Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Review Article(ISSN: 2637-4595)

Economic Aspects to Stakeholders of Education Institutions Between Fashion Design of Seamless Clothes Volume 4 - Issue 3

Elsayed A Elnashar1*, Gabriella M Walek2, Albu Adina Victoria3 and Anca Simon3

- 1Full Professor of Textiles & Apparel, Home Economic Department, Faculty of Specific Education, Kaferelsheikh University, Egypt

- 2President National Fashion League Hungary Association Global Sustainable Fashion Week

- 3Facultatea of Energetic Engineering and Industrial Management, Department of Textiles, Leatherworks and Industrial Management, University of Oradea, România

Received:October 08, 2021 Published: October 22, 2021

*Corresponding author: Elsayed A Elnashar, Full Professor of Textiles & Apparel, Home Economic Department, Faculty of Specific Education, Kaferelsheikh University, Egypt

DOI: 10.32474/LTTFD.2021.04.000187

Abstract

History of Seamless Clothing Technology throw in the tombs of the Egyptian pharaohs serve as an inspiration for today’s textile and clothing industry. And first seamless apparel of waving prototype came out of the Egyptian pharaohs, it was widely used immediately because of the unstable test run of the equipment. the Ancient Egyptian world’s first seamless clothing was officially introduced to the market until Nowadays. many companies of around the world products mainly target luxury goods of high-end customers; the largest seamless clothing manufacturer in all around the world, are the leading enterprises in the whole seamless clothing industry at that moment, and the renewal of its product series represents education institutions between fashion design of seamless clothes the technological development track of the whole industry to stakeholders. In the future, economic aspects with the increasingly obvious design and development trend of “underwear for external wear” of seamless clothing products, the consumption substitution education institutions between fashion design of seamless clothes speed of seamless clothing for traditional textile clothing will also be accelerated, seamless clothing products will become an important supplement to traditional woven and knitted clothing and even nonwoven clothing.

Keywords: Economic Aspects; Stakeholders; Education Institutions; Fashion Design; Seamless Clothes

Introduction

Education of technical institutions has the power to uplift a country and establish a healthy, efficient economy. It has also played a pivotal role in the increase of garments productivity and wages amongst workers and proved to be a successful endeavor for investors. Fortunately, there is much more potential within education to help the world to flourish. The economic benefits of technical institutions such as technical secondary and universities of education are clear for the entire globe. Nevertheless, there are further steps to maximizing productivity and reaping even more economic benefits education of technical secondary and universities between fashion design of seamless clothes (Figure 1). Some ideas are:

a) Increase investment in the quality of technical secondary

and universities schooling, given that technical secondary

education has expanded exponentially already.

b) Promote educational clothes and textiles efficiency in policy

through policymakers and government.

c) Reform clothes and textiles school management systems and

implement more effective performance metrics.

d) Implement more effective and fair approaches to school

funding.

e) Report more data on clothes and textiles schools’ performance.

The seamless garments found in the tombs of the Egyptian

pharaohs serve as an inspiration for today’s textile and clothing

industry. This is definitely an important topic towards the

sustainable fashion’s concepts from some points, as in case of

seamlessness, the design of the garment is minimizing the amount

of material left over and the resources in production by eliminating

the fabric laying, cutting and sewing process. Seamless garments

take 30 percent to 40 percent less time in comparison to the cutand-

sew version minimizing the traditional labor-intensive step of

cutting and sewing. Seamless clothing is a product of tridimensional

one-time forming clothing produced by the seamless circular

knitting device. The products are precisely fitted to the body and

the lack of seams provides an improved comfort at wearing and the

design has a clean look. The creation of the collection is flexible, and

it can be adapted very quickly for the demand with a just in time

production (Figure 2). The whole process can avoid any failure of

the stitching process, and it is cost saving. There is an increasing

demand by consumers for these comfortable clothing, so many

well-known brands create their seamless collection taking into

consideration the mentioned advantages [1-3].

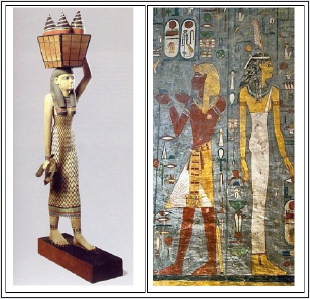

Figure 2: Seamless Clothes of Ancient Egypt at Left, and at Right, It as Tubular silhouettes Stretch fabrics Body-conforming Dressed [14].

In Europe, the Italian brands, play a leading role not only in the design and production of the different seamless products (lingerie, swimwear, sportswear, fashion articles), but also in the production of the necessary cutting-edge circular and 3D machines and technology. Nowadays there are many new developing companies in Far-East, Asia working in this sector. The most famous company on this field is in Italy. They can offer a flexible and innovative seamless technology: the Seamless technology is an innovative concept in producing clothing almost free of seams. This is the result of the commercial and technical synergy among the Companies (Figures 3-6). It provides designers with a multitude of styles and colors in which to create beautifully designed products that fully integrate fashion with function for satisfying a variety of end-users. The seamless knitting machines almost eliminate the need to produce and then sew together pieces of fabric, thus making the seam obsolete” [1-3]. Seamless garments are primarily made from a combination of microfiber yarns, (like Nylon), Lycra, and cotton etc.. It would be important for yarn producers to look for sustainable solutions in their production. There are some positive changes for example, in case of Lycra. The company states, that. Now more than ever, eco-conscious consumers (especially millennials and Gen Z) are looking for sustainable or “green” fashion options to reduce their ecological footprint and feel good about their purchase”. They have already developed LYCRA® T400® Eco Made, which fiber comes from recycled plastics and renewable plant-based resources [1-3]. There are continuous development and new innovation in seamless techniques, and as we see the fibre producers and yarn manufacturers have a role to influence the seamless clothing brands for a more sustainable, eco- and climate-conscious production [1- 3]. Due to the new smart fibres and intelligent materials the range of the seamless products is expanding from the general fashion clothing to special applications, for example regarding the medical and healthcare textiles (bandages, medical stocking etc). The seamless garment has new potentials in the production of smart clothing. The smart clothes are enhanced with technology to add functionality beyond traditional use. They are mostly made from intelligent, advanced textiles using build in circuitry, sensors, and via the smart sensors, these type of garments collect activity metrics and key biometric and the data can be sent to your smartphone (using Al-powered apps) and you can also check your performance or health state in this way [1-3].

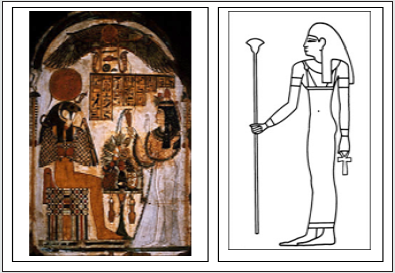

Figure 3: Seamless Clothes of Ancient Egypt ”Queen Nefertariat” Left, and at Right, Stretch fabrics Body-conforming Dressed of ”Queen Ankhesenamun” [14].

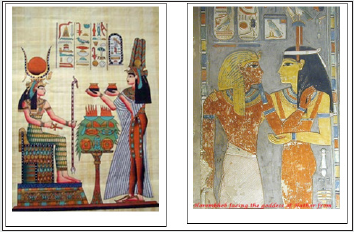

Figure 4: Seamless Clothes of Ancient Egypt , stretch fabric at Left, and at Right, Stretch fabrics Body-conforming Dressed of stretch fabric [14].

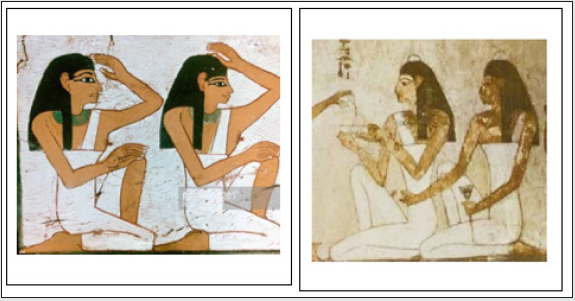

Figure 5: Seamless Clothes of Ancient Egypt , Body-conforming Dressed of stretch fabric, at Left, and at Right, [14].

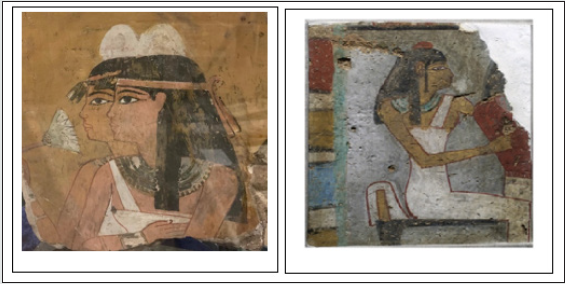

Figure 6: Seamless Clothes of Ancient Egypt , Body-conforming Dressed of stretch fabric, at Left, and at Right.

As the strongest areas of smart closing are underwear,

sportswear and healthcare/medical clothing, and the latter is

expected to grow radically, this also correlates with the future

possibilities of seamless garments. The stakeholders of the textile

and clothing industry should seek opportunities for collaboration in

all priority themes, which are sustainable for our future generations.

Education must be used to transfer information from old, traditional

technologies to today’s new innovative developments, so that the

new generation can acquire a basic knowledge about the subject

[1-3]. When we talk about Ancient Egypt, we should not forget

that even then Egypt had such a high level of technical knowledge

that we still admire today. And when we talk about the textiles and

clothing used at that time, it is natural that seamless garments

should lead us from there to smart clothing, which represents one

of the most significant technological development in the history

of the clothing industry. Our common interest to move for a more

creative, innovative, and sustainable fashion industry using all the

possibilities to change the information with the professionals at

conferences, workshops and to educate the next generation and

enable them to take part also in different projects as well [1-3]. In

Europe we have many projects for the transnational collaboration in

the fashion and textile industry. One of the most important projects

in the creative industry is the WORTH Partnership Project, which is

funded by the COSME program of the European Union (Figure 7). It

creates and supports transnational collaborations between fashion

designers, creative people, manufacturing enterprises (SMEs) and

technology firms looking to develop design-driven and innovative

products. The applicants during the past three calls made many

innovative proposals and very soon the WORTH II https://www.

worthproject.eu/partnership-projects/ is coming to deal with

globally important challenges relating to our issue too [1-3]:

a. Circular economy

b. High-value added solutions

c. Digitized business models

d. Smart materials

e. Social innovation

f. Heritage preservation

Figure 7: Seamless Clothes of Ancient Egypt , Body-conforming Dressed of stretch fabric, at Left, and at Right, as Tubular silhouettes Stretch fabrics [5,8].

Education for Fashion, Textiles & Clothing Technologies

Education for Fashion, Textile & Clothing Technology is a novel initiative of Egyptian faculties of applied arts Egyptian faculties of applied arts promoted with the intention of contributing towards the development of the Clothing and Textile sector through technology and innovation. Further the motive is supported by upskilling the labour force who contributes to the improvement of the industry by offering a range of academic programs from Certificate level up to degree qualification. Egypt Technological Campus Egyptian faculties of applied arts being in line with the government vision as a corporate venture, launching its first enterprise-based textile/clothing learning unit, and Center for Fashion in holding company, Textile & Clothing Technologies Egyptian faculties of applied arts [4], This state-of-the-art technological center in holding company will facilitate towards to help the academic and industries of textiles and clothes, oriented enterprise based undergraduate and post graduate degree programs and research activities for the advancement of the textile complex (Figure 8). Whilst training the young talent to be enterprise-based textile / clothing technologists, the Education will have close association with the textile/ clothing industry and conduct industry-based research to bring about new findings to develop the industry. All efforts will be taken to understand the industry needs and provide solutions that will resolve problems. The modern laboratories and workshops will enhance infrastructure facilities that will enable students to experiment and experience the processes more fully. The Education for Fashion, Textile, and Clothing Technologies will unleash newness and creativity into the world. We thrive on intuition and opportunity. We at the Education value independence and creations, to match youth with practicality and experience, art with craft. We can couple creativity and technology, management and merchandising, work and wonder. We inspire and empower. We promote the new, the different and the courageous. Our courses provide the skills, experience, contacts and confidence to succeed in the competitive world of clothing manufacturing.

Figure 8: Seamless Clothes of Ancient Egypt , Body-conforming of stretch fabric, at Left, and at Right, as Tubular silhouettes Stretch fabrics [8].

Objectives

a) To provide excellent education in textile/clothing studies to

students who enter Egyptian faculties of applied arts as either

school leavers, employed staff and/or mature persons and

earn a reputation for education and vocational training from

the industry at large.

b) To conduct academic, administrative, and other services

effectively, organized and professional manner that will

enhance the image and recognition of the Education bringing

all stakeholders, and customers inspired with seamless

solutions and satisfaction.

The Education for Fashion, Textiles and Clothing Technologies of

Egypt Technological Campus is introducing a series of short courses

for those who wish to embark on either enterprise development

or self-employment activity in the field of garment manufacturing.

These courses are conducted in English/ Arabic languages. They

will be held in Egypt Campus during week-ends. Anyone can apply

but ideally suited for those who wish to learn the basics of garment

manufacturing to develop their entrepreneurial skills. All efforts

will be taken to help the candidates to develop a start-up project.

Methodology and Analysis

Methods this research is designed according to qualitative research method. The phenomenological study approach was used in the research.

Egyptian Creativity and Innovation

Technology and innovation remain the most exciting sectors in the apparel industry and Egyptian despite its many challenges continues to be an innovation hub for the world of apparel. Having a clear vision with a diverse workforce whilst focusing on productivity improvements and being frugal in all our activities is what leads us to sustain such a successful industry. Driven by a clear purpose to care about who our products interact with and the impact it makes on our environment, the apparel industry drives technology and innovation in ways that are changing how the fashion industry works. With this rise of high-tech companies in the region many Egyptian textile manufacturers as a company (Murad Industrial Company) in Elbour city, Egypt (Figure 9). That using Santonin seamless machine, for producing the modern of seamless clothes run their own IT subsidiaries and are equipped for change. It can be noted that with the industrial expansion we advocate Industry 4.0 whilst preparing for the next evolution, which is industry 5.0, in order to be truly sustainable factories of the future. As a growing industry we maintain a strong bond with Government institutes and Universities to advocate the growth of the industry within the country. It is due to maintaining positive ties with Suppliers, Customers and constantly evolving our business models that it has enabled Egyptian to propel itself as the most preferred destination in Global Apparel Manufacturing.

Sustainability meets Textile manufacturing

Egyptian Apparel has championed the cause of sustainable manufacturing for many years. This commitment has seen impressive changes in manufacturing processes, sourcing strategies and product innovation, making Egyptian a leading destination for brands that care about the environmental impact of their garments. In a testament to our commitment, Egyptian industry boasts the world’s the custom-built green apparel factories and Africa’s Neutral fiber Manufacturing. The recent investment in rooftop Solar Panel installations of solar textiles at Egyptian manufacturing facilities is just the inception of the long-term goal in sustaining the environment and being responsible for the limited environmental resources available to us. We are constantly looking for ways to minimize the negative impact on the environment and invest in technologies to uplift environmental sustainability (Figure 10).

Learning Resources for Fashion Design

Clothes and Fashion in ancient Egypt, clothing in ancient Egypt, ancient Egyptians were extremely interested in fashion and its changes. This seems evident from trends seen in tomb scenes where the costumes and styles of the upper classes were soon copied by the lower classes. The most common fabric for clothing (both women’s and men’s) was linen.

Woman’s sheath dress typical of the Old Kingdom [5]

Stretch fabrics Body-conforming Dressed made from linen stretch fabric. May be held in place by stirrup. As straight: Slimlegged Dresses with circumference of leg hem less than 18 inches. (Also called stovepipe dresses) [6]. And we know well there is not any material of spandex where used times to get a Stretch but for stretch potential they are using the Stretch fabric structures like spandex structures. In the middle body: Wrap dress wraps and fastens to one side, either front or back. May be held with button/ buttonhole, tie, or belt. Variations include back-wrap, kimono, surplice, and bathrobe dresses. Was made from transparence of white linen woven fabrics [7]. Wood, gesso, pigment third Intermediate Period, Dynasty 22, ca. 956-712 B.C. Luxor, the Ramses During certain periods, people adored gods through the king, while in other eras, such as the time in which this stela was made, people had direct contact with their deities. Here, a woman named Djed-khonsu-iw-es-ankh (“The God Khonsu Said she will Live”) pours a water offering over a stack of offerings. An example of the water vessel shown on the stela is exhibited to the left/right, and examples of the offering buckets which hang below the table are exhibited to the left/right [5].

Nefertari’s Tomb

In both photos, there are shown as Draped dresses: Dresses with additional fullness pleated, gathered, or draped on one side. (Also called sarong Dresses if wrapped) [6]. Was made from transparence of white linen woven fabrics. Draped: means Dress with additional fullness pleated, gathered, or held to one side. So, Wrap means Dress wraps and fastens to one side, either front or back. May be held with button/buttonhole, tie, or belt. Variations include back-wrap, kimono, surplice, and bathrobe dresses (Figure 11).

Figure 12: Seamless Clothes of baced of Ancient Egypt, Body-conforming of stretch fabric, as sports bra [18].

Results and Discussions

Education of technical secondary and universities between fashion design of seamless clothes. The Economic Effects of high school of textiles and clothes Education, garments, and textiles Education of technical secondary and universities between fashion design of seamless clothes, According to the World Bank, one of the pivotal benefits of education is labor market earnings [8]. Workers with more education earn higher wages than employees with no post-secondary education. The high school of technical textiles and clothes degree does not susceptible to unemployment so workers with a bachelor’s degree. Median college-educated workers earn 80 percent more than those with only a high school education. Additionally, workers with some college education but no completed degree earn 20 percent more than only high school trained employees.

Unified tube seamless stretch clothes theory [5,8]

Woven Seamless of clothe adopt unified theory of stretch on

the potential of interior Woven Seamless of clothe [7]. Resulting

from the stretch raw material and fabric structure which attract

inward, and their relationship to the outside of the energy severity,

Tube seamless stretch fabrics resulting from body size, give threedimensional

effect and aesthetical durability of Woven Seamless

of cloth [7,8]. Women’s Fashion at first right photo and left body

in the left photo: stretch fabrics body-conforming at dresses made

from linen stretch fabric [6]. May be held in place by stirrup. As

straight: Slim-legged dresses with circumference of leg hem

less than 18 inches. (Also called stovepipe dresses). The style of

sundress dress with camisole or halter type top worn for casual

summer wear. As Camisole: neckline just above the bustline, held

by straps over the shoulder. Strap width may vary from very narrow

(spaghetti) to wide. The right women at left photo there is draped

dress with additional fullness pleated, gathered, or draped on one

side. (Also called sarong dress if wrapped). A draped dress with

additional fullness pleated, gathered, or held to one side. Of wrap

dress, wraps and fastens to one side, either front or back. May be

held with button/buttonhole, tie, or belt. Variations include backwrap,

kimono, surplice, and bathrobe dresses. Was made from

transparence of white linen woven fabrics. By Woven Seamless of

clothes between Ancient Egyptian histories in the textile industry

is one of the oldest in the world [7].

The oldest known textiles, which date back to about 5000

B.C., Stretch fabrics Body-conforming Jumpsuit made from linen

stretch fabric. May be held in place by stirrup. As Straight: Slimlegged

with circumference of leg hem less than 8.5 inches. (Also

called stovepipe Jumpsuit) [16]. And we know well there is not

any material of spandex where used there times to get a Stretch

but for stretch potential they are using the Stretch fabric structures

like spandex structures [8]. Asymmetric Jumpsuit that is not the

same on left and right sides. May drape to one side or close to

one side. May cover only one shoulder. (Also called one-shoulder

or toga) [9]. Jumpsuit by one shoulder Combination bodice with

divided or split Jumpsuit. Variations include culotte dress, pant

gown, panel Jumpsuit, and Jumpsuit shift. Jumpsuit Combination of

Jumpsuit and shirt or blouse in one piece. Of Woven Seamless of

clothes between Ancient Egyptian histories in the textile industry

is one of the oldest in the world [7]. The oldest known textiles,

which date back to about 5000 B.C, [10,11] are scraps of linen

cloth found in Egyptian caves [12]. Woven Seamless of clothe the

industry was primarily a family and domestic one until the early

part of the 1500s when the first factory system was established.

Woven Seamless of clothe is a One important difference between

ancient Egyptian and Western aesthetics is that, in the former, there

has been little if any critical discourse on art and beauty until very

recently. Which can be taken as representative of various heterodox

ancient Egyptian traditions after the fifteenth century [7]. Stretch

fabrics Body-conforming Dresses made from linen stretch fabric

[13]. May be held in place by stirrup. As Straight: Slim-legged Dresses with circumference of leg hem less than 18 inches. (Also

called stovepipe Dresses) [6]. And we know well there is not any

material of spandex where used there times to get a Stretch but for

stretch potential they are using the Stretch fabric structures like

spandex structures. Asymmetric; Dress that is not the same on left

and right sides. May drape to one side or close to one side[14]. May

cover only one shoulder. (Also called one-shoulder or toga). Dress

Jumpsuit by one shoulder Combination bodice with divided or split

dress. Variations include culotte dress, dress gown, panel Dress,

and Dress shift. Jumpsuit Combination of pants and shirt or blouse

in one piece. Woven Seamless of clothes between Ancient Egyptian

histories in the textile industry is one of the oldest in the world.

The oldest known textiles [14], which date back to about 5000

B.C., are scraps of linen cloth found in Egyptian caves. Woven

Seamless of clothe the industry was primarily a family and domestic

one until the early part of the 1500s when the first factory system

was established [7,15]. Stretch fabrics Body-conforming dresses

made from linen stretch fabric. May be held in placeby stirrup. As

Straight: Slim-legged dresses with circumference of leg hem less

than 18 inches. (Also called stovepipe dresses) [6]. And we know

well there is not any material of spandex where used there times

to get a stretch but for stretch potential they are using the Stretch

fabric structures like spandex structures [14,16]. Asymmetric

dress that is not the same on left and right sides. May drape to one

side or close to one side. May cover only one shoulder. (Also called

one-shoulder or toga). Camisole: Neckline just above the bustline,

held by straps over the shoulder. Strap width may vary from very

narrow (spaghetti) to wide. Woven seamless of clothes between

Ancient Egyptian histories in the textile industry is one of the oldest

in the world. The oldest known textiles, which date back to about

5000 B.C., Historical research has uncovered ancient Egyptian

formulae for Woven Seamless of clothe many conditions of which

the aesthetical of Woven Seamless of stretch fabric, the reduction of

stretch wrinkling, and there were in circulation at that time recipes

for facilitating hair growth and getting rid of Woven Seamless of

stretch clothes [7,8]. Stretch fabrics Body-conforming Jumpsuit by

one shoulder made from linen stretch fabric. May be held in placeby

stirrup. As Straight: Slim-legged Jumpsuit by one shoulder with

circumference of leg hem less than 8 inches. (Also called stovepipe

Jumpsuit by one shoulder) [6]. And we know well there is not any

material of spandex where used there times to get a Stretch but for

stretch potential they are using the Stretch fabric structures like

spandex structures [17]. Asymmetric Jumpsuit by one shoulder

that is not the same on left and right sides. May drape to one side

or close to one side. May cover only one shoulder. (Also called oneshoulder

or toga). Jumpsuit by one shoulder Combination bodice

with divided or split Jumpsuit. Variations include culottes, Jumpsuit

gown, panel Jumpsuit by one shoulder, and Jumpsuit shift. Jumpsuit

Combination of pants and shirt or blouse in one piece of Woven

Seamless of clothe if these systems designed to acquire the motion

of points on a flexible-moving surface such as cloth to their clothes

of women being massaged with sexual dressed of Woven Seamless

of stretch fabric and in fine linens and garlanded with flowers are

commonly depicted in the art of the time [7,8].

Results of Designs seamless

From Ancient Egyptian history to modern knitting industry,

weaving, it will be the best distinction between seamless clothing

and other clothes within the production technique. The semimanufactured

fabric of seamless clothing is woven knitted directly

from yarn to semi-finished fabric with a maker, while routine

fashion is made from eliminating the whole product [18]. Seamless

clothing factories use tumbler of double clothes and or circular

knitting equipment to weave [7,17,19]. The semi-done textile

woven from a seamless knitting machine is called “Blank cloth”.

Economic aspects to stakeholders of education by using seamless

clothes as benefits [15] are:

a. Body-building and close-fitting.

b. Frictionless and no-chafing.

c. Durable in use.

d. Light-weight.

e. Various customized designs.

f. Cost-saving.

g. Comfortable.

h. Time-saving.

i. Labor –saving.

j. Economic–saving.

k. Using machine by computers(advanced technology).

l. Using fashion trends

Conclusions

The notion that education and economic growth hold a relationship with each other is not a new idea throw the Education of technical secondary and universities between fashion design of seamless clothes. However, what is the extent of this relationship? What role does education play in development countries, and finally, what are the exact economic benefits of education both in the Education of technical secondary and universities, it will be seen.

References

- C Hina Fitness clothing (2020) What is Seamless Clothing?- Seamless Clothes Manufacturer.

- SANTONI® More than 100 years of Innovation (2021) Seamless technology.

- WORTH Partnership Project(2021) incubation program to develop new businesses.

- EL Nashar EA (2002) Woven design with effective the deformational behavior 3D pattern for dresses. Conference the faculty of specific education in Fayum, Cairo University, Egypt.

- EL Nashar EA (2010) A Unified Stretch Theory of Ancient Clothes on Some Basic Knowledge for Fashion Dresses Design. 5th International Textile, Clothing & Design Conference-Magic World of Textiles, Dubrovnik, Croatia, Egypt.

- ELNashar EA, Zakharkevich O, Shvets H, Selesnyova A (2019) Visual Dictionary In Textiles & Apparel. Khmelnytskyi National University Ukraine.

- EL Nashar EA (2019) Woven Seamless of Clothes between Ancient Egyptian History and Future. Latest Trends in Textile and Fashion Designing (LTTFD), Trends in Textile & Fash Design 3(4): 655-657.

- EL Nashar EA (2018) Engineering Aesthetics Science and Ergonomics by Using Technology in Ancient Egyptian for Textiles Design. Journal of Latest Trends in Textile and Fashion Designing Trends in Textile & Fash Design 2(3).

- EL Nashar EA (2021) The TV program About the visual dictionary book with Prof. Dr. Elsayed Ahmed Elnashar 19 May 2021 in Cairo, Egypt.

- Douglas J Brewer, Emily Teeter (2021) Ancient Egyptian Society and Family Life.

- Fashion in Ancient Egypt (2021).

- EL Nashar EA (2018) NanoArt as Multidisciplinary of Nanotechnology with Novel Art for Fashion and Interior Design. Journal Buletinul AGIR 4.

- EL Nashar EA (2018) Philosophy of the Construction Elements of Fashion. Journal of Trends in Textile Engineering & Fashion Technology 4(4).

- EL Nashar EA (2021) Egypt Is A Mother Of Fashion Science 7000 Years Old. BC Online Magazine For Textiles, Clothing, Leather And Technology.

- EL Nashar EA (2019) Contemporary Fashion and its Artistic Values in the Fifth Generation of Technology. Latest Trends in Textile and Fashion Designing (LTTFD) 3(3): 325-327.

- EL Nashar EA (2018) A Unified Fashion Technology in Trends of Textile Engineering Science 7000Bc in Egypt. Journal of Trends in Textile Engineering & Fashion Technology, CRIMSON PUBLISHERS, Eng Fashion Technol 2(1).

- EL Nashar EA (2018) Philosophy of the construction elements of fashion. Online magazine for Textiles, Clothing, Leather and Technology 4(4): 543-544.

- EL Nashar EA (2018) Trends in Mathematical Stitchless Model of Volume Fitting Stretch for Design of Sport Bra. Journal of Trends in Textile Engineering & Fashion Technology CRIMSON PUBLISHERS, Eng Fashion Technol 2(1).

- EL Nashar EA (2018) Engineering Aesthetics Science and Ergonomics by Using Technology in Ancient Egyptian for Textiles Design. Latest Trends in Textile and Fashion Designing, Trends in Textile & Fash Design 2(3): 191-192.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...