Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6794

Research Article2641-6794

Biochar and its Use in Soil: Lessons from Temperate Agriculture Volume 5 - Issue 3

Oelbermann M1*, Berruti F2 and Lévesque V3

- 1University of Waterloo, Maren

- 2Intitute for Chemicals and Fuels from Alternative Resources, Franco

- 3Agriculture and AgriFood, Canada

Received: June 10, 2020; Published: July 01, 2020

Corresponding author: Oelbermann M, University of Waterloo, Maren

DOI: 10.32474/OAJESS.2020.05.000211

Biochar Basics

What is Biochar?

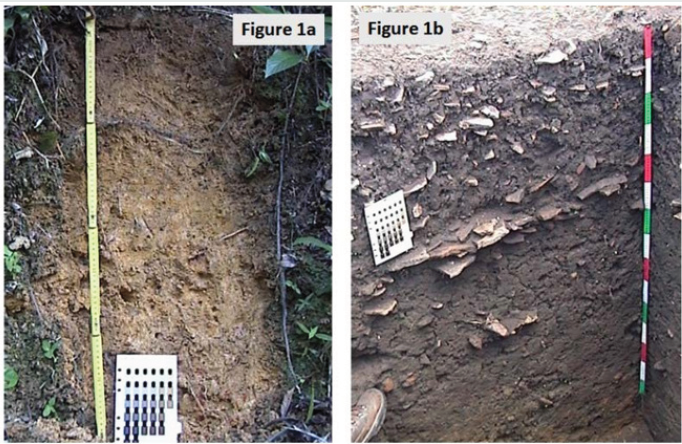

Biochar is a carbon-rich product that is obtained when a sustainable source of biomass is heated without oxygen. Biochar is produced in the same way as charcoal, but their intended use differs. Biochar is manufactured with a specific set of properties (e.g. adsorption properties, ion exchange capacity, low bulk density) for its use as soil amendment and/or adsorbent, whereas charcoal has specific properties (e.g. generating heat) for its use as a fuel. Humans first used biochar in the form of charcoal (as a byproduct from cooking) mixed with broken pottery, animal bones and manure in the Brazilian Amazon. This led to the creation of the Amazonian Dark Earths or Terra Preta more than 2000 years ago by pre-Columbian cultures of this region. Whether these soils were created intentionally or if they were a by-product of human settlements remains unclear. However, Terra Preta soils are highly fertile and have demonstrated the potential for long-term carbon sequestration Figure 1. Based on this premise, researchers have encouraged the deliberate addition of biochar to tropical soils to enhance their fertility. From this work, it was found that biochar substantially improved soil properties and crop productivity, because adding biochar to nutrient-impoverished tropical soils decrease aluminum toxicity and increase soil pH, resulting in enhanced microbial activity and nutrient availability. However, temperate soils have lower iron and aluminum oxide content, a higher pH, high-activity clays, and greater soil organic matter content and will therefore respond differently to biochar than tropical soils. Amending intensively managed temperate soils with biochar is a more recent approach to agriculture, with research still in its infancy. However, a soil amendment like biochar that can maintain or improve soil health, potentially decrease fertilizer input and minimize nutrient leaching will not only place less pressure on soil resources but also contribute to environmental sustainability [1].

Figure 1: Highly leached tropical soil from the Amazon basin (a), and dark earth terra preta soil containing artefacts from Iranduba, Brazil(b).

Biochar Feestocks

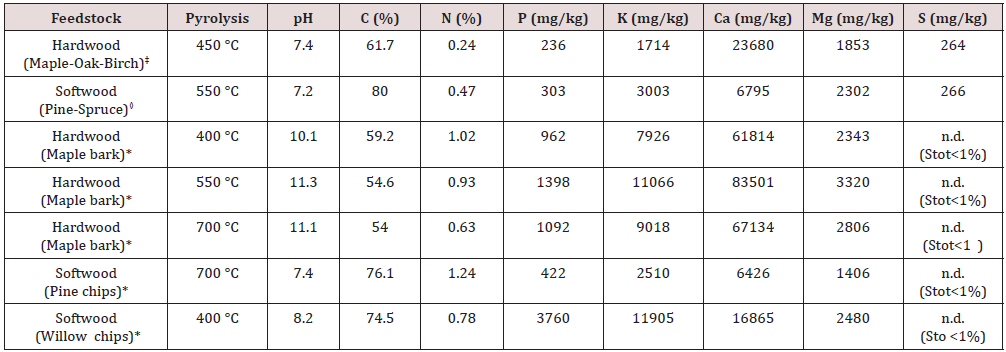

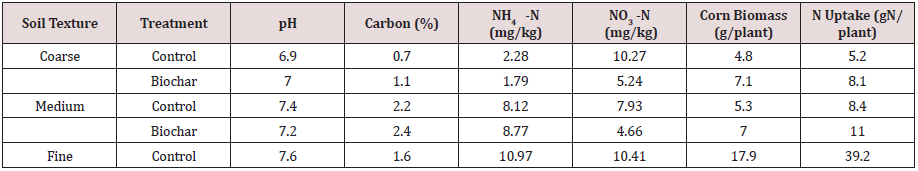

Biochar can be produced from a variety of feedstocks including residues from the agricultural and forest industries (straw, rice hulls, wood chips, nut shells, wood pellets, tree bark, bagasse, manure), organic waste materials and industrial by-products (food waste, paper sludge, pulp, distillers grains), purpose grown biomass (miscanthus and switchgrass), or undesirable invasive grasses (phragmites). Due to biochar’s structure, it is chemically and biologically more stable compared to the organic matter from which it is made. However, the source of the feedstock and the conditions during biochar production (pyrolysis) are major controls on the biochar’s characteristics including its carbon and ash content, pH, elemental composition, and stability Table 1. Not all biochar’s are the same, and the benefits of biochar are not universal. For example, biochar made from animal manure will have a higher nutrient content and is more likely to improve soil fertility. Biochar made from wood waste is more suited to carbon sequestration due to its greater long-term stability. Also, different soil textures will interact differently when the same type of biochar derived from the same feedstock is added Table 2. Adding the same type of biochar to the same soil type but under different climates will not result in the same outcome. Recent research shows that adding biochar in coarse and medium textured soil results in greater fertility improvement than adding biochar to heavy textured soil [2]. Biochar’s can also be engineered to have specific physical and chemical properties by selecting desired feedstock properties and pyrolysis conditions. For example, biochars can be engineered to function as a soil amendment or as a sorbent for pollutants, such as heavy metals and pesticides [1].

Table 1: Chemical characteristics of biochars dervied from various feestocks.

‡ Adapted from Dil, M., Oelbermann, M., Xue, W. 2014. The influence of nitrogen-enriched biochar on maize (Zea mays L.) biomass

and soil biochemical characteristics. Canadian Journal of Soil Science 94:551-562.

◊ Adapted from Mechler, M., Jiang, R., Silverthorn, T.K., Oelbermann, M. 2018. Impact of biochar on soil characteristics and

greenhouse gas emissions: a field study. Biomass & Bioenergy 118:154-162.

* Adapted from Lévesque, V., Rochette, P., Ziadi, N., Dorais, M., Antoun, H., 2018. Mitigation of CO2, CH4 and N2O emissions from

a fertigated horticultural growing medium amended with biochars and a compost. Applied Soil Ecology 126, 129–139.

Table 2: Soil chemical characteristics in soil from southern Ontario with coarse (Delhi), medium (Elora) and fine (Vineland) textures amended with 1 t/ha maple-oak-birch biochar using fast pyrolysis, 450 C.

Information adapted from Dil, M., Oelbermann, M., Xue, W. 2014. The influence of nitrogen-enriched biochar on maize (Zea mays L.) biomass and soil biochemical characteristics. Canadian Journal of Soil Science 94:551-562.

Feedstocks and Quality of Biochar

Different feedstocks have different qualities in terms of

nutrient composition, and as mentioned above, if the same

feedstock is processed under different pyrolysis processes, the

biochar produced has different characteristics. Even using the same

feedstock and pyrolysis processes can sometimes generate slight

differences in biochar characteristics. This is the case for feedstocks

derived from composted food waste. Therefore, using a high-quality

feedstock source is important in order to avoid any negative effects

on soil. Feedstock derived from contaminated sites or feedstock

containing known contaminants which have been converted to

biochar should not be added to agricultural soil. This is because

feedstock containing heavy metals (e.g. lead, zinc, arsenic) and

other contaminants will generate a low-quality biochar containing

heavy metals, polycyclic aromatic hydrocarbons, and dioxins, which

will negatively affect the soil, plants and environment.

Therefore, it is important to use biochar produced from high

quality feedstock and through a consistent pyrolysis process Figure

2. The resultant biochar should also have been characterized

(e.g. carbon, nutrient and heavy metal content). According to the

International Biochar Initiative, a high-quality biochar must contain

at least 60% carbon. Inhibition of crop germination and earthworm

avoidance can be used to test biochar safety. In addition, the use of

a suitable biochar as soil amendment should have these two criteria

of carbon (C), oxygen (O) and hydrogen (H) content according to

Schimmel pfennig and Glaser [3]: O/C ratio<0.4 and H/C ratio<0.6.

Potential Uses of Biochars

Due to its structure and composition, there are many promising applications for the biochar, such as soil amendment, food or feed additive, composite materials, activated carbon, electrodes for batteries or electrolysis cells, metallurgical coke substitute, coal substitute, catalyst for tars, pharmaceutical and cosmetic, and could be eligible for carbon credits. Nanda [4] have published an extensive review on the broad applications of biochar.

How are Biochars Made?

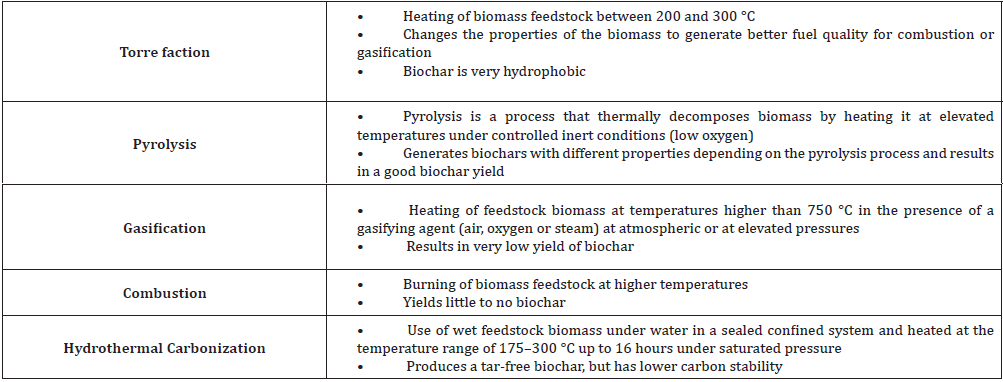

Several reviews have illustrated the different technologies and processes used experimentally and industrially to produce biochar [4,5]. These include Torre faction, pyrolysis, gasification, combustion, and hydrothermal carbonization Table 3. Scale and potential mobility are important considerations in relation to the feedstock supply, logistics, seasonality, further refining, products quantities, characteristics and value, and potential markets.

Torre faction involves heat treatment of biomass under

atmospheric pressure and within a temperature range of 200–300

°C, without oxygen or with limited oxygen supplies. It yields char

with less moisture, higher energy density, lower weight, lower O/C

and H/C ratio, increased hydrophobic nature and resistance to

biological degradation with respect to the original feedstock. Typical

yields of terrified biomass range between 50 and 80%. Gasification

is a thermochemical process carried out at temperatures higher

than 750 °C in the presence of a gasifying agent (typically air,

oxygen, or steam) at atmospheric or at elevated pressures. Under

these conditions, biochar yields are not sufficiently significant to

consider gasification an appropriate biochar production process.

Similarly, combustion is not a suitable biochar production process,

since, theoretically, under good combustion conditions, biochar

yield should be negligible.

Together with Torre faction, pyrolysis and hydrothermal

carbonization are the major processes used for biochar production,

whose characteristics will greatly depend upon temperature, heating

rate, residence time, feedstock type and physical characteristics, and

reactor configuration. Hydrothermal carbonization is performed

with wet feedstock biomass under water in a sealed confined

system and heated at the temperature range of 175–300 °C up to 16

h under saturated pressure under subcritical conditions producing

tar-free biochar (hydrochar) with large number of functional

groups. Hydrochars contain predominantly aliphatic compounds

and more oxygen functional groups and higher cation exchange

capacity than conventional biochar’s. On the other hand, they have

lower surface area, micro porosity, and carbon stability.

Among the various thermal technologies, pyrolysis has been the

most investigated technique and considered the best technology

to produce biochar. The various modes of pyrolysis include slow,

intermediate, fast, flash, and ultra-pyrolysis, carried out under

vacuum, atmospheric pressure or under pressure. Garcia-Nunez

[6] have published an extensive review on pyrolysis reactor

technologies. Due to the balance between primary, secondary

cracking and recombination reactions, bio-oil yields are typically

maximized (up to 70%) at intermediate temperatures (450-550

°C), faster heating rates (100-500° C/s) and short vapor residence

times (< 1~2 s), which are characteristic of fast and flash pyrolysis.

Under these conditions, biochar yields are typically of the order

of 15~20%. On the other hand, higher biochar yields (25~40

%) are achieved at moderate temperatures (300-450 °C), slower

heating rates (~ 1 °C/s) and longer vapor residence times (> 5~10

s), representative of slow or intermediate pyrolysis, when bio-oil

yields vary between 40 and 50% with the balance being gas.

The efficiency of biochar in most applications significantly

depends on its carbon and ash content, surface area, pore size

distribution, alkalinity, hydrophobicity, ion-exchange capacity, and

elemental composition. These properties are subject to variations

depending on the biochar feedstock, pyrolysis temperature,

heating rate, residence time, potential oxidation medium, pre-,

and post-processing treatments. Temperature plays a prominent

role in determining biochar quantity and quality. As the pyrolysis

temperature increases within the broad range between 300 °C and

700 °C, aromatic carbon, ash, surface area, pore volume and pH

increase, while yield, volatile matter, hydrogen and oxygen content,

conductivity and cation exchange capacity decrease. Moisture is

also reported to have certain positive impacts on biochar yield. High

moisture containing biomasses are found to improve the yield of

biochar. Studies on woody and agricultural biomass have reported

biochar yields positively correlated with the lignin content.

Surface area and pore volume are chief parameters to evaluate the

absorption by biochar, particularly for organic molecules. Although

higher processing temperatures increase the specific surface area,

high heating rates favor such increases. Therefore, biochar derived

at higher temperatures are more efficient for adsorption of organic

contaminants due to the higher surface area and pore volume,

whereas biochar generated at lower temperatures is effective for

adsorption of inorganic contaminants due to greater intensity

of O-containing functionalities and higher incidence of cationic

complexes in the soil.

Based on these considerations, the quality of the biochar is

strongly influenced by the reactor technology in which it is produced

and on its operating conditions. Although stoves can produce

biochar, its quality is highly questionable as the operating conditions

are not carefully controlled. Biochars produced in batch mode are

different than biochars produced in continuous operations. Mixing

is a critically important parameter to ensure uniform reaction

conditions and, consequently, product quality control. Mixing

strongly influences heat transfer and, therefore, heating rates of the

reacting biomass and, as discussed, product characteristics. Slow

pyrolysis is carried out in rotating kilns, intermediate pyrolysis is

auger type or mechanically mixed reactors, whereas fast pyrolysis

is carried out in fluidized, circulating fluidized beds or rotating

cone reactors.

Specific Uses of Biochar in Agriculture and Horticulture

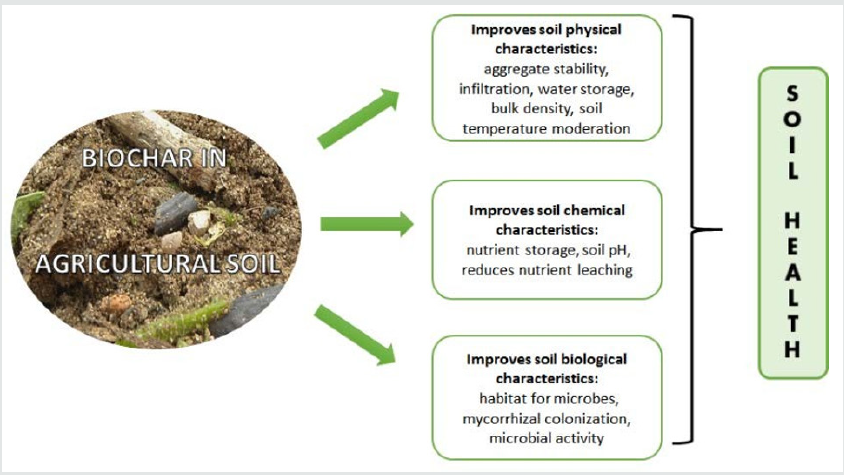

Soil Health

Soil health is defined as the capacity of the soil to function as a living system to sustain biological productivity, maintain environmental quality and promote plant, animal, and human health [7]. The application of biochar to temperate soil has demonstrated improvement or the potential to improve a variety of soil health indicators Figure 3. Biochar can also play an important role in higher- valued horticultural crops. In the horticultural industry, peat is a favored growing medium, but due to its long regeneration time, peat is a non-renewable resource. However, research has shown that 15% (by volume) biochar can be added to peat and improve crop productivity and soil characteristics [8]. Its labile carbon content may stimulate microbial activity and interact with roots and soil bacteria, promoting plant-growth-beneficial microorganisms in peat and in soil [9-12].

The following soil health characteristics, which can also be

linked to the OMAFRA Soil Health Strategy (ahttp://www.omafra.

gov.on.ca/english/landuse/soil-strategy.pdf), have demonstrated

improvement when biochar was added to temperate soil or its use

as a horticultural growing medium Brassard [1]:

• increase water holding capacity and infiltration by adding pore

space and supporting aggregation.

• moderation of soil temperature extremes.

• soil structure through aggregation (better aggregate stability)

and crop root penetration.

• decrease in bulk density.

• increase cation exchange and nutrient storage.

• moderation of soil acidity.

• changes in microbial community composition and substrate

utilization.

• increase microbial activity and diversity.

• increase mycorrhizal fungal colonization.

• increase nitrogen fixation.

• promote beneficial microorganisms for plant growth.

• reduce greenhouse gas emissions.

Crop Productivity

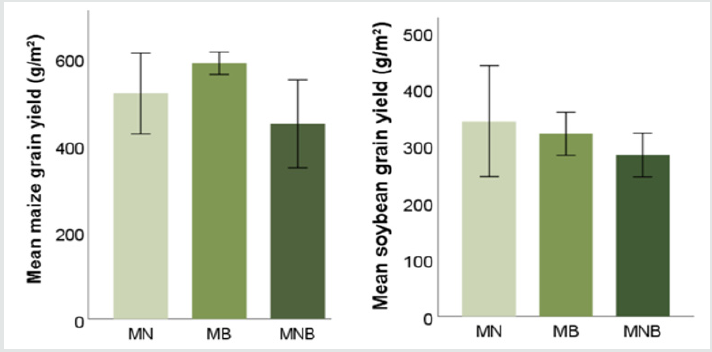

A recent survey evaluated 1000 different research studies on the effect of biochar on crop yield. Although biochar showed favorable results on crop productivity, with a 25% increase in yield, in tropical environments this effect was not observed under temperate conditions. This confirmed that biochar benefits tropical soils but biochar application to the more fertile temperate soils and its effect on crop yield remains uncertain [13]. Low yield responses due to biochar addition have been observed on fertile soils and in some cases low rates of biochar addition did not result in crop productivity. A field study from southern Ontario Figure 4 did not find a significant improvement in corn or soybean production when biochar, derived from pine and spruce wood waste, was added at 3 t/ha and combined with poultry manure [14]. The same study also found that the ratio of shoot to root biomass (shoot/root ratio) for corn or soybeans was lower when soil was amended with biochar. This suggested that crops produced with biochar experienced lower environmental stress (e.g. water stress) than those produced without biochar. Most researchers concur that use of a highquality biochar in temperate soil, although it may not improve crop yield, will have no negative effects on crop productivity, but will improve soil health. The application of biochar in legumebased intercropping system with cereal crop might be beneficial for improving cereal growth and reducing N fertilizer supply. According to the study of Liu [15] the intercropping maize with peanut system with biochar amendment allowed a higher nodule weight on peanut roots promoting a better N fixation, favoring thereby a higher N transfer from peanut to maize. There is currently no information on the effects of biochar on pasture production.

Figure 4: Soybean and maize grain yield in a loamy-textures soil amended with 6 t/ha poultry manure plus 150 kg/ha N fertilizer (MN), or t/ha poultry manure plus 3 t/ha biochar (MB) or 3t/ha poultry manure, 3 t/ha biochar,150 kg/ha N fertilizer (MNB) in southern Ontario. Data provided by T. Silverthorn.

Nutrient Leaching and Crop Nutrient Uptake

Biochar has the ability to retain soil nutrients such as ammonium, nitrate and phosphorus, and this effect is most readily observed in light-textured (e.g. sandy) soils. This provides an opportunity for increased nutrient uptake and reduced leaching of nutrients applied by fertilizers from entering local water sources (e.g. Ontario Great Lakes Strategy Priority: https://www.ontario. ca/page/ontarios-great-lakes- strategy). Some research has suggested that the ability of biochar to adsorb nutrients could result in lower fertilizer requirements; studies are currently underway to assess this component. A laboratory study found that adding low quantity of biochar (1 t/ha) combined with urea ammonium nitrate enhanced corn nitrogen uptake in a coarse-textured soil Table 2. This study also found a higher nitrogen utilization efficiency in fine-textured soil, suggesting that biochar could serve as a carrier for nitrogen [15]. The size of the biochar particles also influences nutrient leaching potential. Typically, large (2 to 4 mm) or medium (1 to 2 mm) biochar particles have a better capacity to adsorb nutrients and prevent them from leaching, whereas small and very vine (0.05 to 1 mm) biochar particles are subject to greater movement in soil and can facilitate the transport of nutrients and other agrochemicals like herbicides [16].

Some studies showed that the presence of biochar reduced phytotoxicity of herbicide residues such as atrazine. However, due to the high-binding capacity of some biochars, it could also render herbicides inactive and make them less effective in controlling weeds. Biochar with a high specific surface area, high micro porosity and highly aromatic carbon influences the persistence, release, and bioavailability of herbicides [17]. Further work on this is currently underway.

Greenhouse Gases

Currently, only a few field studies have evaluated temporal changes in greenhouse gas emissions in soil amended with biochar; and these studies found variable results. For carbon dioxide (CO2) and nitrous oxide (N2O), studies conducted under field conditions reported no effect of biochar on CO2 emissions [18]. A 3-year study from southern Ontario found no difference in CO2 and N2O emissions from soil amended with biochar (3 t/ha), poultry manure and/or nitrogen fertilizer compared to soil without biochar [14]. However, greenhouse gas emissions, particularly N2O, from biochar amended soil are also dependent upon the type of biochar used, based on feedstock type and pyrolysis processes, its addition rate, agricultural management practices, and variation in climate depending on the location of the site. There is also some evidence that the impact of biochar on N2O emissions can change over time as the biochar ages. Ageing of biochar can decrease N2O emissions with time due to stabilization of carbon and nitrogen. However, the use of biochar in mitigating greenhouse gases can also be integrated with Canada’s Climate Change Mitigation Strategies ( https://www.canada.ca/en/ services/environment/weather/climatechange.html).

Carbon Sequestration and Biochar Stability in Soil

Soil carbon sequestration, also known as carbon farming or regenerative agriculture includes various ways of land management practices that encourage the long-term storage of carbon. Increasing carbon in soil can be achieved when the rate of addition of organic matter is greater than its rate of decomposition in soil. Biochar has a molecular structure that makes it more resistant to microbial decomposition, compared to non-pyrolyzed organic matter (e.g. crop residues, manure, cover crops), allowing it to persist in soil for 1000 to 10,0000 years. Biochar contributes to carbon stabilization by promoting aggregate stability and through its association with organo-mineral complexes. Some researchers have speculated that the presence of aged biochar reduces decomposition rates of crop- derived residue carbon in soil and increases crop residue stabilization in soil aggregates [19]. In southern Ontario, a 3-year study did not find an increase in soil organic carbon when biochar was added to soil [14]. This is because measurable changes in soil organic carbon are difficult to detect over the short-term (<10 years), and variation among years have been observed since the soil is not in equilibrium. However, the field study from southern Ontario found a greater concentration of extractable carbon in soil amended with biochar, indicating that a readily available carbon source for the microbial community was present. This suggests that a greater accumulation of decomposing organic matter was likely derived from the biochar and/or its interaction with soil organic carbon and crop roots.

The stability of biochar applied to soil depends on the biochar’s properties and soil mineralogical composition. Evaluating the impact of biochar on soil carbon sequestration and stabilization is difficult since most of these changes are not readily observed over the short-term. Simulation models, if calibrated to the study site’s environmental conditions (e.g. climate, soil characteristics) and land management practices can provide insight into the potential longterm effect of biochar on soil carbon. For example, Dil & Oelbermann [2] simulated the effect of biochar addition on soil organic carbon stocks over 150 years based on soil collected in southern Ontario from Elora (medium texture), Delhi (coarse texture) and Vineland (fine texture). Using the century soil organic matter model, they found that a once application of maple-oak-birch derived biochar at 2 t/ha, compared to other management practices including maizesoybean rotation, continuous maize, addition of manure, and no till, led to a greater increase and long- term stabilization of soil organic carbon at the Elora and Delhi sites. They also found that the quantity of carbon stabilized was influenced by the soil texture, and soil texture also influenced whether carbon was stabilized in active, slow, or passive carbon fractions.

Other Uses of Biochar in Agriculture

Recently, the use of biochar as a livestock feed supplement has also received some interest from the agricultural community. The benefits of biochar as a feed supplement may influence animal health for gastrointestinal decontamination and nutrition. Some studies have shown an improvement in production and livestock health. There has also been some research into using biochar to help reduce ruminant methane production. In southern Ontario, University of Guelph’s Dr. A. Carpenter (Ridgetown campus) is investigating various aspects of biochar as a feed supplement in dairy cows.

Some Precautions

Biochar Storage and Handling

Biochar can form explosive mixtures with air in confined spaces. There is also a danger of spontaneous heating and ignition when biochar is tightly packed. Fresh biochar quickly adsorbs oxygen and moisture, which can lead to high temperatures and ignition. Volatile compounds in biochar can also present a fire hazard, which is more of a concern for low quality biochar. When biochar is mixed with other amendments such as manure or composts, its potential to become flammable is greatly reduced.

Incorporation of Biochar with Soil

Depending on the feedstock and the process used to generate

biochar, the resultant product can take on many forms ranging

from coarse to powdered material. Researchers suggest that it

is important to retain a coarser structure of the biochar as this

maintains its ability to hold water, nutrients and encourages

microbial activity. If biochar is incorporated into the soil as a powder

(less than 50 microns in size), then its capacity to hold water and

nutrients are lost. However, biochars can also be generated for a

specific purpose e.g. enhanced nutrient adsorption.

Uniform topsoil mixing can be achieved by mechanically

applying biochar using a spreader and then mixing it into the

soil by ploughing or disking. When mixing biochar with other

amendments, the same approach of uniform topsoil mixing can be

used. In certain management systems e.g. orchards or vineyards,

the biochar is mixed with the other amendment(s) and top dressed

between rows of trees or vines. Incorporation biochar with liquid

manures can be done when the biochar is applied to the soil surface

in a uniform layer or incorporated into the soil. This can, however,

cause blockages of flow if biochar particles are large or a high

quantity of biochar is used. Therefore, testing of viscosity and flow

of the biochar-liquid manure mixture is recommended prior to its

application at the field scale. Deep- banding of biochar allows for

the placement of the biochar directly into the rhizosphere of the

crop and reduces risk of biochar loss via erosion. Top dressing

biochar is a desirable approach in no-till systems. However, with

top dressing there is a risk of water and wind erosion, especially if

biochar particles have a fine texture. This can be avoided if biochar

is mixed with moist manure.

Application Rates and Combination with Other Amendments

The optimal rate of biochar application to agricultural soil has

not yet been established. Average application rates ranged from

as low as 3 t/ha to 50 t/ha. Optimal rates will depend on biochar

type, soil characteristics and management objectives. To date,

the majority of studies that evaluated the impact of biochar on

temperate soil have added large quantities of biochar (10 t/ha),

but this may also not be a cost- effective approach to produce field

crops. However, the horticultral industry that produces high-value

vegetable crops, the use of biochar as a growing medium may be a

more cost-effective approach compared to currently used growing

media [8].

For field crops, researchers are in agreement that adding only

biochar to temperate agricultural soil will likely result in a minimal,

if any, improvement especially in fine-textured (clay) soil. Instead,

biochar is more effective when mixed with other soil amendments

such as solid or liquid manure, compost and/or fertilizers [20].

This will improve the efficiency of the biochar and the other

amendment(s) than when applied alone. Adding biochar also

reduces the odor of some manures [21,22]. Biochar can be applied

as a single application which can provide benefits for several years

due to its recalcitrance. Since biochar ages in soil and its interaction

with soil changes with time, it is not necessary to apply biochar at

each crop seeding. However, field data is currently not available if it

is more effective to apply a large dose of biochar at once, or if yearly

applications at lower rates is more desirable.

Next Steps: How to Integrate Biochar on Your Farm

The performance and stability of biochar in soil are highly dependent on soil types, plant species, and climate. Growers interested in using biochar on their property should apply it to a small area of their farm and then monitor results in subsequent years. Several key points should be kept in mind when considering the use of biochar as a soil amendment:

• soil texture and fertility;

• nutritional requirements of the plant;

• local climate;

• feedstock quality and pyrolysis process;

• biochar particle size;

• which other amendments will the biochar be mixed with: mineral fertilizer, manure, or other types of organic amendments such as compost;

• what is the objective of using biochar: nutrient retention, improved soil health, carbon sequestration and/or greenhouse gas reduction, etc. For example, biochar used for carbon sequestration should be derived from wood feedstock (highcarbon source) produced at high pyrolysis temperatures for long-term stability. Using biochar with the intended use of increasing soil health/fertility should be derived from a feedstock with a greater nutrient content such as manure. It is recommended that available nutrients, rather than total nutrients, in the biochar should be measured.

Where to obtain biochar?

There is an increasing interest in integrating biochar and

biochar-products in agriculture. However, logistical difficulties

in obtaining biochar and the current high costs of biochar, since

it is still mostly an experimental product, have led to some smallscale

on-site pyrolysis projects. Although do-it-yourself biochar

production may be more cost effective, there are some potential

problems with this approach:

• lack of controlled pyrolysis conditions that result in biochar

with variable characteristics and therefore an inconsistent

product.

• inability to capture toxic and/or greenhouse gases produced

during pyrolysis;

• contamination of feedstock with heavy metals;

• lack of biochar characterization.

• Although biochar obtained from external sources is more

expensive, there are several advantages when using biochar

derived from an established and reputable producer:

• availability of biochar from different and high-quality feed

stocks;

• consistent and high quality biochar;

• characterization of biochar’s attributes;

• Capture of gases produced during pyrolysis.

As the biochar market continues to advance, including

the development of cost-effective mobile units that reduce

transportation costs, applications at the farm-scale will become

more economical in time.

Acknowledgements

This work was generously supported by the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA). We also thank the University of Waterloo and the Canadian Foundation for Innovation for providing infrastructure support. Grauduate students were supported by OMAFRA, Ontario Graduate Scholarship (OGS) and the Natural Sciences and Engineering Research Council (NSERC). We thank H&N Baker Farms for supporting our field work and providing the field site that contributed to the completion of this document.

References

- Brassard P, Godbout S, Lévesque V, Palacios JH, Raghavan V, and et al., (2019) Biochar for soil amendment. In Jeguirim M, Limousy L (Eds.), Char and Carbon Materials Derived from Biomass. Production, characterization, and applications. Elsevier, Netherlands Pp. 109-148.

- Dil M, Oelbermann M (2014) Evaluating the long-term effects of nitrogen-enriched biochar on soil organic carbon and nitrogen using the Century model. In: Oelbermann, M. Sustainable Agroecosystems in Climate Change Mitigation. Wageningen Academic Publishers, Netherlands, pp. 249-268.

- Schimmelpfennig S, Glaser B (2012) One step forward toward characterization: Some important material properties to distinguish biochars. (Special Issue: environmental benefits of biochar.). Journal of Environmental Quality 41(4): 1001-1013.

- Nanda S, Dalai AK, Berruti F, Kozinski JA (2016) Biochar as an exceptional bioresource for energy, agronomy, carbon sequestration, activated carbon and specialty materials, Waste Biomass Valorization 7: 201-235.

- Meyer S, Glaser B, Quicker P (2011) Technical, economical, and climate-related aspects of biochar production technologies: a literature review. Environ Sci Technol 45(22): 9473-9483.

- Garcia-Nunez JA, Pelaez-Samaniego MR, Garcia-Perez ME, Fonts I, Abrego J, and et al., (2017) Historical Developments of Pyrolysis Reactors: A Review 31(6): 5751-5775.

- Doran JW, Zeiss MR (2000) Soil health and sustainability: managing the biotic componet of soil quality. Applied Soil Ecology 15(1): 3-11.

- Lévesque V, Rochette P, Ziadi N, Dorais M, Antoun H (2018) Mitigation of CO2, CH4 and N2O from a fertigated horticultural growing medium amended with biochars and a compost. Applied Soil Ecology 126: 129-139.

- Cheng N, Peng Y, Kong Y, Li J, Sun C (2018) Combined effects of biochar addition and nitrogen fertilizer reduction on the rhizosphere metabolomics of maize (Zea mays L.) seedlings. Plant and Soil 433: 19-35.

- Jaiswal A, Elad Y, Paudel I, Graber ER, Cytryn E, and et al., (2017) Linking the belowground microbial composition, diversity, and activity to soilborne disease suppression and growth promotion of tomato amended with biochar. Scientific Reports 7: 44382.

- Kolton M, Harel YM, Pasternak Z, Graber ER, Elad Y, et al., (2011) Impact of biochar application to soil on the root-associated bacterial community structure of fully developed greenhouse pepper plants. Applied and Environmental Microbiology 77(14): 4924-4930.

- Kolton M, Graber ER, Tsehansky L, Elad Y, Cytryn E (2017) Biochar-stimulated plant performance is strongly linked to microbial diversity and metabolic potential in the rhizosphere. New Phytologist 213(3): 1393-1404.

- Jeffrey S, Abalos D, Prodana M, Bastos AC, van Groeninen JW, et al., (2017) Biochar boosts tropical but not temperate crop yields. Environmental Research Letters 12(5): 1-7.

- Mechler M, Jiang R, Silverthorn TK, Oelbermann M (2018) Impact of biochar on soil characteristics and greenhouse gas emissions: a field study. Biomass & Bioenergy 118: 154-162.

- Liu L, Wang Y, Yan X, Li J, Jiao N, and et al., (2017) Biochar amendments increase the yield advantage of legume-based intercropping systems over monoculture. Agriculture, Ecosystems and Environment 237: 16-23.

- Verheijen FGA, Zhuravel A, Silva C, Amaro A, Ben-Hur M, and et al., (2019) The influence of biochar particle size and concentration on bulk density and maximum water holding capacity of sandy versus sandy loam soil in a column experiment. Geoderma 347: 194-202.

- Mendes-Ferreira K, Junior-Dias AF, Takeshita V, Rego APJ, Tornisielo VL (2018) Effect of biochar amendments on the sorption and desorption of herbicides in agricultural soil.

- Fidel RB, Laird DA, Parkin TB (2019) Effect of biochar on soil greenhouse gas emissions at the laboratory and field scales. Soil Systems 3(8): 1-12.

- Hernandez-Soriano MC, Kerr B, Goos P, Hardy B, Dufey J, and et al., (2016) Long-term effect of biochar on the stabilization of recent carbon: soils with historical inputs of charcoal. Global Change Biology Bioenergy 8(2): 371-381.

- Belcher RW, Jarand ML (2017) Biochars for use in composting, US.

- Lehmann J, Joseph S (2015) Biochar for environmental management: science and technology. (2ndedn), Routledge.

- Glaser B, Haumaier L, Guggenberger G, Zech W (2001) The “Terra Preta” phenomenon: A model for sustainable agriculture in the humid tropics. Naturwissenschaften 88(1): 37-41.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...