Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-1725

Case Report(ISSN: 2641-1725)

QEC Assessment Using at Cable Industry in Order to Prevent Musculoskeletal Disorders (MSD) Volume 4 - Issue 2

Cuellar J*, Solís C, Hernández JM and Velázquez JD

- Area of Industrial Engineering and Management, School of Chemistry, Universidad Autonoma de Nuevo Leon, Cd. Universitaria, San Nicolás de los Garza, México

Received: December 14, 2019; Published: January 07,2020

*Corresponding author: Cuellar J, Area of Industrial Engineering and Management, School of Chemistry, Universidad Autonoma de Nuevo Leon, Cd. Universitaria, San Nicolás de los Garza, 66455, Nuevo León, México

DOI: 10.32474/LOJMS.2020.04.000184

Abstract

There are many activities performed in a repeated way and in a risk positions that cause fatigue and subsequently may origin musculoskeletal disorders (MSD). Although the disorders may appear as a consequence of an intense effort, its development is a multifactorial process, but it usually occurs because the prolonged exposure in certain positions or movements. The purpose of this study was to evaluate the cable manufacturing process with the Quick Exposure Check (QEC) assessment, in order to associate the work demands with fatigue. By a transversal design, 70 operators were studied in different operational activities in a production plant. A prevalent ratio (PR) of 31% back MSD was found. The low back pain is one of the most common condition that affects millions of people, it represents the first cause of temporary disability due to general illness. It is estimated that 80% of the population has suffered at some time during his life. The implementation of the evaluation system CCR was purposed in order to prevent ergonomics risk.

Keywords: Musculoskeletal disorders; Prevalent ratio; Fatigue; Quick Exposure Check

Introduction

There are works related musculoskeletal disorders, which are developed consequently of work-related activities, are a common health problem throughout the industrialized world and one of the major causes of disability. There are increased risks of musculoskeletal disorders, for some body parts; back, neck shoulders and upper extremities of the body. According to the Social Security Institute of Mexico, the MSD increased in the year 2015 by 47%. The development MSD is multifactorial, but it is usually appearing due to prolonged exposure in certain positions and movements that are apparently harmless and are usually ignored until the symptom becomes chronical and a permanent damage. The Quick Exposure Check (QEC) assessment is one of the observational tools developed for health professionals to evaluate the individual’s exposure to accumulative trauma disorders risks [1]. It is a tool widely accepted by ergonomists and health professionals to determine the risk factor to which workers are exposed when performing a task. The QEC assessment is sensitive to change depending to the exposure, before and after an ergonomic intervention. It is a reliable and applicable tool in a wide range of jobs [2]. With a short training, the evaluation can usually be completed in 10 minutes for each task. This tool is used both for research and for making changes in the workplace. It is used in countries such as France, Norway, Iran, Saudi Arabia, Korea, Spain, South Africa, Brazil and Singapore [3].

The risk posture occurs when there is an incompatibility between the body dimensions of the work requirements and workstation design. If certain postures are made for prolonged periods or repetitively, the fatigue rates will increase and the MSD injuries also [4]. The International Labor Organization mentioned that the risk factors that cause MSD development are the force, load manual handling, flexed postures, movements repetitive and psychosocial factors. The low back pain is one of the most common condition that affects millions of people, it represents the first cause of temporary disability due to general illness. It is estimated that 80% of the population has suffered at some time during his life [5].

Method

The cross-sectional study was conducted at an electric cable manufacturing Company in the metropolitan area of Monterrey City, during the month of May 2019. A non-probabilistic sample of 70 workers in the production area was formed. The data collection was made through Quick Exposure Check (QEC) assessment [6,7].

Assessment

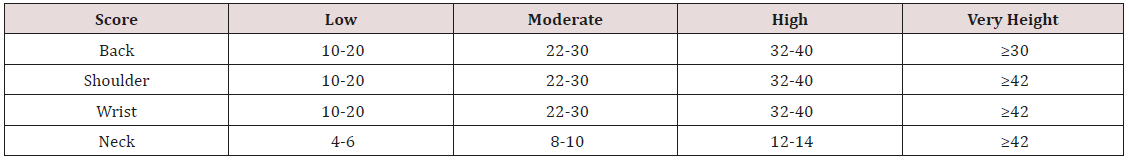

The QEC ergonomic evaluation sheet consists of 15 questions oriented to acknowledge duration, frequency and load weight. The assessment is structured in four blocks, corresponding to body segments (back, shoulder/arm, hand/wrist, neck) and four sections which correspond to additional factors (driving, vibration, fatigue and stress). The scores are selected from the answers obtained. Once identified, the crossing point of the combination is obtained. The rest of the scores are identified in the evaluation. The total segment score is obtained by adding each column partial scores. Finally, the body segment total score is added. The same procedure was repeated for each body segment, and the QEC assessment provides exposure scores for each body area. In order to understand the results, risk factors are load weight, duration, frequency, posture, are considered for each body segment total score. Once the evaluation is completed, body segment crossing score are added with the purpose of obtain risk exposure level (Table 1).

Data analysis

The statistical analysis was made by IBM SPSS Statistics 22.0 program. The prevalence ratio (PR) was calculate and multivariate cluster analysis was performed. Establishing the statistical significance level at p <0.05 and the 95% confidence interval. The first step was to form homogeneous groups of frequency and body postures. For this, a cluster analysis was performed in order to have the maximum homogeneity. After the group with high risk was identified, a table contingency was prepared with the purpose of identify the PR. Finally, statistical significance was performed using Pearson´s χ² test [8,9].

Results

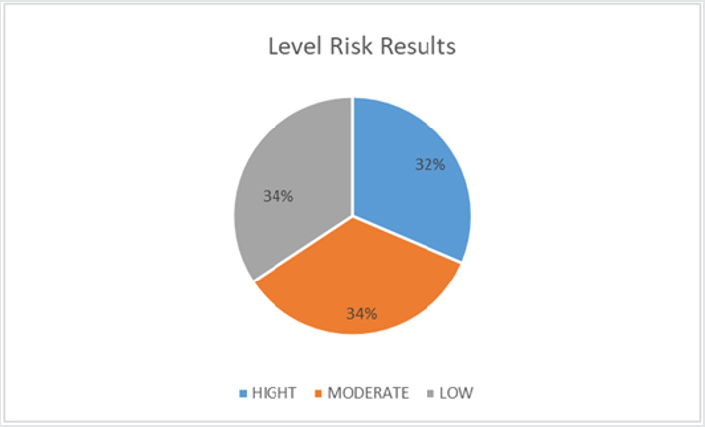

A total of 70 workers participated in the QEC assessment, of which 95% were men. Ages ranged from 18 to 55, with a mean of 33 years (S.D. ± 10.39). The main labor requirements reported were, work´s intensity (repetitiveness) and activities’ kind position (movements, postures and handling of loads). The results of the assessed area are shown in the (Figure1).

22 jobs obtained a final score of 32 point that represent 32% of the jobs evaluated, and 24 jobs got a final score 25 point that represent at 34%. The rest of the areas evaluated were classified with low risk category, according with the exposure level QEC Table 1. The main risk ergonomic problems were found on the back and shoulders, this due to frequency and posture flexed [10,11].

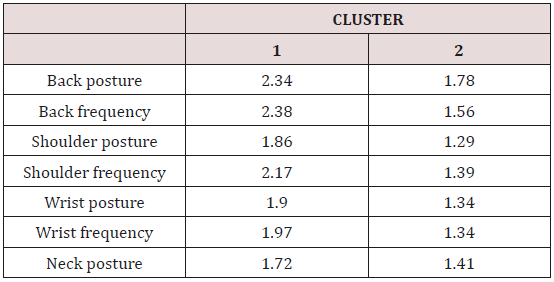

Through Cluster Analysis the 70 workers were associated in two groups. One group was formed by the people with high scores in the back and shoulder posture and the other one with a lows scores in the different body parts (Table 2).

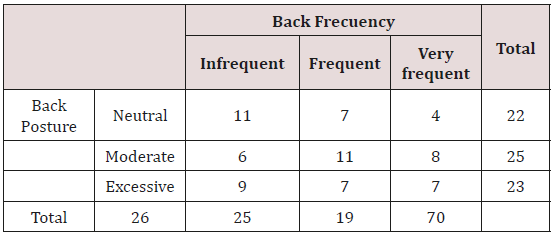

According with the Table 3, 7 workers reported that they had an excessive posture and very frequent movements in the body back. 8 workers reported that they had a moderate posture and very frequent movements, and 7 workers registered excessive posture and moderate frequency in the back. The MSD Prevalence was 31% (n=22) (Table 3).

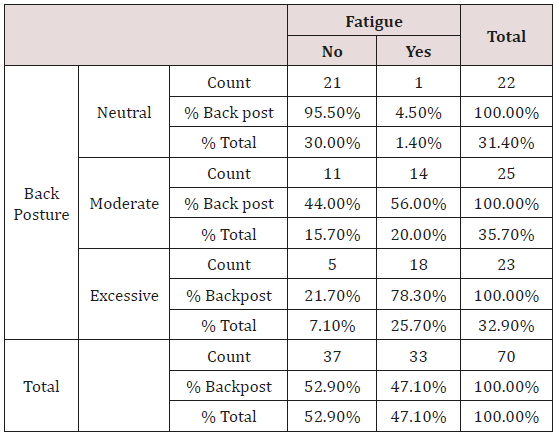

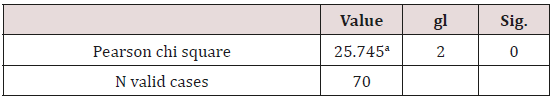

A Pearson´s χ² test was used in order to find association between back posture and fatigue. The result show that 33 workers informed that were tired at the end of the workday, which represents 47%. The workers that were evaluated with an excessive posture, 78% of them reported fatigue (See Table 4). According with the chisquare vale 25.745, could confirm that the PR is 31% of Back MSD (See Table 5).

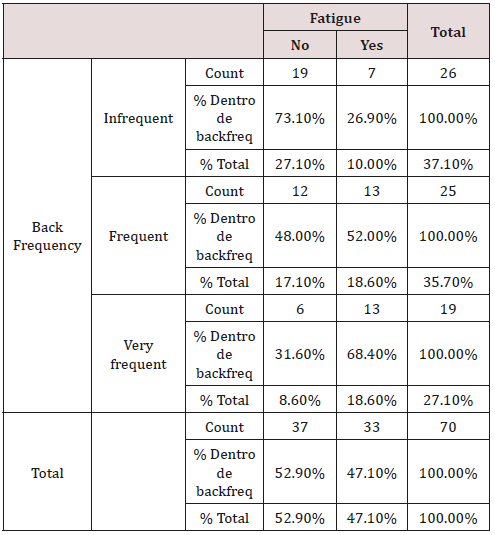

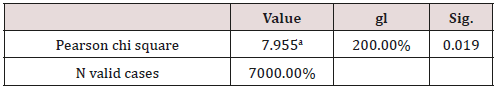

In the same way, Pearson´s χ² test was used in order to find association between back frequency and fatigue. The result show that 19 workers have a very frequent job, and 68% reported fatigue and the end of the workday. The chi-square value was 7.95, so exist a back MSD (Table 6 & 7).

Discussion

The findings of this study showed that 3 of 10 workers reported some type of risk associated with MSD. This result are in harmony with the Mexican national PR. The MSDs are the most frequent occupational diseases in the working population. In the analyzed are exist actives with high frequency and forced postures, and for these reasons some injuries would be development among industrial workers likely. Is very important to mention that exists an incorrect manual handing of loads, because lifting objects from floor level, increases the possibility of back MSD five times [12,13].

We propose the implementation of evaluation system CCR (Complaint, Check, and Redesign). The first step of the system is to know the “complaints” of the workers. According with the Federal Labor Law of México every company with more than 100 workers must to have a medical department. This department must collect work-related complaints in order to identify risk exposure that may origin a MSD. The second step is to “Check” the high incidence area, using the QEC assessment tool once a year. We recommend QEC assessment because is simple and easy to use if it is compared with other assessments. The third step is to “Redesign” the workplace based in ergonomic principles supported mainly in anthropometric measures. Due to the chances that occur in weight and height anthropometric measures need to be review once a year. This study demonstrated that shoulder, back and neck are more at risk in terms of MSD. The workers should receive training on evaluation system CCR in order modify workplaces and eliminate the risks related to work related musculoskeletal disorders.

Acknowledgement

To the Universidad Autónoma de Nuevo Leon (UANL) for financing the realization of this study.

References

- Garet Martin, Boudet Gil, Montaurier Christophe, Vermorel Michel, Coudert Jean, et al. (2004) Estimating relative physical workload using heart rate monitoring: a validation by whole-body indirect calorimetry. 94(1-2): 46-53.

- John Edison Muñoz (2016) Workload Management Through Glanceable Feedback: The Role of Heart Rate Variability.

- Arana Munarriz Victor, Echeberria Aizpuru Iñaki (1999) Monotorización de la frecuencia cardíaca en el estudio de la carga física en el trabajo.

- Keyzerling MW (1988) “Postural Analysis in Industry”. Ergonomics in Manufacturing Raising Productivity through Workplace Improvement. Society of Manufacturing Engineering. The United States of America.

- Balderas-López M, Zamora-Macorra M, Martínez-Alcántara S (2019) Musculoskeletic disorders in workers of tire manufacturing: analysis of the work process and risk of the activity. Acta Universitaria 29, e1913.

- Bingham SA, Goldberg GR, Coward WA, Prentice AM, Cummings JH (1988) The effect of exercise and improved physical fitness on basal metabolic rate. Br J Nutr 61(2):155-173.

- Brighenti-Zogg Stefanie, Mundwiler Jonas, Schupbach Ulla, Dieterle Thomas, Wolfer David Paul, et al. (2016) Physical Workload and work capacity across occupational groups. PLoS One 11(5): e0154073.

- De la Iglesia HA, Gomez BJ, Saenz AR, Ruiz FC, Carmona BA, et al. (1994) Carga de trabajo físico y costo cardiaco: La frecuencia cardiaca de referencia.

- Korshøj Mette, Krustrup Peter, Jørgensen Marie Birk, Prescott Eva, Hansen Åse Marie, et al. (2012) Cardiorespiratory fitness, cardiovascular workload and risk factors among cleaners; a cluster randomized worksite intervention. BMC Public Health 12: 645.

- Oude Hengel Karen M, Blatter Birgitte M, Joling Catelijne I, Van der Beek Allard J, Bongers Paulien M (2012) Effectiveness of an intervention at construction worksites on work engagement, social support, physical workload, and need for recovery: results from a cluster randomized controlled trial. BMC Public Health 12:1008

- Pannnemans Daphnel LE, Westerterp Klaas R (1994) Energy expenditure, physical activity and basal metabolic rate of elderly subjects. Br J Nutr 73(4): 571-581.

- Speakman John R, Selman Colin (2003) Physicla activity and resting metabolic rate. Proc Nutr Soc 62(3): 621-634.

- Rattanamanee Tarit, Nanthavanij Suebsak, Dumrongsiri Aussadavut (2014) Multi-workday vehicle routing problem with ergonomic consideration of physical workload. The International Journal of Advanced Manufacturing Technology 76(9-12): 2015-2026.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...