Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4676

Review Article(ISSN: 2637-4676)

Innovative Indoor Horticultural Systems (iHORT) for the 21st Century Volume 4 - Issue 4

Rajasekaran R Lada1*, Woody Maijers2 and Sjoerd Nieboer2

- 1Department of Plant, Food, and Environmental Sciences, Dalhousie University, Canada

- 2Department of Agri, Food and Life Sciences, Inholland University of Applied Sciences, Netherlands

Received: September 07, 2018; Published: September 18, 2018

Corresponding author: Rajasekaran R Lada, Department of Plant, Food, and Environmental Sciences, Faculty of Agriculture, Dalhousie University, Truro, Nova Scotia B2N5E3, Canada

DOI: 10.32474/CIACR.2018.04.000194

Abstract

- Abstract

- Introduction

- Sustainability of Conventional Agriculture

- Climate Change

- Sustainability of Urban Cities

- Types of Urban Horticulture Systems

- Applications and Adaptation of iHORT systems in Vertical Farming

- Cluster Model for iHORT Business Development

- Training and Capacity building in iHORT

- Future Challenges and Conclusion

- References

With the increasing global population, urbanization, the current unsustainable and expansive agricultural practices would be expected to further elevate the risk of food and nutritional insecurity of the global population, which is recognized as a global threat for the 21st century. This paper reviews the demographic changes, urbanization, sustainability of the conventional agricultural systems, the environmental and resource implications and presents possible sustainable alternatives. While this is still in its infancy, we present a potential integrated, innovative model where the universities, technologists, innovators, investors, municipal councils, provincial and federal governments all can collectively engage, creating iHORT ecosystem to develop an Innovative Horticulture (iHORT) systems that could impact the global society in advancing sustainable horticultural systems for the 21st century and beyond providing food and nutritional security irrespective of any location on this planet, under any dire environmental conditions reducing the carbon footprint. In addition to developing innovative technologies, adopting a cluster business model and flexible, life-long educational approaches would be beneficial for the success of the industry.

Introduction

- Abstract

- Introduction

- Sustainability of Conventional Agriculture

- Climate Change

- Sustainability of Urban Cities

- Types of Urban Horticulture Systems

- Applications and Adaptation of iHORT systems in Vertical Farming

- Cluster Model for iHORT Business Development

- Training and Capacity building in iHORT

- Future Challenges and Conclusion

- References

Global population continues to increase, and it is predicted that it would reach 11 billion in 2100 [1]. Thus, there would be an additional 2.5-3 billion people to feed. This means we need an additional 140 million ha of arable lands to produce food [1]. Urbanization is also on the raise. It is estimated that nearly 2/3rd of the global population live in urban cities, who are to be fed and food generally travels from long distances sometimes as far as 8000- 9000 km in some northern latitude countries like, Canada. Globally, nearly 26% of our current arable lands are already degraded or less fertile. The conventional agriculture (CA) is expansive, contributing to deforestation thus, contributing to species extinction, reducing diversity [2]. CA also uses significant water resources. Nearly, 70% of the fresh water is used for agricultural production (both animal and plant agriculture) while the Earth’s recharge capacity reduced to 40% [1]. In addition, agriculture is known to contribute significantly to the climate change due to use of fossil-fuel based fertilizers, application of liquid manure, tillage practices and methane emissions from animal agriculture [3]. It is estimated that agriculture adds 12,000 megatons of carbon dioxide to the atmosphere each year, which is nearly 24% of total GHG emissions potentially contributing to climate change. Global drought events, increase in global temperatures, sea level raise, increases in heavy precipitation events, flooding are all on the raise, which are attributed to climate change. These factors challenge field crop production and raises significant concerns on food availability and access. Use of pesticides to control insects, diseases and weeds have increased globally contributing to environmental pollutions, contaminating aquifers, rivers, seas and oceans. Some of the agrochemicals used cause significant health risk to human beings and are implicated in neurological disorders, various types of cancers, renal failures, diabetics and skin and eye irritations and so on.

Thus, the conventional agricultural practices are not sustainable, and this alone cannot be a solution for feeding the world in the future. We need to find innovative ways of producing more food with less resources (space, water, nutrients), low carbon foot print and free of agrochemicals. This review is an attempt to provide an insight into various types of innovative indoor horticulture systems (IIHS), the challenges and opportunities and an innovative partnership model for enhancing the viability of the IIHS.

Sustainability of Conventional Agriculture

- Abstract

- Introduction

- Sustainability of Conventional Agriculture

- Climate Change

- Sustainability of Urban Cities

- Types of Urban Horticulture Systems

- Applications and Adaptation of iHORT systems in Vertical Farming

- Cluster Model for iHORT Business Development

- Training and Capacity building in iHORT

- Future Challenges and Conclusion

- References

Sustainability is judged by managing resources in a responsible way without causing irreversible damage to the environment or harming nature and without depleting resources [3]. The extensive agriculture to achieve green revolution with an unprecedented yield increases from 1960s caused a significant pressure on the planets natural resources including land, water and environment. “Land and water resources are central to agriculture and rural development and are intrinsically linked to global challenges of food insecurity and poverty, climate change adaptation and mitigation, as well as degradation and depletion of natural resources that affect the livelihoods of millions of rural people across the world” (FAO, 2011: The State of The World’s Land and Water).

Over the last 50 years, the world’s cultivated area has increased by 12%. The global irrigated area has doubled over the same period, accounting for most of the net increase in cultivated land. In total, global agriculture is estimated to use 11% of the world’s land surface for crop production. Agriculture uses 70% of all global freshwater withdrawals [4]. Models suggest that global agricultural land will have to expand by another 140 million hectares by 2050, a land area roughly the size of Brazil to feed the global population increase by 2100 [1]. While the arable lands are limited for expansion of agriculture, agricultural intensification causes significant environmental damages that include habitat fragmentation, disruption of ecosystems services and reduces biodiversity. Furthermore, agriculture is a leading contributor to global greenhouse gas (GHG) emissions, with agricultural related activities contributing about one-third of the global net CO2 emissions amounting to 12000 megatons per year primarily through deforestation and burning [5].

Water availability will also be a critical factor in food production soon. Farming using irrigation is an extremely productive method, evident in that 40% world’s food production is from 20% irrigated land (300 MA hectares). Under semiarid conditions, yield of nonirrigated crops is substantially reduced (Pimentel, 2009). Model predictions suggest water withdrawals must rise by 11% in the next three decades to meet crop production demands. It is imperative that water-use-efficiency In agricultural systems must increase. Considering all the facts, finite use natural resources, agricultural intensification is necessary to increase production to meet future demands. However, under expansive farming systems, crop yields are maintained through the heavy use of chemical fertilizers, pesticides, and herbicides. Excessive use of these agro-chemicals can lead to pollution of soils and ground-water, and agricultural runoff threatens to damage environments, reducing biodiversity and contributes to eutrophication of freshwater systems. Intensification is also associated with increased GHG emissions related to fuel consumption for equipment, food processing, and chemical production, an example of the latter being that Haber process for nitrate fixation consumes 5% of the world’s natural gas production and 2% of the world’s annual energy supply [6]. It is time that we redefine and redesign our agricultural systems to be resource efficient and sustainable. We need to think about alternative innovative sustainable solutions to feed the world.

Climate Change

- Abstract

- Introduction

- Sustainability of Conventional Agriculture

- Climate Change

- Sustainability of Urban Cities

- Types of Urban Horticulture Systems

- Applications and Adaptation of iHORT systems in Vertical Farming

- Cluster Model for iHORT Business Development

- Training and Capacity building in iHORT

- Future Challenges and Conclusion

- References

Climate change threats to agriculture cannot be ignored. Several global climate change models predict increased incidence of drought, high temperature, extreme low temperatures, frost, flooding, increasing pest pressures leading to unexpected loss of crop production. We have already started seeing this phenomenon in several parts of the world. The impact can disproportionately be significant in world’s poorest regions. Water scarce areas will become much drier and hotter, there will be a decrease in rainfall in semiarid to mid-latitudes and interior of large continents [6]. With climate change some northern latitude countries may benefit by yield increases. Such an impact of climate change can have significant food insecurity problems.

Sustainability of Urban Cities

- Abstract

- Introduction

- Sustainability of Conventional Agriculture

- Climate Change

- Sustainability of Urban Cities

- Types of Urban Horticulture Systems

- Applications and Adaptation of iHORT systems in Vertical Farming

- Cluster Model for iHORT Business Development

- Training and Capacity building in iHORT

- Future Challenges and Conclusion

- References

Cities occupy nearly 2% of the world’s surface. Urban cities are the home for nearly nearly 66% of the global population. It is predicted that this trend will continue to increase [1]. Nearly, 6000 tonnes of food are imported daily to feed the urban population in the megacities around the world [7]. Nearly 75% of the global resources are consumed by the urban population and the urban cities are the major contributors to GHG emissions and centers of water and air pollution [6]. It is imperative to avoid catastrophic effects, the cities must improve sustainability by reducing city’s ecological footprints (water, energy, land and wastes) and become centres of food production rather than food consumption while enabling healthy environment and improve quality of life.

Types of Urban Horticulture Systems

- Abstract

- Introduction

- Sustainability of Conventional Agriculture

- Climate Change

- Sustainability of Urban Cities

- Types of Urban Horticulture Systems

- Applications and Adaptation of iHORT systems in Vertical Farming

- Cluster Model for iHORT Business Development

- Training and Capacity building in iHORT

- Future Challenges and Conclusion

- References

The urban horticulture systems consist of production of crops by non-profit organizations, community gardens, roof-top farming, green walls, land sharing, greenhouses and backyard gardening. While this is a dynamic concept, it still competes for resources such as land, water, energy and labour. There is a potential synergistic effect of urban horticulture systems and building-integrated horticulture. This approach does not require additional space and thus, it is called as indoor farming, zero farming or z-farming. This has the potential with no additional space, utilize residential or industrial waste water, utilize sunlight and sequester higher level of carbon dioxide using the CO2 generated within the building or in the cities. This can be a small space resources recycling or saving system, which could reduce ecological footprint of a city, contributing to sustainability [8]. More recently, vertical farming (VF) has become increasingly popular, generating greater interest and excitement, which can contribute to food security of the cities and perhaps in location where food access is limited such as northern territories where agriculture and food access is constrained by extreme environments.

Vertical farming (VF) is fairly a new concept born out a school project in the USA producing leafy greens for the school kitchen by the students. VF can use any indoor space (thus called indoor horticulture) such as abandoned buildings, tunnels, parking garages or integrated into the building architecture. This can also be integrated into existing greenhouses. The concept of VF is utilization of vertical space effectively and thus, it provides space for multi-layer production (also called multi-layer farming). This system uses hydroponic, aeroponics, aquaponics or nutrient-film technologies to supply water and nutrients. Nutrients are precisely monitored for their pH, EC, BOD and macro- and micro- nutrients using sensor continuously and adjusted as needed and recycled thus contributing to nearly 95-98% of water and nutrient use efficiency without polluting the underground water sources. The evaporated water is also collected and reutilized further contributing to water use efficiency. In VF, there is no need for Sunlight. The light requirements are met by various spectrums of red, blue and far-red LED lights to 18-24-hour photoperiod. The use of LED lights reduces energy costs compared to HS (high pressure sodium) lamps used in greenhouses. Heating or cooling may be needed depending on the location, which can be achieved by recirculating hot/cold water in the buildings or from the geothermal sources.

The VF systems contributes to 95-98% water and nutrient use efficiency, with no runoff, with yields as high as 100 times depending on the crop, and crops can be harvested throughout year. In addition, there are no pesticides or fungicide applied thus, ensuring food quality and safety. There is growing evidence that VF can be the most sustainable way to produce crops. This approach is used in sky farming or space farming or plant factories under any adverse environmental conditions. The growth, maturity and quality can be precisely monitored and manipulated to produce nutritious and phytonutrients rich- food. The automated control systems are used to regulate light intensity, spectral quality, duration, humidity, temperature, carbon dioxide levels, nutrient concentrations. Robotics are used to monitor quality of the produce and for harvesting. Crop produced in VF have no pesticide residues and no agrochemicals (pesticides or fungicides or herbicides) and safe and ready- to- eat. While there need to be a lot of research done to fine tune the iHORT systems in the areas of crop and varietal suitability, the light spectral specificity for each crop and variety, the nutrient requirement, manipulation of growing environment, assessment of quality and phytonutrient concentration, evaluation of energy costs and operational costs in comparison to other production systems, sensor technologies to monitor the quality, automation and robotics, the iHORT systems present a significant hope for a sustainable future. While this may not be a suitable system for all crops and the intension is not to replace the conventional production of field crops, the iHORT systems need to be considered for high value horticulture crops to provide nutritious fruits, vegetables, and herbs throughout the year in a sustainable way. It is our hope that the future city planers and architects integrate iHORT systems into their design to provide sustainable, healthy living solutions as they currently do with providing a spa or a health and fitness club or a swimming pool or a tennis court. iHORT system also have a very short supply chain. Fresh products are directly sold or used, or it directly goes to local market, reducing the carbon foot print significantly as against the conventional production system where the produce is transported to collection centres, then to distribution centres, then to whole sale, then to the market and to the consumers.

Applications and Adaptation of iHORT systems in Vertical Farming

- Abstract

- Introduction

- Sustainability of Conventional Agriculture

- Climate Change

- Sustainability of Urban Cities

- Types of Urban Horticulture Systems

- Applications and Adaptation of iHORT systems in Vertical Farming

- Cluster Model for iHORT Business Development

- Training and Capacity building in iHORT

- Future Challenges and Conclusion

- References

Sky greens, Singapore

Sky Greens is the world’s first low carbon, hydraulic driven vertical farm. It uses green urban solutions to achieve production of safe fresh and delicious vegetables, using minimal land, water and energy resources. They produce sky Nai Bai, Sky Cai Xin, Sky Bai Cai, Sky Chinese cabbage, Sky lettuce, Sky Bayam, Sky Kai Lan, Sky Kang Kong and Sky Spinach. They use a patented vertical farming system consisting of rotating tiers of growing troughs mounted on a “A” type frame. The frame is 9 m tall with 38 tiers of growing troughs which can accommodate various media, soil or hydroponics. This system provides high yield (10 times), high quality, high flexibility, low energy use, low water use and low maintenance.

Plant lab, Netherlands

Plant lab is a privately-owned Dutch company that specializes in controlled environment agriculture with a global reach. Plant lab employs plant production units based on a revolutionary technology and propriety algorithms to optimize production of various crops including potted plants, flowers, specialty foods, vegetables and fruits. They use proprietary mathematical models, state-of the art LED systems, air control advances and a maximum water control system. It also integrates R and D facility to further advance the production system.

London Growing Underground, Grow up Urban Farm, UK

At Growing underground, fresh leafy vegetables and salad greens are produced 33 meters below the busy streets of London using hydroponic systems, LED technology and crops are grown year-round in the perfect, pesticide free environment. The production system is unaffected by the weather conditions. Their hydroponic system uses 70% less water than traditional open field systems and the nutrients are kept in a close loop.

TruLeaf, Truro, Nova Scotia, Canada

Founded in 2011, Truleaf’s systems offer the opportunity to grow a sustainable year-round supply of leafy plants to replace and enhance current sources. The multi-level farm can be built anywhere, offering key advantage of growing plants closer to markets, maximizing freshness and reducing transportation costs and spoilage. Their goal is to enhance the local food supply with year-round reliance on imported produce. Truleaf specialises in high-value crops. Their system includes a customized multi-tier production system and specializes in LED spectrum selection, plant production formulation, automation, and data collection. They produce fresh, quality greens using clean and sustainable practices and supplying to the local stores. Their commercial operation expanded as Good Leaf.

Cluster Model for iHORT Business Development

- Abstract

- Introduction

- Sustainability of Conventional Agriculture

- Climate Change

- Sustainability of Urban Cities

- Types of Urban Horticulture Systems

- Applications and Adaptation of iHORT systems in Vertical Farming

- Cluster Model for iHORT Business Development

- Training and Capacity building in iHORT

- Future Challenges and Conclusion

- References

The success of iHORT systems development heavy relies on the acceptance of the business model in the horticulture cluster. As like in any other successful Fortune 500 companies, iHORT requires a successful business model. The success, the speed of adaptation and growth of this business model is all about creating an “innovative ecosystem”, which provides solutions for the relating to

i) Responsiveness and resilience;

ii) New innovation and business models;

iii) Cross-overs between and among sectors and scientific domains;

iv) Inclusive society;

v) Sustainability and societal embodiment and

vi) Globally and locally balanced.

1. To achieve this, we need to switch our minds

a. From linear towards an integrated innovative ecosystem;

b. From projects towards integrated programmes;

c. From science-driven towards business-driven research and innovation; and

d. From separate stakeholder agendas towards joint agendas of the members in an “ecosystem”.

2. We need a system innovation or transition for the future business models. In creating an innovative business models, the ecosystem may comprise of

i) Entrepreneurs/industries;

ii) Government and policy makers;

iii) Research institutions;

iv) Educational institutions and

v) Investors [9].

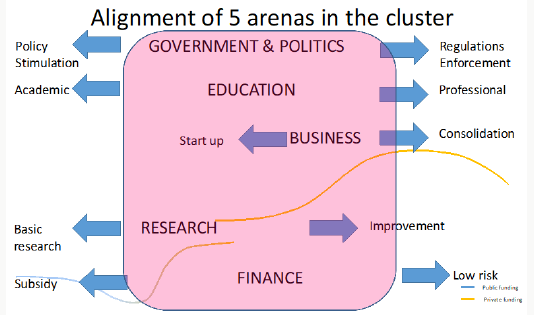

These different network partners are organised in arena’s, with a specific set of drivers and culture. The business is profit driven, the government is power driven, the researchers seeking for recognition etc. The challenge in the innovative ecosystem is to combine and align the different drivers and values. VF is relatively new and very attractive for all stakeholder groups or arenas. Mobilising and feeding the ecosystem to grow is one of the challenges. New intermediary adaptive support structures emerge to activate membership and cross-overs between these arenas [9]. The innovative business model the Greenport West-Holland in the Netherlands developed is business driven (Figure 1). The stakeholders in the cluster signed a public private partnership: Innovation Pact. The business partners defined an ambition to develop a leading cluster for iHort industry in the world. Several essential strategic development topics are identified and accepted by the stakeholders in the ecosystem. Next step is to organise the ecosystem to align all the activities and to get focus of the investments of all the stake holder’s groups in the different arenas. For example: research and educational institutes align the research and educational programs according to the innovation topics of the business. The intermediary organisation, Greenport West-Holland, facilitates and challenges all actors in the network and stimulated cross-overs between the different arenas.

Training and Capacity building in iHORT

- Abstract

- Introduction

- Sustainability of Conventional Agriculture

- Climate Change

- Sustainability of Urban Cities

- Types of Urban Horticulture Systems

- Applications and Adaptation of iHORT systems in Vertical Farming

- Cluster Model for iHORT Business Development

- Training and Capacity building in iHORT

- Future Challenges and Conclusion

- References

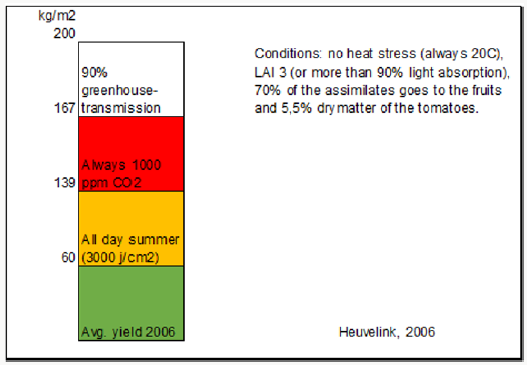

A decade ago, the average yield of a cluster tomato produced in a greenhouse was 60 kg/m2. In theory, the calculated production could be 200 kg/m2 [10] In 2008, in a trial set at the Improvement Centre in Bleiswijk, 100 kg/m2 of tomatoes were produced. However, in the current system of cultivation of tomatoes using artificial light, the targets for crop managers are around 95 kg/m2. The next step is indoor horticulture. Using this innovative cultivation system, it is possible to create the environment to reach yields as high as 200 kg/m2. To reach higher yields or a more sustainable production knowledge is needed. So, training people working in the industry, building their knowledge and capacity using innovative techniques and technologies are essential for the industry’s success and sustainability (Figure 2). For indoor growing, there are various best practice cases in leafy crops, such as lettuce and herbs. However, large scale food production in the main food sources, the experience is limited. Even in the Certhon Innovation Centre (www. certhon.com), a large- scale testing facility for indoor farming, they are constant learning how to cultivate under indoor circumstances. Traditional cultivation methods/ theories are not relevant in this environment (Table 1). The results are impressive, but Certhon realizes that this is just a beginning. There is still a lot to learn, so the results will become even higher.

Figure 2: The changes in tomato yield in relation to various technological advancements. (Source: [10]).

Table 1: Results of pepper trails Certhon Innovation Centre (Source: www.certhon.com).

Dare to learn! The slogan of in Holland university of applied sciences. When this slogan is related to the complex emerging cultivation systems as indoor farming, what is it that should be learned? The answer is: SKILLS. How to approach a complex problem? How to deal with new techniques? Are we able to connect what we know to different circumstances? To accomplish an effective implementation of innovations it’s vital that the industry, government, research facilities and knowledge institutions work together. In the Netherlands, the development of a new curriculum starts by exploring what the needs or demands from the industry are. After consulting the industry, a curriculum mapping is performed. In the curriculum, an important aspect is the structural relationship with the industry. Students will work on assignments or research not only just for curiosity but also for commissioners from the industry. Therefore, the students work and learn always on a relevant issue or topic. The commitment from the government is shown in the infrastructure in the industry for knowledge development and sharing. Together, the university, the industry and the government will become a part of an “academic ecosystem”, creating the opportunities to educate and train necessary skills, advance knowledge and develop appropriate attitude in people needed for the horticultural industry.

The development of “Flexible Learning” programs is a perfect example how the cooperation between companies (industry), government and the university that is flourishing. ‘New’ learning pathways are connecting work- and learning environments together. Furthermore, it becomes clear that in the 21st century we need to adept to a “Life Long Learning”. For example, “Job learning” is a learning method where the job environment is also the learning environment. By creating learning challenges on the work floor and using these challenges to build up evidence in a portfolio on capacity in skills, knowledge and professional attitude. A student determines their own learning path and speed, so the path is personal and customized for each student. All students can graduate with a bachelor’s degree, but the ways to get to this diploma is non-traditional and it is very innovative.

Future Challenges and Conclusion

- Abstract

- Introduction

- Sustainability of Conventional Agriculture

- Climate Change

- Sustainability of Urban Cities

- Types of Urban Horticulture Systems

- Applications and Adaptation of iHORT systems in Vertical Farming

- Cluster Model for iHORT Business Development

- Training and Capacity building in iHORT

- Future Challenges and Conclusion

- References

The challenges relating to population increase, declining resources, climate change, environmental pollution and the sustainability of the conventional agriculture in feeding the global population by 2100 are real. With the integration of current knowledge in plant science and horticulture, current sensor, software, hardware, automation and robotic technologies, we could create a sustainable iHORT production systems to meet the future challenges. The model we described would build partnerships among universities, technologists, innovators, entrepreneurs, investors, policy makers, governments and consumers to create an innovative, inclusive and transparent approach for research, innovation, education and training, creating a climate for investment and engagement of governments at various levels in revolutionizing iHORT technologies for a sustainable future. While there are several questions to be answered regarding cost: benefits, return on investment, energy utilization, carbon footprints, the foremost important solution that the iHORT systems can provide a “safe, pesticides free” food year-round under any environment itself is worth considering as an innovative solution for feeding the world with nutritious, fresh, safe food in the 21st century.

References

- Abstract

- Introduction

- Sustainability of Conventional Agriculture

- Climate Change

- Sustainability of Urban Cities

- Types of Urban Horticulture Systems

- Applications and Adaptation of iHORT systems in Vertical Farming

- Cluster Model for iHORT Business Development

- Training and Capacity building in iHORT

- Future Challenges and Conclusion

- References

- FAO (2017) The Future of Food and Agriculture - Trends and Challenges. Rome.

- Clark M, Tilman D (2017) Comparative analysis of environmental impacts of agri- cultural production systems, agricultural input efficiency, and food choice. Environ Res Lett 12(6).

- Benis K, Ferrao P (2018) Commercial farming within the urban built environment - Taking stock of an evolved field in northern countries. Global food security 17: 30-37.

- Turra A, Alvar lC, Mansilla CA, Areces AJ, Camilo W, et al. (2013) Global environmental changes: Setting priorities for Latin American coastal habitats. Global Change Biology 19(7): 1965-1969.

- Despommie D (2010) The vertical farm: Feeding the world in the 21st century. St. Martin’s Press, New York, USA.

- Lu C, Grundy S (2017) Urban Agriculture and Vertical Farming. Encyclopedia of Sustainable Technologies 2.

- Eigenbrod C, Gruda N (2015) Urban vegetable for food security in cities. A review. Agronomy for Sustainable Development 35(2): 483-498.

- Specht K, SiebertIna R (2014) Urban agriculture of the future: An overview of sustainability aspects of food production in and on buildings. Agriculture and Human Values 31(1): 33-51.

- Maijers W (2016) Rapportage framework kennis on innovatiepact. Kennis & Innovatiepact: Kassa–kunde-kennis. Greenport Westland Oostland 23rd September 2016.

- Heuvelink EP, Kierkels EN (2006) Plant can produce more feather than it does.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...