Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Mini Review(ISSN: 2637-4595)

Woven Seamless of Clothes between Ancient Egyptian History and Future Volume 3 - Issue 4

Elsayed Ahmed Elnashar*

- Kafrelsheikh University, Egypt

Received: November 08, 2019; Published: November 18, 2019

*Corresponding author: Prof. Dr. Elsayed Ahmed Elnashar, Ph.D. Full-Professor of Textiles & Apparel, Faculty of Specific Education, Kafrelsheikh University, El-Geish Street, 33516 Kaferelsheikh City, Egypt

DOI: 10.32474/LTTFD.2019.03.000169

Introduction

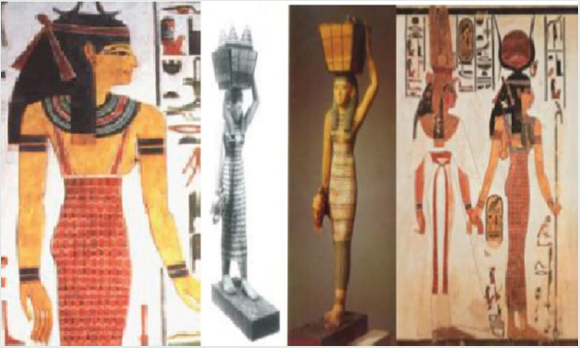

Woven Seamless of clothes between Ancient Egyptian histories in the textile industry is one of the oldest in the world. The oldest known textiles, which date back to about 5000 B.C., are scraps of linen cloth found in Egyptian caves. Woven Seamless of clothe the industry was primarily a family and domestic one until the early part of the 1500s when the first factory system was established. Woven Seamless of clothe is a One important difference between ancient Egyptian and Western aesthetics is that, in the former, there has been little if any critical discourse on art and beauty until very recently. Which can be taken as representative of various heterodox ancient Egyptian traditions after the fifteenth century, whether the middle Kingdom (c.2040-1640 BC) at Bani Hasan in middle Egypt. The earliest example is the tiny ivory statuette of an unknown First- Dynasty King (C. 2929-2770 BC) from Abydos and now in the British Museum. the traditional view that sculpture and painting with textures of stretch fabrics is 3D and painting 2D. Woven Seamless of clothe if these systems designed to acquire the motion of points on a flexible-moving surface such as cloth [1]. Historical research has uncovered ancient Egyptian formulae for Woven Seamless of clothe many conditions of which the aesthetical of Woven Seamless of stretch fabric, the reduction of stretch wrinkling, and there were in circulation at that time recipes for facilitating hair growth and getting rid of Woven Seamless of stretch clothes. and artists and sculptors and painting as Figure 1, were interested in fabric draping qualities. But also, to their clothes of women being massaged with sexual dressed of Woven Seamless of stretch fabric and in fine linens and garlanded with flowers are commonly depicted in the art of the time. The famous loom in Chnem Hotep`s tomb at Bani Hasan appear vertical, Contemporary tomb models like that of Mekhet-Re (C.2020BC) from Deir-el-Bahri clearly show horizontal loom, as well as spinning, plying and warping, the latter done by stretching warp-threads over pegs driven into a wall (Figures 1 & 2).

Figure 1:Illustrates Tube seamless clothes of Woven Seamless stretch dress at sculpture. This illustration is part of an ivory chest, it is decorated in a carved relief of a garden promenade of Tutankhamen and his wife Anch-es-Amun.

The Woven Seamless of clothe led us to the fabric structures to ancient Egyptian women for fitting-form of Tube seamless clothes stretch fabric and aesthetical, and help us for fitting equations, One reason the examined theories fail to identify characteristics essential to Woven Seamless of clothe throw fitting-form Tube seamless clothes of sculpture and painting with textures of stretch fabrics is that they focus on the psychological mechanisms or physical materials stretch fabric of their effects:

1. Unique Woven Seamless of clothe draping qualities:

draping qualities result in formation of very complex 3D shapes

Tube seamless clothes.

2. Dynamic behavior of Woven Seamless of clothe: This

behavioral change in deformation and drape compels

researchers to simulate the Tube seamless clothes flow of the

surface of the material during wear.

3. Non-linear deformation of Woven Seamless of clothe: The

non-linear nature of Woven Seamless of clothe deformation

limits the applicability of conventional.

First order linear models of deformation processes to textile

materials. In the form of the Kawabata fabric Evaluation system

(KFES), provided a tool to measure mechanical properties of

Woven Seamless of cloth.

Tube seamless clothes physical models

Woven Seamless of clothe physical techniques may be computationally more expensive than those of the geometric method may the time required for simulating a simple Woven Seamless of clothe sequence might physical methods use mathematical tools such as differential equations to design models and fuzzy topology. With the addition of a Woven Seamless of clothe visualization system by employing a multi-grid method and scaling technique to calculate Woven Seamless of clothe configurations [2].

Tube seamless clothes of hybrid models

Woven Seamless of clothe integrate techniques both the global geometric features and local physical behavior of Woven Seamless of cloth. The hybrid models usually use the geometric technique to determine the basic shape of Woven Seamless of clothe the simulated cloth and then employ a physical technique to refine the simulation. Deformable model to refine the approximated shape. Since the method is based on approximation of wrinkles, they used a swept surface technique to geometrically model the draped configuration of fabric.

Evaluation of 3D tube seamless stretch clothes

Woven Seamless of clothe the developed parameters were used to objectively evaluate Woven Seamless of clothe stretch. The applicability of these parameters was demonstrated using a three princess dresses. The stretch of the Tube seamless clothes form is analyzed. Using drape coefficient as the only factor for evaluating drape of Woven Seamless of cloth.

Unified tube seamless stretch clothes theory

Woven Seamless of clothe Adopt unified theory of stretch on the potential of interior Woven Seamless of clothe resulting from the stretch raw material and fabric structure which attract inward, and their relationship to the outside of the energy severity Tube seamless stretch fabrics resulting from body size, three-dimensional effect and aesthetical durability of Woven Seamless of cloth [3].

Tube seamless clothes parameters of stretch clothes

Woven Seamless of clothe as describe in the previous section, the processes polygonal model was using to characterize clothes drape after raw point cloud data of the draped clothes was converted to a processed polygonal model. Currently, there is no standard quantitative term or coefficient in use in the Tube seamless clothes and apparel industries to characterize clothes drape. In this research, simple and easy to calculate new parameters for garment drape evaluation

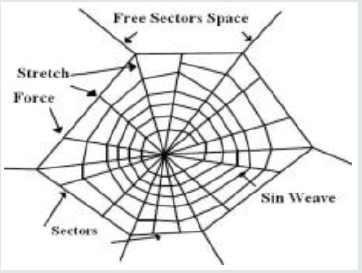

Geometry linear tube seamless stretch clothes of spider weaves

The environment affects the type of woven seamless of clothe the ancient Egyptians wore, since the environment was so hot the ancient Egyptians wore little or no Woven Seamless of clothe at all. If they did wear clothes, they were very thin and light. They also made almost all their Woven Seamless of clothe out of linen because they only had flax plants growing in Egypt. They made most of their clothes out of flax, which they could turn into linen. It’s considered the most important thing to consider when trying to achieve fit. In-Spider Stretch Weaves: The in-spider Woven Seamless of clothe stretch weaves deformation of a fabric due to its own weight is usually very small when most fabrics have a very large tensile modulus. In this study, a parameter was used instead of an actual tensile modulus for numerical stability. The parameter can be regarded as the maximum elastic strain of the fabric,

Conclusion

Woven Seamless of clothe of a unified stretch theory of ancient clothes and practical method to sculptures handle instability with introducing Woven Seamless of clothe stretch force into the dynamic simulation. The proposed method was shown to produce very realistic motion of Woven Seamless of clothe made from a range of Tube seamless fabric types such as: woven fabrics, knitting fabrics, using a uniform [4]. In particular, the power of the new equations response of stretch cloth, which increased stability of our algorithm allowed the simulation of for fashion dresses designs have very important applications in theoretical physics, quantum particle physics, particularly in connections with Woven Seamless of stretch clothe theory, and the integration between 3D body scanned measurement and apparel CAD system, and software that will allow automatic alteration of patterns according to scanned measurements & software that will allow the integration between a apparel CAD systems and textiles.

References

- EL Elsayed A (2010) A Unified Stretch Theory of Ancient Clothes on Some Basic Knowledge for Fashion Dresses Design. 5th International Textile, Clothing & Design Conference-Magic World of Textiles, Dubrovnik, Croatia, Egypt.

- EL Nashar EA (2002) Woven design with effective the deformational behavior 3D pattern for dresses. Conference the faculty of specific education in Fayum, Cairo University, Egypt.

- EL El Sayed (2019) Contemporary Fashion and its Artistic Values in the Fifth Generation of Technology. Latest Trends in Textile and Fashion Designing (LTTFD) 3(3): 325-327.

- EL Nashar EL Sayed A (2018) Engineering Aesthetics Science and Ergonomics by Using Technology in Ancient Egyptian for Textiles Design. Latest Trends in Textile and Fashion Designing, Trends in Textile & Fash Design 2(3): 191-192.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...