Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6921

Review Article(ISSN: 2641-6921)

Use of Coconut COIR in Fiber Reinforced Concrete, Soil and Lime Volume 3 - Issue 4

Ash Ahmed1*, Hafiz Nadir2, Colin Yates3 and Lee Yates3

- 1Associate Professor, Civil Engineering Group, Leeds Beckett University, UK

- 2Doctoral Researcher, Civil Engineering Group. Leeds Beckett University, UK

- 3Conserv Lime Products, UK

Received: October 30, 2020; Published: December 02, 2020

*Corresponding author: Ash Ahmed, Associate Professor, Civil Engineering Group, Leeds Beckett University, UK

DOI: 10.32474/MAMS.2020.03.000166

Abstract

The use of lime as a binder and natural fibers as reinforcements have been in use since ancient human history. However, ordinary Portland cement and concrete have substituted these comparatively cheaper eco-friendlier materials due to their quick setting and strength parameters since the 19th century. However, their large-scale impact on the environment due to greenhouse gases emission has encouraged further research to develop novel composite materials comprising natural fibers like coconut coir and lime as partial cement substitute. In this review study, contemporary research studies conducted by different researchers were explored and has found this field quite encouraging and progressive for modern trends in construction materials. Coir is a material with great potential due to its high strength and ductility comparable to steel; the use of lime or saline treated coir in cement by 1% as optimum quantity and in some cases up to 2% quantity, enhanced the compressive, tensile and flexural strengths up to 5%-20%. Ductility and flexibility of concrete improved with more energy absorption capacity. However, more use of coir did not improve engineering properties of concrete rather deteriorated after 2% use by weight of cement. 1% to 2% coir use in expensive marine soil augmented by 5% use of lime revealed considerable increase in engineering properties of soil especially increase of compressive strength by 1.5 times, increase of compaction factor and plasticity and reduction in shrinkage and liquid limit thus supporting a fruitful use of coir and lime mixture in its properties enhancement. Coir being a natural fiber has a limitation of lesser degradation life so needs to be treated with some suitable natural coating material to enhance its life from 3 to 20 years and needs to be cleaned properly by soaking in lime or saline water to remove lignin, pith, cellulose and silicate crystals. The overall use of coir and lime as substituent of cement binders is highly recommended though further research is required to maximize usage for this economical and eco-friendly material.

Introduction

Cement, concrete, and mortar are considered as the basic materials in the world construction industry. The construction sector contributes one tenth of global GDP up to 15 Trillion USD and causes up to 10% of greenhouse emission mainly due to production of cement, use of fossil fuel, machinery/ equipment, and other petroleum products/ materials [1]. It is estimated that at least 0.9 metric ton CO2 is produced during manufacturing of 1 metric ton of ordinary Portland cement (OPC) [2,3]. Research has focused on preparation of various composite materials which are environmentally friendly, cost effective and consumes the waste products/materials from other industrial sectors [4]. A composite is generally developed by mixing of binding materials like cement, lime and pozzolanic materials with fine or coarse aggregate [5,6]. Such cementitious composite materials are generally characterized by their good compressive strength but weak tensile/ flexural/ torsional strength [5]. Researchers have been endeavoring to introduce new composite materials using lime and pozzolanic binders like volcanic ash (Tuff) as substitute for cement to minimize the pollution and incorporation of natural fibers to improve the strength of novel materials [7].

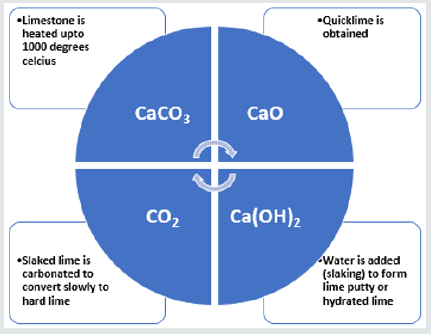

Use of Lime

Lime has been in use for centuries for stone masonry, facade work even in Egyptian, Romans, Greek and Iranians empires in construction of their traditional large-scale architectural master pieces in ancient history dating back to 12000 BC [8]. They have been using lime, marble chips, granite aggregates and lime mortar with horsehair as concrete, joinery, and plastering materials [9]. Lime is found in abundance in the form of limestone/chalk comprising calcium carbonate and mined from naturally occurring quarry sites. Limestone is then heated up to 1000 degrees centigrade to extract burnt or quick lime (calcium oxide) and hydrated with water to get slaked lime (calcium hydroxide) and this process is called a Lime Cycle. When slaked lime is mixed with sand or clay to form a mortar then calcium hydroxide reacts with carbon dioxide to form calcium carbonate slowly while setting down into hard form as shown in below chemical equations and (Figures 1 & 2) [10].

CaCO3 → CaO + CO2

CaO + H2O → Ca (OH)2

Ca (OH)2+CO2→CaCO3+H2O

The lime is used in different forms like hydraulic, non-hydraulic (e.g. lime putty) and hydrated for different purposes in construction industry like mortars, plasters, renders, paints, and powdered forms. Natural Hydraulic lime NHL is a frequently used as mortar lime product which comes in three types of strengths NHL2, NHL3.5 and NHL 5 for interior, exterior and limecrete uses [11]. The use of lime mortars is especially recommended in underwater construction, along coastal lines, flood leaves, break walls/ blocks and for properties enhancement of marine clay soil due to its moisture absorption capability and strength gaining characteristic under water [12].

Use of COIR

One of the most used natural fiber in different sectors, is coconut COIR which belongs to the Palm family [4]. The coir is a hard, renewable, and biodegradable fiber and is produced by extraction of fiber from waste coconut husk by retting process in mainly coastal areas of Africa, Asia, and America [13]. Coir is then soaked in water and NaOH (sodium hydroxide) solution for around a month to separate dirt, silica crystals, moisture, pith etc. to get a clean fibrous product [14]. The coir production in the world is estimated to be around 800,000 metric tons annually [5]. India and Sri Lanka alone contribute majority of coir production in the world [5] which is used in different categories of products like upholstery, ropes, meshes, sacks, construction industry and horticulture. The coir is also used in making anti corrosion mesh nets for use along embankments, slopes stabilization, strengthening of flood bunds and road subgrade. The bitumen treated coir sheets are often used in road surfaces, rail embankments and water/ leakage proofing on wet surfaces [15]. The mature brown coir fiber retted in saline water is generally short in length up to 2-6 inches long with 0.1mm to 0.5mm diameter (Figure 3), comprising mainly of cellulose and water having various cavities along the cross section which increase their stickiness/bonding property. The main composition by weight of coir is 40-45% cellulose/hemicellulose, up to 10-25% moisture, 40-45% lignin/pith/pectin and up to 2.5% traces of ash. Coir fibre has a density of approximately 1.4 g/cm3, up to 590 MPa tensile strength and elongation (ductility) is up to 50% of length; the fibre can swell up to 5% with an average life of 3 years [4,12,14-16]. The tensile strength is very impressive as it is equivalent to the tensile strength of low carbon structural steel. Furthermore, in addition to the strength, with high ductile behavior, these fibers have the potential to enhance the properties of most civil engineering / construction materials. The lime, silica and saline treated coir have shown much improved life if used with cement or lime. Its physical/ chemical properties and cheap availability in abundance suggests its numerous uses in construction industry especially in bituminous mats, marine clay soils, embankment stabilization and cement/lime concrete/mortars for improved life and compressive/ flexural/torsional strengths [12,15,16]. Some of the uses of coir are shown in (Figure 4).

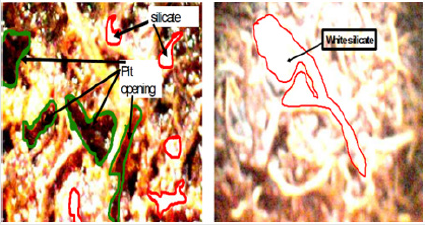

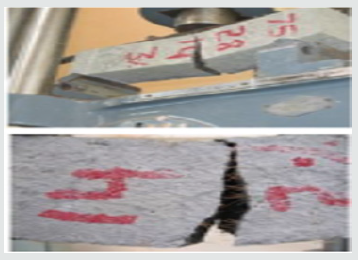

Review of Performance / Use of Lime Treated COIR in Fiber Reinforced Concrete (FRC)

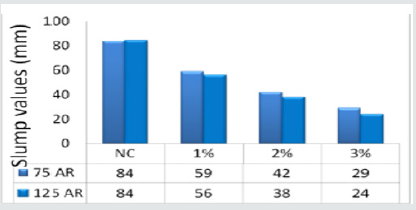

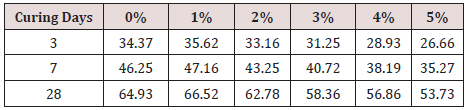

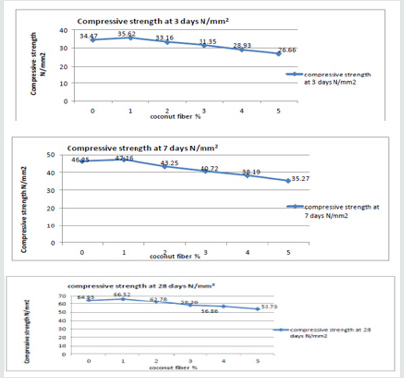

In the last few decades considerable research has been carried out to see the performance and use of coir in cement concrete. Different aspect ratios and percentage by weight of coir in comparison to cement have been used in different studies. The results show an increase of tensile and flexural strength up to optimum use of 2 % coir with up to 125 aspect ratios. Compressive strength of coir fiber reinforced concrete improved till maximum use of 1% coir and then it reduced. Slump test showed that workability of concrete decreased with more percentage of coir. Similarly, maximum 2% use of coir improved the tensile and flexural strengths but more than 2% reduced further improvements. Yalley and Kawan in their study on use of coir for strength improvement of cement concrete observed that cleaning of coir before its use with saline water is essential process to get rid of pith, lignin, silicate particles and moisture [17-19]. An observation was made using electron microscopy and it was ascertained that soaking of coir in saline or lime water solution for 7 days cleaned much of undesired particles from coir than soaking it in normal water for 30 days (Figures 5 & 6) [20]. Shreeshail et al. carried out slump test to assess workability of lime treated coir FRC and worked out that it decreased gradually with enhanced use of coir from 84 mm slump of normal concrete to 24 mm of slump with 3% use of coir with 125 aspect ratio AR as shown in (Figure 7). The results suggest decreased workability of concrete if coir fiber is used more than 1% [21]. Udhay and Ajitha conducted compressive testing on lime treated coir fiber reinforced concrete (FRC) cubes for 3, 7 and 28 days strength for 1% to 5% use of coir fiber and observed reduction in strength with all ratios except 1% use of coir where a nominal increase of 3% was observed in compression strength which gradually decreased more than 1% coir use as shown in Table 1 and (Figures 8 & 9) [22].

Figure 9: Graphs showing compressive strengths of samples with 0% to 5% Coir FRC on 3,7 and 28 days [22].

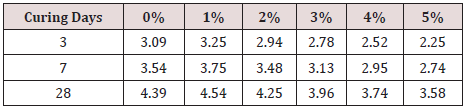

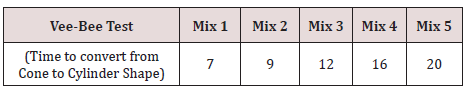

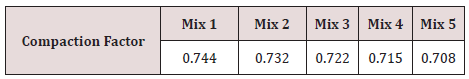

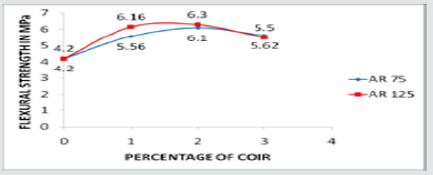

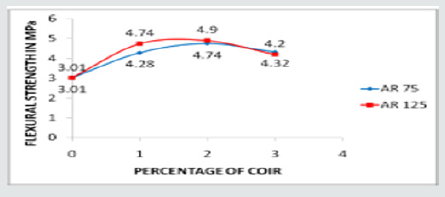

The data/graphs illustrated in Table 2 and (Figures 10 & 11) show the results/effects of mixing of coir in cement concrete on split tensile strength of the composite for 3, 7 and 28 days. The split tensile strength increased by around 3.5% from 0-1% use of coir and coir reinforced showed ductility and cylinder remained intact after the cracking instead of immediate rupture (Figure 11). The split tensile strength started to decrease for all coir fiber content greater than 1%. It can be inferred that coir up to a certain quantity can be useful to mix in concrete to improve strengths and to impart post crack ductile behavior, however, increased quantities have an adverse effect on workability and mechanical properties [22]. It has been observed that increased quantity of coir in concrete more than 1-2% increases difficulty in compaction and workability. The Vee-Bee test and compaction factor readings conducted by Udhay and Ajitha are illustrated in Table 3, 4 which show that time has increased for transformation of concrete shape from cone to cylinder from 7 seconds for 1% coir mixture to 20 seconds for 5% coir mixture. Similarly, compaction factor reduced from 0.744 for 1% coir to 0.708 for 5% coir mixture. This is attributed to coir fiber properties of stickiness due to cavities in its structure which do not allow proper compaction or even distribution of fibers and result in reduced compaction factor, compressive strength and tensile strength if used more than 1% quantity [22]. Sheeshail et al. conducted experiment on enhanced job mix formula of concrete with 1:1.94:2.93 with aspect ratio of 75 and 125 using 1% to 5% of coir for 7 days and 28 days curing. They found the optimum coir fiber usage at 2% for improved results of compressive, tensile and flexural strengths as shown in (Figures 12-16) [21].

Figure 10: Graphs showing Split Tensile Strength of Coir FRC samples with 0% to 5% Coir FRC on 3,7 and 28 days. [22].

Sheeshail et al, (2014) conducted experiment on enhanced job mix formula of concrete with 1:1.94:2.93 with aspect ratio of 75 and 125 using 1% to 5% of coir for 7 days and 28 days curing. They found the optimum coir fiber usage at 2% for improved results of compressive, tensile and flexural strengths as shown in (Figures 12-16) [21]. The optimum flexural strength of 6.16-6.3 MPa for coir FRC was observed with 125 aspect ratios with 28 days curing with 1- 2% use of coir as shown in (Figures 14-16) [22]. The use of hydraulic lime as pozzolanic binder and coir fiber are recommended to be used as environmentally friendly substitute of OPC concrete [23]. Current research should focus on development of pollution free low-cost composite materials to minimize the dangerously increasing challenge of greenhouse gases emission effects from manufacturing of OPC and use of cement concrete [24]. The natural fibers obtained from agricultural waste like coir, sisal, rice husk ash, palm ash and bamboos etc. are good materials to be incorporated in concrete to increase biodegradable contents and use of waste materials [25].

Performance & use of COIR and Lime in Soils

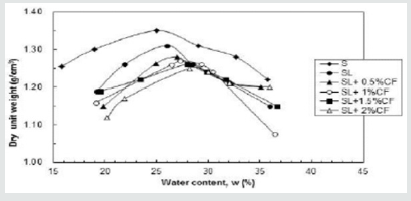

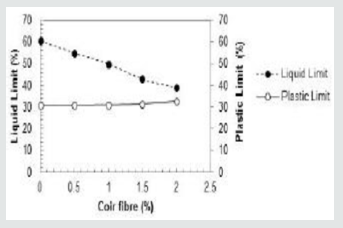

There exist different types of soil based on their composition, water absorption, grain size, porosity, shrinkage, swelling, liquid limit, plastic limit, bearing capacity and compressive strength etc. The soils like marine clay which has lesser bearing capacity and more swelling or expansion on absorption of water are considered as weaker soil and need to be treated to improve geotechnical properties to act as a good bearing structure [26]. Any infrastructure constructed on expansive or swelling marine soil experience heavy cracking and failure over a period if remain untreated [27]. The most economical and eco-friendly solution is to treat the soil with naturally occurring materials and bio-degradable organic fibers and industrial waste materials [25,28]. Recent findings have identified use of lime and coir fiber as a good mixing material for enhancement of soil properties. Lime mixed with 1-2% coir fiber have shown better strength properties especially in swelling soils. The lime and coir have been considered good to reduce the liquid limit of marine soils which contain more water than their liquid limit [29]. Anggraini et al. investigated the use of 5% lime with 0.5% to 2% coir in marine clay and observed that the dry density of this soil mixture decreased due to lesser weight (density) of lime and coir composite whereas it improved the water absorption capability and water contents increased up to 13% with use of 5% lime and 2% coir as shown in (Figure 17) [30]. They observed that the optimum plastic limit was found at 5% lime with 2% coir whereas minimum liquid limit was observed with this composite as shown in (Figure 18) [30].

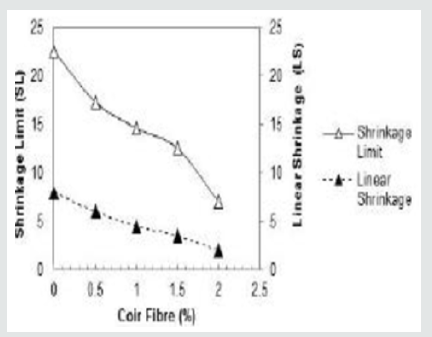

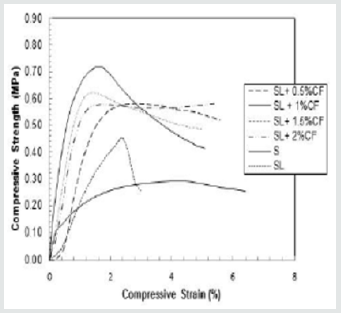

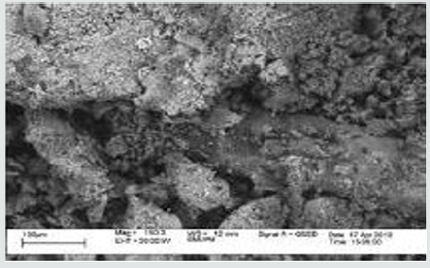

Shrinkage limit and linear shrinkage limit were reduced with the use of lime and coir and showed minimum values at maximum 2% use of coir with 5% lime stabilization in the soil as shown in (Figure 19) [30]. The compressive strength of lime-coir composite soil was observed at its optimum level with 5% lime and 1% coir and it increased by 1.5 times the untreated soil from 0.3 MPa to 0.75 MPa. However, decrease in compressive strength was observed if coir quantity was increased more than 1% as shown in (Figure 20) [30]. The reduction in compressive strength of lime-coir treated soil with more than 1% coir can be attributed to coir fiber structure having cavities in the fibers which produce lumps and decrease contact with soil particles giving rise to more voids and lesser compactness and reduced absorption of lime contents to soil due to more coir fibers [31-33]. The presence of silicate crystals, lignin, pith, and cellulose in coir fiber also results in reduced compressive strength if more quantities are used. This factor was studied by conducting scanning electron microscopic analysis as shown in (Figure 21) [30].

The white dots in the figure show presence of silicate with coir fibers and lumps of clay adhered to fibers because of the cavities. The presence of this adhesion increased the compactness and shear resistance of soil composite till 1% use of coir fiber but after that it started to decrease the density of soil, compactness, and creation of clay lumps. All this results in voids and unevenness in the structure of soil due to non-uniform spread of coir fibers which can be seen visibly from the SEM picture. Therefore, it can be inferred that use of 5% lime with optimum level of 1-2% coir fiber are suitable for expensive soils like clay marine soil. Since the coir fibers are biodegradable having a life of 3-4 years; therefore, coating of nonhazardous environmentally friendly natural coating materials may be used to enhance the coir fiber life to around 20 years [34].

Potential use of COIR in Limecrete and Mortars

The lime with horsehair was used to increase its tensile strength as found in Roman construction as a layer/mesh net in lime mortar used for stone masonry [8]. It is advisable to consider studying the use of natural fibers in lime mortar and limecrete for enhancement of their physical and chemical properties. The properties of compressive, tensile, and flexural strengths exhibited by lime mortar and limecrete are quite similar to cement mortar and class C20 concrete that is strong in compression and weak in tensile & flexural behavior. The use of fibers in lime products generally give enhanced engineering properties like toughness, compressive strength, increased tensile (torsional) strength, water retention capability, better insulation, water proofing and embankment/slope stabilization along the water streams. Recent findings show lime treated soil with coir mesh or nets have improved stabilization of embankments and stream banks, flood bunds due to its slow setting under water and anti-erosion control capability of coir, as shown in (Figure 22) [35]. Stefanidou et al. in their studies on lime mortars and different fibers suggested that mixing of wooden cellulose natural fibers like sisal or coir increase compressive strength, tensile strength, flexural strength, fracture & cracking energy, static elastic modulus, and porosity. The use of wooden cellulose fibers is economical and nontoxic to environment with more absorption of industrial waste from other sectors [12]. It is recommended that further research should be conducted on use of coir in limecrete with different percentages and aspect ratios for hydraulic and hydrated limes.

To summarize, the coir is obtained from coconut husk and belongs to the palm family of fibers. It’s extremely strong in tension (up to 590 MPa), which is similar to steel, tough and is very ductile (50% elongation at failure). Given it is economical in comparison to other alternatives, e.g. steel and polymers (polypropylene) and environmentally friendly and ethically sourced, there is tremendous potential to use COIR which can be used in cementitious materials, limecrete and treatment of expensive soils. The optimum values of coir considered feasible range from 1% in concrete and soil. The durability of coir fiber can be increased to 20 years by treating with natural materials. The compressive strength can be enhanced by around 10-15% and flexural strength up to 20-25% with use of maximum 1% coir in concrete. Expensive marine soils have shown considerable enhanced engineering properties with use of up to 1% coir and 5% lime. The compressive strength of marine soil increased by 150% while shrinkage and liquid limit were decreased, and plastic limit increased with use of coir and lime thus increasing the stability of marine soil. The use of coir and lime in concrete and soil along the water streams is highly recommended due to their absorption and setting capability under water and stabilization of slopes and embankments.

Conclusion

a. The use of cement in construction industry is a major contributor of greenhouse gas emissions. Therefore, use of lime as a partial substitute of cement is highly recommended to facilitate the battle against climate change.

b. Use of coconut coir has great potential to enhance the properties of construction materials due to its high tensile strength (up to 590 MPa) and ductility (50%).

c. The research on use of lime and coir has shown that only 1-2% coir and up to 5% lime use in any composite are recommended to improve performance as greater quantities has negligible effect.

d. It is recommended the coir is cleaned and treated with saline or lime and with some coating material to increase the efficiency and effective life of coir. This process can be bypassed if the coir fibre is encased in a lime-based matrix.

e. Use of coir along water streams in the form of meshes, ropes or trunks have shown considerable effectiveness against erosion and water seepage and are recommended to use for embankment stabilization and water retention.

f. Further research should focus on the development of low carbon lime-based concrete (limecrete) and lime mortars & renders with coir fiber reinforcement for increased robustness, strength, ductility, and sustainability.

References

- Chisholm Hugh (1911) Coir Encyclopedia Britannica. 6(11th), Cambridge University Press, USA.

- Rehan R, Nehdi M (2005) Carbon dioxide emissions and climate change: policy implications for the cement industry, Environmental Science & Policy 8: 105-114.

- Worrell E, Price L, Martin N, Hendriks C, Meida LO (2001) Carbon dioxide emissions from the global cement industry. Annu Rev Energy Environ 26: 303-329.

- Rajkumar MR (2017) Recent Advances in Materials, Mechanics and Management, in: 3rd Conf. Mater. Mech. Manag., Trivandrum (India) p. 450.

- Ministry of MSME India, (2017) 63rd Annual report Coir Board, New Delhi, India.

- Nitin T, Neelima S (2020) An experimental study on the behavior of lime and silica fume treated coir geotextile reinforced expansive soil subgrade International Journal Engineering Science and Technology Journal 23: 1214-1222.

- Sudhira HS, Ann Jacob (2000) Reuse of By-Products in Coir Industry: A Case Study. Internet Conference on Material Flow Analysis of Integrated Bio-Systems.

- Ty-Mawr Lime Industries Ltd, Sustainable building materials for healthier homes.

- Oates JAH, Projet de (1998) Lime and Limestone - Chemistry and Technology, Production and Uses. Wiley 472pp.

- Peter B (2013) The lime cycle for high-calcium lime.

- Conserv (2020) STONE TECH (Cleveland) Ltd. t/a Conserv.

- Stefanidou M, Papachristoforou M, Kesikidou F (2016) Fiber-reinforced lime mortars, Conference paper :4th Historic Mortars Conference held in Greece, Greece.

- Thomas Bjorkan (2011) The limestone quarry at Akselberget, Bronnoy, Norway, USA.

- How coir is made material making history used processing product industry machine History Archived 2006-07-14 at the Wayback Machine.

- Satyanarayana KG, kulkarni AG, Rohatgi PK (1981) Structure and properties of coir fibres, Regional Research Laboratory, Trivandrum, Proc. Indian Acad Sci (Engg Sci) 4(4): 419-436.

- Ferdus Alam (2014) An Overview of Coconut or Coir Fiber Dept of Textile Engineering Southeast University, Dhaka, Bangladesh,

- Hy-Tex Coir Mesh Erosion Control Products UK.

- Sutton K, Rayan W (2020) Erosion Control and Slope Stabilization using Coir, Washington University Publications, and research, USA.

- Yalley PP, Kwan A (2012) Coconut Fibre as enhancement of concrete. School of Civil Engineering Cardiff University, UK.

- ElAshkar NH, Mohr B, Nanko H, Kurtis KE (2002) Durability of pulp fiber-cement composites to wet/dry cycling, International Conference on Advances in Building Technology 4-6(1): 233-237.

- Shreeshail BH, Jaydeep C, Dhanraj P, Amar K (2014) Effects of coconut fibers on the properties of concrete, IJRET: International Journal of Research in Engineering and Technology 3(12).

- Uday VS, Ajitha B (2017) Concrete Reinforced with Coconut Fibres, International Journal of Engineering Science and Computing 7(4).

- Grist E, Paine K, Heath A (2016) Hydraulic lime - pozzolan concretes: Properties, uses and research needs. in MR Jones, MD Newlands, JE Halliday, LJ Csetenyi, L Zheng, MJ McCarthy & TD Dyer (Edn), The 9th International Concrete Conference 2016: Environment, Efficiency and Economic Challenges for Concrete, Dundee, pp. 314-326.

- Jones MR, Newlands MD, Halliday JE, Csetenyi LJ, Zheng L, et al. (Eds.) (2016) The 9th International Concrete Conference 2016: Environment, Efficiency and Economic Challenges for Concrete pp. 314-326.

- Agopyan V (1998) Vegetable fiber reinforced building materials- development in Brazil and other Latin American countries. Concrete Technology and Design Natural Fibre Reinforced Cement and Concrete, 5: 208-240.

- Rosenbalm D, Zapata CE (2017) Effect of wetting and drying cycles on the behavior of compacted expansive soils, Journal of Materials in Civil Engg 29(1): 04016191,

- Inkoom S, Sobanjo J, Barbu A, Niu X (2019) Prediction of the crack condition of highway pavements using machine learning models, Struct. Infrastruct. Eng 15: 940-953,

- Thirumalai R, Babu SS, Naveennayak V, Nirmal R, Lokesh G (2017) A review on stabilization of expansive soil using industrial solid wastes, Engineering 9: 1008-1017.

- Rao DK, Raju GP, Sowjanya C, Rao JP (2009) Laboratory studies on the properties of stabilized marine clay from Kakinada Sea Coast, India. International Journal of Engineering Science and Technology 3(1): 422-428.

- Anggraini V, Afshin A, Haslinda N (2014) Effect of coir fiber and lime on geotechnical properties of marine clay soil, 7th International Congress on Environmental Geotechnics: 7iceg2014, Australia, Volume: 2014: 1430-1437.

- Cai Y, Shi,B, Ng CWW, Tang CS (2006) Effect of polypropylene fibre and lime admixture on engineering properties of clayey soil. Engineering Geology 87(3-4): 230-240.

- Sivakumar Babu G, Vasudevan A, Sayida M (2008) Use of coir fibers for improving the engineering properties of expansive soils. Journal of Natural Fibers 5(1): 61-75.

- Prabakar J, Sridhar R (2002) Effect of random inclusion of sisal fibre on strength behaviour of soil. Construction and Building Materials 16(2): 123-131.

- Gaw BG, Zamora-Palacios SA (2010) Soil Reinforcement with Natural Fibers for Low-Income Housing Communities.

- 15 Amazing uses of coconut fiber by World Press 2016.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...