Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2643-6736

Research Article(ISSN: 2643-6736)

Determination of the Inverse Kinematic of the Industrial Robot Yaskawa-Motoman-Gp7 Through Analytical and Recursive Calculation Volume 3 - Issue 5

Ricardo José Marques da Silva, Jeferson Nicacio de Mendonça, Vitor Araujo Francisco and Rogério Adas Pereira Vitalli*

- Department of Robotic Engineering Advanced Robotics Institute (IAR), Santo André, Brazil

Received:August 4, 2022 Published: August 15, 2022

Corresponding author: Rogério Adas Pereira Vitalli, Department of Robotic Engineering Advanced Robotics Institute (IAR), Santo André, Brazil

DOI: 10.32474/ARME.2022.03.000172

Abstract

Robotic manipulators have positioning problems, speeds, and forces applied on any type of movement. One of the most important activities of industrial robot control is the definition of its movements in three-dimensional space. To perform these movements your joints, need to move and to define these positions in the spaces we need to first calculate the direct kinematics and then the calculation of the literal and numerical inverse kinematics. The methodology used in this exploratory scientific research will be developed, based on experimental tests, bibliographic references and case study carried out in the laboratory of the Advanced Robotics Institute (IAR), applied in the industrial robot model YASKAWA-MOTOMAN-GP7. The work contributes to an analysis and proof of inverse kinematics. The results are the determination of inverse kinematic equations using an algebraic mathematical method, capable of proving the developed model, which applies to industrial robots.

Keywords: Direct Kinematics; Inverse Kinematics; Denavit Hartenberg Notation

Introduction

The new technological concept of industries guides to a paradigm of production, leveraging productivity, increasing profitability, reducing costs, and improving the quality of processes. The history of industrial automation is characterized by periods of rapid technological changes, and the result of this has been the development of automatons capable of performing the most complex tasks with the highest level of sophistication and precision possible. It was precisely in this context that industrial robotic manipulators emerged [1]. The Denavit-Hartenberg notation (also called DH parameters) to describe the geometry of the mechanism, being a fundamental tool of the roboticist. Given a description of a manipulator, we can make use of algorithm techniques to find industrial robot positioning solutions in Cartesian space [2]. Such manipulative robots are considered an indispensable part in modern factories, due to the ability to perform the most varied types of tasks of high level of complexity and dangerousness, efficiently and reliably, with cost/benefit ratio.

In the literature, the kinematics of manipulator robots are approached through two models, direct and inverse kinematics [3-5]. Direct kinematics consists of finding the orientation and position of the terminal effector from the vector of angles of the joints and the geometric parameters of the model. Denavit and Hartenberg [6] proposed a matrix method for systematic modeling and solution of problems that use the technique of direct kinematics. Inverse kinematics is considered an effective technique of control of a robotic arm, consisting of finding the vector of joint angles, from the orientation and position of the terminal effector. It presents great challenges due to the nonlinearity of equations and multiple solutions for manipulators with many degrees of freedom [4,5]. The development of a numerical algorithm to find the angular positions for a defined work in relation to its terminal element in Cartesian space, contains the solution of the inverse kinematic problem through the recursive numerical method that uses the geometric model.

Literature Review

Direct Kinematics

Kinematics in robotics is a form of representation referring to the geometric explanation of the structure of links of an industrial robot. From the geometric equation, one can obtain the connection between the concept of spatial geometry of the joints and the theory of the coordinates of the final effector to determine the position and orientation of an object. The purpose of direct kinematics is to determine the position and relative orientation of the robot in relation to its original coordinates and the angles of the joints.

Denavit-Hartenberg Notation (DH)

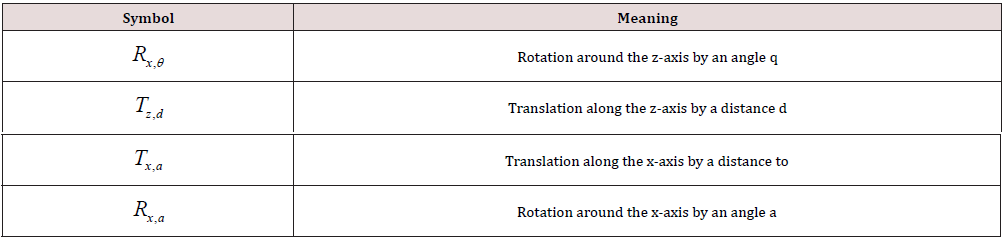

The Denavit-Hartenberg notation [5] makes it possible to determine the four parameters related to rotation, translation, torsion and distances between centers of gravity of a chain of kinematic pairs. According to [6] a systematic notation was proposed to assign an orthonormal coordinate system with the rule of the right hand, one for each link in an open kinematic chain of links. Since these coordinate systems fixed to the link are assigned, transformations between adjacent coordinate systems can be represented by a homogeneous coordinate transformation matrix [5,6]. According to Craig [5] in the original DH representation, the joining axis is associated with the z-axis and each matrix is represented by the product of four basic transformations involving rotations and translations as we can observe in equation (1).

Figure 1 shows the DH parameters with a graphical representation:

To obtain the homogeneous transformation matrix (equation 2) that goes from the base to the end of the final effector, we have to multiply all the transformation matrices obtained by the HD algorithm, that is, the resulting matrix can be considered as the solution of the problem of direct kinematics according to equation (3) [7].

To obtain the homogeneous transformation matrix (equation 3) that goes from the base to the end of the final effector, we have to multiply all the transformation matrices obtained by the HD algorithm, that is, the resulting matrix can be considered as the solution of the problem of direct kinematics according to equation (3) [8-14].

Inverse Kinematics

Inverse kinematics is considered an effective technique of control of a robotic arm, consisting of finding the vector of joint angles, from the orientation and position of the terminal effector. It presents great challenges due to the nonlinearity of coupled equations and multiple solutions for manipulators with many degrees of freedom [15,16]. Traditional methods can be used to calculate the inverse kinematics of robotic manipulators, such as geometric, numerical- itetic and algebraic, considered laborious if the geometric structure of the manipulator is too complex [17]. The resolution of problems that deal with direct kinematics of manipulators is possible, when compared to the reverse form [16]. In reverse kinematics, the angles between the joints can be determined by the parameters of the links and the position of the effector in the workspace according to Figures 2 & 3.

There are two analytical methods of solutions: Geometric and algebraic. Geometric Method: it seeks to decompose the spatial geometry of the mechanism into various problems of flat geometry; using its resources, the angles of the joints are determined. Algebraic Method: Given consists of and solves a set of nonlinear equations resulting from equality =, where it is given in terms of the variables of the joints, via direct kinematics. In order to control the position and orientation of a terminal element of a robot to reach its object, the solution of inverse kinematics is based on the frames of the terminal element of a robotic arm of i axes eats its parameters of joint and link, from there one wishes to find the angles of joint

According to the overall results, we performed an analysis of each of the links, according to the observations of the DH parameters for the system in question. The first step is to multiply the inverse transformation matrix of the link by the complete homogeneous transformation matrix of the mechanism under study. Next, there is a new transformation matrix multiplying the inverse transformation matrix of the link by a reference generic transformation matrix, as presented in equation 5:

The Figure 5 shows the detail of the wrist movement represented with the initials N(yam), S (pitch), and A(Roll).

Methodological Procedures

The methodology used in this exploratory scientific research will be developed, based on experimental tests, bibliographic references and case study applied to the Robot YASKAWA-MOTOMAN- GP7 in the laboratory of the Advanced Institute of Robotics (IAR). This model was chosen because it is of the articulated type that is widely used in industries. The articulated type of manipulator has its configuration similar to that of a human arm, due to its set of 6 rotational joints, which can be separated into two groups that make up the base and the first of the manipulator correspondent to the movement of the arm. Figure 4 shows a schematic drawing of this robot with the dimensions of its mechanical structure. One of the characteristics that differs from this standard robot model is the misalignment of the center of the base with the center of the end of the manipulator. This misalignment can be seen in Figure 4, which clearly shows that the link in which the fist is located 40 mm to the right with respect to the center of the robot base. To identify the respective joints of this robot, Figure 5 shows the joints j1, j2, j3, j4, j5 and j6 in a schematic way [18]. The approach adopted for the determination of direct kinematics of this robot is part of the preliminary analysis of possible movements and recognition of the types of links and joints co-respondents to the system. Then, based on the information acquired, coordinate systems are adopted for the axes to be studied with a view to determining the Denavit-Hartenberg parameters of the robotic arm under study (Table 1).

Direct Position Kinematics

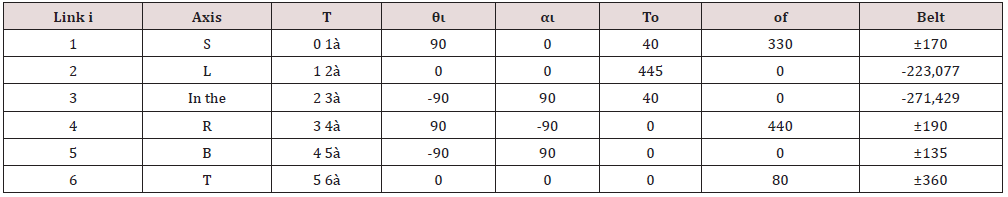

For the calculation of direct position kinematics, the literal table is mounted with the DH parameters. THE DH parameters require a schematic model of the robot, as well as its characteristics, reference system and joining variables according to the convention and Denavit-Hartenberg. Figure 6 shows the model developed for this case study. From Figure 6, the Denavit-Hartenberg table is defined, according to Table 2. The units used are millimeters for length and degrees for the angles [19].Figure 6: Design of the Robot YASKAWA-MOTOMAN-GP7 with the identification of their respective joints.

Inverse Position Kinematics

Given, a set of nonlinear equations resulting from equality =, is composed and resolved in terms of the variables of the joints, via direct kinematics.

Inverse Transformation Arrays Method

Using a six-degree freedom manipulator, it is initially known to be known and given by:

Inverse kinematics is calculated by applying the following formula:

MATLAB©

MATLAB©, short for Matrix Laboratory, is a simple and direct language software used for mathematical calculations, which has high computational performance and a wide library of predefined mathematical functions. These features allow programming prob lems to be solved more simply than in other computational languages [6]. The software used to mathematically demonstrate and prove the Denavit-Hartenberg algorithm was developed in the MATLAB© R2022a of MathWorks, software often used by researchers to perform calculations and systems in general. As an extension of MATLAB©, there are toolboxes specific to each search area [20]. The first step was to define the Denavit-Hartenberg parameters [5] for each joint and link, replacing the actual values of angular relationship between one joint and another and the translation (in millimeters) between joints of the Robot YASKAWA-MOTOMAN-GP7. The values were obtained from the manufacturer’s datasheet. Then, these matrices were multiplied, we obtained the final homogeneous transformation matrix, T06, which provides the mapping of coordinates from the base to the end of the tool according to equation 12. Figure 7 demonstrates the final homogeneous transformation matrix of the robotic manipulator. (Direct Kinematics).

Next, we will show the mathematical model of a matrix referenced t1 literally and numerically and later the inverse cinematic of hers for a better understanding of the proposed study. The algorithm used in MATLAB© software should be able to determine the entire set of joint variables (θ1,θ 2,...θ n) associated with a given position and orientation. The main point of this definition is that in the case of multiple solutions, it is not always possible to calculate all. The inversion of the homogenous matrix (Direct Kinematics) is one of the most effective ways to find the angles of the robotic manipulator joints (inverse kinematics). The difference between the two methods, is that when we work the solution in an analytical or “closed” way, we have the actual parameterization of the robot and with numerical methods the results are approximated.

Results and Discussion

The methodology used to obtain the results regarding direct kinematics and inverse kinematics pointed to the initial analysis of the Structure of the YASKAWA-MOTOMAN-GP7 Robot and to the relationship of the Denavit-Hartenberg parameters for each axis of the robot. Then, these values were related through transformation matrices for the same axes. Finally, these matrices were summed up, giving rise to a matrix of final transformation of the robot, whose positioning at point T refers to the sum of the others (six links). The representation of D-H results in obtaining a homogeneous 4x4 transformation matrix, representing that transforms the coordinates of the system from link i to the i-1 system of the anterior link. With this, you can express the coordinate transformation from system “i” to system “i-1”. The kinematic modeling ready to be applied to the controller is then obtained for experimental tests and system control simulations. By calculating direct kinematics, it is possible to determine the x and y coordinates once the coordinates of the joints are known. The resulting matrix can be considered as the solution of the problem of direct kinematics as shown in Figure 8, that is, the product of all transformation matrices obtained by D-H results in the solution of direct kinematics.

Singularity

In a singular or degenerate configuration, some of the columns of the matrices become linearly dependent and, consequently, do not generate the full range of end-organ velocities. Under such conditions, the manipulator loses one or more degrees of freedom and thus there will be directions in which the terminal organ will not be able to move, whatever the speeds of the joints. In short, the freedom of movement is restricted. Close to singular configurations, some speeds of the links, required to move the terminal organ with reasonable Cartesian speeds, would become excessively large. All manipulators have singularities at the boundary of their workspace, and some may have at internal points of this space, usually caused by the alignment of two or more axes and joints. In a kinematic system with 6 axes, a distinction must be made between 3 positions of singularities. These are: the singularity above, the extended position, and the uniqueness of the manipulator axes. The Figure 9 shows an example of a singularity.

Validation of Results

The following is the numerical result of all direct and reverse matrices , which were validated in the Fanuc 200ID industrial robot in the Laboratory of the Advanced Robotics Institute. The solution to the problem of finding the joint angles needed to position the tool reference system, with respect to the workstation system, is divided into two parts (Figures 10-13). First, we make the transformations to find the handle system, with respect to the base system, and then we use the inverse kinematics to calculate the angles of the joints. An important result in kinematics is that, according to our definition of solvency, all systems with rotational and prismatic joints with a total of six degrees of freedom in a single serial chain are solvable. However, this generic solution is numeric [5].

Conclusion

Inverse kinematic equations were obtained based on the pseud matrices. In this article we determined the equations of inverse kinematics and direct kinematics of the robot YASKAWA-MOTOMAN- GP7 and using the MATLAB software we perform the calculations of the homogeneous transformation matrices of the HD Notation we found the values of the theta angles for each of the axes. With the angles at hand, we can work safely and avoid the uniqueness in the robotic manipulator, increasing its useful life and consequently the productivity and profit of the industries. The solution to the problem of finding the joint angles needed to position the tool reference system, with respect to the workstation system, is divided into two parts. First, we make the transformations to find the handle system, with respect to the base system, and then we use the inverse kinematics to calculate the angles of the joints. An important result in kinematics is that, according to our definition of solvency, all systems with rotational and prismatic joints with a total of six degrees of freedom in a single serial chain are solvable. However, this generic solution is numeric. In the literal way, even with the use of software, it is complex to develop the result. Seeing what happens inside each robot joint, its mechanisms and how it facilitates human life on the factory floor motivated us to carry out this study. We engineers take solutions where there are problems and recursive kinematics is another proof that leaves us satisfied after seeing the tests carried out in practice, within the Laboratory of the Advanced Institute of Robotics.

Thanks

The authors thank the Advanced Institute of Robotics - IAR, which ceded its structure of robots and software to enable the realization of this work.

References

- Agustian, Indra, Novalio Daratha, Ruvita Faurina, Agus Suandi, et.al (2017) Robot Manipulator Control with Inverse Kinematics PD-Pseudoinverse Jacobian and Forward Kinematics Denavit Hartenberg. Journal of Electronics and Telecommunications (JET).

- Assad Uz Zaman Md, Md Rasedul Islam, Mohammad Habibur Rahman, Ying Chih Wang, e Erin McGonigle (2021) Kinect Controlled NAO Robot for Telerehabilitation. DE GRUYTER.

- Barker, L Keith (1986) Modified Denavit-Hartenberg Parameters for Better Location of Joint Axis Systems in Robot Arms. Nasa Technical Paper.

- Corke, Peter I (2007) A Simple and Systematic Approach to Assigning Denavit–Hartenberg Parameters.

- Craig, John J, Heloísa Coimbra de Souza, Reinaldo A C, Bianchi (2012) Robotics. São Paulo: Pearson Educatin do Brasil.

- Denavit J, RS Hartenberg, e ILL Evanston (1955) A kinematic Notation for Lower-Pair Mechanisms Based on Matrices. Journal of Applied Mechanics 2(2).

- Dias, Rafael Thiago, and Márcio Antônio Bazani (2022) Robotic Manipulator Dynamics With 4 Degrees of Freedom. Graduation Work, Ilha Solteira, UNESP.

- Ding, Feng, e Cong Liu (2018) Applying coordinate fixed Denavit–Hartenberg method to solve the workspace of drilling robot arm. International Journal of Advanced Robotic Systems.

- Flanders, Megan, e Richard C Kavanagh (2015) Build-A-Robot: Using Virtual Reality to Visualize the Denavit–Hartenberg Parameters. Electrical and Electronic Engineering, University College Cork, Ireland.

- Granja M, N Chang, V Granja, M Duque, e F Llulluna (2016) Comparison between Standard and Modified Denavit-Hartenberg Methods in Robotics Modelling. Proceedings of the 2nd World Congress on Mechanical, Chemical, and Material Engineering. Budapest: Escuela Politécnica Nacional.

- Laus, Luis Paulo, Alfranci Freitas Santos. Laus method for kinematic modeling of robots. Technology and Humanism sd.

- Oliveira, Alex Rodrigo Monteiro De (2022) Kinematic modeling of the IRB 8700 robotic manipulator. Course Completion Work, Ilha Solteira, UNESP.

- Otoboni, Vinícius Machado (2022) Reverse Kinematics and Programming of a Robotic Manipulator With 3 Degrees of Freedom. Course Completion Work, Ilha Solteira, UNESP.

- Prada, Erik, Srikanth Murali, L ubica Miková, e Jana Ligusová. (2020) Application of DENAVIT HARTENBERG Method in Service Robotics. Acta Mechatronic - International Scientific Journal about Mechatronics.

- Qingsheng, Luo, E Julpri Andika (2018) Analysis of Kinematic for Legs of a Hexapod Using Denavit-Hartenberg Convention. Sinergi 22(2).

- Rocha CR, A Dias, e CP Tonetto (2010) A comparison between the Denavit–Hartenberg and the screw-based methods used in kinematic modeling of robot manipulators. ELSEVIER - Robotics and Computer-Integrated Manufacturing 27(4): 723-728.

- Silva, Sérgio Ricardo Xavier da, Rafael Gonçalves Bezerra de Araújo, Francisco Henriques de Lemos, Fabien Lisias Alcântara Delebosse (2012) Mathematical Modeling of The Direct Kinematics of The Robot Fanuc Lr Mate 200ic With Simulation In MATLAB©. XL Brazilian Congress of Engineering Education. Salvador: COBENGE.

- Thomas, Mervin Joe, ML Joy, e AP Sudheer (2020) Kinematic and Dynamic Analysis of a 3 PRUS Spatial Parallel Manipulator. Chinese Journal of Mechanical Engineering.

- Waldron, Kenneth, E James Schmiedeler Kinematics. Robotics Foundations sd.

- Zijia Li, Josef Schicho (2015) Mechanism and Machine Theory. Elsevier.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...