Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6921

Mini Review(ISSN: 2641-6921)

Recent Advances in Smart Materials Categories Volume 2 - Issue 2

Ali Hilal-Alnaqbi1* and Sawsan Dagher2

- 1Abu Dhabi Polytechnic, Abu Dhabi, UAE

- 2Electromechanical Engineering Technology, Abu Dhabi Polytechnic, Abu Dhabi, UAE

Received: November 15, 2019; Published: December 02, 2019

*Corresponding author: Ali Hilal-ALNAQBI, Abu Dhabi Polytechnic, Abu Dhabi, UAE, Email ID:Ali.Alnaqbi@adpoly.ac.ae

DOI: 10.32474/MAMS.2019.02.000135

Abstract

Smart materials are a group of materials that alter its properties based on changes in their environment, thus making them stimuli-responsive materials. This study provides an overview of the six main categories of the recently used smart materials, namely, piezoelectric materials, photovoltaic materials, shape-memory materials, magneto strictive materials, thermoelectric materials, and chromogenic materials.

Keywords: Piezoelectric; Photovoltaic; Shape-Memory; Magneto strictive; Chromogenic

Introduction

Smart materials play a huge role in new technologies, which was

recently addressed by several reports. Smart materials and systems

will be specifically, critical to the enhancement of quality of life,

economic welfare, productivity, and sustainability. The adoption of

smart materials is associated with other rapidly rising technologies,

including nanotechnology, microelectronics, biotechnology, new

manufacturing processes, and robotics. Nowadays, companies

and commercial sectors have been utilizing smart technologies

in many of their products. The construction sector, being a

huge contributor to sustainability and energy consumption, has

improved its performance since implementing some of these

products; self-cleaning materials, self-healing constituents, anticorrosion

coatings, and smart windows. Furthermore, smart

technologies have been utilized for biomedical applications such as

smart drug delivery, antibacterial treatments, and cellular repair.

Smart materials are high-performance engineering materials, in

which one of their properties can be altered in a predictable or

controllable manner such as

(i) Mechanical Properties (E.G. Shape, Stiffness, Viscosity)

(ii) Thermal Properties

(iii) Optical Properties

(iv) Electromagnetic Properties

These properties can be changed by an external stimulus or

environment such as temperature, pressure, light, laser heating,

radiation, microwaves, voltage, electricity, pH, moisture, chemicals,

magnetic field, or mechanical force. Smart materials revert to their

original states once the external stimulus is removed, since the

change is reversible and can be repeated many times [1].

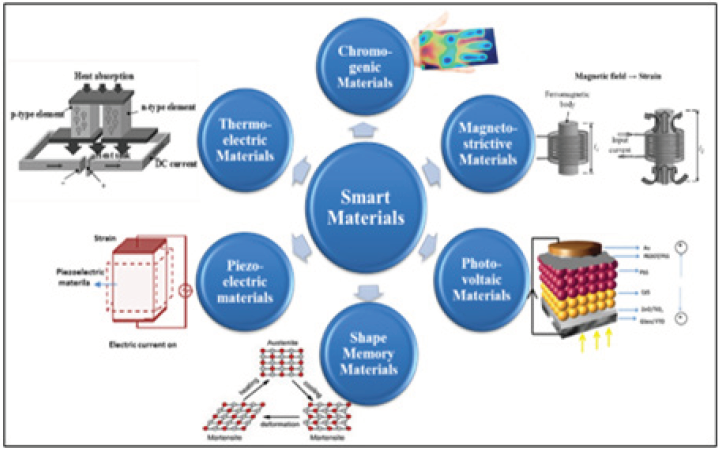

Classes of Smart Materials

Recently a wide variety of smart materials are developed and can be utilized in numerous scientific fields. Each has different properties that can be changed for specific applications. The common emerging classes of smart materials are shown in (Figure 1) as following: Piezoelectric materials generate a voltage when stress is applied. Piezoelectric effect is reversible, in which a stress will be produced when an electric field is applied. The most common piezoelectric material is a single crystal quartz. Other materials are PZT, lithium tantalate, lead titanate ceramic, barium titanate, lithium niobate, and piezoelectric polymers. Polymers have lower piezoelectric constant than ceramics, thus the shape change of piezoelectric polymers is less than that of piezoelectric ceramics considering the same amount of voltage applied. Also, ZnO thin film is extensively used in piezoelectric devices for acoustic wave’s generation, due to the fact that ZnO has a large electromechanical coupling [2]. Photovoltaic materials have the ability to convert light into electricity, known as photoelectric effect, using semiconducting materials such as silicon, gallium arsenide and nanomaterials (e.g. ZnO, TiO2, CuO, PbS). Photovoltaic materials absorb photons of light. As the photons’ energy equal to or greater than the band gap of the material electrons can be excited, creating mobile electrons and holes, these free electrons generate an electric current that can be used as electricity [3-10].

Shape-memory materials are stimulus-responsive materials that can be actuated on demand to recover their original shape, after being quasi-plastically distorted. Shape memory materials are ideal for an integrated intelligent system, in which the structure can sense the environmental change and then generate reactive motion as pre-programmed. The most common shape-memory materials are shape-memory alloys (SMA) and shape-memory polymers (SMP), in which a deformation in shape or size is obtained in response to temperature changes or stress changes (pseudoplasticity). Furthermore, magnetic shape memory alloys can be stimulated by applying a magnetic field to change their shape. The basic concept of the SMA working mechanism, that it will recover to its original form when heated beyond a certain temperature (i.e., the transformation is reversible), and the transformation in both directions is instantaneous. To fix the original “parent shape,” the alloy must be held in position and heated to about 500°C (932°F). This process is usually called shape setting. The actuation temperature can be determined accurately based on the SMA composition. SMA are a group of metallic alloys such as nitinol (TiNi) which, as previously mentioned, can return to their original shape and size when subjected to a memorization process between two transformation phases (martensite and austenite phases), which is temperature dependent. The martensite structure is stable at low temperatures and the austenite structure is stable at higher temperature. When a SMA is heated, it begins to transform from martensite into the austenite phase. This transformation phenomenon is known as the shape memory effect (SME). SMA exhibits large stress and strain factors, long fatigue life, and chemical corrosion resistance. SMP are distinguished from SMA by its unique properties such as light weight, ease of processing, high shape recovery of up to 400% plastic strain, chemical stability, transparency and low cost. Consequently, SMP are widely used for aerospace applications such as light actuators, structural parts with reduced size during transport, and expandable/deployable structures [11-13].

Magneto strictive materials change their shape (expand or contract) under the influence of magnetic field. Because of the rotation and alignment of the molecular dipoles and magnetic field boundaries of the material as a response to a magnetic field. This causes the material to strain and elongate, and vice versa, adjust their magnetization when mechanical stress is applied. Ferromagnetic materials are the most effective magnetostricive materials, due to the fact that they are isotropic with few impurities, which allows their molecular dipoles to rotate easily, and can be used to produce vibrations. As the applied magnetic field increases in intensity, the magneto strictive strain on the material increases. Magneto strictive materials include nickel, Co-Ni, Fe-Al, Fe-Ni (Permalloy), Fe-Co, Co- Fe-V, CoFe2O4 and NiFe2O4, and some rare earths and their alloys and compounds. Magneto strictive materials are used in several applications including actuators and sensors, ultrasonic cleaning devices medical devices, underwater sonar, industrial vibrators, vibration, and noise control systems [14]. Thermoelectric materials can directly convert heat into electricity and vice versa, based on See beck and Peltier effect. Thermoelectric materials utilize lost thermal energy or waste heat into efficient electricity for cooling applications. The most commonly used thermoelectric material is based on bismuth telluride (Bi2Te3). A typical thermoelectric material should have high electrical conductivity and low thermal conductivity such as Bi2Te3 and PdTe with piezoelectric impedance (ZT) about 1. However, these materials have some drawbacks, such as high cost, low stability at high temperatures, and environmental concerns. As an alternative, currently, intensive research is going on developing nanostructured thermoelectric materials. Thermoelectric materials are utilized in optoelectronic devices, solid state thermoelectric cooling, biothermal batteries, space applications, cooling devices and automotive power generation. Nevertheless, further improvements are required for optimization of both materials and devices’ performance [15-18].

Moreover, chromogenic materials are materials that change their color as a response to external stimuli (changes in environmental condition) this property is utilized in a wide range of applications. Four types of chromogenic materials are available based on the external stimuli that triggers the change in its color, these four types of chromogenic materials are

a. Photochromic materials, exhibit a change in color in response

to light, (e.g., light-sensitive sunglasses in which their color

become darker in the presence of bright sunlight)

b. Thermochromic materials show alteration in color according

to the change in their temperature

c. Electrochromic materials which change their opacity when a

voltage is applied (e.g., liquid crystal displays)

d. Halochromic materials change their color as a result of acidity

change

One application of halochromic materials is in paints for metal coating, thus corrosion in the metal can be indicated by the change in the color of the paint layer covering the metal. The process in which these materials change color is named chromism. In principle, the stimulus alters the equilibrium of electrons inside the molecule, which further leads to breaking the chemical bonds in the Chromogenic material. Consequently, altering some of the materials’ optical properties, such as absorption, transmission, reflectance, or emission. When the stimulus terminates, the material returns to its original electronic state, retrieviving its original optical properties (i.e., initial color or transparency) [19].

Conclusions

Smart materials are key to future solutions in technological advancements, impacting distinct fields, such as, pharmacy, engineering, biology, chemistry, architecture, automotive industry, and communications. The technology of smart materials is significantly impacting modernity and civilization, nowadays, it is the most auspicious technology that expand efficiency and save resources by swiftly reacting to corrosion, pH changes, water content, temperature, mechanical forces, and many other. This can outspread the service life of components and structures, reducing life cycle costs of structures including inspection, maintenance, and repair costs. Wisely acknowledging, understanding, and monitoring the configuration and microstructure of any new material is the key to enhancing and developing a smart material. Modern and advanced smart materials will unquestionably enhance the quality of our life.

References

- Zhang Z,Demir KG,Gu GX (2019) Developments in 4D-printing: a review on current smart materials, technologies, and applications. International Journal of Smart and Nano Materials 10: 205-224.

- Kim SW, Lee TG,Kim DH,Lee KT, Jung I, et al. (2019) Show more Determination of the appropriate piezoelectric materials for various types of piezoelectric energy harvesters with high output power. Nano Energy 57: 581-591.

- Dagher S,Haik Y,Tit N,Ayesh A (2015) PbS/CdS Heterojunction Quantum Dot Solar Cells. Journal of Materials Science: Materials in Electronics 27: 3328-3340.

- Tit N, Dagher S,Ayesh A,Haik Y (2014) Quantum confinement effects on electronic properties of ZnO Quantum Dots. Advanced Science, Engineering and Medicine 6: 1158-1166.

- Dagher S, Ayesh A, Tit N, Haik Y (2014) Influence of reactant concentration on optical properties of ZnO nanoparticles. Materials Technology: Advanced Performance Materials 29: 76-82.

- Dagher S,Haik Y,Ayesh A,Tit N (2014) Synthesis and optical properties of colloidal CuO nanoparticles. Journal of Luminescence, 151: 149-154.

- Tit N, Dagher S, Ayesh A, Haik Y (2012) Bowing character in wurtzite ZnO-based ternary alloys. Journal of Electronic Materials 41: 3111-3318.

- Dagher S,Haik Y, Ayesh A, Tit N (2014) Heterojunction solar cell based on p-type PbS quantum dots and two n-type nanocrystals CdS and ZnO. Springer International Publishing Switzerland Chapter p. 43.

- Dagher S, Yousif Z,Abdulkareem I,Alameri S, Haik Y (2014) Dye and nanoparticles-sensitized solar cells. Springer International Publishing Switzerland Chapter p. 44.

- Khashan S,Dagher S, Tit N,Alazzam A,Obidat I (2017) Novel method for synthesis of Fe3O4@TiO2 core/shell nanoparticles. Surface & Coatings Technology 322: 92-98.

- Fang CH,Zheng Y,Chen J,Yam MCH,Wang W (2019)SuperelasticNiTi SMA cables: Thermal-mechanical behavior, hysteretic modelling and seismic application. Engineering Structures 183: 533-549.

- Fahimi P, Eskandari AH, Baghani M, Taheri A (2019) A semi-analytical solution for bending response of SMA composite beams considering SMA asymmetric behavior. Composites Part B: Engineering 163: 622-633.

- Friend C (2001) Shape-memory alloys. Encyclopedia of Materials: Science and Technology (2ndedn),pp. 8445-8451.

- Zhou J,He Z,Rong C,Xue G (2019) A giant magnetostrictive rotary actuator: Design, analysis and experimentation. Sensors and Actuators A: Physical 287: 150-157.

- Cai B, Hu H, Zhuang HL, Li JF (2019) Promising materials for thermoelectric applications. Journal of Alloys and Compounds 806: 471-486.

- Dagher S,Soliman A,Ziout A,Tit N,Hilal-Alnaqbi A, et al. (2018) Photocatalytic removal of methylene blue using titania- and silica-coated magnetic nanoparticles. Materials Research Express 5: 065518.

- Khashan S, Dagher S,Al Omari S, Tit N, Elnajjar E, et al. (2017) Photo-thermal characteristics of water-based Fe3O4@SiO2 nanofluid for solar-thermal applications. Material Research Express 4: 055701.

- Dagher S, Hilal-Alnaqbi A, Tit N, Khashan S, Al Naimat F, et al. (2018) Thermal efficiency of a direct absorption solar collector using magnetic nanofluids. 5th International Conference of Renewable Energy: Generation and Applications (ICREGA18), IEEE Xplore, UAE University, UAE.

- Granqvist CG, Green S,Niklasson GA, Mlyuka NR,von Kræmer S, et al. (2019) Advances in chromogenic materials and devices. Journal of Alloys and Compounds 806: 471- 486.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...