Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2643-6736

Mini Review(ISSN: 2643-6736)

Unconventional Machining Process: Magnetorheological Fluid-Based Surface Finishing Volume 2 - Issue 4

Saurabh Pathak1,2* and Rajni Verma1,3

- 1School of Engineering, RMIT University, Australia

- 2Department of Mechanical Engineering, University of Melbourne, Parkville, Australia

- 3School of Physics, The University of Melbourne, Australia

Received: March 17, 2020; Published: June 09, 2020

Corresponding author: Department of Mechanical Engineering, University of Melbourne, Parkville, VIC, 3010 Australia

DOI: 10.32474/ARME.2020.02.000141

Abstract

The development of new material with significantly improved properties, miniaturization of devices and complex design necessities in numerous domains of engineering, demands high productive, efficient and precise machining processes. Unconventional machining process (UMP) or non-traditional machining process provides solutions to these challenges and has extended their utility for the machining of complex shapes precision machining (micro-nano finishing), newly developed materials (alloys, composites, polymers, metals, rubber etc.). UMP have shown potential in the domain of micro-nano machining and provides better proposition with numerous intrinsic recompences which makes UMP a suitable substitution of the conventionally used machining process. The opportunities challenge, and recent developments of MRF based UMP method have been studied including several pragmatic applications in diverse manufacturing and industrial domains. This UMP techniques can further be modified to utilized it at its full potential in various engineering applications.

Introduction

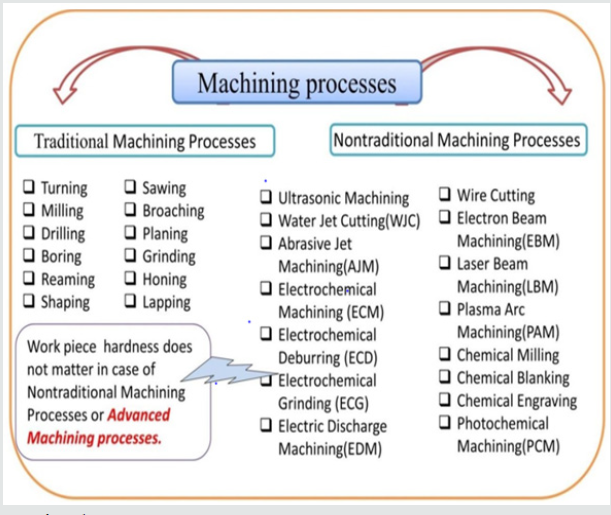

The current progression in engineering technologies demands high precision quality manufacturing system whit high productivity to meet the current requirements of the industries. This creates a distinctive opportunity for the developments of novel and efficient machining processes which meets the specific criteria for the fabrication of desired products. The development of new materials with significantly improved properties such as hardness, strength, toughness, flexibility etc. are difficult to process with conventional machining processes [1,2]. UMP provides the prospect to produce components and shapes of relatively new materials having complex design requirement with precise dimensional features and parameters. The rapid growth of hybrid materials and miniaturization of devices high precision defect free machining is recommended to meet the desired efficiency. Composites and alloys with greater physical properties like toughness, tensile strength compressive strength, resilience etc. has gained lots of popularity as it provides an efficient solution for the needs to the present-day demand in numerous fields like applied thermo power and storage, biotechnology and food processing, power generation, transportation, material synthesized, etc. Various conventional manufacturing techniques have been employed such as turning, shaping, lapping, honing, blanking etc. are used in machining which utilizes a high strength cutting tool with specified tool geometry. These processes are limited because of their lower rate of material removal (MRR), lower precision, tool wear etc. To overcome these challenges unconventional or advanced machining processes arose which does not use any material and energy in its direct form is utilized for machining. Figure 1 shows the general classification of the classification of the machining process listing various machining techniques [3].

Unconventional Machining Process

UMPs are also termed as advanced machining processes or non-conventional machining process but looking at their spectrum of various uses in small and medium scale industries in last decade, non-conventional or non-traditional termed is faded off and UMPs are now termed as advanced machining process (AMP). UMP technique can be defined as the machining process which does not require any sharp cutting-edge tool for material removal from work piece. It utilizes thermal, mechanical, electrical, chemical, magnetic energy or combination of these energy for material removal. In conventional or traditional machine process like milling, turning etc. require workspace clamping which are not easy for the irregular and complex shapes. Also, the surface-finish obtained with these processes are not satisfactory for various sophisticated mechanical components with high precision requirements. Traditional methods are not appropriate to machine extremely firm, fragile and inelastic material whereas UMP suits perfect for these requirement as they use direct energy, so problem encountered in conventional methods regarding the tool failure does not occur with these methods [3].

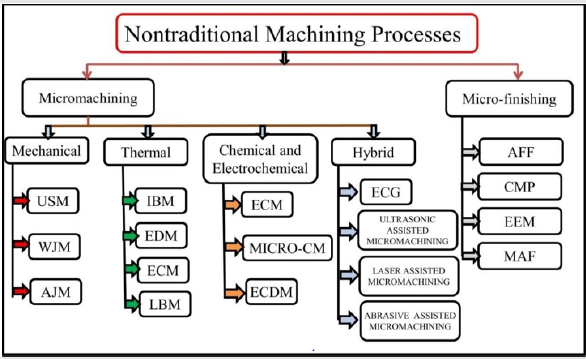

Component with intricate and complex three-dimensional shapes can also be machined with these non-traditional methods. The main advantages of these processes are higher material removal rate i.e. high productivity, no residual stress, workpiece clamping is not required, better quality, less Material wastage, and complex geometries & delicate part can easily be machined. A few UMP processes have been invented based on the specific requirement of the devised product. UMP techniques can be mainly classified in three different classes founded on the energy used for material removal; mechanical, thermal and chemical & electrochemical. The material removal mechanism is entirely different in UMP, as traditional methods involves force application on the workpiece with a cutting tool and direct physical contacts between work piece and tool take place whereas in UMP various forms of energy are used which replaces the cutting tool [4].

Classification of Unconventional Machining Process

Machining are generally pronounced as the material removal from the workpiece through cutting, using single/multi-point cutting tools, grinding and UMP utilized by various energy sources. The main categories of the machining methods are shown in Figure 1. To control the major problems encountered in the processing of the novel and complex material and shapes, tools are usually made of advanced materials which are driven by novel and cuttingedge methods. Furthermore, the conventional tools of machining methods and processes be contingent by different methods drilling, sawing, broaching, etc. Although, conventional methods similar to forming be contingent on energy from electrical motor, hydraulics and gravitational forces. Moreover, the UMPs are not pretentious by mechanical behavior of novel and complex material which can produce multifaceted profiles by governing diverse processing characteristics of the methods. UMP methods can broadly categories in two sub sections, micromachining and micro-finishing. Various non-Traditional machining processes with their appropriate classification has been depicted in Figure 2 [4].

Magnetorheological Fluid (MRF) Based Surface Finishing

One of the most popular UMP finishing methods is abrasive

flow (AF) machining which is founded on the abrasive-slurry

based working media conceded over the workpiece through

channels or nozzles or fitting assemblies, were presented to

retort to the cumulative industry demands. The particles of the

abrasive constituent suspended in the slurry ignoble stream

of (AF) machining performance as multi- movement/cutting

boundaries upsetting the roughness peak. Further, to improve the

(AF) machining performance and make them more controllable,

the MRF based machining was introduced. MRF based machining

is a novel micro/nano finishing processes which involves rotation

of the workpiece and daunting an external magnetic field using MR

fluid as working fluid providing assistance for the manipulations

and improvement of surface finish due to enlarged applied forces

on the workpiece [5-13]. In the same way, twirling the inlet flow by

fixed twirler blades, is castoff which also intensifies the workpiece

surface. forces and then increase the material removal rate which

is having lower outlay and energy ingesting associated with the

condition of rotation of the workpiece [6,9,11].

The working fluid termed MRF belongs to the category of the of

advanced material or smart fluids which can be utilized to regulate

the machining by daunting an external magnetic field. For finishing

operation, distinctively an MRF containing abrasive particles of the

micron sizes and magnetic particles are synthesized with paraffin

as the liquid medium and grease oil to separate magnetic particles

from each other to enhance the stability. So, MRF can be tuned by an

externally applied magnetic field which delivers large normal and

tangential forces on the workpiece surface by magnetic particles. By

applying an external magnetic field, MRF presents non-Newtonian

characteristics displaying viscoelastic behavior [5-7,10,12].

MRF based surface finishing operations for high precision

machining employs abrasive mixed slurry mixture of dine abrasive

particles and MRF to achieve micron level finishing. The use of

the MRF in the slurry is done to guide the nozzle more precisely

to follow a specified path which in turn will help in improving the

control over the process of machining. The mechanism of material

remove in this process is propagated by the impact of the abrasive

particles on the uneven surface of the workpiece which is directed

by the gradient magnetic field [5,6,9,12,13].

Conclusion

The current development in the field of micro/nano manufacture method leads to invention of unique and complex topographies and entities in micro/nano-meter for advanced applications. Although these features cannot be made through the conventional machining process which leads to the development of the novel UMP machining methods. UMP uses the machining of provides major advantages for processing and fabricating 3D complex shapes and nano/micro level finishing which is not economical or feasible by conventional method. MRF based finishing is UMP process which is gaining lots of popularity as it is more controllable and provides better surface finish over the conventional process. These techniques have tremendous potential to substitute the current surface finishing methods. The present mini review of the UMPs provides an overview of the various UMP methods and prospects of the MRF based finishing method.

References

- AlamZ, Khan DA, Jha S (2019) MR fluid-based novel finishing process for nonplanar copper mirrors. The International Journal of Advanced Manufacturing Technology101(1):995- 1006.

- YoussefAH (2015) Nontraditional Machining Processes-an Overview. in Machining of Stainless Steels and Super Alloyspp.141-177.

- Jahan M (2019) Electro-Discharge Machining (EDM). Modern Manufacturing Processes pp.377-409.

- Zhong ZW (2008) Recent Advances in Polishing of Advanced Materials. Materials and Manufacturing Processes23(5):449-456.

- Singh A (2020) Tuning the magneto crystalline anisotropy and spin dynamics in CoxZn1-xFe2O4 (0 ≤ x ≤ 1)nano ferrites.JournalofMagnetismand Magnetic Materials493:165737.

- Jahan N (2017)Enchantment in viscoelastic properties of flake-shaped iron based magnetorheological fluid using ferrofluid. Colloids and Surfaces A: Physicochemical and Engineering Aspects529:88-94.

- Jain K (2019) Dynamic magneto-optical inversion in magnetic fluid using NanoMOKE. Journal of Magnetism and Magnetic Materials475: 782-786.

- Jain K,Pathak S,Pant RP (2016) Enhanced magnetic properties in ordered oriented ferrofibres. RSC Advances6(75): 70943-70946.

- Mishra A (2019) Measurement of Static and Dynamic Magneto-Viscoelasticity in Facile Varying pH Synthesized CoFe2O4-Based Magnetic Fluid. IEEE Transactions on Magnetics55(12): 1-7.

- Noorjahan (2017) Dipolar Interaction and Magneto-Viscoelasticity in Nanomagnetic Fluid. Journal of Nanoscience and Nanotechnology18(4):2746-2751.

- Noorjahan (2018) Improved magneto-viscoelasticity of cross-linked PVA hydrogels using magnetic nanoparticles. Colloids and Surfaces A: Physicochemical and Engineering Aspects539: 273- 279.

- Pathak S (2019) Improved thermal performance of annular fin-shell tube storage system using magnetic fluid. Applied Energy 239: 1524-1535.

- PathakS (2017) Magnetic Fluid Based High Precision Temperature Sensor. IEEE Sensors Journal17(9): 2670-2675.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...