Lupine Publishers Group

Lupine Publishers

Menu

Review Article(ISSN: 2641-6875)

Features of Low-Temperature Microwave Processing of Tobacco Volume 2 - Issue 5

Asadova IB1*, Kurbanov MR2, Shamilov EN1

- 1Institute of Radiation Problems, Azerbaijan National Academy of Sciences, Baku, Azerbaijan

- 2Central Botanical Garden, Azerbaijan National Academy of Sciences, Baku, Azerbaijan

Received: April 4, 2021; Published: April 13, 2021

*Corresponding author: Asadova IB, Institute of Radiation Problems, Azerbaijan National Academy of Sciences, Baku, Azerbaijan

DOI: 10.32474/CTBM.2022.02.000147

Abstract

The paper outlined an effective method for curing tobacco, which includes the combined action of a microwave electromagnetic field and light with a wavelength of 400-700nm. The developed method made it possible to obtain tobacco material with high taste and moderate speed. The high efficiency of the proposed method has been proven by IR and X-ray photoelectron spectroscopy.

Keywords: Tobacco; Microwave Processing; IR And X-Ray Photoelectron Spectroscopy; Low-Temperature

Introduction

Tobacco leaves were processed in various methods in order to obtain high-quality products with pleasant taste sensations [1].Usually various gases, vapors and liquid solutions are used for removing the bitterness of tobacco. Simultaneously, the use of chemical reagents does not introduce the desired changes in the composition of tobacco, and the complexity and duration of these procedures make them unprofitable. The closest to the technical solution is a method of processing tobacco, according to which it is cooled in a sealed container to a temperature of T= 230 K with the container immersed in a cooling mixture (solid CO2 + acetone) [2]. However, this method also does not allow to remove the bitterness and burning of tobacco, but rather removes nicotine and tar, the presence of which in a certain amount in tobacco is necessary. This goal is achieved by freezing tobacco leaves with liquid nitrogen [3]. The combined action of a microwave field and low temperature (to T=77K) on tobacco leaves makes it possible to remove bitterness and pungency. It is known that the natural fermentation of cured tobacco leaves is the most important process of forming the quality of tobacco raw materials. In the fermentation process, traditional heat treatment is used. However, the supply of heat and its penetration into the tobacco material takes a lot of time and requires a lot of energy. Therefore, the development of fundamentally new methods to accelerate the fermentation process of tobacco raw materials is very relevant. The used method which includes exposure to an electromagnetic microwave field is, in fact, the only accelerated method for curing tobacco material today. At the same time, it is important that tobacco intensively absorbing electromagnetic waves, heat up everywhere. In other words, it is heated from the inner layers to the outer [4].This method is carried out by simultaneous air blowing [5], which causes an acceleration of moisture transfer. The disadvantage of the known method is that the tobacco leaves obtained after drying remain green. Naturally, residual chlorophylls negatively affect the quality of tobacco.

The moisture of tobacco leaf is one of the main parameters affecting the fermentation process and, consequently, the quality of tobacco. Therefore, we set ourselves the task of finding more efficient ways of drying. At the same time, it is necessary to consider the fact that dry tobacco loses its elasticity during improper processing, as a result of which economic losses increase, and excessively moist raw materials easily splash. Therefore, obtaining dry tobacco leaves with a given moisture content and with the best taste qualities is of particular importance. Moreover, green and dried fermented samples of tobacco leaves of the “Samsun, Trapeozoid” type grown in Azerbaijan were used for the study. The tab- lets were obtained from finely ground samples of tobacco leaves to record radiothermoluminescence (RTL) spectra. The samples were irradiated with gamma radiation using 60Co gamma-isotope source for 3 hours (10.8 kGy) at T= 77K. In the present work, the effect of simultaneous low-temperature and microwave treatment on the number of tobacco leaves is studied by IR spectroscopy.

Experiments

As an object of study, aromatic and skeleton types of green tobacco leaves, (Samsun, Trapeozoid) grown in Azerbaijan, were selected. Low-temperature and microwave processing of tobacco leaves was carried out on a laboratory unit “UHF-tobacco” [6]. At the same time, tobacco leaves are rapidly cooled in liquid nitrogen (T = 77K), placed in one layer on a microwave oven conveyor and subjected to microwave field treatment with a frequency of 400 MHz at a radiation power of 50 kW. Microwave heating was carried out with simultaneous air blowing which previously purified from carbon dioxide, and light treatment with a wavelength of 400-700 nm. The choice of the spectral range 400-700 nm is due to the fact that the absorption band of residual chlorophyll is at 665 nm and photoirradiation of tobacco leaves in this region does not lead to a deterioration in the quality of tobacco [7]. IR spectra of tobacco pressed with KBr in the form of tablets were measured using Specord-71 IR spectrometer

Results and Discussion

It is known that the tobacco leaves are processed in various ways in order to obtain high-quality products with pleasant taste characteristics. Simultaneously, a number of investigations were carried out to remove the bitterness of tobacco under the influence of various gases, vapors and liquid solutions [7-8]. However, the use of chemical reagents leads to undesirable effects. Moreover, the complexity and duration of these procedures made them unprofitable.

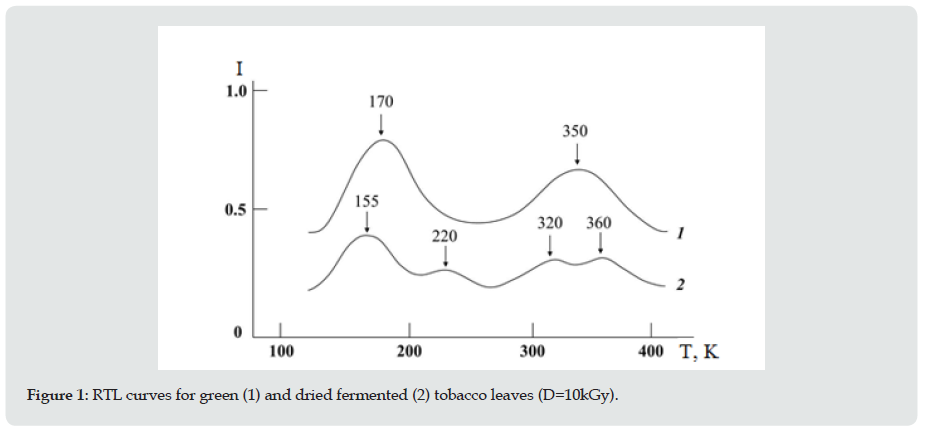

The features of radiothermoluminescence (RTL) of green tobacco leaves in a wide temperature range of 80÷450K have been studied. The luminescence curves of green tobacco leaves are characterized by the presence of maxima at temperatures of 170 and 350 K (Figure 1). After curing and fermentation of tobacco leaves, the intensity of all peaks decreases, a broad and diffuse peak (halfwidth ΔT1/2 ~ 35 K) at T = 350K split into two comparative narrow peaks with maxima at T = 320K (ΔT1/2 ~ 35 K) and T = 360K (ΔT1/2 ~ 25K) and new RTL peaks appear with a maximum at T = 220K (Figure 1). The appearance of a low-temperature peak at T = 170 K may be due to the presence of structural moisture in the tobacco composition. This is evidenced by a decrease in its intensity by ~ 2.5 times and a shift of the maximum by 15K towards lower temperatures as the degree of curing increases. Apparently, molecular water, which is in the steric environment of alkaloids, has an indirect effect on the taste of tobacco. In the literature, another works were devoted to the technical solution of this survey. According to one of them, tobacco is cooled in the geometric container to a temperature of 230 K with the container immersed in the cooling mixture (solid CO2 + acetone). However, the disadvantage of the method is that tobacco loses a significant part of its nicotine and tar during such technical processing, which the presence of these components in a certain amount is extremely necessary.

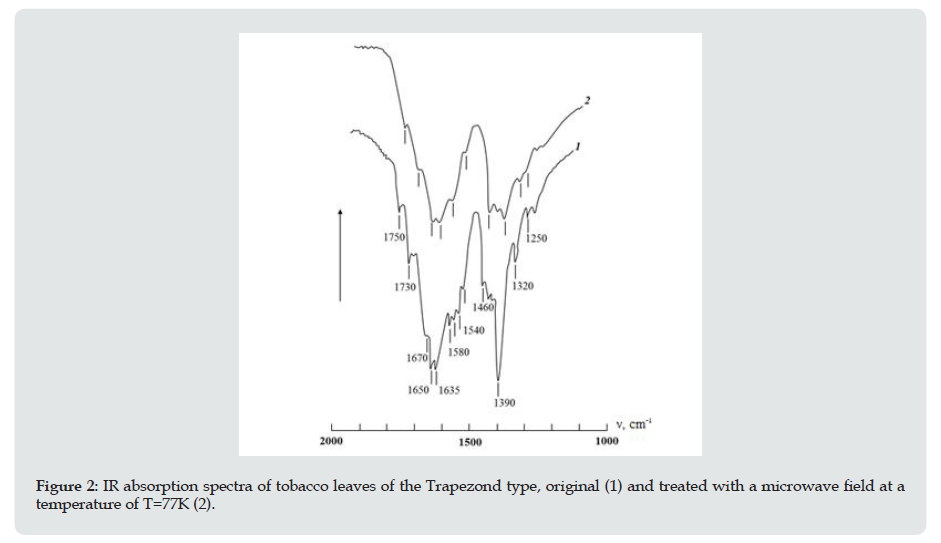

It should be noted that the influence of the microwave field leads to a change in the chemical composition of tobacco leaves. This change is clearly seen in the IR spectra. Comparison of the IR spectra of the original and microwave-treated tobacco leaves shows that the main changes are observed in the region of 1000-200 cm-1 (Figure 2). According to (5, 6), the 1390 cm-1 band refers to bend ing vibrations of CH3 groups, and 1460 cm-1 to bending vibrations of common alkyl (CH3 and CH2) groups that make up lipid-saturated fatty acids, described by the formula R-COOH with linear and non-linear carbon chains R = CH3,(CH2)n. In low-grade tobacco, carbon chain branching is mainly the accumulation of lower acids, which adversely affect the quality of tobacco. When treated with a microwave field, the total intensities of the 1390 and 1460 cm-1 bands are redistributed and reduced, which is associated with the breaking of branched chains and a decrease in their lengths. From the change in the intensities of the bands at 1250 and 1320 cm-1, which is a consequence of the superposition of in-plane deformation vibrations of CO and OH groups, one can judge the proximity of the chain branching site to the carboxyl group. These changes are indicative of the degree of improvement in the quality of processed tobacco leaves. In the original tobacco leaves, a significant amount of protein causes a strong taste of bitterness, which negatively affects the quality.The main protein macromolecules are amino acids, which have two types of functional groups

Figure 2: IR absorption spectra of tobacco leaves of the Trapezond type, original (1) and treated with a microwave field at a temperature of T=77K (2).

- acidic carboxyl – С-О-ОН

- basic amino group (-NH2, -NH-).

In the IR spectra, the stretching vibrations of the amino groups are at 3300 cm-1, and the bending vibrations are in the frequency range of 1590-1650 cm-1 (Figure 1). We have tried to remove bitterness and pungency by the combined action of a microwave electromagnetic field and low temperature (77K). Simultaneously, tobacco leaves cooled in liquid nitrogen were treated with a microwave field and the change in the chemical composition of tobacco leaves was traced by the IR spectroscopy of the sample. By changing the intensities of the bands associated with the breaking of branched chains, the amount of lower acids that adversely affect the quality of tobacco was determined. It should be noted that the low-temperature microwave treatment proposed by us did not lead to a significant change in the structure of various carbohydrates containing catonic and functional aldehyde groups. In addition, it is known that the quality of the finished tobacco product is strongly influenced by the curing and fermentation processes. At the same time, residual chlorophyll significantly reduces its quality. Therefore, we considered it expedient to improve the quality of the finished product by accelerating the decomposition of chlorophyll. This goal was achieved by us by searching for new methods of curing and fermentation, devoid of shortcomings that adversely affect the quality of the product. The searches have shown that one of these methods is the dielectric heating of tobacco, since mainly dielectric heating is strongly manifested on materials with low thermal conductivity and heat-resistant properties. It is clear that the impact on tobacco leaves - as a dielectric of electromagnetic fields would allow the flow of photo - and thermochemical reactions not only on the surface, but throughout the entire volume.

The intensity of deformation vibrations of amino groups decreases by ÷1.5 times after low-temperature microwave treatment of tobacco leaves. This is due to a decrease in the number of proteins of various structures. However, low-temperature microwave treatment does not lead to a significant change in the structure of various carbohydrates containing catonic and aldehyde functional groups (-C-O-H, -C-O). Therefore, the intensity of the band at 1750 cm-1 practically does not change. Comparison of the relative changes in the intensities of the carbohydrate and protein bands of the original and processed tobacco leaves shows that the values of the percentage of carbohydrates to proteins increase. This once again indicates an improvement in the quality of tobacco after low-temperature microwave processing. It should be noted that one of the advantages of microwave curing is that, in addition to local thermal effects, the electromagnetic field also induces the probability of uniform photochemical reactions of individual enzymes, which makes it possible to obtain high-quality products.

It is known that the chemical composition of tobacco leaves changes during fermentation. The color is gradually leveling out, approaches monophonic and the green disappears. Simultaneously, a high residual content of chlorophyll leads to the accumulation of substances that adversely affect the quality of tobacco. Based on the above material, we are concluded that it is advisable to accelerate the decomposition of residual chlorophyll in order to improve the quality of the finished product. We achieved this goal by the fact that microwave heating, driven at a frequency of 400–1000 MHz, was carried out with simultaneous blowing with air which previously purified from carbon dioxide and treatment with light with a wavelength of 400–700 nm. The proposed method of curing tobacco allowed us to obtain dry tobacco leaves with yellowish color, which met the requirements for high-grade tobacco products. This was achieved due to the fact that tobacco leaves were irradiated with light with a wavelength that causes photooxidation of green pigments. At the same time, simultaneous blowing with air purified from carbon dioxide sharply suppressed the natural process of photosynthesis in tobacco leaves, and the frequency of the used electromagnetic field provided the necessary duration of processing and curing of the leaves.

Our experiments have shown that curing tobacco at a microwave field frequency below 400 MHz is undesirable, since this slows down the process of removing moisture from the leaves. Curing at a frequency above 1000 MHz is also undesirable, since the rate of moisture removal from the leaves exceeds the rate of photooxidation of green leaves, due to which the finished product retains its green color. Since combustibility is one of the most important qualitative characteristics of tobacco raw materials, we investigated the conditions for this process to occur in tobacco processed using above described method. A comprehensive study of the tobacco combustion process was carried out by X-ray diffraction methods, infrared-photoelectron spectroscopy, as well as differential thermal analysis.

Based on the determination of temperature intervals for exothermic effects, criteria were established both for the tobacco fermentation and for its degree. Studying the processes of pyrolysis and oxidation of tobacco, as well as determining the temperature transitions of the decomposition of its components with an analysis of the composition and structure, after each stage of pyrolysis, makes it possible to purposefully control the content of alkaloids (in particular, nicotine) and tar in tobacco, as well as to conduct comparative assessments of their quality. The obtained data on the combustibility of tobacco also correlate well with the data on the microelement composition of tobacco preparations obtained by us using spectral analysis method. Atomic adsorption method has shown that the studied tobacco samples contain trace elements, such as - Pb, Sn, Cr, Mn, Ni, Al, Ti, Si, Mg, Ca, Mo, K, Cu, Zr, Na, Co, Sr , Fe, V, Y. It was found that Si (15-17%), Al (-2%), Mg (-3%), Ca (-9%) and Na (more than 1%). A certain correlation was found between the amount of K and Fe and the tobacco variety. It is shown that the highest grade of tobacco is characterized by a higher content of K and a relatively low content of Fe. The investigated samples of tobacco had practically no chlorine and sulfur-containing compounds. It is concluded that the types of tobacco grown in the territory of Azerbaijan have a rich microelement composition and they are characterized by higher quality indicators [8].

References

- Han XL, Jia SR, Zhang WJ (2016) Analysis of Daqu produced in different seasons. J Inst Brew 122: 397-402.

- Ming HM, Liu YC, Zhou YC, Cheng W, Yang WJ (2010) Effect of temperature on the quality of Moutai-flavor Daqu. J China Brew 7: 157-159.

- Yang DY, Fan GX, Wang DQ, Lu YH (2007) Microbes in High Temperature Starter. J Liquor-mak Sci Technol 5: 37-41.

- Meng Z, Xiong ZH, Zhong QD, Bai ZH (2010) Application of PCR-DGGE to Analysis of Bacteria. J Food Fermen Ind 10: 159-162.

- Men GC, Jiang GH (2020) Correlation between microbial diversity and volatile flavor components of Taorong-type Daqu. J China Brewing 39(10) .

- Li LS, Li LL (2020) Analysis of Microbial Community structure and Flavor Composition of Maotai-flavor Daqu. J Modern Food Science and Technology 36(8).

- Tang B, Liu JY, Zhou QW, Li AJ, Wan CH, Tang YH (2011) Phylogenetic diversity analysis of bacteria in gujing-flavor, Liquor Daqu. J Food Fermen Ind 9: 36-40.

- Liu YB, Wang XH, Zhao ZJ (2019) The High-yield Glucoamylase Strains in Daqu: Screening and Optimization of Enzyme Production. J Chinese Agricultural Science Bulletin 36(33): 108-113.

- Luo HB, Huang ZG, LiH, Wei CH (2009) Study on Microbial Community Metabolism. J Southwest Univ 7: 180-184.

- Li ZJ, Huang D (2020) Isolation and Identification of Two Heat-resistant Molds in Daqu at Medium-high Temperature and Comparison of Their Enzyme Production Characteristics. J Food and Fermentation Sciences and Technology 56(3)

- Soon WW, Hariharan M, Snyder MP (2013) High-throughput sequencing for biology and medicine. J Mol Syst Biol 22: 1-14.

- Qing, N, Li DF, Yang RF (2011) The application of high-throughput sequencing technologies in the research of microbiology. J Acta Microbiol Sin 4: 445-457.

- Anandhakumer C, Kizaki S, Bando T (2015) Advancing small-molecule-based chemical biology with next-generation sequencing technologies. J Chembiochem 16: 20-38.

- Fan WL, Xu Y (2000) Review of Daqu enzyme’s research. J Liquor Making 3: 35-40.

- Wang HY, Xu Y (2015) Effect of temperature on microbial composition of starter culture for Chinese light aroma style liquor fermentation. J Lett Appl Microbiol 60: 85-91.

- Zheng XW, Rezaei Tabrizi M, Rober Nout MJ (2011) Daqu-A Traditional Chinese Liquor Fermen. Starter. J Inst Brew 117: 82-90.

- Su Y, Yang L, Li H (2015) Bacterial communities during the process of high-temperature Daqu production of roasted sesame-like flavour liquor. J Inst Brew 121: 440-448.

- Yan LC (2012) The analysis of high-temperature Daqu microbes’ structure and wine function bacteria breeding and the research of fortified Daqu. C. Fujian Normal Univ 6: 53-66.

- Wu SW, Zhang ZG, Li XH (2011) Current research and development prospects of Daqu microbes in the production of Daqu. J China. Brew 5: 8-12.

- Huang GQ, Sun X P Microbial Community Structure and Diversity during Compound Xiaoqu liquor fermentation based on high throughput sequencing Technology. J Food Science.

- Xue Y, Guo Z (2020) Analysis of microbial diversity in Shihua Baijiu Daqu based on Mi Seq technology. J China Brewing 39(7) .

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...