 858-863.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...