Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2690-5779

Review ArticleOpen Access

Instant Multi-Flash Autovaporization as Basis of An Innovative Deodorization Process. Application To Sunflower Oil Volume 1 - Issue 5

Amal ZEAITER1,2,3, Colette BESOMBES3, Larbi RHAZI4, Amira HADDARAH1, Tayssir HAMIEH1,2, Karim ALLAF3*

- 1Lebanese University, Doctoral School of Science and Technology, Lebanon

- 2Lebanese University, Faculty of Sciences, Lebanon

- 3La Rochelle University, Laboratory of Engineering Science for Environment LaSIE - UMR-CNRS 7356, 17042 La Rochelle, France; Phone: +33685816912 (ORCID: 0000-0002-7600-5903); Colette Besombes: (ORCID: 0000-0001-8961-1542)

Received: August 09, 2021 Published: September 29, 2021

Corresponding author: ALLAF Karim, La Rochelle University, Laboratory of Engineering Science for Environment LaSIE - UMRCNRS 7356, 17042 La Rochelle, France; Phone: +33685816912 (ORCID: 0000-0002-7600-5903); Colette Besombes: (ORCID: 0000-0001-8961-1542)

Abstract

The paper discusses the use of wavelet transform for modal identification and damage detection. The aim is to solve an inverse problem for damage detection of engineering structures using wavelet analysis. Wavelet transform is discussed within the framework of inverse problems; critical aspects and implementation issues for modal identification and damage detection are provided. A dynamic test on a masonry wall and a short example of an eight-storey steel frame building are presented to demonstrate the potential of the approach.

Keywords: Inverse Problems; Ill-Posed Problems; Wavelet Transform; Modal Identification; Damage Detection.

Introduction

Industrialists are interested in sunflower oils of the oleic variety (Rasor et al. 2014) because of the presence of a majority content of monounsaturated fatty acids, which consider partly the resistance to oxidation of the oil for food use and on the other hand give the profile of its nutritional value (Morin and Pagès-Xatart-Parès, 2012). Various conventional processing techniques are used to extract and then refine oilseed oil (Lamas et al., 2014). Oil extracted by mechanical press or solvent is called crude oil and contains a number of impurity compounds directly defining the aroma, color, appearance, shelf life, storage of oil, texture, and smell. In fact, the refining of oil extracted by pressing (Tasan et al., 2011) is becoming increasingly important because of the huge vegetable oil market, with different cultures and communities. The role of refining is to eliminate these impurities (Gotor et al. 2016) from the oil and to improve the organoleptic and sensory properties that induce the oil quality and meet the consumer requirements (Verleyen et al., 2002).

The refining of sunflower oil includes several stages: degumming, neutralization, bleaching and deodorization of the oil which is the final stage of refining (Erickson, 1995). The deodorization process has become an increasingly important step in industrial production and refining lines (Allaf et al., 2018a). In order to eliminate a large part of the aromatic compounds, the conventional processes (Petrauskaitè et al., 2000) consist of subjecting the oil to an elevated temperature (from 220 to 260 ° C) (Medina-Juárez et al., 2000), using a superheated steam stream under high vacuum (260 to 800 Pa) (Evrard et al., 2007) (Tsiadi et al., 2001). Despite these severe treatment conditions, the conventional deodorization process at industrial scale is weakly effective and the treatment time is approximately 3 hours, which implies an effect on the final product cost and quality (Brevedan et al., 2000). The industry concerned is seeking to define new refining operations that are so efficient that they would be adequate with different consumer requirements for highly controlled quality. On the other hand, our study aimed to perform new deodorization processes (Pal et al., 2015). This autovaporization process removes volatile compounds (Torres-González et al., 2009) responsible for odors in the oil as well as undesirable substances, pesticide, and mycotoxins’ residues, unsaturated hydrocarbons, free fatty acids, aldehydes, and ketones (Black, 2009). Thus, a specific deodorization step using the Multi-Flash Autovaporization MFA at low temperature (below 80 °C) was planned and studied.

Materials and methods

Raw materials

The oil samples used are oleic types. They were obtained from cold-pressing extraction of the sunflower in-shell seeds at the laboratory of La Rochelle University, France. These seeds were obtained from the company Presse de Gascogne in Cologne (France). Once extracted, the samples were stored in amber bottles until analysis and maintained at 10 °C.

Protocol of MFA

In the first part of our experimental study was studied the impact of the texturing by instant controlled pressure drop DIC treatment on the cold-pressing extraction of sunflower oil. Whereas the present second part consists of studying the instant Multi-Flash Autovaporisation MFA as a deodorization process for sunflower oil extract (Figure 1). The experimental protocol for MFA treatment was carried out at the laboratory scale by subjecting the oil in a hermetic chamber to cyclic pressure variations, possibly at different temperature levels.

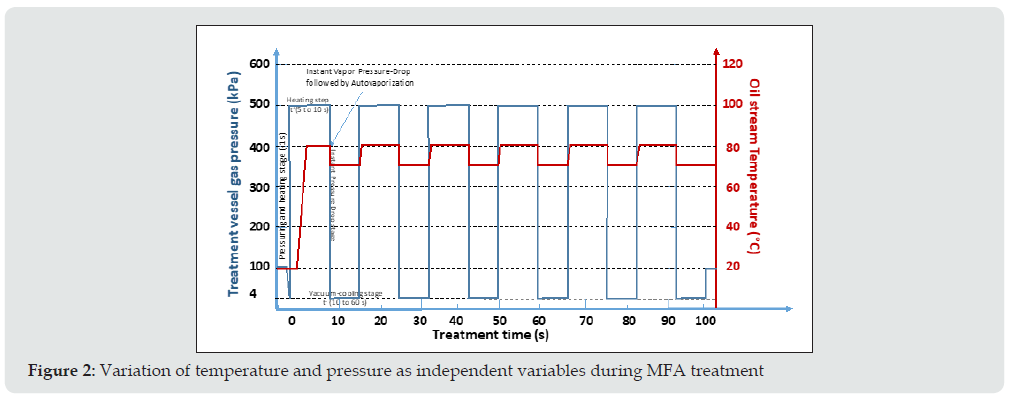

The operation of instant Multi-Flash Autovaporization was performed in several successive cycles (Figure 2) under non-severe conditions (usually, with a pressure P+ between 300 and 600 kPa, a vacuum level of 4 kPa, and a temperature independently ranged from 20 to 80 °C as against 240-270 °C for the conventional method) (Kruidenberg, 2009) (Dudrow, 1983) (Kemény et al., 2001), for hundreds of about 20-second cycles. The experimental study of this “Multi-Flash Autovaporization” MFA was performed in comparison with the “conventional thermal evaporation” CTE, carried out at a similar temperature. In both operations, sensorial assessments were coupled with Gas Chromatography Mass-Spectroscopy analyses.

Instant Multi-Flash Autovaporization MFA treatment

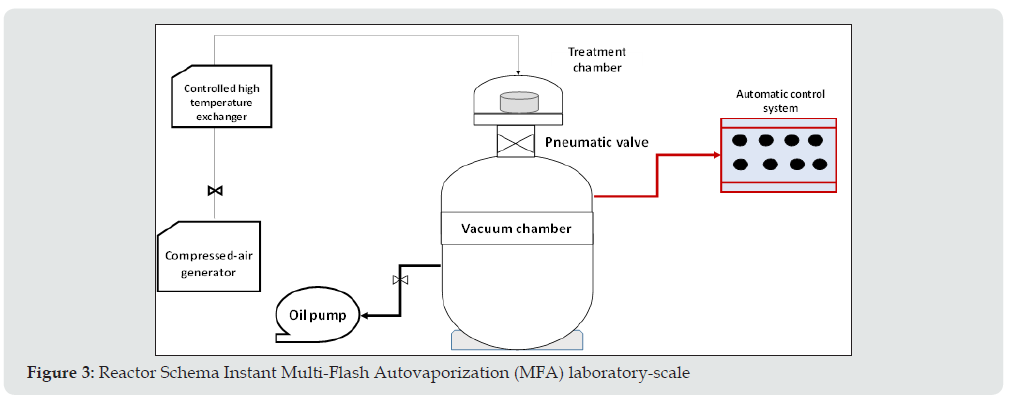

The operating system MFA-deodorization process of the sunflower oil using instantaneous Multi-Flash Autovaporisation (Figure 3) consists of placing the oil in a treatment vessel at cyclic variations in pressure involving successive compression and decompression. The first phase, a 3-bar compression, was achieved by injecting an edible grade compressed air from an adequate compressor. The pressure increase has been regulated by an air admission valve. If oxidation risks are considered, a neutral gas (example: nitrogen N2) can be used as a substitute for air. The second phase is an instant decompression, which is ensured by the abrupt opening (less than 0.1 s) of a pneumatic valve located between the process vessel and the vacuum tank. Closing this valve indicates the end of a cycle and the beginning of the next cycle. The pressure thus oscillates between two values: the high-pressure level (P+) and the vacuum level or low pressure (P-). Thus, each cycle starts 1/ with an initial vacuum, tracked by 2/ the high-pressure in the treatment vessel, which is maintained for a time (t+), and 3/ an instant pressure drop, followed by a certain vacuum tempering time (t-) before starting the next cycle. This vacuum step allows evacuating the air, water, and other evaporated aromatic molecules.

Deodorization as refining of vegetal oils

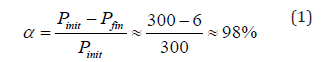

The instant autovaporization leads to an exceptionally wellcontrolled effective reduction of vapor. Indeed, although the treatment temperature is much lower than the boiling point of aromatic molecules, the total pressure-drop from Pinit of 300 kPa towards Pfin of 6 kPa, results in a removing factor (Reduction Ratio) a that normally relates all gas compounds; air and each of aromatic molecules:

In our case, at each instant decompression, 98% of the vapor of each type of volatile molecules should be eliminated from the “atmosphere”. This would be a much higher rate than removing such molecules by mass-convection, even at high air velocity conditions:

The Deodorization relative ratio DDR is calculated as follows:

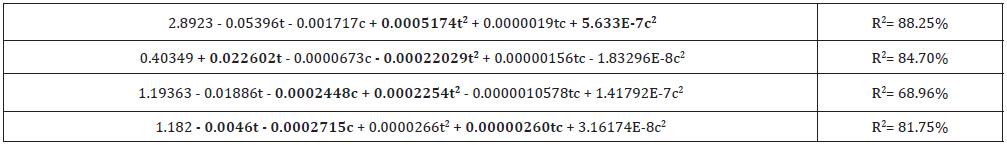

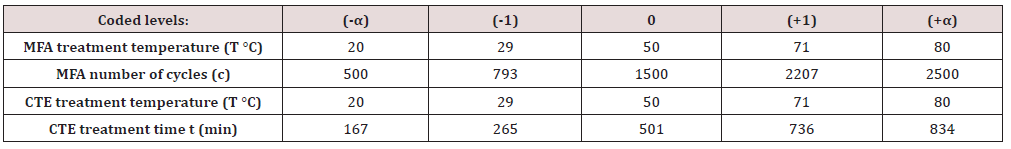

Experimental Design DoE

A response surface methodology (RSM) of a five-level rotary central composite design of experiments CCD-DoE was used to identify and optimize the impact of the various operating parameters of the MFA and CTE as two independent processes for deodorizing cold pressed crude vegetable oil. This DoE experimental plan was adopted after a literature review, preliminary tests, and previous experiments in our research laboratory in the field of essential oil extraction and desolventation (Mnayer, 2014) (Allaf et al., 2014b) (Allaf et al., 2013a). All operating parameters of MFA were kept constant (high-pressure level P+= 300 kPa; high-pressure time t+ and low-pressure time t-, at 10 s, each). For MFA, only the two operating parameters of the number of cycles (C) and the compressed air temperature (T) varied from 500 to 2500 cycles, and from 20 to 80°C, respectively. While for the CTE, the processing parameters were the processing time (t) and the compressed air temperature (T) ranged from 167 to 834 min and from 20 to 80°C, respectively (Table 1).

Table 1: Values of the processing parameters of temperature T and number of cycles C of Multi-Flash Autovaporization MFA; and temperature level T and treatment time t of the conventional thermal evaporation CTE as deodorization processes of crude cold-press vegetable oil.

Statistical analyses

The experimental results were statistically analyzed using STATGRAPHICS® plus software for Windows® (Statgraphics centurion XV, StatPoint Technologies, Inc., Rockville, USA). Each response being considered as dependent parameter Y was a function of the independent processing parameters xi. Variance (ANOVA) with a p-value of 5% was selected to determine the significant differences between the independent variable parameters. The Pareto diagram presents a vertical bar chart that indicates the significance level and identifies the impact of each processing parameter. The second-order empirical model of the response parameter Y as a function of the independent operating parameters can be checked by the regression coefficients R2. General trends, response surfaces, and optimal treatment conditions were presented to manifest Y as functions of the independent operating parameters.

Assessment methods and processes

Evaluation of the deodorization process by isolating and identifying the aroma molecules

The analyses of the aroma compounds were performed using Solid Phase Micro-Extraction (SPME) coupled to a Gas Chromatography/Mass Spectrometry (GC/MS) system. 100 mg of oil were placed in a 20-ml headspace and subjected to slow treatment. Before closing the vial, the headspace was rinsed with nitrogen to avoid auto-oxidation of the samples, which were balanced in an auto-sampler furnace at 60 °C for 10 min. Once equilibrium was reached, a silica fiber (Supelco, 595 North Harisson Road, Bellefonte, PA 16823-0048 USA) was used covered with polymer film and protected in the hollow needle to expose the volatile molecules of sample in the headspace to 60 °C for 15 min. After exposure, the fiber was dipped directly into a GC injector heated to be deployed out of the protective hollow needle for the volatile desorption. The SPME fiber was left in the injection port for reconditioning before being exposed to the free space of the next sample for 20 min (Snyder et al., 1985) (Carasek and Pawliszyn, 2006).

To quantitatively and qualitatively achieve such analyses, a Gas Chromatography GC (Agilent 7890A C.A.; USA) system was used with automatic injector 7693, coupled to a mass detector MS (Agilent technologies polo C.A.; USA). The column of HP-5MS (5% Phenyl Methyl Siloxane) (30 x 0.25 mm, 0.25 pm thick), had a temperature program initially maintained for 1 min at 40 °C, followed by a ramp of 5 °C/min up to 250 °C with a 2-min holding time. The vector gas was helium at 1 ml min-1 and a detector temperature of 250 °C. The SPME injection was splitless mode, with 5 min desorption at 250 °C. The total analysis time was 45 min for each molecule, and volatile compounds were identified by NIST library MS mass spectra as well from the literature. They were also identified from the experimental retention indices (Bocci and Frega, 1996) (Leão et al., 2014).

Determination of the free fatty acids

The fatty acid profile was quantified by Gas Chromatography GC Agilent 19091S-43 (Kyoto, Japan). The GC unit was equipped with an HP-5MS (5% Phenyl Methyl Siloxane) 30 m*350 μm capillary column and the 0.25 μm film thickness. Hydrogen was used as a carrier gas. The initial oven temperature was 155 °C for 10 min and a maximum of 240 °C. A volume of 0.8 μl of each sunflower oil sample was eluted and injected using a syringe in split mode and the injector temperature was maintained at 270 °C. Fatty acids were identified using the National Institute of Standards and Technology of the United States (NIST’98, Gaithersburg, MD, USA) National Library MS Spectral Mass Database.

Determination of tocopherol content

Tocopherol has a great antioxidant activity (Drissi et al., 2004). The identification and determination of the different forms of tocopherols (α, β, γ, and δ) of the oleic variety of sunflower oil were analyzed by high-performance liquid chromatography HPLC (SpectraPhysics, Thermo Separation Products, USA) in accordance with ISO 9936 (Tan and Brzuskiewicz, 1989). Total tocopherol was determined by the sum of the concentrations of the 4 forms expressed in μg/g oil. Tocopherol separation was performed by an HPLC equipped with a fluorescence detector with 298 nm as excitation wavelength and 344 nm as emission wavelength. Manipulation consisted of mixing 1 g of sunflower oil with 1 ml of acetone; vortex for a few seconds before injecting the mixture on a C18 column (250 mm*4.6 mm) and 5 μm in particle size (Macherey-Nagel Ltd., Düren, Germany). The mobile phase consisting of acetonuria and methanol (75:25 v/v), was supplied with a flow rate of 1 cm3/min by the Delta Chrom SDS 030 HPLC pump. The integration was performed using the chromatographic station software CSW32 (Data Apex Ltd., Prague, Czech Republic) by comparing the retention times of the molecules to those of the standard solutions.

Results and Discussions

Fundamental thermodynamic analysis

The first fundamental thermodynamic analysis was achieved based on the absolute volatility (expressed in Pa) of each component which contributes to the formation of the aroma flavor. Absolute volatility is determined as the vapor pressure versus the temperature. These computed data should be the first basis of the definition of deodorization by CTE and/or MFA treatments in terms of the processing temperature range. The low volatility of these aroma components can be correlated with the requirements of the specific experimental process taking into account their specific individual behavior versus both CTE and MFA. Data issued from the software ACD/I-Lab allow getting the absolute pressure of each compound vapor versus the equilibrium temperature (one example is given in Figure 4). Because of the weak volatility of these molecules, the MFA should better be used for removing a main part of the aroma vapor with each cycle. In the current work, without requiring a high-temperature level, the successive MFA cycles assured an effective and relevant deodorization.

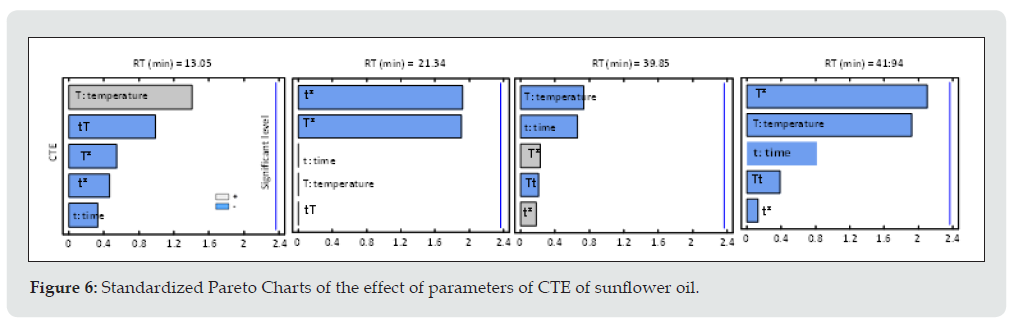

Multi-Flash Autovaporization MFA deodorization vs CTE by GC-MS

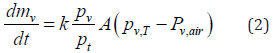

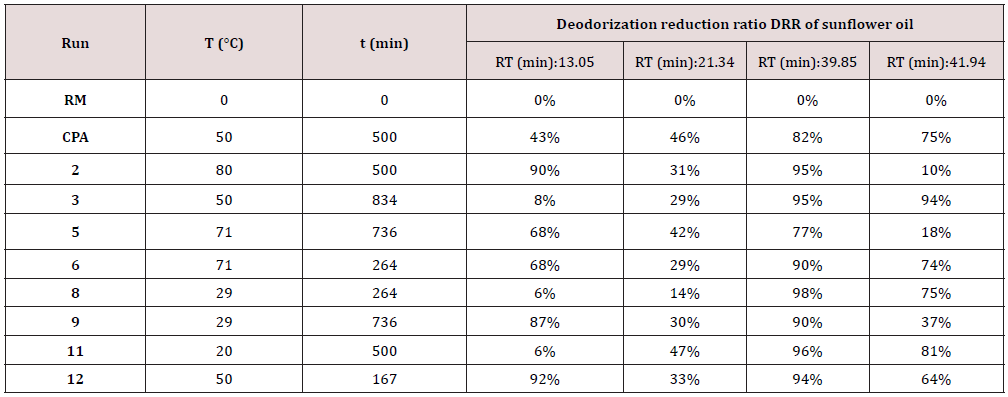

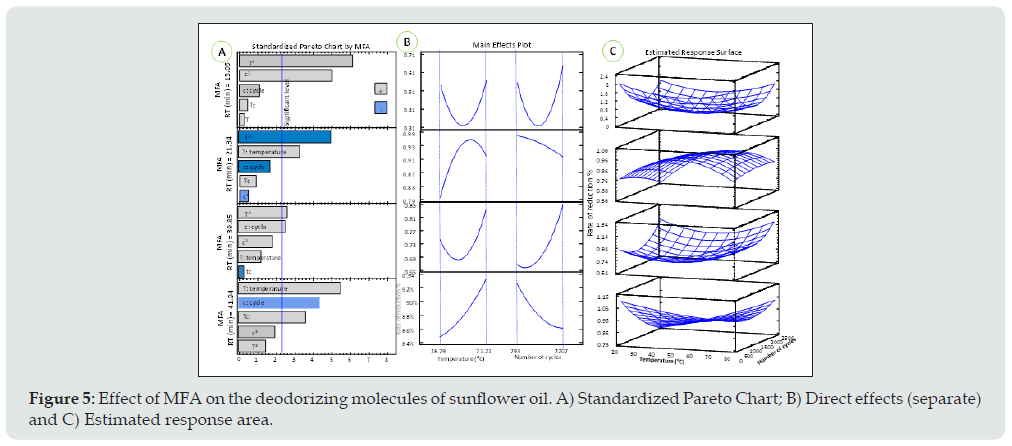

Table 2 and Table 3 represent the variation of the reduction ratio of some aroma molecules of sunflower oil versus the different processing conditions of MFA and CTE, respectively. These molecules were identified thanks to their retention times and by using the internal library of the GC-MS system. The use of instant autovaporization as a deodorization process was proved to be highly efficient compared to the use of the CTE. In a further step, statistical analysis results (Figure 5 and Figure 6) graphically represent the Pareto Chart, direct trends, response surface, a second-order empirical model with the regression coefficient R2 and the optimal point. These results define the impact of the effects of the two operating parameters of MFA temperature (T) and the number of treatment cycles (C), and the temperature (T) and the treatment time (t) of the CTE of sunflower oil. The Pareto Chart (Figure 5.A) which reveals the analysis of variance (ANoVA) shows a very significant effect of the variation of the two MFA operating parameters on the reduction of the four most important aroma molecules of sunflower oil in comparison with the conventional deodorization (Figure 6). Moreover, the diagram of the main trends and the response surface (Figure 5. B.C) confirm these correlations versus the two operating parameters T and c.

Table 2: Impact of the Multi-Flash Autovaporization MFA conditions on the deodorization reduction ratio DRR of sunflower oil

(RT= 13.05 is Hept-2-enal, and RT= 21.34 is non-2-enal and for RT=38.85; RT=41.94 are the Terpenic alcohols/aldehydes).

Table 3: Impact of the conventional thermal evaporation CTE conditions on the deodorization reduction ratio DRR of sunflower oil

(RT= 13.05 is Hept-2-enal, and RT= 21.34 is non-2-enal and for RT=38.85; RT=41.94 are the Terpenic alcohols/aldehydes)

Figure 5: Effect of MFA on the deodorizing molecules of sunflower oil. A) Standardized Pareto Chart; B) Direct effects (separate) and C) Estimated response area.

Second-order empirical models (Table 4) were established from a statistical study with a p-value of 0.05 which represents equations for each retention time (13.05; 21.34; 39.95; 41.94) with their regression coefficients R2 of the order 88.25%; 84.70%; 68.96%; 81.75%, respectively. As well, these analyses give us optimal conditions of the two operating parameters necessary for the reduction of these molecules designated by their retention times with a reduction that can reach (32%; 56%; 65%; 75%, respectively).

These results highlight the efficiency of the MFA processing as a well-controlled deodorization operation according to the refining industry requirements versus the parameter impacts on the quality.

Fatty acid compounds of sunflower oil versus MFA and CTE treatment conditions

GC gas chromatographic analyses were used to determine the fatty acid compounds of sunflower oil. Table 5 represents the composition of saturated and unsaturated fatty acids of the oleic variety, consisting mainly of palmitic acid (C16:0), stearic acid (C18:0), oleic acid (C18:1) and linoleic acid (C18:1) after MFA treatment and by CTE. The results of these analyses prove that whatever the processing conditions of MFA and of CTE were, the composition of the fatty acid was almost similar to that of untreated fatty acids (RM).

Furthermore, the statistical analyses revealed by Pareto Charts (Figure 7 A and B) and analysis of variance (ANOVA) confirm this observation by an absence of any significant effect of the operating parameters. This proves the quality preservation of oil after both treatments.

Table 5: Average values of fatty acid compounds of the oleic variety sunflower oil for raw material (RM), and MFA and CTE treatments

Figure 7: Pareto charts of the evolution of the fatty acid compounds of cold-pressed sunflower oil following deodorization by MFA and CTE

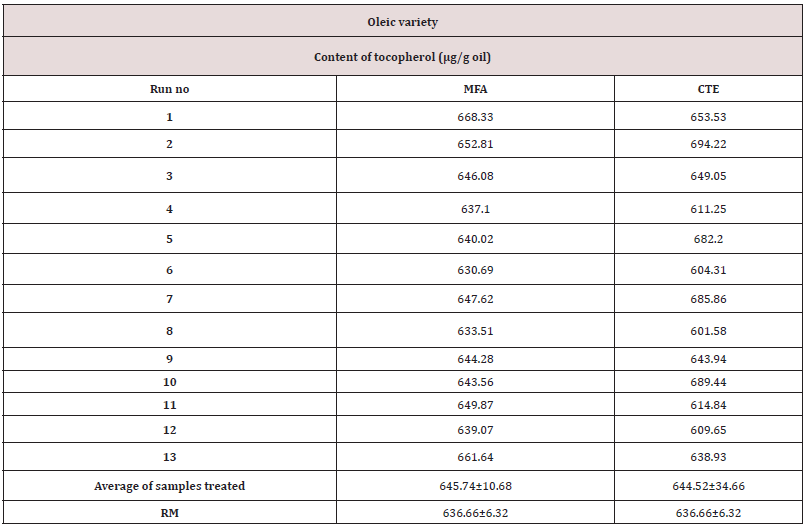

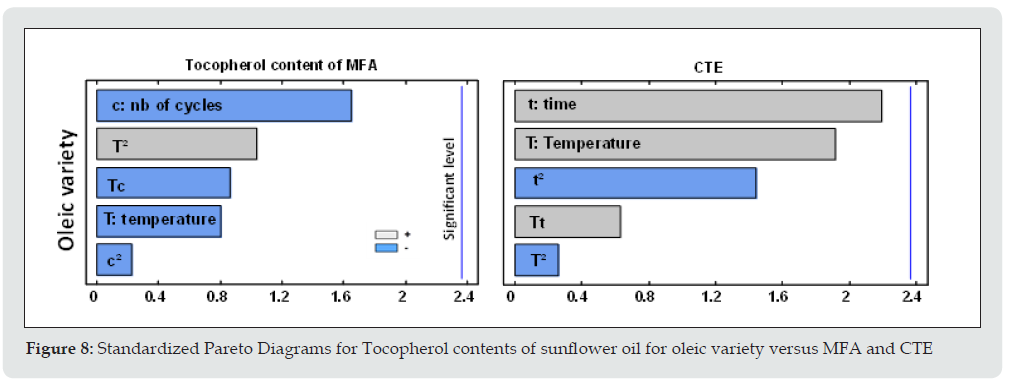

Tocopherol content of sunflower oil versus MFA and CTE treatment conditions

The HPLC analyses of tocopherol content expressed in (μg/g oil) of oleic variety sunflower oil are illustrated in Table 6. These results show a weak variation in tocopherol content following the application of different treatment conditions by MFA and CTE compared to those not treated. In addition, Figure 8 of both Pareto Charts confirms the absence of degradation of tocopherol content by the absence of significant effect of any processing parameter.

Table 6: Tocopherol contents of the oleic variety of sunflower oil for the different MFA and CTE treatment conditions.

Figure 8: Standardized Pareto Diagrams for Tocopherol contents of sunflower oil for oleic variety versus MFA and CTE

Conclusion

From the oilseed industry’s perspective, the process of deodorizing vegetable oil is one of the most important steps in the production and refining lines. This process is devoted to eliminating the main part of the aromatic compounds thus improving the organoleptic characteristics. However, such an operation should be performed without any impact in deteriorating the nutritional quality and the lipid composition of the finished products. Thus, the conventional thermal evaporation CTE issues are correlated with low efficiency and high degradation of quality. Indeed, the CTE deodorization requires a high-temperature level which normally leads to an alteration of the oil quality. The current work was aimed at the study of the new Autovaporisation Multi-Flash MFA as an innovative deodorization operation and its realization at a temperature close to ambient temperature, involving numerous instantaneous pressures drop cycles of about 300 kPa towards a low pressure of 3-5 kPa. Statistical analyzes of experimental results through ANoVA with a p-value of 0.05, the Pareto charts, direct trends, the response surface, and the second-order empirical model with the regression coefficient R2 reveal the significant impact effects of the two MFA operating parameters of the temperature (T) and the number of treatment cycles (c) on the reduction of the aroma molecules of the extracted cold sunflower oil. This innovative operation makes it possible to replace the conventional methods of deodorizing oil with high temperature of different types of oils, while preserving the stability of the quality, with low energy consumption.

References

- Rasor AS, Duncan SE (2014) Fats and Oils - Plant Based, in: Clark S, Jung S, Lamsal B (Eds.), Food Processing. John Wiley & Sons, Ltd, Chichester, UK, pp. 457-480.

- Morin O, Pagès-Xatart-Parès X (2012) Huiles et corps gras végétaux : ressources fonctionnelles et intérêt nutritionnel. Ol. Corps Gras Lipides 19(2): 63-75.

- Lamas DL, Crapiste GH, Constenla DT (2014) Changes in quality and composition of sunflower oil during enzymatic degumming process. LWT - Food Sci. Technol. 58(1): 71-76.

- Tasan M, Gecgel U, Demirci M (2011) Effects of storage and industrial oilseed extraction methods on the quality and stability characteristics of crude sunflower oil (Helianthus annuus L.). Grasas Aceites 62(4): 389-398.

- Gotor AA, Rhazi L (2016) Effects of refining process on sunflower oil minor components: a review. OCL 23(2): D207.

- Verleyen T, Sosinska U, Ioannidou S, Verhe R, Dewettinck K et al. (2002) Influence of the vegetable oil refining process on free and esterified sterols. J Am Oil Chem Soc 79: 947-953.

- Erickson DR (1995) Chapter 5 - Overview of Modern Soybean Processing and Links Between Processes, in: Practical Handbook of Soybean Processing and Utilization. AOCS Press, pp. 56-64.

- Allaf T, Tomao V, Ruiz K, Bachari K, El Maataoui M, et al. (2018) Deodorization by instant controlled pressure drop autovaporization of rosemary leaves prior to solvent extraction of antioxidants. LWT - Food Sci. Technol. 51(1): 111-119.

- Petrauskaitè V, De Greyt WF, Kellens MJ (2000) Physical refining of coconut oil: Effect of crude oil quality and deodorization conditions on neutral oil loss. J Am Oil Chem Soc, 77: 581-586.

- Medina-Juárez LA, Gámez-Meza N, Ortega-García J, Noriega-Rodriguez JA, Angulo-Guerrero O, et al. (2000) Trans fatty acid composition and tocopherol content in vegetable oils produced in Mexico. J Am. Oil Chem. Soc. 77(7): 721-724.

- Evrard J, Pagès-Xatart-Pares X, Argenson C, Morin O (2007) Procédés d’obtention et compositions nutritionnelles des huiles de tournesol, olive et colza. Cah. Nutr Diététique 42: 13-23.

- Tsiadi AV, Stavrides E, Handa-Corrigan A (2001) Nitrogen bubble refining of sunflower oil in shallow pools. J Am Oil Chem Soc. 78: 381-385.

- Brevedan MIV, Carelli AA, Crapiste GH (2000) Changes in composition and quality of sunflower oils during extraction and degumming. Grasas Aceites 51(6): 417-423.

- Pal US, Patra RK, Sahoo NR, Bakhara CK, Panda MK, et al. (2015) Effect of refining on quality and composition of sunflower oil. J Food Sci Technol, 52: 4613-4618.

- Torres-González M, Angulo-Guerrero O, Oliart-Ros RM, Medina-Juárez LA (2009) Effect of physical refining on chemical and sensory quality of coconut oil. Grasas Aceites 60(1): 96-101.

- Black JM (Ed.) (2009) Temas Selectos en Aceites y Grasas Volumen 1- Procesamiento, Cincias Exatas edition. ed. Editorial Blucher, São Paulo (SP).

- Kruidenberg M (2009) Method for processing vegetable oils. US7598407B2.

- Dudrow FA (1983) Deodorization of edible oil. J. Am. Oil Chem. Soc. 60: 272-274.

- Kemény Z, Recseg K, Hénon G, Kővári K, Zwobada F (2001) Deodorization of vegetable oils: Prediction of <Emphasis Type="Italic">trans</Emphasis> polyunsaturated fatty acid content. J Am Oil Chem. Soc. 78: 973-979.

- Mnayer D (2014) Eco-Extraction des huiles essentielles et des arômes alimentaires en vue d’une application comme agents antioxydants et antimicrobiens (phdthesis). Université d’Avignon.

- Allaf T, Fine F, Tomao V, Nguyen C, Ginies C, et al. (2014) Impact of instant controlled pressure drop pre-treatment on solvent extraction of edible oil from rapeseed seeds. OCL 21(3): A301.

- Allaf T, Tomao V, Besombes C, Chemat F (2013) Thermal and mechanical intensification of essential oil extraction from orange peel via instant autovaporization. Chem. Eng. Process, Process Intensif 72: 24-30.

- Snyder JM, Frankel EN, Selke E (1985) Capillary gas chromatographic analyses of headspace volatiles from vegetable oils. J. Am. Oil Chem. Soc. 62(12): 1675-1679.

- Carasek E, Pawliszyn J (2006) Screening of Tropical Fruit Volatile Compounds Using Solid-Phase Microextraction (SPME) Fibers and Internally Cooled SPME Fiber. J Agric Food Chem. 54: 8688-8696.

- Bocci F, Frega N (1996) Analysis of the volatile fraction from sunflower oil extracted under pressure. J Am Oil Chem, Soc. 73(6): 713-716.

- Leão KMM, Sampaio KL, Pagani AAC, Da Silva, MAAP (2014) Odor potency, aroma profile and volatiles composition of cold pressed oil from industrial passion fruit residues. Ind. Crops Prod. 58: 280-286.

- Drissi A, Girona J, Cherki M, Godàs G, Derouiche A (2004) Evidence of hypolipemiant and antioxidant properties of argan oil derived from the argan tree (Argania spinosa). Clin. Nutr. 23(5): 1159-1166.

- Tan B, Brzuskiewicz L (1989) Separation of tocopherol and tocotrienol isomers using normal- and reverse-phase liquid chromatography. Anal. Biochem. 180(2): 368-373.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...