Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6921

Review Article(ISSN: 2641-6921)

Materials Driving Survivability, Radiation Hardening, and Shielding of Integrated Circuits in a Radiation Environment Volume 4 - Issue 1

Jacek Karpiesiuk*

- Expert in Construction and Building Specialties, Bialystok University of Technology, Poland

Received: March 18, 2021; Published: March 31, 2021

*Corresponding author: Bahman Zohuri, Adjunct Professor, Business Analytics School, Golden Gate University, Ageno School of Business, San Francisco, California

DOI: 10.32474/MAMS.2021.04.000177

Abstract

With recent renewal interest in survivability, radiation hardening against cold or hot x-ray as well as high power laser energy among defense companies and military communities, radiation shielding of military equipment becomes an imperative task and requirement. Materials used in radiation shielding is one way to go to protect any vulnerable digital circuits in form of an integrated circuit, and consequently selecting of such ICs for a radiation environment also becomes a necessity as part of survivability requirements. Thermomechanical properties of materials as part of shielding are also going to play a huge role as part of protection of these ICs as well. With most countries getting involved with their nuclear arsenal development, protection of our assets in space or on ground such as electric circuits and grids is another issue that we need to think about to survive a nuclear burst both Endo and Exo-atmospheric circumstance. The effects of nuclear explosions produce both immediate and delayed destructive effects, that requires choice of right and proper protective materials for ICs to be shielded and survivable in such radiation environment driven by a nuclear weapon burst. Nuclear weapon effects in term of blast, thermal radiation, electromagnetic pulse, and prompt ionizing radiation, etc. are part of concerns for choosing the proper materials. Radiation shielding is based on the principle of attenuation, which is the ability to reduce a waves or ray’s effect by blocking or bouncing particles through a barrier material. This short review is discussing different holistic issues in respect to selected materials and integrated circuits in respect to survivability and shielding within a radiation environment, either man-made or natural.

Keywords: Integrated circuits; digital circuits; radiation shielding; electromagnetic pulse; electromagnetic interference; electromagnetic compatibility

Introduction

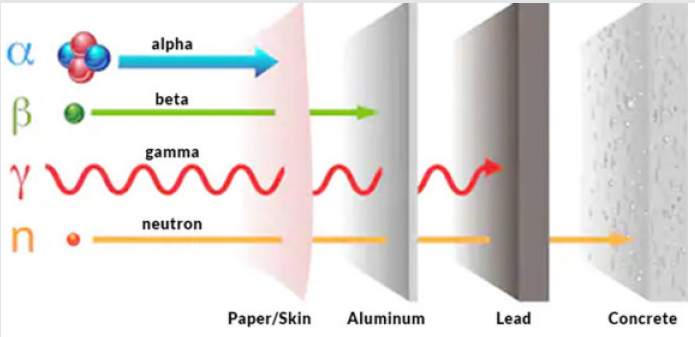

To start with, we introduce the basic concept of radiation by

describing what it is and then we move on to introduce types of

shielding materials that we need to protect our assets, as well as

going through different radiation types of radiation as illustrated

in (Figure 1), that we need to shield ourselves, biologically, health

care wise and medical imaging to the yields from nuclear energy

burst, nuclear medicine and non- destructive testing cross different

industries and on earth and in the space as well as ground assets

within defense communities. As illustrated in (Figure 1) to X-Ray

radiation both cold and hot X-Ray radiation as well has High Energy

Laser (HEL) radiation. We then talk about different source of

radiation either man-made or natural ones that one need to shield

against it no matter what field of application we are considering.

Under effort of As Low as Reasonable (ALARA) driving a principle

that strives to minimize the exposure of ionizing radiation to

people and environment by choosing and introducing the proper

materials, while considering economics, technology, and social

factors. Considering all the factors, and the number of materials to

choose from, consulting with a shielding materials expert within

such community of experts in the field of radiation shielding and

survivability, is essential to finding the most effective solutions to

your shielding needs.

It all starts with the type of radiation that is present. Materials

interact differently with different types of radiation. For example,

tungsten can attenuate gamma radiation effectively, but when

exposed to neutron radiation, secondary gamma rays can be produced. Materials that are strongest at attenuation gamma

radiation are tungsten and lead, while high density concrete and

borated polyethylene are better materials for stopping neutrons on

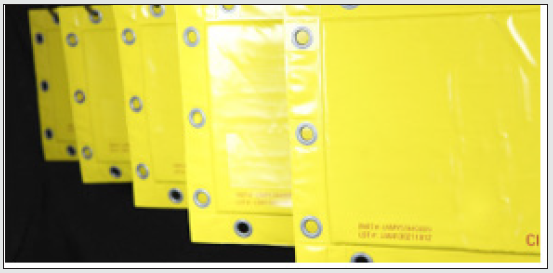

its track. (Figure 2) is illustration of such materials. Choosing the

right material will allow you to save space and use less material.

A shield of high-density concrete can take half the space of

regular concrete with the same shielding properties. Flexibility of

a material is also important to think about when considering the

space requirements. A flexible material like metal impregnated

polymers might be more suitable to shield a round object like a

pipe, as it can be wrapped around tightly as (Figure 3), shows such

wrapping materials.

Materials that are used in radiation shielding, are consistent

of certain physical and chemical properties that would be able

to enhance shielding to level of assigned survivability of certain

Service Level Agreement (SLA), depending on the environmental

conditions that need to take place. Radiation shielding is imperative

as radiation can be a serious concern in nuclear power facilities,

industrial or medical x-ray systems, radioisotope projects, particle

accelerator work, and several other circumstances. Containing

radiation and preventing it from causing physical harm to

employees or their surroundings is an important part of operating

equipment that emits potentially hazardous rays. Preserving both

human safety and structural material that may be compromised

from radiation exposure are vital concerns, as well as shielding

sensitive materials, such as electronic devices and photographic

film. From military application perspective, any Integrated

Circuits (ICs) that are embedded in any electronic devices as

part of military equipment’s need to be radiation harden in case

of directed exposure to X-Ray radiation either cold or hot as well

type of particle radiation type shown in (Figure 1), here resulted

from any nuclear explosion either Endo or Exo-atmospheric burst.

Integrated Circuits these days are digital rather than analog if form

of old tubes technology that we could find in any electronic devices

such as old Radios representing Transistor, Capacitors or Resistors.

Digital circuits are designed and manufactured in Semiconductor’s

industries in form of either Bipolar or CMOS infrastructures.

However, most of these industries are pushing CMOS approach

that is heavily driven by reduction of chip’s footprint on these

day’s 25” wafer processing, toward sub-micron technology path.

Although from survivability, point of view the Bipolar IC’s have a

better chance than CMOS circuits to not to have any latch-up events

due to Transient Radiation Effects on Electronics (TREE) from a

Single Event Upset (SEU) or System Generated Electromagnetic

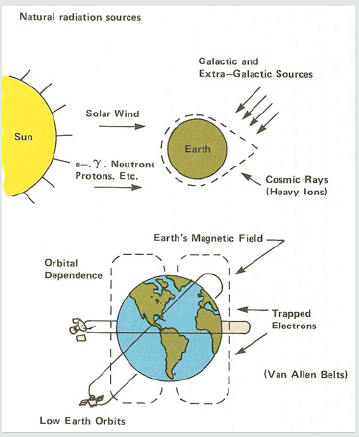

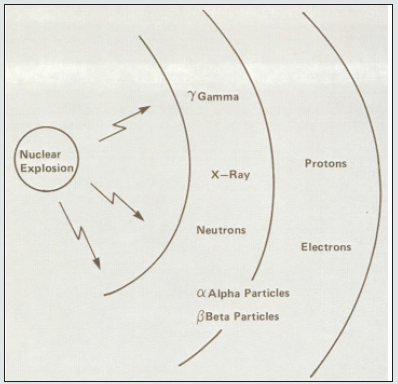

Pulse (SGEMP) [1]. All these above events could take place either

naturally as a source or man-made type such as nuclear explosion,

where the intensity of radiation depending on the yield of weapons

in question as illustrated in (Figures 4 & 5). Environments with

large amount of ionizing radiation, either natural or man-made,

create special design challenges for integrated circuits, typically for

RF power amplifier chips [2]. A single charged particle can knock

thousands of electrons loose, resulting in electronic noise and signal

spikes. In the case of digital circuits, this can lead to results that

are inaccurate or unintelligible. It is a particularly serious problem

in designing artificial satellites, spacecraft, military aircraft, nuclear

power stations and nuclear weapons. The process of regulating the

effects and degree of penetration of radioactive rays varies according

to the type of radiation involved. Indirectly ionizing radiation,

which includes neutrons, gamma rays, and x-rays, is categorized

separately from directly ionizing radiation, which involves charged

particles. Different radiation shielding materials are better suited

for certain types of radiation than others, as determined by the interaction

between specific particles and the elemental properties of

the shielding material. Moreover, in the case of digital circuits, this

can lead to results that are inaccurate or unintelligible. It is a particularly

serious problem in designing artificial satellites, spacecraft,

military aircraft, nuclear power stations and nuclear weapons. Typical

sources of exposure of electronics to ionizing radiation are the

Van Allen radiation belts for satellites, nuclear reactors in power

plants for sensors and control circuits, residual radiation from isotopes

in chip packaging materials, cosmic radiation for spacecraft

and high-altitude aircraft and nuclear explosions for potentially all

military and civilian electronics [3].

As part of protecting the ICs or any other assets against radiation threat is the shielding and packaging materials. Is the way to go, as it was stated in above. When it comes to protecting against radiation, the basic radiation protection principals or radiation safety tips involve time, distance, and shielding. Time, in this case, means to limit exposure to the minimum amount possible. Distance means staying as far from radiation sources as possible as a best practice. The intensity of radiation generally follows the inverse square law, meaning that it falls off with the square of the distance from the source. Moving twice the distance away from a source of radiation reduces the intensity of exposure by a factor of 1/22 or one fourth the value. Beyond time and distance, making use of effective shielding is the other approach to managing exposure to radiation. But what materials protect against radiation? The most common ones used include lead, concrete, and water - or a combination of these. Below

X-Ray and Gamma Radiation Shielding Materials

In most common cases, radiation such as X-Ray or Gamm- Radiation source, either natural or man-made, high density-density materials with high atomic number Z are more effective than lowdensity with atomic number Z alternatively has a better shielding effect for blocking or reducing the intensity of radiation. However, low-density materials can compensate for the disparity with increased thickness, which is as significant as density in shielding applications. Lead is particularly well-suited for lessening the effect of gamma rays and X-Rays due to its high atomic number. This number refers to the number of protons within an atom, so a lead atom has a relatively high number of protons along with a corresponding number of electrons. These electrons block many of the gamma and x-ray particles that try to pass through a lead barrier, and the degree of protection can be compounded with thicker shielding barriers. However, it is important to remember that there is still potential for some rays making it through shielding and that an absolute barrier may not be possible in many situations [4].

Alpha and Beta Shielding

In most cases, high-density materials are more effective than low-density alternatives for blocking or reducing the intensity of radiation. However, low-density materials can compensate for the disparity with increased thickness, which is as significant as density in shielding applications. Lead is particularly well-suited for lessening the effect of gamma rays and x-rays due to its high atomic number. This number refers to the number of protons within an atom, so a lead atom has a relatively high number of protons along with a corresponding number of electrons. These electrons block many of the gamma and x-ray particles that try to pass through a lead barrier, and the degree of protection can be compounded with thicker shielding barriers. However, it is important to remember that there is still potential for some rays making it through shielding and that an absolute barrier may not be possible in many situations [4].

Neutron Shielding

Material such as Lead is quite ineffective for blocking neutron

radiation, as neutrons are uncharged and can simply pass-through

dense materials. Materials composed of low atomic number

elements are preferable for stopping this type of radiation because

they have a higher probability of forming cross-sections that will

interact with the neutrons. Hydrogen and hydrogen-based materials

are well-suited for this task. Compounds with a high concentration

of hydrogen atoms, such as water, form efficient neutron barriers

in addition to being relatively inexpensive shielding substances.

However, low-density materials can emit gamma rays when blocking neutrons, meaning that neutron radiation shielding is most

effective when it incorporates both high and low atomic number

elements. The low-density material can disperse the neutrons

through elastic scattering, while the high-density segments block

the subsequent gamma rays with inelastic scattering [4]. Because

neutron radiation presents so many inherent dangers, top-of-theline

neutron shielding protection is critical. Neutrons have neither

a positive nor a negative charge, resulting in a wide range of energy

and mass levels that must be blocked. Neutron radiation dangers,

therefore, must be handled with the utmost care and attention

to detail, whether dealing with nuclear power facilities, medical

X-ray systems, radioisotope projects, or particle accelerator

work. Hazardous rays can cause serious and long-lasting physical

harm to the people exposed to them, and structural material and

environments can also be damaged beyond repair by radioactive

waves. Electronic devices and photographic film are a couple of the

more sensitive mediums that can be easily damaged [5].

Given that lead is a heavy element or high atomic number Z

(heavier than around 80% or so of the other elements found on the

periodic table), it is a common choice for use in fabricating radiation

shielding products. Lead is fabricated into different product forms

to provide radiation shielding and protection, and which includes

these types:

a. Lead Sheets, Plates, Slabs, & Foils

b. Lead Shot

c. Lead Wools

d. Lead Epoxies

e. Lead Putties

f. Lead Bricks

g. Lead Pipe

h. Lead-clad Tubing

i. Lead-clad Pipe

j. Lead Sleeves

k. Lead Glass

l. Lead-Polyethylene-Boron Composites

Lead can also be added to concrete or cinder blocks for use

in wall construction. By adding unperforated sheets of lead to the

blocks and extending the sheet beyond the edge of the concrete

block and overlapping shield of lead can be embedded in a wall to

form an effective radiation barrier utilizing a continuous lining of

lead sheet. A similar approach can be used to create lead shielded

doors and door frames. As with the wall construction, it is important

to overlap the lead that is used in the door frame with the lead that

is used in the wall construction to provide a continuous lead barrier

that will function as an effective shield. There is other source of

event that is driven by man-made nuclear explosion that we need to

protect both biological and integrated circuits from and few, which

can be named are Electromagnetic Pulse (EMP), Electromagnetic

Interference (EMI) that are driven by the yield from a nuclear

explosion with Endo or Exo-Atmospheric burst. An EMP that is

resulting from above-atmosphere level detonation of a nuclear

device produces enough radiation to wreak havoc with electrical

systems. The blast produces a very brief but intense electromagnetic

field that can quickly induce very high currents in electrical devices,

shorting them out. The stronger the electromagnetic field — the

“pulse” the stronger the current, and the more likely electrical

devices are to “blow out.” It’s akin to a power surge that shorts out

your refrigerator or TV when too much voltage surges through the

electrical outlet… on a whole other scale.

Any digital integrated circuit built in any electronic device

requires to have a capability in order to be compatible to function

in such environment or to be Electromagnetic Compatible (EMC).

It is very obvious, when transition from analog circuit such as

old tube moved into path of digital circuits and consequently

manufacturing of transistor and eventually, Integrated Circuits

(ICs) in form of semiconductor, the combination of package of

sequence of events such as EMP and EMI driving a need for EMC for

the ICs becomes a necessity for shielding such as electronic devices.

These semiconductor devices, however, are more susceptible to the

effects of radiation than the old tubes and have to be made more

survivable or obey the requirement for EMC.

The survivability of these semiconductor devices is combination

of both an innovative design and shielding procedure. Packaging of

these semiconductor ICs within a layer of combined materials such

as Gallium (Ga)/Arsenide (As) provides a better protection layer

against the concerned radiation by design and Gallium Arsenide

Next Generation Semiconductors Market Expected to Grow to $22

Billion by 2026. As illustrated in (Figure 6), Next generation GaAs

semiconductors promise to bring a huge market, not totally replacing

the existing semiconductor market, but ultimately making a huge

dent in it. The ability to replace silicon semiconductors, a market

that is $500 billion dollars in 2020 makes one sit up and take notice.

The existing silicon semiconductor market is a pretty good size for

a market that barely existed in 1975. Next generation GaAs support

the signal speed that is needed to implement 5G. GaAs works in a

way that silicon cannot. The potential for the next generation GaAs

wafers is staggering, with the overall semiconductor market likely

to surpass $20 trillion by 2026 as the new industrial revolution

takes hold and 5G supports IoT that connects all things together.

Once economies of scale are realized these semiconductor GaAs

markets are expected to really take off. The sheer size of the global

semiconductor market at $500 billion dollars in 2020 shows that

the potential for next generation semiconductor technology is

truly exciting. The IC’s built-in wafer of GA/As and packaged with

these two combined materials are the best way shielding against

any natura or man-made radiation and they better opportunity of

survivability over-time.

The gallium arsenide wafers are next generation technology because they operate faster than the silicon semiconductors, they support a new, faster network called 5G. Gallium arsenide GaAs represents the next generation of semiconductor chips because the chips can do things that the silicon chips cannot do. GaAs does have a considerably higher bandgap than silicon. It is a direct bandgap semiconductor with a zinc blende crystal structure. Sensing for autonomous and electric vehicles is one use of technology. 3D Sensing for consumer electronics and use for lasers is common. Units are used in radar and lasers. The benefits of using GaAs in devices derive in part from the characteristic that GaAs generates less noise than most other types of semiconductor components. As a result, it is useful in weak-signal amplification applications. Due to these benefits related to generating less noise, GaAs is a suitable replacement for silicon in the manufacture of linear and digital ICs. A gallium arsenide wafer is also known as the Gallium arsenide substrate.

Conclusion

With the development of astronautic techniques, the radiation effects on Integrated Circuits (ICs) have been recognized by people. Environments with high levels of ionizing radiation create special design challenges for ICs. To ensure the proper operation of such systems, manufacturers of integrated circuits and sensors intended for the military aerospace markets adopt various methods of radiation hardening. The environmental conditions that the shielding is placed in is also important to consider. How well a material can withstand heat, if the shielding will be moved and potentially bumped and if the material must hold any structural load are all important factors in the environment that need to be considered. Shielding properties can change when put under stress or heated. Dents and damage to the material may also lessen the ability for a material to shield properly [6]. Safety is important in selecting the right shielding solutions. Leaded glass for example comes in several options including safety glass. Clear Leaded Acrylic is also a viable option to making durable clear shielding that is shatter resistant. Exposed lead may not be permitted in some scenarios due to the toxicity of lead, so polymers mixed with bismuth, tungsten or iron may be a better, non-toxic alternative [6]. Cost is an important to consider when selecting the appropriate shielding material for a job. Lead is a very effective and inexpensive shielding material compared to materials like tungsten and could work just as well for a lot of scenarios. Related to cost, another factor that needs to be considered is the ease of shipping, handling, and installation. Choosing between installing leaded drywall or sheet lead is one example where shipping and installation need to be considered [6].

References

- Higgins DF, Lee K, Marin L (1978) System-generated EMP. IEEE Trans. Electromagnetic Compatibility 20: 14-22.

- Barbara NV, Schrimpf RD, Kerwin WJ (1990) Ionizing-radiation-induced degradation in electronic power amplifiers. Proceedings of the Conference Record of the 1990 IEEE Industry Applications Society Annual Meeting pp. 1667-1672.

- Holmes-Siedle AG, Adams L (2002) Handbook of Radiation Effects. Oxford University Press, England, UK.

- Materials Used in Radiation Shielding. II Thomas.

- The Dangers of Neutron Radiation, Frontier Technology Corporation.

- Paul Rochus ‘Choosing the Right Radiation Shielding: Factors Considered by a Shielding Materials Expert’. Marshield.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...