Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6794

Reearch Article2641-6794

Sensor for Landmine Detection using Unmanned Vehicle Metal Detector and Mobile Computing Technology Volume 4 - Issue 4

Nouman Hassan1*, Zeeshan Haider2, Shahzad Anwar3,4, Shamaraz Firdous4 and Chen Yi Hong1

- 1School of computer, China West Normal University, China

- 2Capital University of Science and Tech. (CUST), Islamabad

- 3Institute of Biophysics, Chinese Academy of Sciences, China

- 4National Institute of Lasers and Optronics (NILOP), Islamabad, Pakistan

Received: February 05, 2020; Published: February 19, 2020

Corresponding author: Nouman Hassan, School of computer, China West Normal University, China

DOI: 10.32474/OAJESS.2020.04.000194

Abstract

Land mines impose humanities, social, psychological and economic consequences. To eliminate the threat of mines, the only possible solution is to remove them individually without causing any damage. In this paper we design and developed simple and cost-effective system that can used to detect the buried controlled wirelessly to avoid human causalities. Our proposed system aims to detect the landmine without any physical contact with landmine detector by a robotic vehicle operated by robotic car and signal at mobile. There are currently more than 500 million landmines are buried in more than 70 countries and demining of these mines will take decades. A satisfactory demining rate can only be accomplished by using new and enhanced technologies such as enriched sensors, well-organized manipulators and mobile unmanned robots. The concept and idea are formed into physical hardware mechanisms from theoretical stages by construction of prototype and then software program combined into the proposed system so to investigate and test the model that had been developed. The designed model is skilled of spotting mines, controlling himself from stepping over it and notifying the operator about the location of the mine.

Keywords:Sensor; Land mine detector; Robotic System; Wirles Wi-Fi; Raspberry Pi3; Software programing

Introduction

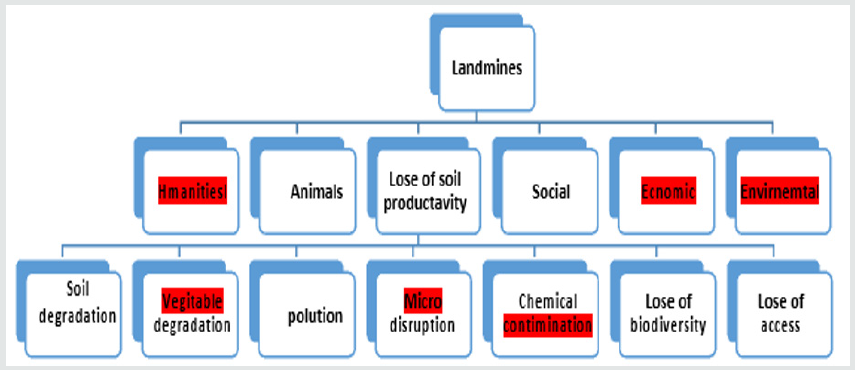

Several world wars and grievances in humanities give birth buried landmine problem. The detection and exclusion of landmines are at current a thoughtful economic, humanitarian, environmental and political issue. There exists a mutual importance in resolving this problem, and a solution is being pursued in many engineering fields. The UN- Mine action services describe that since 1960s more than 100 million mines have been spread across the globe and posing a threat in more than 78 countries. In this process approximately millions of peoples, and animals lose their lives by being struck by landmines and countless injured. Unarmed civilians are the primary victims of anti-personnel landmines; commonly the children, women and the elderly [1-3]. The landmine is a device for killing the humanities, animal and the area in which fixed become no go area. with it through direct pressure. There are several methods for landmine detection including manual and automatic methods. Some are satellite and airborne sensors for detection of minefields and landmines, focusing on multi-temporal aerial photographs and satellite images with some other method focus on some of the most common remote sensing technologies in landmine detection [4-6]. Landmine not only dangerous for humanities but produce several other loses as mention in Figure 1. A lot of research has been already done regarding landmine detection, extracting and demining. remote sensor technology, manual man handling detectors, device using electromagnetic coils, nuclear quadruple resonance, metal robotic vehicles, and lightbased imaging detectors are examples of research done in this area [7-9]. For all these technologies, detection is most probably done by expert humans manually by holding a detector to scan a desired area of land. All these techniques are costly time consuming and dangerous for life.

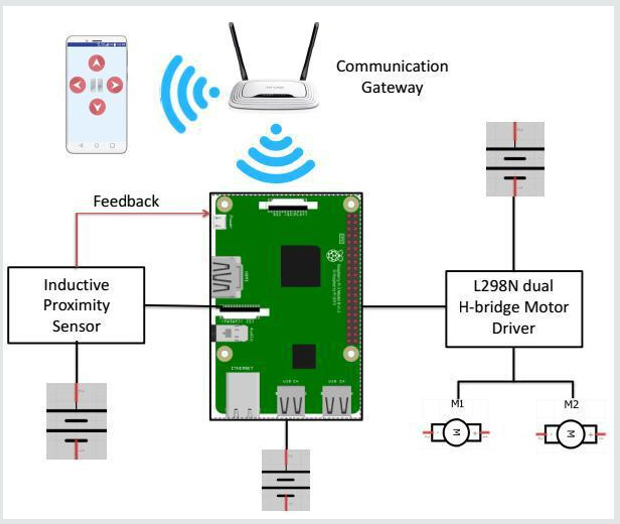

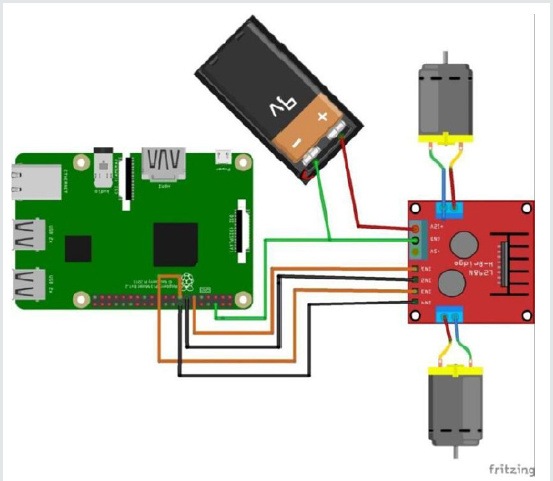

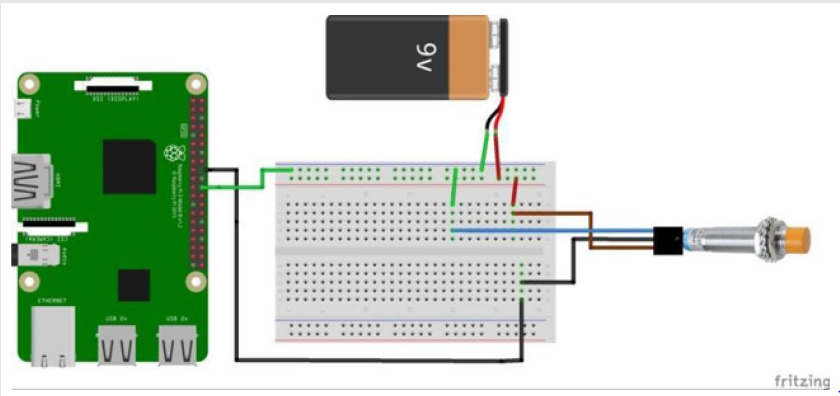

In this paper, we are using wireless technology to control the movement of robot through a mobile device. The wireless control signal using a mobile phone connected to internet system or Wi-Fi through android based applications will provide information. The built in Wi-Fi module of Raspberry Pi 3 takes appropriate action for the movement of DC motors. These motors are interfaced with the Raspberry Pi 3 model B with L298N dual H-bridge motor driver. Depending upon different commands received from mobile application, the vehicle has different movements such as stop, forward, backward, right and left. We are using inductive proximity sensor for the detection of metals and mines. The project is intended to develop a vehicle that can detect the metals ahead of it on its path. The inductive proximity sensor is interfaced with Raspberry Pi 3. Whenever the robot detects a mine or metal it transmits a signal to the mobile phone, informing the operator about the Landmine or metal. The signal is encrypted with AES algorithm for secure transmission [10]. This project produced a prototype landmine detection and pointing robot localization, autonomous navigation and mapping, for proposed metal detection system and novel landmine marking system.

System Operation Procedure

The proposed system function through an android device for transmitting signal to raspberry pi system. Bluetooth device used as transmitter to android phone for interaction. The voice commands recognized by the module and then transmitted through the Bluetooth device. These commands are detected by the robotic vehicle in order to move it in left, right, backward and front directions. The Bluetooth receiver mounted on raspberry pi is used to recognize the transmitted commands and display as information. The controller then drives the vehicle motors to move it accordingly. This is done with the use of a driver IC used to control the movements. The Bluetooth technology used to transmit and receive data allows for remotely operating the system within a good range. Remote operated robot is used for one moving object is developed such that it is moved as per commands are given by the module and that command is received by robot and robot is matched the given command with stored program and then set the command as per voice using wireless communication [11].

Metal Detector

The proposed metal detector producing an alternating magnetic field due to an oscillator generating an AC current that passes through a coil. If a portion of electrically conductive metal is near to the coil, eddy currents will be prompted in the metal, and thus it generates its own alternating magnetic field. If another coil acting as a magnetometer is to measure the magnetic field, the change occurs in the magnetic field due to the detection of metallic object. A metal detector functions by producing an electromagnetic field which is picked up alongside the ground. Any metal set up will disturb the electromagnetic field by altering it and this variation will be designated by a buzzer or display for the operator. A metal consists of two groups of pure copper wire windings. An electrical current is passed from one of the windings and this generates an electromagnetic field. Any metal object which is brought closer to the field will alter it and this disturbance is picked by the receiver winding. The result of this disturbance is the send to the operator control box. This information is displayed with the help of an audio buzzer or LCD display [12].

Metal Detector Sensor

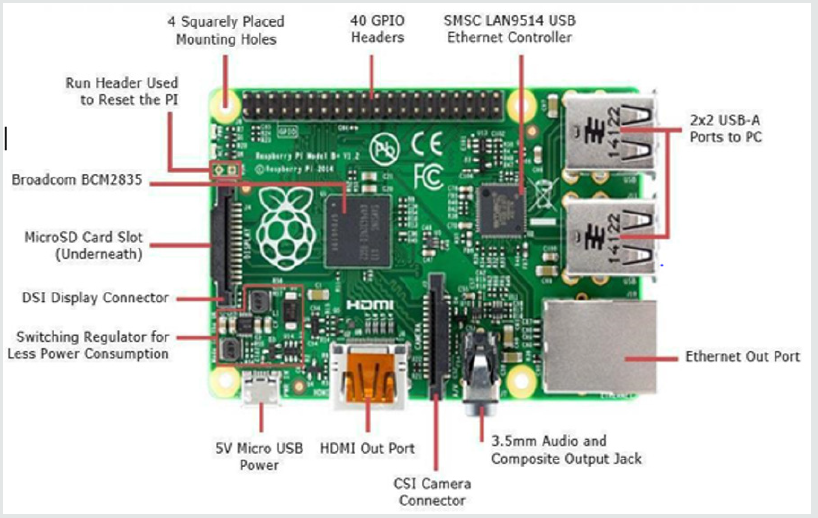

The metal detector sensor is used to monitor the presence of landmine present underground. The Raspberry Pi is a small single board computer, developed by the Raspberry Pi foundation located in UK. The main purpose of this microcomputer to support teaching and provide help in learning computer science in developed countries and educational environments. The peripherals such as cases, mice and keyboard are not incorporated with Raspberry Pi. However, some fixtures are included in various unofficial and official bundles. According to the official report of the Raspberry Pi foundation more than 5 million Raspberry Pi boards sold till the January 2015, which makes it the best-selling computer brand in the UK . Till November 2016, more than 11 million pieces are sold [13,14].

The Raspberry Pi boards and peripheral device support memory capacity are different from each other. The block diagram in Figure 2, describes the boards A, B, A+ and B+. The A, A+, and Pi Zero boards are not enabled with USB hub and Ethernet components. A supplementary USB port is used to internally connect the Ethernet Adapter. In A, A+ and Pi Zero boards, the System on a chip (SoC) and USB ports are connected directly. The Pi 1 board B+ and later models are enabled with Ethernet/USB chip holds a five-point USB port. In these five ports, four are available. However, the Pi 1 model B only provides two of them. On the Pi Zero board, the SoC and USB ports are directly interconnected. However, but a micro USB (OTG) port is used for this purpose. The Raspberry Pi 3 board with having a Cortex-A53 quad-core processor is 10 times faster than Pi 1 as shown in Figure 3. This is due to the use of the instruction set and task threading. The Pi 3 is also 80% faster from Pi 2 in parallel task. The Raspberry Pi 2 with having 1GB RAM and Cortex A7 quad-core CPU running at 900 MHz processor is 4-6 times faster than its older boards. While it is 14 times faster than Raspberry Pi 1 model B.

System Flow Diagrams

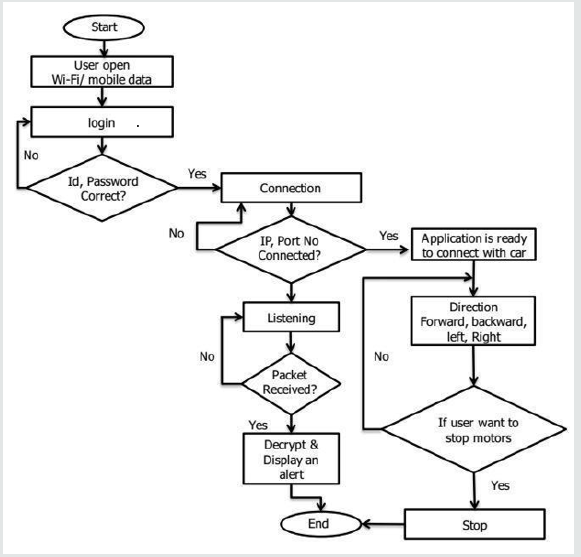

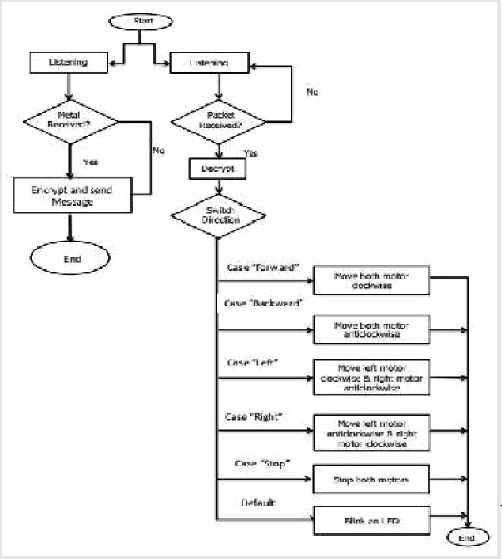

Flow diagram of mobile application and its operation is shown in Figures 4&5.and Raspberry Pi motor control and metal detection flow chart in Figure 6.

Hardware Interface

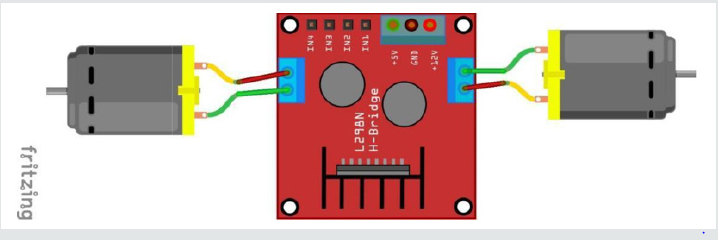

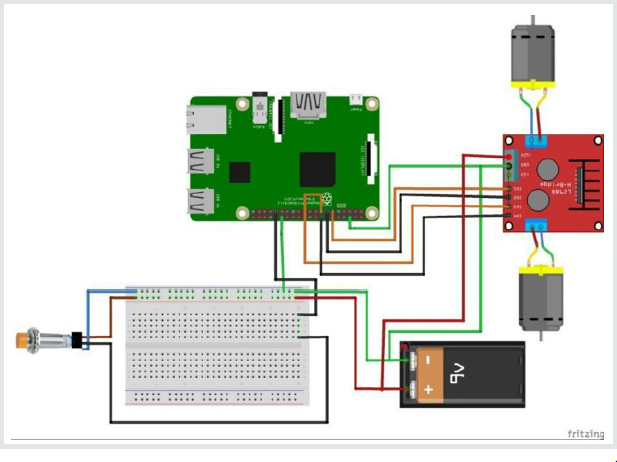

The H-Bridge, dual Motor L298N motor controller interface with DC Motors, shown in Figure 6 and Raspberry Pi, Power Suppliers, L298N and DC motors interface in Figure 7. The Proximity sensor, power suppliers and Raspberry Pi 3 interface is shown in Figure 8.

The System Interface

The system interface of detector board is shown in Figure 9.

Software Application

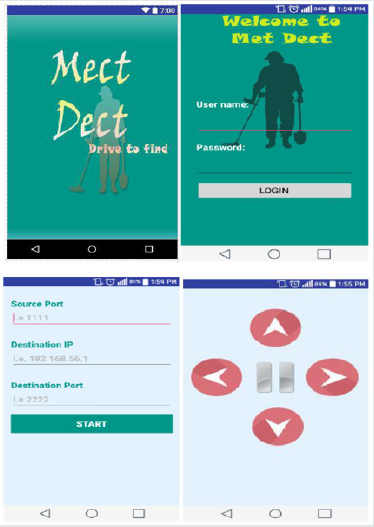

An android application is used to remotely control the detector car. To achieve the purpose, an android application is developed to remotely control the car with high level of efficiency. The application can work with smartphones and tabs having android version 5.0 Lollipop and latest versions. The application is named as MetDect as shown in Figure 10 (a-d). The MetDect is a simple android application, which communicates with the Raspberry Pi 3 Model B board placed on the robotic car. It has efficient and simple user interface. A data packet containing the direction signal is transmitted to Raspberry Pi 3. The application also alerts the user with an alarming message and voice signal whenever a metal is detected. The MetDect application has four different interfaces, Splash interface, Log in interface, Connectivity interface and Motor Control interface. This is the first GUI based interface displayed to the user whenever the user starts the application. The splash screens wait for five seconds and play a welcome sound. This is the first screen that comes after the splash screen. This screen consists of two edit text, one of them asking for username while the other is for password. This screen protects the application and detector car from unauthorized access. This screen prompts for username and password. If the username and password is correct, then it will display a log-in successful message to the user and continue to next screen. If the password or username is incorrect it will provide a message to enter the username and password again. The metDect lof in interface prompts the user to enter the IP address of Raspberry Pi 3 and port no of the executing application, as both IP address and Port no are required for communication when using the UDP protocol. As Raspberry is configured with a static IP address and port no for the project, so whenever the user enter the correct IP address and port no it will display a Toast message to inform the user that you are connected to the Raspberry Pi. The interface also prompts the user to enter the port no for android application.

The connectivity interface provides the base to drive the motor in four directions. Whenever, the user clicks on the button. A corresponding signal is passed to the Raspberry Pi and the motor walk through the specified direction. The interface also includes a stop button which causes the motor to stop movement.

Several researchers work on landmine detection technology and publish articles which could be found in the literature review [15]. Most of them use an ordinary microcontroller to control the moving detection vehicle. Most of the techniques related to simple metal detector and sending few images to the central unit. All these systems consist on computer control, with heavy computing system. But the weight of a real computer is not accepted to be used in such context. Besides, its price will always be a problem when the unit is damaged and needs to be replaced. Raspberry Pi would be the best solution for the problem. The proposed system can overcome the disadvantage of limited frequency range operation. The system can be used both indoor and outdoor navigation. We developed cost effective device leads to compensation in performance. It is safer and more efficient as they provide a safe route through mine fields. The speed data transferring and transmission quality to improve central unit destination that is based on web server and a data base server application to store data regarding navigational field for current mapping and detection or future investigation purpose.

Conclusion

With the high-level achievements in mobile computing and

robotics, we are able to successfully design and develop a metal

detector vehicle. The proposed system is capable of detecting

buried metals and landmines and marking the exact location and

controlling itself from stepping over it. The vehicle can be remotely

controlled with the help of mobile phone and wireless technology.

Whenever the vehicle detects a Landmine or metal, an encrypted

acknowledgement signal is transmitted to the mobile application

to inform the operator about interest field and detected metal. The

vehicle is capable to move in various directions, such as forward,

backward, left, right and stop. The outcome of the project validates

that a huge amount of effectiveness and usefulness is to be sure

accomplished utilizing the developed framework. The developed

system is checked to be very helpful for both civilians and soldiers.

The inductive proximity sensor works at an appropriate steady

speed with having no issue.

The objective of this project is to development and operation of

an efficient low-cost and small size automatic land mine detector.

This detector is based on a Raspberry Pi minicomputer to act as

the brain of a small robot to automatically detect and transfer the

information about any found metal object to a central unit that will

be later responsible of investigating the received data to benefit

from it in determining the location and maybe the danger of the

found object for safer extract or disable it.

References

- Robledo L, Carrasco M,Mery D (2009) A survey of land mine detection technology. International Journal of Remote Sensing30(9): 2399-2410.

- Duttine A, Hottentot E (2013) Landmines and explosive remnants of war: a health threat not to be ignored. Bulletin of the World Health Organization 91(3): 160-160A.

- Bharath J (2017)Automatic Land Mine Detection Robot Using Microcontroller. International Journal of Advance Engineering and Research Development 4(3): 12-23.

- Rapillard P (2014) Walton M, Humanitarian and Developmental Impact of Anti-Vehicle Mines. Journal of Conventional Weapons Destruction 18(3): 22-27.

- Kale M, Ratnaparkhe V,Bhalchandra A (2013) Sensors for Landmine Detection and Techniques: A Review. International Journal of Engineering Research & Technology 2: 1.

- Patri A, Nayak A, Jayanthu S(2013) Wireless Communication Systems for Underground Mines, A Critical Appraisal. International Journal of Engineering Trends and Technology (IJETT) 4(7): 105-9.

- Kathuria A, Gupta A, (2015) Challenges in Android Application Development: A Case Study. International Journal of Computer Science and Mobile Computing 4(5): 294 – 299.

- Ghribi W, Badawy AS, Rahmathullah M, Changalasetty SB (2013)Design and Implementation of Landmine Robot. 2(11): 250-256.

- AchutManandhar, Peter A Torrione, Leslie MCollins, Kenneth Morton D (2015) Multiple-Instance Hidden Markov Model for GPR-Based Landmine Detection. IEEE transactions on Geosciences and remote sensing 53(4): 1737-1745.

- Saravanan N, Kaviyarasi R, Malini P(2017) Wireless Land Mine Detection and Surveillance Robot. in International Journal of Advance Engineering and Research Development 4(3): 77-80.

- Sudac D (2013) Improved system for inspecting minefields and residual explosives. IEEE transactions on Nuclear instrumentation15(4): 108-120.

- Jaradat MA (2012) Autonomous navigation robot for landmine detection applications. IEEE transactions on Mechatronics and its Applications 16(3): 1-5.

- Gini ML, Ohnishi K, Pagello E (2010) Advances in Autonomous Robots for Service and Entertainment. Robotics and Autonomous Systems 58(7): 829-832.

- Rodriguez J, Castiblanco C, Colorado J (2014) Low-cost quadrotor applied for visual detection of landmine-like objects. IEEE transactions on Antennas and Propagation 22: 51-68.

- Nicoud J, Habib M (2015) The Pemex-B autonomous demining robot: Perception and Navigation strategies. IEEE transactions on Intelligent Robots and Systems 3: 419- 424.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...