Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6921

Research Article(ISSN: 2641-6921)

Mathematical Model to Monitor Application Of Silica Fumes, Iron Slag And Rice Husk Ash on Compressive Strength For Partial Replacement of Cement Volume 3 - Issue 4

Eluozo SN* and Amanamba EC

- Department of Civil Engineering, College of Engineering, Gregory University Uturu Abia State, Nigeria

Received: December 30, 2020; Published: January 26, 2021

*Corresponding author: Eluozo SN, Department of Civil Engineering, College of Engineering, Gregory University Uturu Abia State, Nigeria

DOI: 10.32474/MAMS.2021.03.000169

Abstract

This paper monitors the variation increase of compressive on partially replacement of copper slag with fine aggregate, the study observed the fluctuation of growth rate of the compressive strength; these were examined to generates the behaviour of the material intermesh of its reaction on strength development, the variation is from the level of compaction, placement and segregation during concrete transport and its placement, including bleeding of concrete that were thoroughly examined. The parameters developed influence based on the fluctuation from the stated parameters that reflects on the growth rates of compressive strength, the derived modeling and simulation monitor the behaviour of concrete properties in different water cement ratios and curing age, the dosage of the addictives were monitor on the simulation, the highest compressive strength were generate at forty percent duration time of twenty eight days of curing, this implies that the replacement of the fine aggregate with copper slag at forty percent developed the optimum compressive strength.

The study applied modeling and simulation to monitor other concrete properties that were not considered in the experimental process, this were to determine their variations rate of influence on the compressive strength, the variation of water cement ratios were monitored, the behaviour of the effect on water cement were evaluated, the influence from porosity were also monitor, the study observed reduction of porosity that reflected increase in compressive strength, the simulation subjected the predictive values to validation with experimental values, this was in agreement with the experimental values by Satyanarayana and Saikiran 2019 [1], further study were carried on the existing study whereby the curing age were monitor within 3, 7. and 28days, but 14 days of curing were integrated to monitor the compressive strength of curing age, the generated predictive values were also validated with experimental data, this implies that the develop predictive model can be applied to monitor the growth rate of compressive strength numerically and analytically, this concepts has generated the required results making the model imperative to predict compressive strength at any curing age.

Keywords: Modeling; compressive strength; mechanical properties; fine aggregate; copper slag

Introduction

Self-compacting concrete (SCC) has been current Centre of study currently now. Several experts on the application of concrete to monitor inherent properties of the concrete have not yet understood it obviously. High performance of Concrete (HPC) and Self compacting concrete (SCC) has observed not to be the same, both designed materials are different, but they are essentially in the application of special admixture [2]. This may be due to the application of chemical substances including mineral admixtures, that is why the study of its micro cracks more essential in Compared to NC [3-6]. Experts in several literature has evaluated that increase in densities will definitely increase the compressive strength of concrete including that of tensile strength and it fracture energy, while the characteristics will decrease with an increase in its density [7,8] more so, fracture behaviour of plain concrete is the fundamental of most conducted research on the observation of reinforced concrete including prestress concrete structures and that of fracture mechanics, experimental research has ascertained the influence on aggregate fracture behaviour in concrete, it has been investigated by experts that the size in aggregate experienced decrease in brittleness of harden concrete and observed increase in fracture energy including fracture toughness [9-11] several studies has been observed in other materials application for high concrete strength using 3/8 all in –one aggregate, these has produced several results using different admixture and mixed designed, these has also generated the effect from water cement ratio including concrete characteristics [12-15].

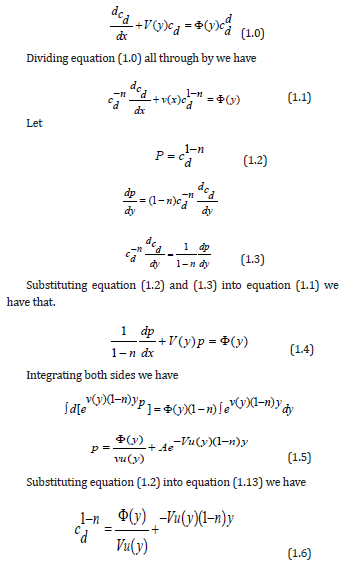

Theoretical Background

Materials and Method

Experimental procedures

Compressive Strength Test Concrete cubes of size 150mm×150mm×150mm were cast with and without copper slag. During casting, the cubes were mechanically vibrated using a table vibrator. After 24 hours, the specimens were demoulded and subjected to curing for 1-90 days and seven-day interval to 28 days in portable water. After curing, the specimens were tested for compressive strength using compression testing machine of 2000KN capacity. The maximum load at failure was taken. The average compressive strength of concrete and mortar specimens was calculated by using the following equation 5.1.

Compressive strength (N/mm2) = Ultimate compressive load (N)

Area of cross section of specimen (mm2)

Results and Discussion

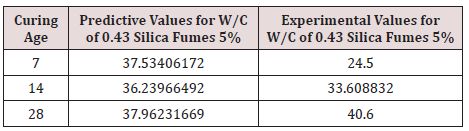

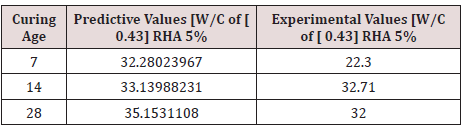

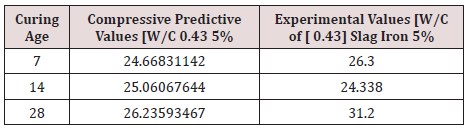

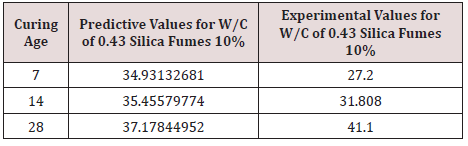

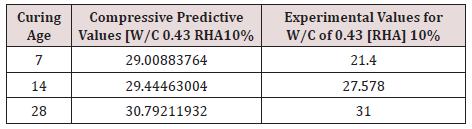

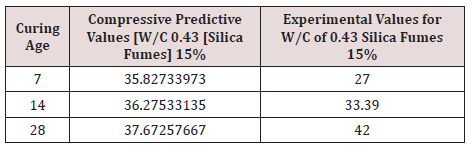

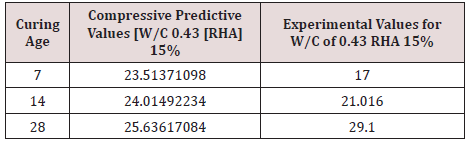

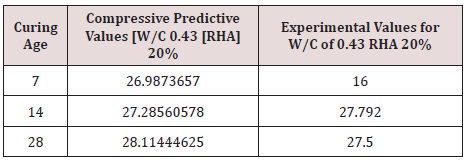

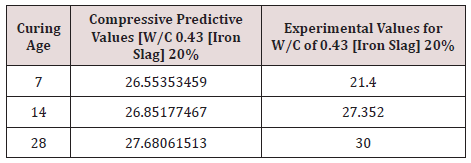

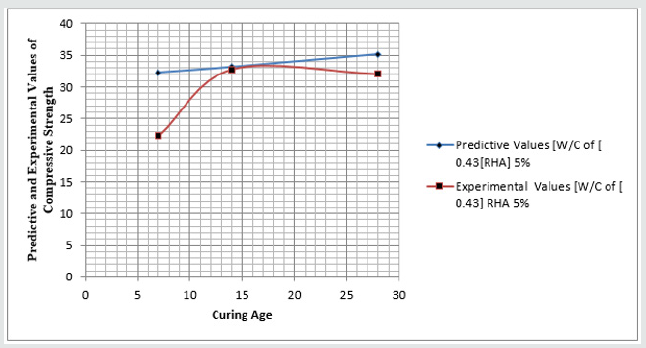

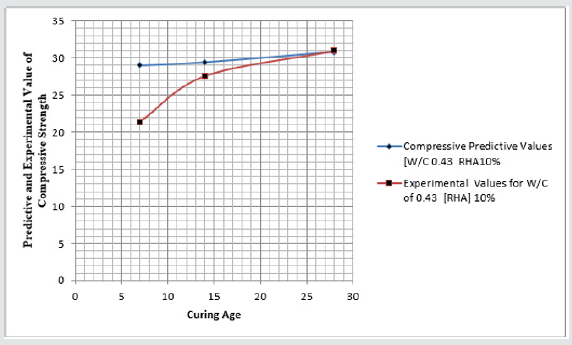

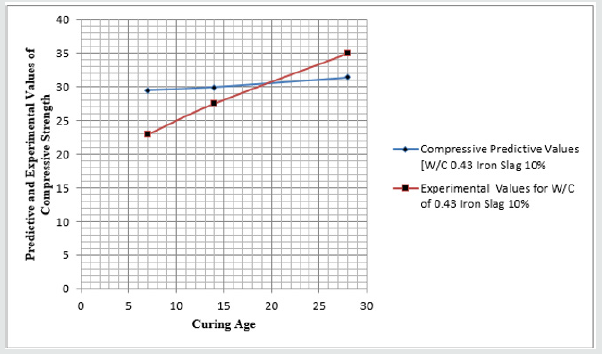

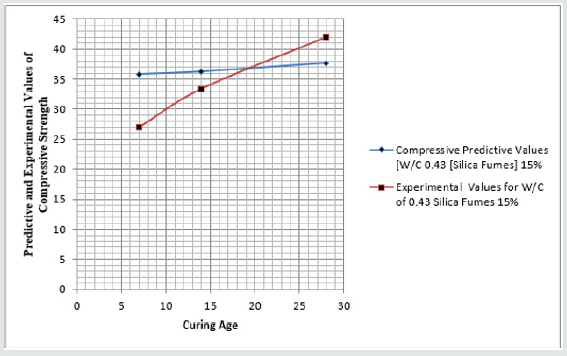

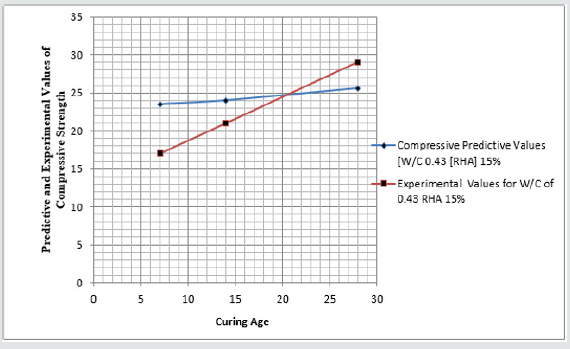

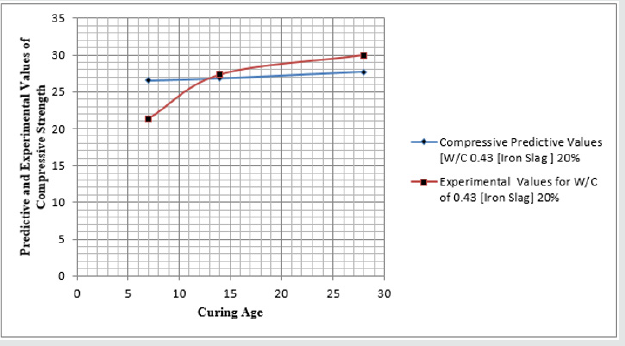

Figure one to twelve explained the behaviour of copper in the mixed reaction of the model concrete design, the figures experienced variations in their growth rate, these are basically due to some variation in compaction, and transportation of the concrete including bleeding, the model concrete reflected these observed reaction on the concrete formation, the effect from these stated parameters caused the fluctuation that reflected on the growth rates of the compressive strength in study, another development are the mixed proportions, concrete properties such as variation of the dosage in the addictives was applied as partial replacement of cement, the experimental study carried by experts has generated significant results substituting copper slag for fine aggregate, this can be observed by Satyanarayana and Saikiran [1] where the developed concrete model designed generated the fluctuation that are caused by these factors stated above, the dosage of that material generated the required signed strength development, these are determined by the percentage of partial replacement of copper slag for fine aggregate, the effect from variations of water cement ratios were monitored in the study Tables 1-12 (Figures 1-12).

The decrease in compressive strength between 0.17 and 0.20 were examined as it is expressed in the graphical representations, these conditions explained the influence from water cement ratios in all the figures, the application of the material from the compressive growth rate generally has showed tremendous improvement in strength development, it rapid increase in strength were evaluated from the behaviour of the material in its setting time, while that of other concrete properties developed more influence in any concrete grades formation, the advantage of aggregate was observed on the strength development, these are based on its surface texture either smooth or rough, but smooth surface were examined to increase its workability, while that of the rough type generate stronger bond between the paste and the aggregate creating higher strength. but replacing aggregate with copper slag were examined to develop higher strength compared to that of fine aggregate, the output of the mixed designed reflected this in the figures above, the study applied modeling and simulation has thoroughly expressed the influenced of the concrete properties, the predictive and experimental were subjected to validations, and both parameters generated best fits correlations.

Conclusion

The study applied modeling and simulation to predict the compressive strength with partial replacement of fine aggregate with copper slag has been applied in concrete strength development. It has always increase the strength of concrete thus decrease environmental pollution, space problem and reduced the cost of concrete, The application of modeling and simulation techniques expressed various parameters effect from concrete properties, the variation of concrete porosity were monitored in the different water cement ratios and curing age, the refection of the parameters were examined, while that of the concrete densities were observed in the simulation system, the concrete mixed designed were examined to reflect it influence on the dense of the concrete, variations of water cement ratios were also examined, the system monitored and evaluates there rate of effect on compressive strength. The study expressed these parameters on the simulation because most of these parameters were not monitored to determine that various rates of effects on compressive in the design of concrete grades experimentally, but the application of modeling and simulation were able to monitor their various effect thus determined their rates at different curing time.

References

- Satyanarayana GVV, Saikiran CH (2019) Effect on Mechanical Properties of M35 Grade Concrete by Partial Replacement of Fine Aggregate with Copper Slag. International Journal of Innovative Technology and Exploring Engineering (IJITEE) 8(12): 3759-3762.

- Ode T, Eluozo SN (2016) Predictive Model on Compressive Strength of Concrete Made with Locally 3/8 Gravel from Different Water Cement Ratios and Curing Age. International Journal of Scientific and Engineering Research 7(1): 1528-1551.

- Druta C (2003) Tensile strength and bonding characteristics of self-compacting concrete. MSc thesis, Louisiana State University, USA pp.115.

- Wittmann FH (2002) Crack formation and fracture energy of normal and high strength concrete. J Ind Nat AcadSci 27(4): 413-423.

- Hamid Eskandari, Muralidhara S, Raghu Prasad BK, Venkatarama Reddy BV (2012) Fracture properties of Self Compacting Concrete for Notched and Un-notched Beams. Global Journal Research in Engineering Civil and Structural Engineering 12(1).

- Ode T, Eluozo SN (2016) Model Prediction to Monitor the Rate of Water Absorption of Concrete Pressured by Variation of Time and Water Cement Ratios. International Journal of Scientific and Engineering Research 7(1): 1514-1527.

- Giaccio G, Rocco C, Zerbino R (1993) The fracture energy (GF) of high strength concrete. Mater Struct 26(161): 381-386.

- OdeT, Eluozo SN (2016) Calibrating the Density of Concrete from Washed and Unwashed Locally 3/8 Gravel Material at Various Curing Age. IJSER 7(1): 1514-15574.

- Amparano FE, Xi Y, Roh YS (2000) Experimental study on the effect of aggregate content on fracture behavior of concrete. Eng Frac Mech 67(1): 65-84.

- Appa Rao G, Raghu Prasad BK (2002) Fracture energy and softening behavior of high strength concrete Cem Con Res 32(2): 247-252.

- OdeT, Eluozo SN (2016) Compressive Strength Calibration of Washed and Unwashed Locally Occurring 3/8 Gravel from Various Water Cement Ratios and Curing Age. IJEGS 4(1): 462-483.

- Ode T, Eluozo SN (2016) Predictive Model to Monitor Variation of Concrete Density Influenced by Various Grade from Locally 3/8 Gravel at Different Curing Time. IJEGS 4(1): 502-522.

- Jaja GWT, Eluozo SN, Ezeilo FE (2019) Modeling and simulation of flexure strength of self-compacting concrete modified with fly ash and super plasticizer. RJREI 3(1): 26-35.

- Ode T, Eluozo SN (2016) Predictive Model to Monitor Vitiation of Stress –Strain Relationship of 3/8 Gravel Concrete with Water Cement Ration [0.45] at Different Load. IJEGS 4(1): 409-418.

- Kishi T, Hosoda A, CB Gurung, S Kittiwuttichusinp (2000) Effect of drying / autogenous shrinkage on ductility / fracture mode of beam and self-repairing function of expansive agent. Pro JCI 22(3): 511-516.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...