Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2644-1209

Review Article(ISSN: 2644-1209)

Contact Lens Materials and Modalities Volume 1 - Issue 2

Phani Krishna Athreya M* and Gaurav Kumar Bhardwaj M

- Assistant professor, Department of Optometry and Vision Science, Amity University Haryana, India

Received: January 31, 2018; Published: February 12, 2018

Corresponding author: Phani Krishna Athreya, Assistant professor, Department of Optometry and Vision Science, Amity Medical School, Amity University Haryana-122413, India

DOI: 10.32474/TOOAJ.2018.01.000106

Abstract

Introduction: Past two decades have seen a steep rise in the usage of contact lenses and that brought a major revolution in the materials research, design and manufacturing technologies. This also impacted the optometrists thus influencing the patient usage, modalities and duration. The current article briefs the changes in the field of contact lenses and the changing trends.

Methods: Contact lens materials and its manufacturing, wearing modalities and changing trends in prescribing them were identified, reviewed and summarized as per the topic requirements from scientific papers, authentic articles, books and websites to cover the challenges our ancestors have faced and the solutions that were provided in the past were summarized for the reader in an easy accessible way.

Conclusion: Newer generation of contact lens materials made an average contact lens wearer comfortable by wearing lenses for longer hours without discomfort and with minimal complications. Due to the advent of newer lens materials, practitioners have been given more options for choosing a best suited lens based on specific wearer requirements and needs. In this way, newly available materials and designs make the lens wear safer and less prone to complications by shifting the patient from conventional to planned replacement lenses (PRL) and from PRL to daily disposables to ensure a healthy and safer vision.

Keywords: PMMA; Rigid Gas Permeable Lenses; HEMA; Silicone Hydrogels; Extended Wear; Flexible Wear; Daily Disposables; Multifocal Contact Lenses; Aspheric; Toric

Abbreviation: CAB: Cellulose Acetate Butyrate; RGP: Rigid Gas Permeable Lens; P-HEMA: Poly Hydroxy Ethyl Methacrylate; PVP: Poly Vinyl Pyrolidone

Introduction

Contact lenses are medical devices commonly used to correct the vision without the need of spectacles. Even though the concept was very old, till 1887, a structure similar to our today's contact lens was not made. A first contact lens like structure was made in 1887 by F. A Muller by blowing glass to make a prosthetic eye. In 1930's a first contact lens made up of glass was used which covers whole the cornea and a small part of sclera was used for vision correction making glass the first contact lens material [1]. In 1937, a material named Poly methyl methacrylate (PMMA) was introduced as a contact lens material which mimics todays' scleral lens of a larger diameter. In 1948, Kevin Tuohy made a contact lens called "Microlens" which covers only cornea with 10 to 12 mm diameter [1,2]. After using PMMA as a contact lens material for some time, hypoxic complications arise due to it’s very poor oxygen permeable nature after use, making.com to explore for newer lens materials. Currently, due to its zero-oxygen permeability, it is used to make diagnostic trial contact lenses instead of actual contact lenses due to its ability to retain the parameters, ease of care and maintenance [3].

Rigid Gas Permeable Lenses (RGP)

Noting the importance of Oxygen permeability, few developments were made to the material to be permeable to oxygen. In the year 1972, Cellulose acetate butyrate (CAB) was proposed as a material to use by Irving Fatt, later in 1978 CAB as a contact lens material got FDA approved. A term (RGP) Rigid gas permeable lens was coined and the lens made with this (CAB) material was manufactured in 1978 in United States [2,4]. In the advent of silicone usage in the medical industry, Siloxane methacrylate material was developed in 1970 by using silicone molecules bonded to methyl methacrylate structures making a contact lens more oxygen permeable [2]. Siloxane acrylates material was patented in 1974 under the name Polycon and was introduced commercially in 1979 which lead the wearing time longer than CAB due to its high oxygen permeability without showing any hypoxic changes in the cornea. However, it was observed that the siloxane acrylate lenses tend to attract more of lipid and less of protein deposits on the lens surface, making the care and regime of newer RGP lens materials different than the previous lens. These deposits lead to lesser lens life than the previous lenses [2].

"Boston" a contact lens material manufacturing company started to develop working towards parameters like oxygen permeability, strength and deposit resistance for improved lens on eye performance since 1972. Elements Fluorine and Carbon were used in specific proportions to synthesize Fluoro-siloxane acrylates and Fluorocarbon acrylates were found effective in controlling the lipid deposits to occur on the lens surface with increased oxygen permeability. These materials still stand good in terms of availability, deposit resistance with good oxygen permeability [5]. Addition of Silicone, Fluorine and Carbon with appropriate amounts made it possible to achieve highest levels of oxygen permeability ever, leading to continuous wear, flexible wear and extended wear modalities possible. During this period in 1987, Fluoro-silicone acrylate material was made available [6]. Due to changing trends in the contact lens market and due to innovations in soft contact lens materials, there is a constant and a sharp decline in the RGP wearers that was observed in the past two decades due to the comfort achieved by soft contact lenses [7].

Silicone Elastomer

In 1956, Silicone elastomer material was developed by Walter Becker which has a highest ever oxygen permeability which is more flexible than RGP lenses, making the contact lens industry to explore newer ways of improvising the lens material in terms of flexibility But, for a product to manufacture out of silicone elastomer was not possible at that time due to its flexible nature, poor wettability and the material adheres to the cornea(suction). Later in 1981 a lens made up of silicone elastomer material was commercialized for correcting children to use as an overnight wear lens due to its exceedingly high oxygen permeability. This material got approved for 30 day continuous wear for non-aphakic prescriptions in 1983 making it the first extended wear lens to be produced [6,8]. Till now these elastomer lenses are available as a mode of correction for aphakia (congenital and acquired) cases mostly in children [9]. The only drawback with these lenses is the brittleness of the material and affinity to attract lipid deposits, making its usage declined in this decade [6,8].

Soft Contact Lens (Hydrogels)

Progress in contact lens materials was extremely rapid and the market equations of using RGP lenses were quickly changed after the development of Poly hydroxy ethyl methacrylate (P-HEMA) as a lens material in 1963 by Otto Wichterle. This material coined a new term called "soft contact lens" due to its soft and flexible nature. The lens made with HEMA was available in 1971 as a commercial product [2,6]. The usage of HEMA as a lens material in the current contact lens market still holds good. After the invention of HEMA as a hydrogel material, the comfort obtained by a wearer lead the path for a term called intermittent contact lens wear, which is not possible with RGP due to the discomfort it caused to an average wearer. However, the water content which is the only source of oxygen transmission through the hydrogel lens was too less when compared to RGP lenses due to their movement and tear exchange. There is a need for a diverse care and regime to be followed to soft contact lens wearers for which different contact lens solutions were devised to clean, rinse, disinfect, and hydrate and to store these lenses.

Due to limitation of water content and oxygen permeability in hydrogel lenses, there were diverse complications that were seen in the soft contact lens users and the users due to the comfort of the lenses, tend to sleep with the lenses on the cornea making the condition more worsen [10]. Observing these diverse ocular changes, few of the traditional RGP practitioners were reluctant to shift their practice and keep on dispensing RGP lenses only [11]. As there is a limitation in increasing the water content that we achieve with hydrogel lenses, scientists started to explore new ways to increase the oxygen passing through the lens which can enable the wearer to achieve better comfort lens with lesser complications [12]. Concept of Disposable soft contact lenses came into the field in 1985-1986 as the increasing complications can be counteracted by discarding the lenses before the deposits on the lens surface become sufficient enough to create problems like discomfort, bulbar conjunctival redness, allergic reactions in the upper tarsal conjunctiva and lack of oxygen supply due to deposits [13]. Gradually, frequent replacement lenses were so frequently replaced due to increasing in water content of the lenses that there is a need for a modality termed Daily disposable lenses in 1994-1995 to ensure maximum comfort and good ocular health with no requirement of care and maintenance which is a boon for existing, new contact lens wear. As the production need to meet the consumer needs a new manufacturing method called cast moulding turned the disposable modality a practically possible reality [2,14].

Even now, majority of the contact lens market share in developing countries is still contributing to Hydrogel lenses where as in developed countries, majority of the population is using silicone hydrogels and daily disposable hydrogel lenses for their visual needs [15-17]. In this stage, Silicone elastomers were more easily available and used in the market as a commercial product leading the materials science experts to turn their vision towards it. This change made them to think and combine the silicone with hydrogel lenses which set a stage for the generation of silicone hydrogels. The first silicone hydrogel lens was marketed in 2002 [2,9].

Silicone Hydrogels

In soft contact lenses the silicone material is incorporated based on the skeletal structures of classical hydrogel materials like HEMA and thereby making it a better lens material by incorporating:

a) OH groups for increasing the bound water content of the lens materials [18]

b) Materials like polyvinyl pyrolidone (PVP) for improving the wettability of the lenses [18]

Due to the innovation of Silicone hydrogel contact lenses, high oxygen transmissibility is made possible, hence by minimizing corneal hypoxia changes that include corneal oedema, Descemet’s membrane folds, microcysts, limbal hyperaemia and neovascularisation [19]. There are a few patient related .difficulties with these new lenses due to increased stiffness than existing hydrogels, hydrophobic nature and more attraction of lipid deposits. So, there is a need for a better and improved materials and designs making them readily acceptable by the patient [9]. In 2010, Custom made silicone hydrogel lenses are made available in the market [20]. In case of Silicone hydrogel lenses, these inventions can be technically classified into three phases in which the lens materials are synthesized by not only decreasing the stiffness of the lens material, but also by increasing the wettability and water content to a desired level for enhancing the comfort level of silicone hydrogel wearer equal to that achieved by a hydrogel contact lens wearer [18,19,21,22].

Developments in Silicone Hydrogel Materials

-

a) Properties (Table 1)

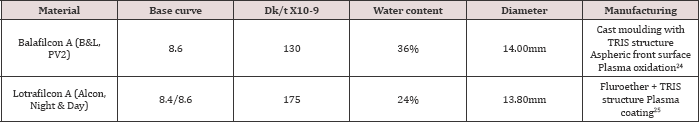

Table 1: First generation lenses.

1. Good Dk

2. Slightly stiffer

3. Deposit prone surface

4. Decreased Wettability

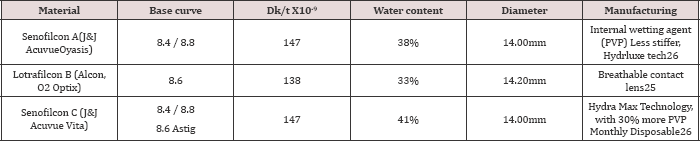

Table 2: Second generation lenses

b) Properties (Table 2)

2. Flexible lens material

1. Improved wettability

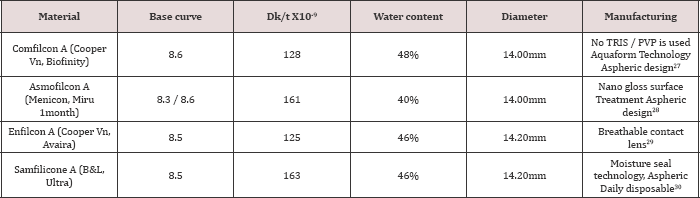

c) Properties (Table 3)

Table 3: Third generation lenses.

1. Better Water content

2. Decrease stiffness

3. It is a Breakthrough technology, which redefines the soft contact lens relationship between Dk and water content by having a higher Dk than water content predicts!

Contact lens advancements in the Future

a) Myopia control contact lenses are very soon going to be available in Asian countries where Myopia is more prevalent.

b) Aberrometers values combined with prescription can help customize the correction to a personalized contact lens manufacturing is possible soon [23].

c) A Multifocal design of contact lens which can have an autofocus capability near the pupillary centres of the eyes using fluid dynamics can be manufactured and fitted which can help.com gain complete visual satisfaction to the wearer [23].

d) Health monitoring systems embedded in the form of a computer chip in contact lenses will help.com plan our diet and treatment plan based on the parameters like blood sugar level, intraocular pressure [24].

e) The use of LCD crystals in the bulk of a silicone hydrogel lens can help.com to use virtual projection; digital screens in the near future will aim for [23].

f) In Contact lens materials, even though the penetration of silicone hydrogels in the current market is low, majority of the market share will shift using this material due to its break thought the invention of improved oxygen permeability, it can retain their share well in the markets in the future [17,23].

g) Improvements like anti bacterial coating on contact lenses are giving promising results which can help use them for extended wear without any worry of infections. Possibilities for making a Photo chromatic contact lenses are explored and will be achieved soon [25-29].

Modality

Silicone hydrogels will take the majority of the market and will exist even in future. Mostly the contact lenses have a freedom to wear and remove easily whenever we want and where ever you want [30-34].

Conclusion

Contact lenses have an exponential growth in material development, design and production in the last two decades.Newer technologies in the coming years can help.com make a more productive, versatile, comfortable and safer wearing lenses for the coming generations ahead [35-39].

References

- Thompson, Anne Austin (1993) History of Contact Lenses. Basics of Contact Lenses 1: 12-13.

- Terry, Robert, Meredith Reyes "History of Contact Lenses." A2.

- Kastl PR, WC Johnson (1990) Fluoroperm Extended Wear RGP Contact Lenses: II. Front Toric Fitting. CLAO J 16(1): 53-56.

- Thompson, Anne Austin (1993) History of Contact Lenses. Basics of Contact Lenses 1: 14.

- Bennett (2001) "RGP Insights." Contact Lens Spectrum.

- A Brief History of Contact Lenses. GP Contact Lenses.

- Morgan Philip B, Nathan Efron (2008) The Evolution of Rigid Contact Lens Prescribing. Contact Lens and Anterior Eye 31(4): 213-214.

- Thompson, Anne Austin (1993) History of Contact Lenses. Basics of Contact Lenses 1: 15.

- Lindsay Richard G, Jessica T Chi (2010) Contact Lens Management of Infantile Aphakia. Clinical and Experimental Optometry 93(1): 3-14.

- Holden Brien A (1998) Corneal Deswelling Following Overnight Wear of Rigid and Hydrogel Contact Lenses. Current Eye Research 7(1): 49-53.

- Fonn Desmond, Brien A Holden (1988) Rigid Gas-Permeable vs. Hydrogel Contact Lenses for Extended Wear. Optometry and Vision Science 65(7): 536-644.

- Bomgardner Melody M (2017) Making Better Contact Lenses. CEN RSS Chemical & Engineering News 95(13): 29-33.

- Thompson, Anne Austin (1993) History of Contact Lenses. Basics of Contact Lenses 1: 16.

- Contact Lenses Timeline (2006) Contact Lenses A Historical Timeline.

- Thite, Nilesh (2013) Contact Lens Prescribing Pattern in India-2011. Contact Lens and Anterior Eye 36(4): 182-185.

- Morgan, Philip B (2011) Global Trends in Prescribing Contact Lenses for Extended Wear. Contact Lens and Anterior Eye 34(1): 32-35.

- Efron Nathan (2010) Trends in Australian Contact Lens Prescribing during the First Decade of the 21st Century (2000-2009). Clinical and Experimental Optometry 93(4): 243-252.

- Sweeney D (2004) Silicone Hydrogels: Continuous-Wear Contact Lenses. Butterworth Heinemann.

- Szczotka Flynn Loretta (2008) Looking at Silicone Hydrogels across Generations. Optometric Management.

- A Brief History of Contact Lenses (2015) GP Contact Lenses.

- Stone Ralph P (2007) A New Perspective for Lens Care Classifying Silicone Hydrogels. Silicone Hydrogels.

- Yeung Karen K (2017) Contact Lenses and Comfort: It's a Material World. Review of Cornea and Contact Lenses > Contact Lenses and Comfort: It's a Material World.

- Sylvan Harvard (2016) Contact Lenses: The Next 30 Years. Contact Lens Spectrum.

- Papas Eric (2013) Contact Lenses 2020: What's in Store for the Future? Contact Lens Spectrum.

- Are Antimicrobial Coatings the Future for Contact Lenses? American Op- tometric Association.

- Dutta Debarun (2016) Melimine-Coated Antimicrobial Contact Lenses Reduce Microbial Keratitis in an Animal Model. Investigative Opthalmol- ogy & Visual Science 57(13): 5616-5624.

- Nichols Jason J (2018) Contact Lenses 2017. Contact Lens Spectrum.

- Chou Brian (2008) The Evolution of Silicone Hydrogel Lenses. Contact Lens Spectrum.

- British Contact Lens Association. Silicone Hydrogel Contact Lenses.

- Pure Vision2 Contact Lenses. Bausch + Lomb.

- Academy for Eye Care Excellence™. AIR OPTIX® NIGHT & DAY® AQUA Contact Lens Parameters, Myalcon.com AIR OPTIX®.

- Innovation Is Needed to Elevate the Monthly Contact Lens Wearing Experience. ACUVUE® VITA® Brand Contact Lenses for Professionals.

- Cooper Vision. Biofinity Contact Lenses (Comfilcon A). Biofinity Contact Lenses, Cooper Vision.

- Miru 1month Menicon. Miru 1month Menicon, Menicon Co,. Ltd.

- Enfilcon A Avaira, Cooper Vision.

- Bausch + Lomb ULTRA Contact Lenses. Ultra Contact Lenses, Bausch and Lomb.

- 1-DAY ACUVUE®TruEye® Brand Contact Lenses. VISTAKON®, Johnson & Johnson.

- My Day®. Cooper Vision®.

- Alcon Dailies Total1. DAILIES TOTAL1® Contact Lens Technology, Alcon.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...