Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6921

Research Article(ISSN: 2641-6921)

Laser-Treated Microstructure and Mechanical Properties in Ultralight Rolled and Annealed Mg-7.28Li-2.19Al-0.1Y Alloy Sheets Volume 3 - Issue 5

Furong Cao*, Bijin Zhou and Renjie Liu

- School of Materials Science and Engineering, Northeastern University, Shenyang, PR China

Received: March 04, 2021; Published: March 15, 2021

*Corresponding author: Furong Cao, School of Materials Science and Engineering, Northeastern University, Shenyang 110819, PR China

DOI: 10.32474/MAMS.2021.03.000175

Abstract

A new Mg-7.28Li-2.19Al-0.1Y alloy has been fabricated by rolling, and the rolled and annealed sheets were subjected to laser surface treatment. The microstructure and mechanical properties were investigated. The rolled alloy demonstrates ultimate tensile strength (UTS) of 299.48 MPa and elongation-to-failure (EL) of 15.71%; the annealed alloy demonstrates the UTS of 211 MPa and EL of 26.5%; laser treated rolled sample exhibits the UTS of 215 MPa and EL of 21.96%, and laser treated annealed sample exhibits the UTS of 205 MPa and EL of 19.15%. Laser treatment refines significantly the grains of Mg-7.28Li-2.19Al-0.1Y alloy, but laser treatment does not improve its mechanical properties due to its role of softening in the present alloy. The laser treatment softening phenomenon in this alloy is the first report of laser treated Mg-Li alloy.

Keywords: Mg-Li alloy; laser surface melting; microstructure; mechanical property

Introduction

Due to the demand of fuel savings and energy efficiency, lightweight magnesium alloys were investigated widely due to their high specific properties and potential applications in transportation systems. Mg-Li alloys, the lightest nontoxic metallic material up to date, recently have captured extensive attention [1-6]. Due to bad mechanical properties of binary Mg-Li alloy, aluminum (Al) element is usually added to the binary alloy to strengthen the alloy. In the meantime, Yttrium (Y) with a high melting point can also be added to the binary alloy to refine its microstructure and improve its mechanical properties. Therefore, a novel dual-phase-dominated Mg-7Li-2Y-1Y (wt. %) alloy is designed. Laser surface treatment (LST) is a rapid solidification process and consists of laser surface remelting or melting (LSR or LSM), laser shock peening (LSP), and laser ablation. The grain refinement and corrosion resistance of metallic materials can be improved greatly via LST. Zhang, et al. [7] investigated the microstructures of Mg-3Nd-1Gd-0.5Zr alloy via LSR and found significant grain refinement. Liu, et al. [8] reported that LSP improved the electrochemical corrosion resistance of AZ31 magnesium alloy. The pioneering work of Schemme, et al. [9] reported the rapid solidification microstructure of Mg-Li alloy via LST and found remarkable grain refinement. Zhang, et al. [10] recently have reported the improvement of corrosion resistance in Mg-10Li-3Al-3Zn alloy due to LST. However, it is regretful that they did not report the mechanical properties of Mg-Li alloys. To the authors’ knowledge, there appears to be no information available investigating the mechanical properties and microstructure evolution in novel Mg-7Li-2Y-1Y alloy fabricated by rolling and annealing. Thus, in this work, a superlight Mg-7Li-2Y-1Y alloy was fabricated by rolling and annealing. Its microstructure evolution and mechanical properties following LSM were investigated.

Experimental Procedure

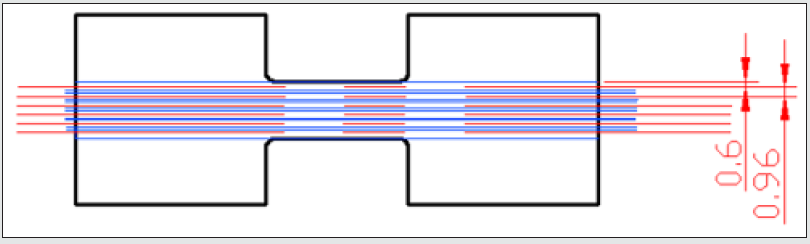

The purities of raw materials Mg, Al, and Li were more than 99.9 wt. %. Mg, Al, and Al-30 wt. % Y master alloy were melted in an electric furnace with a flux of LiCl and LiF (3:1) under the protection of argon (Ar) atmosphere. After they melted, Li blocks wrapped by aluminum foil were pressed into the melt under the protection of argon atmosphere. The melt was cast in a water circulated copper mold to obtain an Mg-7Li-2Al-1Y alloy (wt. %) ingot. The analyzed chemical composition of the ingot was Mg-7.28Li-2.19Al-0.1Y. After homogenization at 200 ˚C for 20 h, the ingot was hot rolled at 300 ˚C to a plate 5 mm in thickness with a percent reduction of 77.3% and cold rolled to a sheet 2 mm in thickness with a percent reduction of 60%. The annealing system was 350 ˚C for 3 h. Dog bone specimens with dimensions of 10 mm in gauge length, 6 mm in width, and 2 mm in thickness whose direction was parallel to rolling direction were stamped on a hydraulic press. Tensile tests were conducted at a crosshead velocity of 3 mm/min on CMT5105 microcomputer controlled electronic universal tester. Specimens for optical microstructure observation were polished by conventional metallographic methods and etched in a solution of 10%HCl+90%EtOH. The etched specimens were observed on Olympus DSX500 microscope. Laser surface treated position of the samples is shown in (Figure 1). The model of laser apparatus was JHM-1GY-400. The scanning velocity was 5 mm/s. The pulse width was 4 ms. The pulse frequency was 30 Hz. Average power was 250 W. The duty cycle (CT) was 16%, and the defocusing amount (△) was +3 mm. The protective gas was Ar, and the blowing flux was 25 L/min; the side protective gas flux was 15 L/min, and took on 45 degree with top blowing gas flow and was in parallel to the welding direction.

Results and Discussion

Microstructural Evolution of Mg-7.28Li-2.19Al-0.1Y Alloy

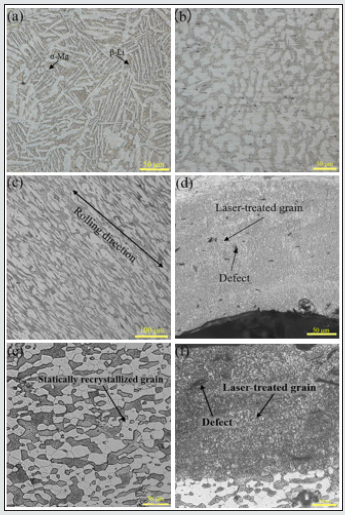

Figure 2: Microstructures of Mg-7.28Li-2.19Al-0.1Y alloy fabricated by (a) cast, (b) homogenization, (c) rolling, (d) laser treatment following rolling, (e) annealing, and (f) laser treatment following annealing.

(Figure 2) presents the microstructures of Mg-7.28Li-2.19Al- 0.1Y alloy in different processing states. As shown in (Figure 2a), the as-cast microstructure is a dual phase microstructure and consists of acicular dendrites formed by rapid water cooling. HCP (hexagonal closed packed)-structured white α-Mg phase and BCC (body centered cubic)-structured gray β-Li phase are visible. As shown in (Figure 2b), the homogenized microstructure becomes rounded and acicular dendrites disappear. As shown in (Figure 2c), fine and banded grains appear due to the action of rolling force. As shown in (Figure 2d), significant grain refinement occurs due to laser treatment following rolling or LSM. As shown in (Figure 2e), the static recrystallization occurs due to annealing, and equiaxed grains appear. As shown in (Figure 2f), significant grain refinement occurs due to laser treatment following annealing. These evidence demonstrate that LSM results in significant grain refinement in the Mg-7.28Li-2.19Al-0.1Y alloy fabricated by rolling and annealing.

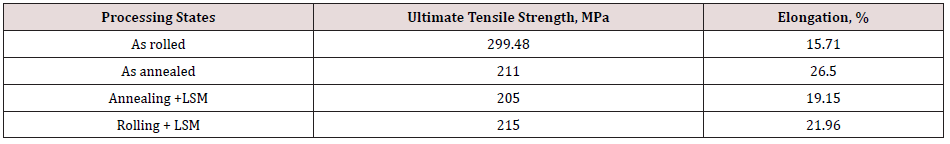

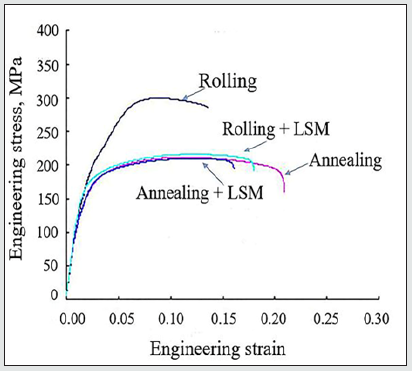

Figure 3: Engineering stress-engineering strain curves of Mg-7.28Li-2.19Al-0.1Y alloy in different states.

(Figure 3) shows the engineering stress-engineering strain curves of Mg-7.28Li-2.19Al-0.1Y alloy in different states. Table 1 shows the data of mechanical properties of Mg-7.28Li-2.19Al-0.1Y alloy. The as-rolled samples exhibit the highest ultimate tensile strength (UTS) of 299.48 MPa and the lowest elongation to failure (EL) of 15.71%o The as-annealed samples exhibit the highest EL of 26.5% with the UTS of 211 MPa. Laser treated rolled sample exhibits the UTS of 215 MPa and EL of 21.96%, and laser treated annealed sample exhibits the UTS of 205 MPa and EL of 19.15%. LSM treatment does not improve the mechanical properties of this alloy although significant grain refinement occurs. Possible causes of decrease in mechanical properties in this alloy are analyzed as follows. Firstly, LSM leads to the decrease in dislocation density and number of dislocations inside a grain due to laser-treated rapid melting and solidification. Thus, dislocation strengthening due to rolling is lessened after LSM. Secondly, although significant grain refinement occurs in this laser-treated alloy, solidified defects or the existence of pores result in the weakening of stress concentration and the heterogeneity of stress distribution in the microstructures. As a result, the LSM samples are prone to earlier failure at the defects and are difficult to accumulate enough strength. Thus, solidified defects result in the invalidity of Hall- Petch strengthening. Thirdly, due to high density heat input of laser, the LSM samples are softened instead of being hardened, and their UTS data are equivalent to those of the annealed samples in terms of the comparison of properties. Liu, et al. [11] investigated the effect of laser parameters on the mechanical properties of AZ61 alloy, and they found that the mechanical properties of laser-treated AZ61 alloy are superior to those of as-cast AZ61 alloy, and the UTS of laser-treated AZ61 alloy is 93% higher than that of as-cast AZ61 alloy. Also, Ballokova, et al. [12] reported that LSR improves the tribological performance of AZ61 alloy and AZ61/Al2O3 composite, and the wear rate is decreased by 48%. These reported results in laser-treated AZ61 alloys are contrary to our property results of Mg- 7.28Li-2.19Al-0.1Y alloy. This indicates laser-treated parameters have an important influence on the mechanical properties. Further investigation is required to solve this issue. After all, the laser treatment softening phenomenon in the present alloy is the first report of laser treated Mg-Li alloy.

Conclusion

The rolled alloy demonstrates ultimate tensile strength (UTS) of 299.48 MPa and elongation-to-failure (EL) of 15.71%; the annealed alloy demonstrates the UTS of 211 MPa and EL of 26.5%; laser treated rolled sample exhibits the UTS of 215 MPa and EL of 21.96%, and laser treated annealed sample exhibits the UTS of 205 MPa and EL of 19.15%. Laser treatment significantly refines the grains of Mg-7.28Li-2.19Al-0.1Y alloy, but laser treatment does not improve its mechanical properties due to its role of softening in the present alloy.

Fund Projects

National Natural Science Foundation of China (No.51334006).

References

- Cao Furong, Zhang Jian, Ding Xin, Xue Guoqiang, Liu Siyuan, et al. (2019) Mechanical properties and microstructural evolution in a superlight Mg-6.4Li-3.6Zn-0.37Al-0.36Y alloy processed by multidirectional forging and rolling. Materials Science and Engineering A 760: 377-393.

- Dutkiewicz Jan, Kalita Damian, Maziarz Wojciech, Faryna Marek (2020) Superplastic Deformation of Mg-9Li-2Al-0.5Sc Alloy after Grain Refinement by KoBo Extrusion and Cyclic Forging. Archives of Civil and Mechanical Engineering 20: 121.

- Wang Guowei, Song Dan, Li Cheng, Klu Edwin Eyram, Qiao Yanxin, et al. (2019) Developing Improved Mechanical Property and Corrosion Resistance of Mg-9Li Alloy via Solid-Solution Treatment. Metals 9: 920.

- He Yuqing, Peng Chaoqun, Feng Yan, Wang Richu, Zhong Jianfeng (2020) Effects of Alloying Elements on the Microstructure and Corrosion Behavior of Mg-Li-Al-Y Alloys. Journal of Alloys and Compounds 834: 154344.

- Kang Z X, Lin K, Zhang J Y (2016) Characterisation of Mg-Li Alloy Processed by Solution Treatment and Large Strain Rolling. Materials Science and Technology 32(5): 498-506.

- Li Yi, Guan Yanjin, Zhai Jiqiang, Lin Jun (2019) Hot Deformation Behavior of LA43M Mg-Li Alloy via Hot Compression Tests. Journal of Materials Engineering and Performance 28: 7768-7781.

- Zhang Duyao, Qiu Dong, Zhu Suming, Dargusch Matthew, StJohn David, et al. (2020) Grain Refinement in Laser Remelted Mg-3Nd-1Gd-0.5Zr Alloy. Scripta Materialia 183: 12-16.

- Liu Huaile, Tong Zhaopeng, Zhou Wangfan, Yang Yu, Jiao Jiafei, et al. (2020) Improving Electrochemical Corrosion Properties of AZ31 Magnesium Alloy via Phosphate Conversion with Laser Shock Peening Pretreatment. Journal of Alloys and Compounds 846: 155837.

- Schemme K, Hornbogen E (1991) First Examinations of Laser-treated Mg-Li-Al Alloys. Metall 45(10): 1007-1010.

- Zhang Lin-Jie, Zhang Hai-Bo, Lei Xiao-Wei, Wang Rui, Han Bai-Feng, et al. (2020) Laser Processing of Mg-10Li-3Al-3Zn Alloy Part II- Improving Corrosion Resistance of Multi-phase Mg Alloys by Laser Surface Processing. Journal of Manufacturing Processes 56: 571-580.

- Liu Shuai, Yang WenSheng, Shi Xiao, Li Bin, Duan Shengchao, et al. (2019) Influence of Laser Process Parameters on the Densification, Microstructure, and Mechanical Properties of a Selective Laser Melted AZ61 Magnesium Alloy. Journal of Alloys and Compounds 808: 151160.

- Ballóková Beáta, Falat Ladislav, Puchý Viktor, Molcanová Zuzana, Besterci Michal, et al. (2020) The Influence of Laser Surface Remelting on the Tribological Behavior of the ECAP-Processed AZ61 Mg Alloy and AZ61-Al2O3 Metal Matrix Composite. Materials 13(12): 2688.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...