Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4706

Review Article(ISSN: 2637-4706)

The Synthesis of Alginate Microparticles and Nanoparticles Volume 3 - Issue 1

Yuri S Pestovsky* and Agustino Martínez-Antonio

- Center for Research and Advanced Studies of the National Polytechnic Institute (Cinvestav), Genetic Engineering Department, Mexico

Received: June 08, 2019; Published: June 24, 2019

Corresponding author:Yuri S Pestovsky, Center for Research and Advanced Studies of the National Polytechnic Institute (Cinvestav), Genetic Engineering Department, Mexico

DOI: 10.32474/DDIPIJ.2019.03.000155

Abstract

Alginate is a natural polysaccharide that is widely used as a component of pharmaceuticals and in food industry. Alginate particles can be used for encapsulation of substances with the necessity of prolonged release. They can also provide appropriate microenvironment for cells. Here the methods of the synthesis of alginate beads, micro- and nanoparticles are reviewed with special attention to the calcium alginate ones. The results from publications that did not deal with alginate particles but, to our opinion, could be applied in this field are also included in order to give an outline for possible future research. The suggested applications of the particles are mentioned as well. The two main methods for the synthesis of calcium alginate particles are internal and external gelation, but the external gelation techniques can be themselves subdivided into several subtypes. Currently, a technique being able to produce alginate nanoparticles with any desirable size does not exist. We analyze the possibilities of employing aerosolization method for this purpose. The potentials to overcome the problem of burst release of the encapsulated substances by means of cyclodextrin inclusion complexes and employing additional crosslinking agents are also discussed. The clinical application of alginate nanoparticles is still limited because of the burst release of encapsulated drugs and the poor size control of the particles formed. Further research must concentrate on overcoming these problems and on topical application of alginate particles without entering bloodstream rather than on investigation of model drug release in vitro without taking the above-mentioned problems into account.

Keywords: Calcium alginate; Alginate beads; Alginate microparticles; Alginate nanoparticles; Drug encapsulation; Particle size control; Aerosol

Introduction

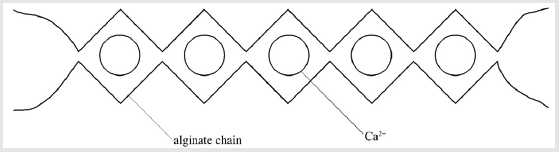

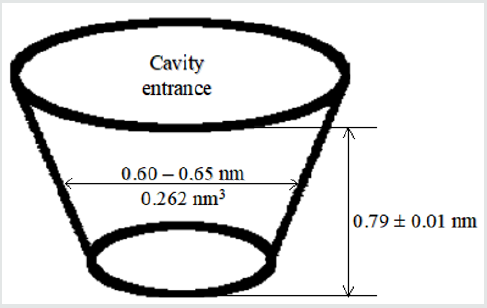

Alginates are polysaccharides. The commercially available ones come from brown algae. They are linear copolymers of (1→4)-linked units of β-D-mannuronic acid and α-L-guluronic acid. The molar ratio between them and their distribution along the commercial polymer depend on the algal source, its location, age, collection season and extraction technique. Guluronic acid residues can form so-called egg-box complexes with calcium ions or some other divalent metal cations leading to gel formation (Figure 1). The name ‘egg-box’ is used because, if depicted schematically, the cations look like eggs situated inside puckered boxes formed by four guluronic acid residues of two superimposed chains. Mannuronic acid residues have much less affinity to metal ions [1]. Barium ions have more affinity to alginate than the calcium ones. If reacted with calcium alginate at lower concentrations, they create new gelling junctions. At higher concentrations, barium ions also displace calcium ions from existing junctions [2].

To extract alginate, algae are usually washed with organic solvents and water, dried and milled. After acid pretreatment, alginate is solubilized with Na2CO3 . The crude extract is concentrated, dialyzed against water and then freeze-dried or precipitated with ethanol. Acidification or treatment with Ca2+ can be used instead. Brown algae are abundant in nature; however, the possibility of cultivating them exists as well [1]. The viscosity of aqueous sodium alginate solution rapidly increases with its concentration. For example, the addition of 10% of alginate to water leads to a ~100-fold increase in viscosity. But the poly electrolyte nature of alginate has little effect on its hydration, and in the above example less than 3.7% of the water molecules present in solution is involved in alginate hydration. Such a large viscosity increase is determined by the polysaccharide network, with large bulk-like water pools present between the polysaccharide chains [3].

Sodium alginate may act as a mucoadhesive polymer. A comparative study of adhesion between buccoadhesive compacts and pig buccal mucosa or sodium alginate solution revealed that the results were of similar performance [4]. Sodium alginate was proposed as a mucoadhesive component of a nasal gel [5] or in buccal patches containing salbutamol sulfate [6]. Sodium alginate conferred in situ gelling mucoadhesive properties and retarded drug release from liquid rectal suppositories. These suppositories were successfully tested on Guinea pigs to alleviate symptoms of histamine-induced bronchospasm [7]. Sodium alginate was also evaluated as an excipient in salbutamol sulfate sublingual films [8] and tablets [9]. However, drug release was found to be too slow in the films [8] or too rapid in tablets [9]. Only salbutamol sulfate tablets formulated from granules containing mastic and sodium alginate excelled commercial tablets in the terms of drug release when tested on rabbits [10]. In combination with hydroxy propyl methyl cellulose and propylene glycol sodium alginate was used in the formulation of terbutaline sulfate sublingual films [11]. Sodium alginate could be also used as a component of plugs for water-soluble parts of crosslinked gelatin capsules containing pellets with encapsulated salbutamol sulfate. The plug absorbed the surrounding fluid, and began to release the drug through the swollen matrix and was finally ejected out of the capsule by erosion of the material. The usability of the system was shown on rabbits [12].

Chitosan-alginate complex was proposed as an excipient for orodispersible tablets, and their disintegration time was so short that it was even referred to as a ‘super dis-integrant’ [13]. One optimized formulation containing the excipient for 5-fluorouracil tablets, suitable for trans buccal and rectal drug delivery, contained this chitosan-alginate complex along with the same components un-complexed in order to avoid burst release and to improve the mucoadhesive properties [14].

Sodium alginate itself also has a therapeutic effect. When admixed to foods for diabetic human patients, it decreased gastric emptying rate and rises glucose in blood, serum insulin and plasma C-peptide levels [15]. Orally administered, sodium alginate significantly alleviated small intestinal enteritis in rats, caused by treatment with the anti-inflammatory drug indomethacin, and this relief seemed to be independent of the sodium alginate viscosity administered [16]. Oral disposal of sodium alginate to rats with colitis led to a significant reduction of colonic damage, decreased lesion formation [17,18] and inhibited mucosal injury [17]. Orally administered alginate oligosaccharide obtained from hydrolysis of sodium alginate by Bacillus subtilis improved histopathological and biochemical parameters of mice having ovalbumin-induced asthma in a dose-dependent manner [19]. Rats fed with sodium alginate drank more water, and their urine volume and pH rose sharply. In contrast, calcium alginate caused very little changes in the same parameters [20].

Commercially available calcium alginate swabs were used for sampling nasal flora for subsequent DNA extraction [21]. The mucoid exopolysaccharide produced by the pathogenic bacterium Pseudomonas aeruginosa is alginate, but it has low immunogenicity if it is not conjugated with a carrier protein. Even in the form of conjugate it is non-toxic if administered intraperitoneally to mice or guinea pigs and non-pyrogenic if administered intravenously to rabbits [22]. When alginate beads with encapsulated tumor cells were implanted to mice, a process of angiogenesis was observed in the implants zone. The beads were prepared from commercially available alginate [23]. It may be considered as a further proof of alginate biocompatibility.

Sodium alginate was also shown to be beneficial for agriculture. Being administered as dietary supplement to the white shrimp Litopenaeus vannamei, it acted as an immunostimulant and improved its resistance against the attack of Vibrio alginolyticus bacterium [24]. Sodium alginate digested with alginate lyase promoted root elongation of rice, carrot [25], lettuce [26] and barley plants [27,28] even under hypoxic conditions [28]. It was hypothesized that digested alginate might initiate some signal transduction pathway [27,28]. Under hypoxic conditions digested alginate also caused enhancement of the activity of the enzymes regenerating NAD+ [28].

Alginate oligomers promoted the germination of unhulled rice and Komatsuna seeds as well as tobacco callus differentiation. The mixture of oligomers was assumed to contain so-called oligosaccharine, an oligosaccharide inducing unusual proliferation and/or differentiation of plant cells. There are several kinds of oligosaccharines. They act as a chemical signal for the stimulation of hormone synthesis [29]. The promoting effect of alginate oligosaccharides on root formation and growth in rice was mediated by endogenous indole-3-acetic acid [30]. But proliferation of the microalga Chlamidononas reinhardtii was repressed by the same oligomers [29]. It should be noted that only digested sodium alginate shows this effect. And the possibility of alginate degradation by the lyases of soil bacteria is assumed [28]. Therefore, it is speculated that these active substances can be formed from alginate under natural conditions. Another notable advantage of alginate is its ability to bind micronutrients. Some important Mn, Cu, Zn and Mo fertilizers are MnCl2 , CuSO4 ·5H2O, ZnCO3 and Na2 MoO4 ·2H2O, respectively [31]. Manganese can be complexed with alginate by addition of MnCl2 to the gelling solution of CaCl2 or BaCl2 , and slow release of manganese ions from the beads into physiological saline has been reported [32] because the affinity of alginate to Ca2+ is higher than to Mn2+ [33]. The beads containing Ba and Mn could be used for manganeseenhanced magnetic resonance imaging and were tested on rats [32]. The use of CuSO4 [34] or CuCl2 [35] as a gelling solution led to copper alginate hydrogel being able to release copper ions into simulated body fluid [34] or into phosphate buffer (pH 6) [35] in a prolonged manner. The use of basic zinc carbonate for zinc alginate hydrogel formation using internal gelation method has also been reported. The hydrogel was active against E. coli [36]. Molybdenum can be adsorbed by preformed calcium alginate beads preferably in the form of H2[MoO4] or [Mo(H2O)6]3+ at pH 2 and released back up to 50% into 0.1M HCl. If radioactive molybdenum is used, the method is suitable for radiotherapy [37]. Copper ions from CuCl2 may also be adsorbed onto preformed calcium alginate beads [38]. Copper alginate shows activity against Staphylococcus aureus, Staphylococcus epidermidis, Staphylococcus pyogenes and E. coli [34].

The biodegradability of unmodified alginate particles, their ability to bind micronutrients and the beneficial effect of alginate make them promising carriers of agrochemicals. This is especially important because in a recent review [39] the authors expressed great concerns regarding the use of nanoparticles in agriculture because of the negative impact of metal and oxide nanoparticles on soil microorganisms, earthworms and even on cultivated plants.

Alginate beads can also have industrial applications:

• Wastewater treatment. The beads with encapsulated horseradish peroxidase could be reused up to 3 times, although the encapsulation decreased enzyme activity in comparison with the free enzyme [40]. In another report, the efficiency of phenol removal by encapsulated horseradish peroxidase was demonstrated by reducing to half the initial phenol quantity after only 5 reaction cycles [41].

• Food industry. Xylanase immobilized in alginate beads may be used for fruit juice clarification [42]. Lactobacillus helveticus and Streptococcus thermophilus immobilized in alginate beads were intended for use as lactic starters in milk fermentation [43]. Alginate particles with encapsulated healthy nutrients can also be used as components of functional foods.

• Enzyme production by cells immobilized in alginate beads. A good example is glucoamylase [44]. In this case fungus Thermomucor indicae-seudaticae was immobilized in alginate beads, and cane molasses was used as a cheap medium [44]. In all these applications alginate is exploited because of its natural origin, i.e. it cannot be a harmful admixture if separated incompletely. Beads (and not nanoparticles) are chosen because they can be easily separated by sedimentation. As could be seen above, not only enzymes themselves but also enzyme-producing bacteria can be immobilized in alginate beads.

In contrast to metal nanoparticles, alginate particles can be modified either before or after their synthesis. In the former case, bulk alginate is modified and then used to prepare the particles. This way is usually preferable from the two options because it avoids the leak or destruction of encapsulated substance during the modification. The chemical modification of alginate is reviewed widely in [45].

Alginate microparticles and nanoparticles are usually used to encapsulate and carry various substances, and the goal of many studies is to achieve sustained release of them. It should be noted, however, that the results of experiments dealing with the release of poorly water-soluble drugs might often be misinterpreted, because the drug not found in the solution is assumed to remain encapsulated in the particles. However, it may decompose after the release or simply precipitate out. Supersaturated solutions with varying extent of supersaturation can also be formed, making the results irreproducible. Special care must be taken in the case of putting the particles into a dialysis bag, because the films act as an additional diffusion barrier. If centrifugation is used for separation of the medium with the released substance from the nanoparticles, the pressure generated during the process can disturb the equilibrium. It can also make difficult resuspending the nanoparticles in the fresh portion of medium for further incubation [46].

For consistency, throughout this review we will use the following terms (even if different names for them were used in the respective publications):

• Encapsulation efficiency: the percentage of the substance that was encapsulated (i.e. not lost).

• Loading efficiency (expressed in percent): the ratio of the weight of the successfully encapsulated substance regarding to the total weight of the particle. Some authors calculate loading efficiency using different formulae, but we will give their values without a special discussion. We have rounded encapsulation and loading efficiencies as well as zeta potentials to the nearest integer values.

• Nanoparticles are considered smaller than 1µm. Microparticles have size from 1 to 1000µm. Beads have size in a millimeter range. We have rounded bead size to the first decimal place.

Also, some authors term their particles ‘microcapsules’. However, we will use this term only if they have demonstrated or at least assumed the presence of a liquid core in their particles. In other cases, we will refer them to as microparticles.

Alginate-chitosan particles

Since alginate is a polyanion and chitosan is a polycation, they can form a polyelectrolyte complex upon mixing, provided both of them are charged, i.e. at suitable pH. This mixture can spontaneously form particles. The pKa of alginate carboxyl group is close to 5, and that of the ammonium group of chitosan is about 6.2 [1].

Alginate-chitosan nanoparticles were prepared by dropwise addition of a chitosan solution containing glutathione into an alginate solution at pH 4, under stirring. If prepared at 0.75 alginate: chitosan ratio, the formed nanoparticles with encapsulated glutathione had the following characteristics: size 361nm, polydispersity index 0.33, zeta potential 27mV [47,48]. At 1.5 alginate: chitosan ratio, the values were 212nm, 0.4 and 23mV, respectively, although the storage stability decreased, making these nanoparticles less suitable for application. In the same way, the pH increase from 5.0 to 6.5 and further caused aggregation [48]. The encapsulation efficiency was 27% [47] or 80% at ratio 0.75 and fell to 1% at ratio 1.5 [48]. The respective investigations were aimed to achieve the synthesis of mucoadhesive nanoparticles with an encapsulated NO donor needed for treat important diseases because of the multifaceted role of NO in vivo. Therefore, encapsulated glutathione was nitrosated inside the nanoparticles by adding sodium nitrite to the solution. S-nitrosoglutathione decomposition at 400µM was delayed by its encapsulation in the nanoparticles. At 18µM encapsulated S-nitroso glutathione was not cytotoxic to cultured Chinese hamster lung fibroblast cells (V79), whereas free S-nitroso glutathione was slightly cytotoxic at the same concentration. This assay could enable the use of these anti microbial nanoparticles in pharmaceutical applications such as wound healing without severe side effects [47,48].

Later, the same technique was used by the same group to encapsulate mercaptosuccinic acid and nitrosate it inside the particles. In this case, the hydrodynamic size of the nanoparticles was ~750nm. The encapsulation efficiency was 89%. Burst release of NO in aqueous solution was followed for 4 hours, although the release in the normal mode continued for 6 hours more. These nanoparticles were assayed for topical application for bovine mastitis. The minimal inhibitory concentration of the nanoparticles for Staphylococcus aureus determined in vitro was 125-250µg/ml. The number of colony forming units was 10-fold and 1000-fold lower after bacteria were incubated with nitrosated nanoparticles at 500µg/ml for 4 and 7 hours, respectively, compared with bacteria growth in the presence of empty nanoparticles at the same concentration and time. The CFU drastically decreased further upon the addition of a second dose of nitrosated nanoparticles. For E. coli the minimal inhibitory concentration exceeded 2000µg/ml, i.e. these nanoparticles were inefficient against this bacterium. The 50% cytotoxicity concentration of the nanoparticles for cultured HEp-2 cells was 640µg/ml. Chitosan nanoparticles without alginate at the same concentrations of the acid released more NO at higher rates. Nevertheless, it was concluded that NO-releasing nanoparticles might be used to combat bacteria for treating and preventing bovine mastitis [49].

Spherical alginate-chitosan beads with encapsulated lemongrass oil having size of 1.8-2.1mm displayed significant antibacterial and antioxidant activity. For unencapsulated oil the same activity was observed only at higher concentration. This beneficial action was attributed to the strong interaction between chitosan and the oil. This kind of beads has potential applications as a greener agent for medical purposes [50].

The following advantages of alginate-chitosan particles can be underlined:

• Chitosan can enhance drug bioavailability by its capacity of infiltration into the mucus layer of the small intestine with subsequent opening of tight junctions of epithelial cells [51].

• Unlike calcium alginate, alginate-chitosan polyelectrolyte complex cannot be disintegrated by chelatoring agents. Their main disadvantage could be the necessity to use an acidic solution of chitosan because of its insolubility at neutral pH.

Preparation of alginate particles without employing gelation

Now we describe the techniques for preparation of particles from bulk sodium alginate or its solution as well as spontaneous formation of particles of modified alginic acid in water. The resultant particles are usually intended to be ready to use. However, dry sodium alginate particles can be later treated with CaCl2 solution in order to convert them to calcium alginate particles.

There exists a patented technique for producing alginate, cellulose, starch or collagen particles from bulk substances by ball milling with the possibility to control particle size from 100nm to 50µm. The resultant nanoparticles containing therapeutic proteins have shown efficacy in treating solid tumors, single dose vaccination, and oral delivery. For instance, tumor-bearing mice that received these nanoparticles containing Texas red and cisplatin showed significant tumor size diminishing. If the same nanoparticles were coupled to dendritic cell-binding peptide and contained encapsulated pneumococcal surface protein A, together with an adjuvant, they were effective to combat the bacterial load of the mice that was reduced (in the terms of infected tissue volume) after exposition to nanoparticles. The nanoparticles produced by the same milling technique were also used to induce passive immunity against anthrax toxin in mice by means of oral delivery of monoclonal antibodies developed versus anthrax toxin [52].

Another technique consists in dropwise addition of pure ethanol or acetone to 1% sodium alginate in water containing drug solution in dimethyl formamide. Mixing [53] and cooling down to 3-5 °C is needed during the process. At low mixing speed aggregation was observed [54]. These microparticles can be separated by filtration, washed with the same solvent and dried on air, in a heating oven [53] or in a desiccator [54]. Using nitrofurazone as an example of an encapsulated drug, the loading efficiency and yield of microparticles decreased as the particle size increased from 5 to 30μm with ethanol dripping rate increasing. The presence of 0.1% ammonia [54] (pH 8-9) and of a surfactant was needed in order to avoid particle aggregation in the case of nitrofurazone. Other drugs, viz. acridone, tetracycline, dibazole and metronidazole were encapsulated in the same way (but without ammonia), although the encapsulation conditions needed to be optimized for every drug separately. The yield varied from 31% for metronidazole to 77.5% for tetracycline, and the loading efficiency varied from 2% for metronidazole to 43% for nitrofurazone [53]. In a later publication, the same group reported that in the case of nitrofurazone the yield of microparticles was 81% with a loading efficiency of 34%. Spray drying instead of filtration was recommended to increase the yield [54]. The stability of nitrofurazone-loaded microparticles resuspended in water was reported to increase with pH [53]. At 1% and 2% of particles (nitrofurazone concentration was 0.34% and 0.68%, respectively) these solutions were more active against E. coli, P. aeruginosa, P. vulgaris, S. aureus and B. subtilis than aqueous nitrofurazone solution having drug concentration less than 0.02% because of its insolubility. In the case of Candida albicans the same solutions of microparticles excelled in antifungal activity nitrofurazone solutions in DMSO with the concentrations of 1% and 2% [54]. The ability of the particles to form stable suspensions and to enhance drug solubility in water broadens the field of drug application [53,54]. The encapsulated drugs are expected to be more stable under ambient conditions [53].

Spray drying the sodium alginate solution containing the payload (caffeine-loaded peptidic nanoparticles) yielded microparticles having size of about 4μm. The crosslinking with CaCl2 solution increased their mean size to 7.4µm but decreased their shrinkage and slowed down the release of caffeine into simulated gastric fluids. The particles are potentially bioactive because of the presence of antioxidant peptides [55]. Spray drying the solution containing sodium alginate, pectin and gentamicin sulfate at inlet temperature of 90 ºC was used for wound dressing preparation. The volume diameter at the 50th percentile (spanning from 310 to 1003nm for various samples), the width of particle size distribution, water content and drug release rate increased with nozzle spray mesh diameter and with feed solution concentration at constant ratio of the components. Flowability of the powders, the adhesive strength of the gel formed from them in contact with simulated wound fluid as well as its activity at 0.25mg/ml of gentamicin sulfate against Staphylococcus aureus and Pseudomonas aeruginosa showed the opposite tendency. Antimicrobial activity was expressed as the diameter of the zones of clearance around the two samples spotted on agar plates with the spread bacterial culture after incubation for 24 hours. For Staphylococcus aureus the activity of two samples was also tested in culture medium after 3, 6, 9 and 12 days of incubation. The particles were mainly spherical, but other shapes appeared when either feed concentration or mesh nozzle increased, and further increase led to large collapsed particles. All the particles were composed of smaller aggregated particles. The encapsulated drug was being released in simulated wound fluid in Franz-type diffusion cells for up to 5 days. Loading efficiency was around 24-27% with an encapsulation efficiency between 70 and 83%, and for all the samples initial burst release was observed. At 40 °C and 75% relative humidity drug content was preserved for 6 months with only slight increase in water content. Swelling rate in contact with simulated wound fluid depended on particle size. The yield increased with feed solution concentration but decreased with nozzle spray mesh diameter. The nanoparticulate powder may be used as a self-consistent formulation having great potential application in the treatment of both acute and chronic infected wounds [56].

Low molecular weight alginic acid prepared by acid hydrolysis of sodium alginate formed nanoparticles itself (without calcium ions) when its hydroxyl groups were functionalized with oleoyl residues. The nanoparticles were loaded with vitamin D3 by addition of its solution to the reconstituted solution of vacuumdried nanoparticles. Loading efficiency increased with the vitamin concentration from 0.3 to 0.9%, but the encapsulation efficiency also decreased from 68% to 46%. Mean nanoparticle hydrodynamic diameter also decreased from 559nm to 305nm, and particle formation rate was sped up when substitution degree increased. An unimodal particle size distribution was revealed. In simulated gastric fluid they retained spherical shape and released ~40% of the encapsulated vitamin for 3 hours. But in simulated intestinal fluid they became irregularly shaped, their hydrodynamic diameter was 757nm and burst release of 40% of the vitamin occurred, with 60% of the vitamin released after 7 hours. The nanoparticles can be used as oral carriers for liposoluble nutraceuticals [57]. The great disadvantage of sodium alginate particles is the very limited possibility of prolonged drug release because of sodium alginate solubility leading to fast disintegration of the particles. The particles of modified alginic acid offer convenient manipulation, but the need of its prior chemical functionalization limits the applicability of the technique for non-specialized, e.g. biomedical laboratories.

Production of Alginate Particles Using Other Particles as Cores

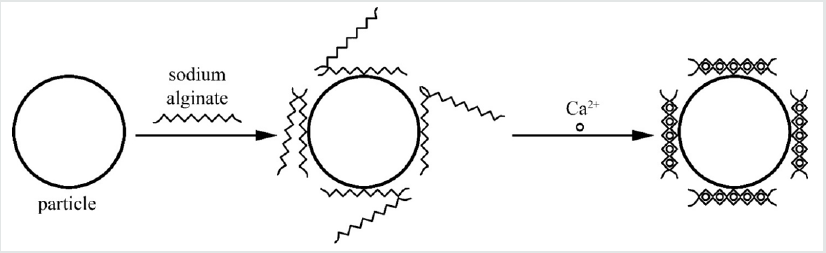

In this method, sodium alginate is physically adsorbed or covalently linked to the surface of other particles. The particles can also be formed already capped with alginate. In some cases subsequent gelation with CaCl2 is carried out. For CaCO3 particles there is a possibility of their generation simultaneously with alginate gelation.

Dropwise addition of chitosan nanoparticles with encapsulated bovine serum albumin modified with rhodamine isothiocyanate to sodium alginate solution at controlled pH yielded negatively charged nanoparticles having hydrodynamic diameter of several hundred nanometers depending on the solution composition. The highest diameters were registered in water. The nanoparticles successfully delivered the protein into cultured cells, with the localization depending on cell type. Significant increase in peroxide production by HCEC cells was observed at 300 and 600µg/ml of empty nanoparticles after exposure for 4 hours. However, there was almost no superoxide production after either 4 or 24 hours of exposure. The metabolic activity of LN229 and MCF-7 cells remained unchanged for up to 72 hours of incubation with the empty nanoparticles. But MDA-MB-231 and HCEC cells displayed significantly decreased metabolic activity at nanoparticle concentration above 180µg/ml after 72 hours of exposure, but not after 24 hours. Similar survival decrease at these concentrations of nanoparticles was observed for A549 cells. Dose dependencies acquired after 24 or 72 hours of exposure were almost the same. Survival of HT29 and CaCO2 cells was significantly increased only after exposure to 600µg/ml of the nanoparticles for 72 hours. The nanoparticles have potential applicability as nanocarriers in cancer therapy [58]. A similar technique was used for enoxaparin encapsulation. The proposal was to evaluate nanoparticles loaded with this low molecular weight heparin for its oral delivery, controlled and prolonged release in order to improve patient compliance. In this, chitosan nanoparticles were covered with sodium alginate (applied in phosphate buffer) and treated with CaCl2 . Parameters of the optimized formulation were as follows: average size 335nm, spherical, polydispersity index 0.37, zeta potential –31mV, encapsulation efficiency >70%, drug release in simulated gastric fluid for 2 hours 2%, in simulated intestinal fluid for 14 hours ~60%. Degradation and erosion of nanoparticles was identified as a possible drug release mechanism. The pharmacokinetic parameters of the drug given orally to fasted rats through cannula in a dose of 50mg/kg body weight were improved. Nevertheless, those of intravenously administered free enoxaparin at 1mg/kg were better. 75% of the encapsulated drug applied at 2mg/ml reached across the intestine to the serosal fluid for 90 minutes, as shown in vitro by means of everted intestinal sac model. 900 IU of orally administered encapsulated drug reduced thrombus formation by 59% compared with buffer. Significant uptake of the nanoparticles by the intestinal mucosa for 1 hour was shown by administration of nanoparticles loaded with fluorescein isothiocyanate instead of the drug through gastric cannula to fasted rats. Therefore, the nanoparticles proved their utility as oral delivery vehicle for enoxaparin. Such a vehicle is a foremost requirement for non-invasive and non-hospitalized treatment of vascular disorders (deep vein thrombosis, pulmonary embolism and venous thromboembolism). But subcutaneously injected free drug was even better [51].

Microspheres loaded with dermatan sulfate were formed by its complexation with chitosan with subsequent addition of the resulting solution to sodium alginate solution followed by spray-drying. The spray-dried microspheres were collected in CaCl2 solution in 90% ethanol and then vacuum-dried. Their properties (including shape) significantly depended on buffer, pH and polyelectrolyte ratio, because these parameters influenced polyelectrolyte complex formation. The objective of the study was to achieve sustained delivery of dermatan sulfate from microspheres intended for its site-specific delivery. The particles had size around 2.3 µm and zeta potential from –27 to –48mV. Encapsulation efficiency was up to 96% with loading efficiency of around 4%. They released dermatan sulfate in Tris buffer for more than 10 days. After incubation for 48 hours at 10mg/ml in culture medium they increased growth of cultured mouse fibroblasts (NIH 3T3) up to 170-200%. Free dermatan sulfate at 400µg/ml had the same effect. Therefore, released dermatan sulfate was structurally intact and retained its bioactivity. The microspheres synthesized at pH 5 had slightly higher stimulatory effect than those synthesized at pH 3.5. A clear dose dependence of the stimulatory effect was observed at 1-10mg/ml of the microparticles. If chitosan was omitted, the microparticles exhibited rapid burst release, and partially dissolved microspheres fused and formed a network. The microspheres have great potential to be used in tissue engineering applications because dermatan sulfate is an emerging therapeutic agent for tissue regeneration [59].

Another unusual technique was used for the encapsulation of fungicide prochloraz. To the oil-in-water emulsion of prochloraz stabilized by surfactant cetyltrimethylammonium bromide prehydrolized tetraethyl orthosilicate was added. It resulted in its further hydrolysis and silica shell formation around the pesticidecontaining drops. After a drying step the silica shell was further modified with amino groups and coupled with alginate using carbodiimide chemistry. The resulting microcapsules were dried again and treated with metal chlorides in solution. This was done in order to use them in agriculture as a nanofertilizer and nanopesticide at the same time. Their size (after drying and redissolving) was ~2.5µm with homogenous distribution. Fungicide loading efficiency was about 30% (w/w). Prochloraz release for 60 days in 30% (v/v) methanol in water was shown. The degradation rate of free prochloraz increased with temperature and was also high under strong acidic and alkaline conditions. In contrast to this, the microcapsules were insensitive to pH, protected the encapsulated fungicide from decomposition under ultraviolet irradiation, and temperature increase just caused some release alteration. They are expected to increase disease resistance of plants. The delivery system may be extended to other photosensitive or pH-sensitive pesticides [60].

Treatment of Triticum aestivum L. seeds with aqueous solution of patented silver nanoparticles capped with sodium alginate for 1 day resulted in concentration-dependent uptake of the nanoparticles at 0.01-10mg/l. At 1-10mg/l of the nanoparticles slight increase of water uptake by the seeds was observed. The increase of seed germination as well as of shoot and root dry weight was observed. The stimulatory effect decreased with nanoparticle concentration. The aim of the study was to elucidate the stimulatory effect of silver nanoparticles at low concentrations on wheat growth at early stages of ontogenesis. The nanoparticles were referred to as an example of a prolonged action form of a biogenic metal produced by means of ‘green nanochemistry’ and acting as a plant growth stimulant [61]. We have produced calcium alginate nanoparticles with gold core (Figure 2). At first, gold nanoparticles were synthesized by tetrachloroaurate reduction with polyethylene glycol using a method modified from [62]. After physical immobilization of sodium alginate onto their surface and resuspending into water CaCl2 solution was added. The reaction protocol must be followed very thoroughly in order to avoid extensive aggregation and destabilization of the nanoparticles. The size of the nanoparticles can be adjusted by means of auto metallography. Selection of other volumes of water and CaCl2 solution allowed us to produce stable aggregates [63].

An interesting dependency of the thickness of a layer of physically adsorbed sodium alginate on magnetite (Fe3O4) nanoparticles expressed as particle size on experimental conditions was revealed. The average diameter of the nanoparticles dripped onto a TEM grid was 70nm. But if the same nanoparticles (without their separation from alginate solution) were sprayed onto the grid, their average size became 14nm. Aerosolization of the same core magnetite nanoparticles mixed with sodium alginate solution of another concentration into CaCl2 solution led to nanoparticles with average diameter of 8nm. If chitosan and sodium tripolyphosphate were used instead of alginate and CaCl2 , the sizes of the resulting nanoparticles were also unequal in the three cases. The nanoparticles were intended for drug delivery or hyperthermia therapy of cancer [64].

By mixing a solution containing CaCl2 , doxorubicin hydrochloride and a plasmid encoding p53 with another solution containing sodium carbonate and sodium alginate, nanoparticles containing simultaneously DNA and doxorubicin were prepared. Due to the existence of alginate the growth of CaCO3 based coprecipitates could be effectively retarded. The resulting nanoparticles had size about 145nm and zeta potential –14mV, and these parameters for the nanoparticles without alginate were 300nm and –2.5mV, respectively. The encapsulation efficiency was 89% for DNA and 84% for doxorubicin. Loading efficiencies were 10% and 1%, respectively. About 40% of encapsulated doxorubicin were released in water for 48 hours with initial burst release. Proliferation of HeLa cells exposed to the nanoparticles at 37 °C for 48 hours was completely inhibited, and apoptosis was induced. Therefore, they have promising applications in cancer treatments. Cell inhibition rate was dose-dependent at 0.1-0.4µg/ml of doxorubicin. It was always higher for encapsulated doxorubicin. The nanoparticles containing 2µg of DNA displayed slightly higher cell inhibition rate than those containing 1µg of DNA. At 0.2µg/ml of doxorubicin most HeLa cells became rounded or detached from the plate, and blebbing occurred. The nanoparticles without alginate led to lower cell inhibition rates. If the nanoparticles contained another plasmid (pGL3-Luc) and did not contain doxorubicin, no cytotoxicity was found [65]. Layer-by-layer absorption of alginic acid and protamine in water or 0.5M NaCl (pH 5.5) onto spherical calcium carbonate microparticles produced in the presence of alginic acid and having size from 2 to 12μm with subsequent dissolution of the CaCO3 core in HCl or EDTA was also reported. The microcapsules synthesized in this way could be used for the encapsulation of polymers and their pH-dependent release, as demonstrated for dextrane conjugated with fluorescein isothiocyanate [66].

Although not stated in the respective publications, the great advantage of this method is the improved particle size control. For example, the techniques of synthesis of metal nanoparticles with predictable size already exist. Another advantage is the possibility of encapsulating the substances into some types of core particles instead of encapsulation into the alginate layer. In this case the alginate layer acts as an additional diffusional barrier. But the existence of a core particle limits versatility and the possibility of food or biomedical application of these particles. However, this is a convenient method of generating micro- or nanocapsules by chemical dissolution of some types of core particles.

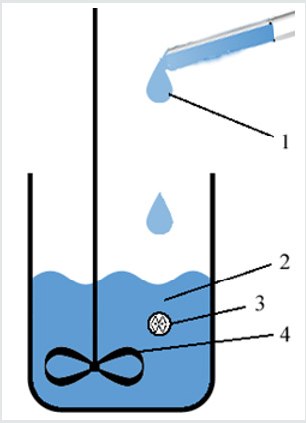

Figure 3: Alginate particle prepared using emulsification method. 1 – encapsulated drug; 2 – alginate core; 3 – empty micelle.

In this method, an aqueous solution of sodium alginate containing an insoluble calcium salt (usually carbonate) is emulsified into an oil phase (Figure 3). Upon addition of an acid, calcium ions are liberated inside the alginate drops converting sodium alginate into calcium alginate, i.e. to a hydrogel, and the drops become being particles.

The technique of emulsification-internal gelation was useful for glucose oxidase encapsulation. A water-in-oil emulsion consisting of mineral oil, surfactant Span 80, acetic acid and sodium alginate solution – previously ultrasonicated with calcium carbonate – was prepared. Then water was added, the emulsion was stirred, and the formed beads were rinsed with Tween 80 and water. The resulting empty beads were incubated in buffered enzyme solution followed by chitosan coating. In the wet state the microparticles had volume-based mean diameter of 138µm. After lyophilization, storage at -20 °C and rehydration the immobilized enzyme lost 10% of its activity, and the uncoated beads collapsed. Loading and encapsulation efficiencies were 10% and 80%, respectively, and depended on enzyme loading pH. Loading efficiency increased with enzyme concentration, while encapsulation efficiency did not. Both parameters decreased with chitosan concentration, but the activity of the immobilized enzyme reached a maximum peak at 0.5% chitosan. It was concluded that these nanoparticles had the potential to serve as a useful and efficient delivery system for therapeutic proteins. Interestingly, at high enzyme concentrations the immobilized enzyme exceeded in activity the free one [67]. In a related report, no coating was applied, and canola oil was used as oil phase. Dry CaCO3 powder was ground prior to application to decrease grain size from 30µm to 2.5µm. CaCO3 substitution for oxalate or tartrate was unacceptable because too low pH was required. Otherwise, phosphate was rejected because of too large grain size, and citrate produced large beads with a high variability in size distribution. At CaCO3 /alginate monomer ratios higher than ¼, residual insoluble calcium salt was observed inside the particles. The alginate particles had mean diameters from 50 to 1000µm. The use of low guluronic and low or medium viscosity alginate gave a narrowest particle size distribution, but high guluronuc content and homopolymer blocks led to stronger gels. If Span 80 concentration increased up to 1%, the mean particle size decreased asymptotically. The particles were stronger and more spherical when using larger amounts of acetic acid while limiting the pH reduction by enhancing the buffer capacity of sodium alginate solution using carbonate buffer. Further reduction of polydispersity was achieved by dropping the oil phase into the acidic buffer solution in water. The synthesis can be carried out under sterile conditions, and its potential application may be cell immobilization [68]. A similar protocol did allow the encapsulation of mouse insulinoma 6 cells. For this, to the sodium alginate solution containing a suspension of CaCO3 and cells in their culture medium mineral oil was added followed by the addition of acetic acid previously mixed with mineral oil. After that, a buffered saline solution mixed with culture medium was added to neutralize the pH. All the experiment was carried out under agitation, and its rate determined the particle size. It could be made from ~200 to 2000μm (circularity was 0.9), the distribution was close to normal but very wide. The beads were separated by centrifugation, washed and separated by filtration. CaCO3 was not completely dissolved, and its grains remained inside the alginate beads. The beads had lower compressive stress resistance than those produced by extrusion using a commercial encapsulator. MOPS buffer provided better cell survival than HEPES buffer under optimized conditions (pH, buffer concentration, emulsification and acidification time). Cell division inside the beads was observed, and the encapsulated cells produced insulin at higher concentrations than single cells. The emulsion process is potentially suitable for cell therapy and transplantation purposes [69]. The use of paraffin oil has also been reported. In this case, a homogenized CaCO3 suspension in a solution containing sodium alginate, chitosan and drug (salbutamol sulfate) was added into liquid paraffin oil containing Span 80. After emulsification, liquid paraffin containing glacial acetic acid was added, and stirring was continued until CaCO3 was solubilized. Then CaCl2 solution containing Tween 20 was added to recover the beads by decantation. Beads were washed with the same solution and then with acetate buffer. The parameters for the optimized formulation were as follows: spherical, size 591±40µm, encapsulation efficiency 95%. These values increased conforming to increasing polymer concentration. Cumulative drug release after 2 hours at pH 1.2 was 7%, after subsequent 3 hours at pH 6.8 (phosphate buffer) 10%, and after 5 hours at pH 7.4 (phosphate buffer) 99.6%. It was concluded that the hydrogel particles were the potential system for colon delivery of salbutamol sulphate via oral route for chronotherapy of nocturnal asthma [70].

However, in another publication [71] it was stated than salbutamol sulfate absorption site was not colon, moreover, it would degrade in colon, although no data was presented. Using the same technique as that in the previous report, alginate microparticles having mean size from 4 to 7µm (depending on recovery protocol) with immobilized insulin were synthesized. The particles were recovered from the oil phase by washing it with acetate buffer and separated by decantation. The remaining particles were recovered by centrifugation. The difference between the recovery protocols were centrifugation rate and additives to the buffer (CaCl2 , Tween 80, solvents). Only the protocol employing acetone, isopropanol and hexane retained the secondary structure of insulin. The encapsulation efficiency was more than 75% with the particle recovery yield around 70%. The particles were uniform and spherical with a rough surface. It should be noted that all the formulations showed burst release of all the encapsulated insulin for 5 min in simulated gastric solution without enzymes. But the technology was claimed as promising for insulin delivery due to the gentle methodology of producing microparticles [72]. In order to evaluate the effectiveness of insulin-loaded nanoparticles on its permeability across intestinal cells, another encapsulation technique was used. Here the alginate solution contained dextran sulfate, poloxamer 188 and ultrafine calcium carbonate suspension. Sorbitan monooleate was used for emulsification of this solution into paraffin oil under stirring and ultrasonication. Insulin solution in HCl was added simultaneously with acetic acid solution in oil under the same conditions. Nanoparticles were washed and coated with chitosan, polyethylene glycol and albumin. At the time of coating they were treated with CaCl2 . Their average size was 300nm with polydispersity index 0.17, zeta potential 29mV, encapsulation efficiency 31% and loading efficiency 6%. The nanoparticles released up to 35% of insulin at pH 1.2 for 2 hours. At pH 5.5 burst release was observed. Dye-labeled nanoparticles applied at 0.5mg/ml were found at the cell membranes and probably inside Caco-2 and HT29-MTX cells co-cultured in a 90:10 proportion. Nevertheless, at 0.1-1mg/ml they had relatively low cytotoxicity for separately cultured AGS, Caco-2 and HT29-MTX cells. At 0.5 mg/ml the nanoparticles enhanced insulin permeation through a monolayer of Caco-2 and HT29-MTX cells co-cultured with Raji B cells (a model of intestinal wall) from the apical to basolateral direction at pH 5.5 and especially at pH 7.4. Insulin permeability was demonstrated to be mediated by clathrin endocytosis. The clinical potential of the nanoparticles for the oral delivery of insulin and therapy of type I diabetes mellitus was envisaged [73].

Internal gelation using canola oil containing acetic acid and surfactant Span 85, and sodium alginate solution containing CaCO3 nanoparticles (116-244nm depending on the conditions, zeta potential 14mV) capped with surfactant AOT carried out in an electro dispersion reactor allowed size control of the microparticles by peak voltage increase in the range of 412 to 10µm. Further peak voltage increase did not decrease the bead size substantially, i.e. the method is currently limited to microparticles. Dried particles aged in CaCl2 solution had a diameter of about 5µm. The flow rate ratio also significantly influenced the droplet size. The particles were highly porous because of CO2 release during their formation and were spherical with a wrinkled surface. Only a slight amount of CaCO3 was required to induce gelation, viz. 0.01M for 4% (w/v) alginate, although much higher concentrations were used in practice. The microparticles appeared suitable for encapsulation of pharmaceutical compounds [74].

A technique of internal gelation without employing emulsification has been reported. Mixing CaCl2 with DM-nitrophen™ leads to a complex. This complex has a Kd of 5nM that dramatically increases after UV photolysis. Bulk hydrogels prepared in this way were intended for patterned microscale 3D cell culture, and their applicability for human cell encapsulation was demonstrated. But the high cost of DM-nitrophen™ limits its applicability [75].

In a previous review [76] the following advantages of emulsification-internal gelation method were stated:

• Particle size can be easily controlled from a few nanometers (potentially) to millimeters by controlling oil viscosity, sodium alginate type and concentration, surfactant concentration, and emulsification conditions, including mixing.

• The particles are homogeneous.

• Low shear protects fragile encapsulants.

• Scale-up potential is almost unlimited without the loss of particle size control

The following disadvantages were pointed out:

• High porosity of the particles.

• Possible loss or inactivation of encapsulated proteins during formulation and washing steps

Additional concerns:

• If mineral oils (paraffin oil, isooctane, silicon oil, etc.) are used, they may cause environment-related problems.

• Acid concentration must be carefully calculated to avoid overdosing [76].

External Gelation

In this method a soluble calcium salt (usually chloride) induces alginate gelation. But simple mixing the solutions of sodium alginate and CaCl2 yields bulk hydrogel without any particles. Therefore, special techniques are used.

Emulsification coupled with external gelation

Here sodium alginate solution containing a drug being encapsulated is emulsified in an oil phase. The emulsion droplets formed act as templates for the formation of spherical particles. Then CaCl2 solution is added converting the drops to particles [77].

Surfactants are usually used to stabilize the emulsions. However, sometimes they are not employed. The addition of sodium alginate solution to sunflower oil with subsequent homogenization by mixing, addition of CaCl2 solution and acetic acid and another homogenization step led to beads. They were separated by centrifugation, washed with hexane and water followed by treatment with isopropanol: water mixtures with increasing concentration of isopropanol up to 100%. The last step was supercritical drying. The loading was carried out by bead incubation at 40 °C at 120 atm with ibuprofen for 24 hours. Bead characteristics were as follows: loading efficiency 30.5%, pore size 35nm, surface area 359.5m2 /g. High loading efficiency makes these aerogel beads efficient drug carriers [78].

In a simple technique employing a surfactant, CaCl2 solution was added to that of sodium alginate containing 5-25% PEG-1500 or 0.5-5% Tween 80 at pH 5 under sonication. The nanoparticles were separated from the reaction mixture by centrifugation after 24 hours [66,79]. They had average diameter of 210-540nm but were prone to collapse during drying [66]. The amount of PEG1500 and Tween 80 was about 64mg and 19mg, respectively, per one gram of lyophilized nanoparticles independently of the initial concentrations of these stabilizers in sodium alginate solution. In the presence of Tween 80 some hydrophobic regions were formed inside the nanoparticles. The nanoparticles containing polyethylene glycol on the surface are expected to have low immunogenicity, and those having Tween 80 are expected to cross blood-brain barrier [79].

Nanoparticles were also produced by dropwise addition of sodium alginate solution containing a plasmid encoding enhanced green fluorescent protein to the solution of AOT in toluene. Then CaCl2 solution was added. After washing with acetone and water the nanoparticles were separated by centrifugation. They had a core consisting of sodium alginate, and a membrane consisted of calcium alginate. Their morphology depended on the position on the respective point on the phase diagram, and that was in turn determined by the toluene: alginate: AOT ratio. Only in one region separated and spherical nanoparticles having size 55-100nm (average size 80nm) were formed. Transfection of cultured NIH 3T3 cells performed using the nanoparticles (at 2µg/ml of encapsulated DNA) and the complex of DNA with polyethyleneimine has shown comparable results after 48 hours, but the nanoparticles performed more slowly. The nanoparticles were proposed as non-viral vectors for gene therapy. Once internalized by non-phagocytic cells via endocytosis pathways, they could undergo quick erosion and elicit osmotic swelling, hence facilitating endosomal escape of gene to the cytoplasm [80].

Alginate microparticles can be used as a source of Ca2+ ions causing gelation of sodium alginate solution (in phosphate buffered saline) they were placed into [81]. The latter solution may contain peptides [81,82], oligonucleotides [81] or cells to be delivered by subcutaneous injection close to a tumor site. The solution had a volume of 150µl and contained ~106 microparticles. Gelation in vivo occurred for several minutes. The gels remained intact in mice for more than 21 days and than dissolved [81]. The peritumoral gels carrying antigen-pulsed dendritic cells accumulated CD4+ T-cells but did not attract a significant amount of CD8+ T-cells, and the effect on established tumor growth was limited. If the gel also contained interleukin-15 super agonist, it could be released for over 2 weeks in vitro (in RPMI growth medium) and for 5-7 days in vivo. This gel retarded tumor growth and caused transient reduction of the size of larger tumors. This effect was mainly caused by the cytokine, with dendritic cells providing only a minor effect. The average suppression of tumor growth caused by the above-mentioned gel, the same gel without the cells but containing the cytokine and Tolllike receptor-9 agonist CpG and the gel containing only the cytokine but injected two times was equal. Local immunotherapies may be used for treatment of unresectable tumors and sites of surgical resection to combat local recurrence. Local immune response might make the tumors to become in situ vaccines themselves [82]. The microparticles with the average diameter of 20μm were synthesized as follows. Sodium alginate solution in phosphate buffered saline was added dropwise to the solution of Span 80 and Tween 80 in isooctane. After homogenization of the resulting solution CaCl2 solution was added followed by another homogenization step, centrifugation and washing with isooctane and water [81].

A close technique can be used to form alginate nanocapsules. Nanocapsules are vesucular systems having oily or aqueous core surrounded by a polymeric membrane. The drug is mixed with an organic solvent, and the mixture is slowly added to aqueous solution of sodium alginate containing a surfactant, and an oil-inwater emulsion is formed under sonication. Finally, CaCl2 solution is slowly added, and resulting calcium alginate forms a drop membrane. This method is reviewed in [77].

Sometimes liquid paraffin can be used as an oil phase. The solution containing guar gum, sodium alginate, Tween 80 and drug (salbutamol sulfate) was added dropwise to liquid paraffin followed by the addition of CaCl2 solution and incubation. Another preparation was produced by dropwise addition of a solution containing chitosan, sodium alginate, the drug and acetic acid to liquid paraffin followed by addition of dioctyl sodium sulfosuccinate and of glutaraldehyde solution in toluene. All the experiments were carried out under stirring. The microparticles produced were filtered, washed with petroleum ether and dried. They were spherical with average size of about 438µm. Encapsulation efficiency was more than 95%. Their incubation in simulated gastric fluid for 2 hours and subsequently in simulated intestinal fluid for 10 hours caused gradual release of more than 85% of the encapsulated drug. Salbutamol sulfate is used in the management of bronchopulmonary diseases involving bronchospasm, and its sustained release dosage forms are needed to reduce frequent dosing (3-4 times a day) [83]. Interestingly, a close technique without the use of a surfactant was reported. Salbutamol sulfate and liquid paraffin were added to a solution containing sodium alginate, hydroxypropyl methylcellulose and starch. Homogenization and stirring led to a stable emulsion that was extruded through a needle into CaCl2 solution and incubated in it followed by filtration, washing and drying. The beads were mixed with magnesium stearate and manually filled into empty hard gelatin capsules. The capsules were administered to fasted rabbits through plastic tubing followed by flushing of water. They remained in the stomach for more than 6 hours. Their floating time in simulated gastric fluid in vitro was also more than 6 hours. The capsules used for the experiment with rabbits also contained BaSO4 . Encapsulation efficiency and bead size increased with hydroxypropyl methylcellulose and starch amount increase. This might be due to emulsion viscosity increase. Bead density decreased with hydroxypropyl cellulose amount increase and starch amount decrease. Drug release after 10 hours of capsule floating in simulated gastric fluid decreased simultaneously. For the optimized formulation encapsulation efficiency and drug release were 70% and 57%, respectively, with the average bead diameter of 1.9mm and density of 0.85g/cm³. Bead surface was rough and had small pores. These stomach-specific floating systems might be beneficial over the conventional oral dosage forms (prone to tolerance development after repeated administration) because of prolonged gastroretentive delivery of drugs with improved bioavailability, therapeutic efficacy and patient compliance [84].

In order to ensure production of calcium alginate nanoparticles without damaging the biomolecules being encapsulated, reversed phase inversion temperature method has been proposed. In this case, the mixture of aqueous sodium alginate solution, decane and tetra ethylene glycol monododecyl ether employed as a surfactant was equilibrated at the temperature slightly below the phase inversion temperature of this system. Then the mixture was quickly transferred to a temperature well above it leading to formation of water-in-oil emulsion, and CaCl2 addition to this emulsion led to the formation of nanoparticles. The most stable particles were produced if CaCl2 was added as a simple solution, not as waterin-oil emulsion. All the synthesis was carried out under stirring. In order to separate the nanoparticles, decane was added leading to precipitation of micrometer-sized structures with an irregular shape. The nanoparticles remaining in solution were spherical and homogeneous with mean radius of 50nm and size distribution ~20-120nm in radius. The yield of nanoparticles was ~18%. The amount of the surfactant and decane remaining in the sample was below 0.01 wt.% and 0.2 wt.%, respectively. The procedure has potential to be scaled up and to be adapted for use with pharmaceutically acceptable oils. The size of the resulting particles makes them suitable for delivery of biomacromolecules to cells and certain mucosal tissues [85].

In an approach developed at the same time by another group, both sodium alginate (containing bovine serum albumin as a model protein) and CaCl2 aqueous solutions were emulsified in isopropyl myristate using dioctyl sodium sulfosuccinate as a surfactant. CaCl2 microemulsion was poured dropwise into the alginate one followed by ultrasonication. The nanoparticles were separated by centrifugation and washed with acetone. The size of the particles was about 500nm, but particles smaller than 100nm were also present. Loading efficiency was 40%. The nanoparticles showed burst release of the encapsulated protein into phosphate buffered saline for 15 min, followed by a plateau and than by sustained release of all the remaining protein for more than 8 hours. The released protein did not suffer covalent aggregation or degradation by fragmentation. The nanoparticles were intended for oral protein drug delivery, and the components for their preparation were pharmaceutically acceptable [86].

A possibility to produce alginate particles without using water has been reported. This technique involves addition of mixture of drug (salbutamol sulfate), sodium alginate, CaCl2 and PEG-400 into molten PEG-6000. All the reagents (except PEG-6000) were applied as powders. The resulting mixture was cooled rapidly at -20 °C and then powdered in a mortar followed by sieving. Particle size range for different formulations was 6.75-9.8µm. They had rough surface [87]. Interestingly, particle size increase with sodium alginate concentration increase reported for encapsulation of the same drug by dripping method [88] was observed here as well. Drug release in phosphate buffer decreased with sodium alginate concentration increase and increased with PEG-6000 proportion decrease. This was explained by hydrogen bonds between alginate and polyethylene glycol. All the formulations tested showed burst release with subsequent release of the remaining drug for several hours. They were intended for pulmonary drug delivery by means of a dry powder inhaler [87].

The advantages of the method are the same as those stated above for emulsification-internal gelation, except particle homogeneity. The additional advantages are easier formulation because of no need for finely dispersed insoluble calcium salt, decreased porosity and the absence of acid. The disadvantages are the use of oil and usual need for surfactants with questionable biocompatibility. Therefore, these nanoparticles have rather low chances for food applications, but limited agricultural or even biomedical use is possible. It should be noted, however, that surfactants make the nanoparticles less prone to aggregation. Therefore, the nanoparticles produced by this method must have enhanced stability.

Microfluidic devices

The advances in microfluidics paved the way to its application in nanotechnology, the synthesis of calcium alginate nanoparticles not being an exception. The parts of microfluidic chips can be manufactured in the laboratory from plastic by means of commercially available computer-controlled laser cutters.

For the synthesis of alginate microparticles having diameters in the range 50-2000µm with a variation less than 5% a microfluidic chip has been invented. A stream of sodium alginate solution was focused by two sunflower seed oil streams leading to emulsion that was dripped into CaCl2 solution, and microparticles formed and precipitated at the interface between the phases. The emulsion size increased when the aqueous flow increased. When the oil flow increased, the emulsion size decreased. Increasing both oil and alginate solution flow rates while maintaining the flow rate ratio resulted in smaller emulsions. Gold nanoparticles were encapsulated into the alginate microparticles at the time of their synthesis. The microparticles were freeze-dried and than vacuumdried, but most of them retained spheroid shapes. The approach will provide many potential uses for pharmaceutical applications such as targeted drug delivery and DNA transfection [89]. In another microfluidic device liquid paraffin containing Span 80 was used as the continuous phase and sodium alginate solution containing Na2 SO4 served as the dispersed phase. The droplets of the mixture were collected in BaCl2 solution. This led to the formation of barium alginate microspheres with BaSO4 nanoparticles inside. The microspheres were washed and stored in NaCl solution. They were spherical with the diameter 229-284 µm (average 250µm). Their size could be modulated by adjusting the flow rate ratio of the two phases. The distribution of BaSO4 nanoparticles was denser on the edge of the microspheres than in their interior. The aggregation of the nanoparticles was not observed. BaSO4 dispersion density increased with Na2 SO4 concentration increase, but at 0.4M Na2 SO4 the precipitate appeared on the microsphere surface making it brittle. The microspheres were suggested as an embolic agent synthesized by means of droplet microfluidics and intended for transcatheter arterial embolization. In this method an embolic agent is injected through a microcatheter guided by a radiographical instrument in order to cause artery occlusion and to prevent nutrient supply to the tumor. At 5mg/ml the microspheres were not cytotoxic to HepG2 cells. After injection of them at ~30mg/ml to the renal artery of healthy rabbits interlobular and arcuate arteries became almost completely filled with the microspheres possessing excellent X-ray visibility. These microspheres showed better and longer lasting X-ray visibility after embolization if compared with commercially available calcium alginate microparticles that did not contain BaSO4 . The described microspheres present exciting opportunities for potential clinical applications in transcatheter arterial embolization therapy and for noninvasive tracking and mapping of the fate of the embolic agents in vivo [90].

Needless to say about the great advantages of microfluidic devices. They simplify scaling up while minimizing batch-to-batch variations and labor requirements. Moreover, they can be part of more complex devices and enable synthesis of nanoparticles in the field. The possibility to synthesize nanoparticles in small quantities is promising for personalized medicine. However, not every specialist can invent them, and it would be impossible for many poorly equipped or non-technical (e.g. purely biomedical) laboratories to construct them.

Water-in-oil-in-water emulsions

In more complex variant of the technique, the water-inoil emulsion is further emulsified in water containing another surfactant, and then CaCl2 solution is added. Calcium alginate nanoparticles (500-700nm, zeta potential around –13mV) stabilized by AOT and polyvinyl alcohol were synthesized by gradual addition of calcium chloride solution to water-in-oil-in-water emulsion of sodium alginate containing doxorubicin or rhodamine being encapsulated. Loading efficiency for these drugs was 5% and 4%, respectively. The nanoparticles enhanced doxorubicin cytotoxicity to cultured cancer cells in a dose-dependent manner (at 0.01-0.1µg/ ml for MCF-7 cells and at 0.1-10µg/ml for NCI-ADR/RES cells) by extending its way to nucleus overcoming P-glycoprotein-mediated efflux without the use of additional P-glycoprotein inhibitors. At highest concentration of the encapsulated doxorubicin no viable cells were observed. Overexpression of P-glycoprotein results in the development of multidrug resistance of cancer cells, but drug encapsulation in nanoparticles overcomes this effect. Increased therapeutic efficiency was associated with an increase in the level of cellular and nuclear drug accumulation [91]. Similarly produced nanoparticles enhanced activity of encapsulated methylene blue in photodynamic therapy of cultured cancer cells (at ~0.5-20µM in a concentration-dependent manner for MCF-7 cells) by promoting its nuclear delivery and increasing production of reactive oxygen species. Decreased viability of 4T1 cells was observed only at the highest drug and light doses (at 0.6µM and 2400mJ/cm² but not at 0.3µM or at 1200mJ/cm²). The parameters of the nanoparticles were as follows: average diameter 79nm, surface charge 19mV, encapsulation efficiency 82%. Methylene blue can be used as a photosensitizer in photodynamic therapy of cancer, but its clinical use has been limited because of insufficient therapeutic efficacy. The respective study was aimed at enhancement of its efficiency by means of encapsulation in nanoparticles [92]. Lyophilized nanoparticles produced using the same technique and by the same group increased the efficiency of photodynamic therapy based on 8µM free or encapsulated methylene blue and directed against 4 cultured cancer cell lines under ambient conditions. They also reduced mammosphere formation by cancer stem cells present in the culture of MCF-7 cells under normoxia and hypoxia. It was achieved by switching the mechanism of radical generation to a type I reaction requiring much less molecular oxygen. This is significant because of a usually hypoxic tumor microenvironment. The loss of efficacy at low concentration of oxygen is a major limitation of photodynamic therapy, and it can be overcome by promoting type I chemistry by methylene blue encapsulation in nanoparticles composed of polymer and surfactant that are both anionic. The nanoparticles were spherical with a hydrodynamic diameter of 275nm, zeta potential of –20mV and loading efficiency of 7%. Aggregates were separated by centrifugation [93]. The AOT-alginate nanoparticle system is a promising delivery vehicle for anticancer photodynamic therapy with methylene blue [92,93]. The diameter of the freeze-dried nanoparticles with simultaneously encapsulated doxorubicin and methylene blue was 40nm if measured by means of atomic force microscopy and ~73nm if measured using dynamic light scattering. Aggregates might form, but they were separated by centrifugation. Drug loading was 7% and 13%, respectively. Their administration via a lateral tail vein to mice with drug-resistant mammary adenocarcinoma at 4 and 8mg/kg, respectively, followed by light exposure slowed down the tumor growth and increased mice survival. 15% of tumor cells were apoptotic compared with 1% if nonencapsulated drugs were administered. The nanoparticles also damaged tumor neovasculature. Nanoparticlemediated combination of chemotherapy and photodynamic therapy has significant therapeutic potential against drug-resistant tumors, for it could overcome drug resistance by invoking multiple anticancer mechanisms. Encapsulation of the drugs in alginate nanoparticles may result in significantly enhanced intracellular accumulation and production of reactive oxygen species [94]. Encapsulation efficiency of methylene blue could be increased up to 99.8% by sodium alginate and AOT concentration increase as well as by decrease of the volume of the AOT phase. But it decreased with the amount of drug added to the formulation. Many other ‘model drugs’ could also be encapsulated, for example verapamil, clonidine, diclofenac and fluorescein. The encapsulation efficiency and release profile strongly depended on drug composition. The release of weakly acidic diclofenac in phosphate buffered saline was faster than that of acidic doxorubicin and verapamil, but even the release of 70% of encapsulated diclofenac lasted for 7 days with initial burst release. The encapsulation efficiencies for these drugs were 6%, 60% and 77%, respectively. Two drugs could be encapsulated simultaneously, but the release became faster. The zeta potential of the nanoparticles was in the range of –25 to –35mV. Surfactant-polymer nanoparticles would be useful for sustained delivery of water-soluble drugs, maybe together with imaging agents [95]. Similar technique was used for encapsulation of pesticide imidacloprid in order to investigate the ultimate effect of this pesticide in the form of nanoformulation. The nanoparticles had the following characteristics: size ~150nm (aggregates were present), encapsulation efficiency 99%, loading efficiency 2.5%. Increasing the concentration of AOT was found to increase particle size. Increasing the concentrations of both sodium alginate and AOT led to encapsulation efficiency increase, but the effect was complex. The encapsulated pesticide was less cytotoxic against cultured Vero cells at 5 and 10µg/ml if compared to free imidacloprid. But it was more effective against leafhoppers after 11-15 days of spraying 150ml of its 0.145-mg/l solution on ~10 Okra (bhindi) plants growing on a total area of 1m². Nano formulations of pesticides will reduce the amount of pesticide needed, decrease the environmental pollution, side effects and the amount of pesticide residues in food. They will be beneficial for economy, be of increased safety for the farmer or pesticide applicator and offer targeted delivery [96].

As can be seen, the double emulsion technique is much less popular than those involving water-in-oil emulsions. They share the same disadvantages, but the former one is more labor-consuming and requires two surfactants. However, the technique may provide somewhat better particle size control, because the maximum size of the aggregates is limited by the size of the micelle.

Dripping method

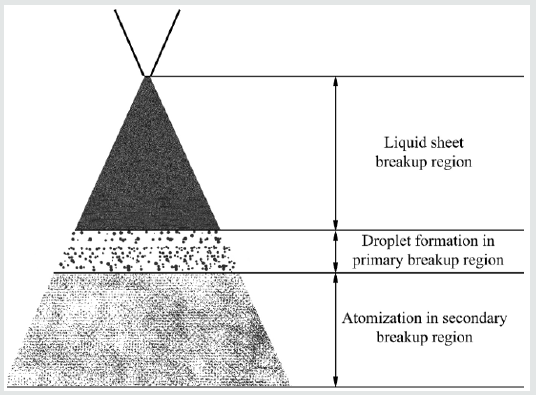

The simplest way to produce particles using external gelation is dripping one solution into another one (Figure 4). When a drop of sodium alginate solution faces Ca2+ ions, gelation immediately occurs onto its surface preventing its dissolution. Then Ca2+ ions slowly diffuse inside the drop to induce gelation in all its volume, and the drop becomes a particle.

Figure 4: Dripping method. 1 – sodium alginate solution; 2 – CaCl2 solution (or vice versa; a drug can be in either solution); 3 – alginate particle; 4 – stirrer.

Dripping CaCl2 into sodium alginate

If CaCl2 solution is being dripped into sodium alginate solution, so-called pre-gel is initially formed. This pre-gel is a colloidal solution (i.e. nano- or microparticles) of calcium alginate hydrogel that has not separated into a new bulk phase yet. This separation (i.e. aggregation) can be prevented by addition of chitosan or other stabilizers. However, the optimization of reaction time (before separation of the particles) and of concentrations of CaCl2 and sodium alginate makes possible the synthesis of nanoparticles even without stabilizers.