Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-1725

Research Article(ISSN: 2641-1725)

“Lean Management” a Method of Improving Change Management in Healthcare Organizations Volume 4 - Issue 3

Joanna Jasińska1* and Hab2

- 1University of Social, Computer & Medicine Science, Poland

- 2University of Social Sciences Computer Science and Medicine, Vice-Rector for Education and Development, Poland

Received: January 06, 2020; Published: January 13, 2020

*Corresponding author: Joanna Jasińska, University of Social, Computer & Medicine Science, Poland

DOI: 10.32474/LOJMS.2020.04.000186

Abstract

The aim of this article is to present selected ways of developing the management in medical institutions in Poland with the help of Lean Management. The author concentrates on processes of changes in clinical hospitals which include dealing with special tasks in healthcare system, diversity of tasks, medical technology, diversity of relationships with the surrounding, financing from few different sources, limits of resources (especially public ones). The article leads to a conclusion that Lean Management should be a way of thinking.

Keywords: Lean; Management; Health services; Health care units restructuring

Admission

The production management system developed and

implemented at the Toyota concern in the period after World War

II was recognized as a kind of miracle in the area of management

systems, enabling the improvement of productivity, quality and

efficiency of enterprises. For years, it was introduced to production

systems, as well as in health care and many entities operating in

various sectors of the economy under the name Lean Management,

Lean Production or simply Lean. Lean in management means

eliminating losses and any factors not adding value to a product

or service. The key ingredient of Lean is continuous improvement

[1]. According to Graban, Lean is a set of tools, management

system and philosophy, whose introduction can change the way

of organization and management of medicinal entities. “A lean

system is a method that allows hospitals to improve the quality of

patient care by reducing the number of errors and reducing waiting

times” [2]. Permanent pursuit of perfection in the management

of manufacturing processes is not without a negative impact

on the satisfaction of healthcare system employees. It is often

not connected with raising salaries, improving work safety or

improving working conditions.

The purpose of this article is to indicate selected directions for

improving change management in healthcare entities in Poland

using the Lean Management concept. Changes in management were

presented in the aspect of restructuring activities undertaken in

healthcare entities. Particular attention will be focused on change

processes in multi-specialized hospitals, which have the following

features:

a) Performing specialized tasks in the field of health protection,

b) Multi-tasking,

c) Using highly advanced medical technologies,

d) The multiplicity and diversity of relationships with the

environment,

e) Financing from several sources.

Specialist hospitals, due to their organizational complexity, are

subject to change processes, which results not only from legally

imposed obligations [Act of 15 April 2011 on medical activities: Dz. Of Laws 2011 No. 112, item 654], but also from the decisions of

managers managing entities. These institutions are implementing

changes in the financial and organizational area. The effectiveness

of actions resulting from centrally made systemic decisions aimed

at restoring the financial balance of public health care facilities

in Poland has been undertaken since the 1990s and is now being

continued. As part of the so-called Plan B in the years 2009–2016

[Resolution No. 58/2009 of the Council of Ministers of 27 April

2009 on establishing a multiannual program called ‘Support

for local government units in actions stabilizing the health care

system’]. The restructuring changes program at that time covered

80 independent public health care facilities [Rydzewska 2017, p.

179-187].

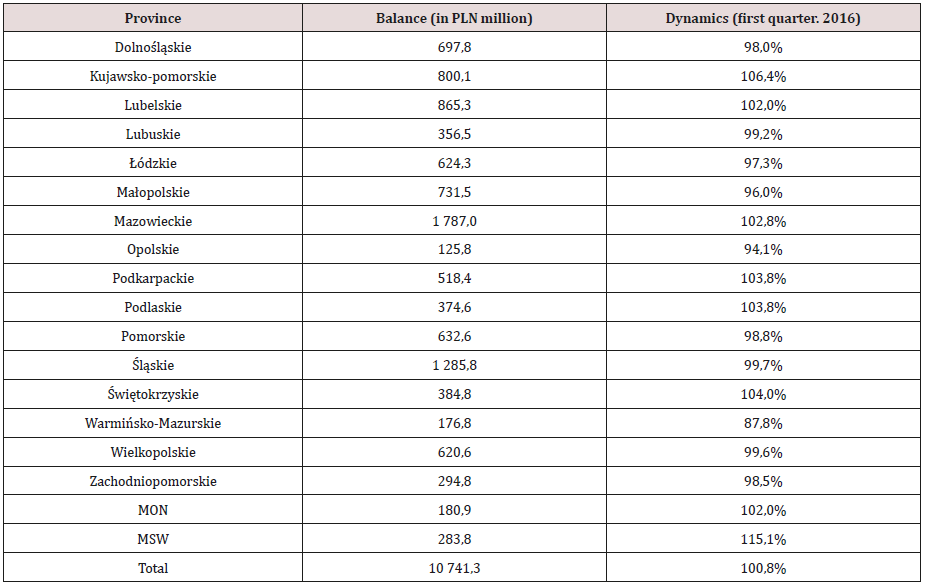

Source: Dynamics of total SPZOZ liabilities, broken down by

voivodships. MZ information based on survey data obtained from

voivodship offices, the Ministry of the Interior, the Ministry of

National Defense, medical universities and SPZOZ supervised by

the Ministry of Health, http://www.mz.gov.pl/

Despite a number of initiatives at the level of the Ministry of

Health and at the level of management by public local governments

of public health care facilities, their debt not only has not stabilized,

but - as the latest data shows - it increases in the scale of the health

system Table 1. In view of such facts, it is justified to seek and

implement solutions that are good practices enabling rational and

effective / lean resources of medical organizations while reconciling

the interests of recipients of medical services.

Lean Management Concept Main Assumptions

A number of Lean Management terms have been presented in

the literature. This concept is presented as business management,

which assumes adapting it to market management conditions

based on continuous organization rationalization processes

and its relations with the environment. These processes should

concern the introduction of changes in the organization in terms of

operations, property structure, management, shaping the attitudes

of employees focused on “slimming” the organization [3]. In another

term, the emphasis is on ways of reducing the cost of generating

added value for the customer by rationalizing employment,

infrastructure, expenditure on current and investment activities,

and working time [4]. The main principle of Lean Management

is primarily the elimination of waste to reduce the costs of the

entity’s operations while ensuring adequate added value for the

client [5]. In a different approach, Lean Management is combined

with the organization management method, especially in the

process of implemented changes [6]. It emphasizes rationalization

by restructuring the organization’s resources and the way they

are used, taking into account the conditions arising from its

environment. In the term Lean Management, the role of “slimming” the organization in order to improve the productivity and quality

of products is emphasized [6]. As it results from the quoted terms,

the Lean concept refers to both the internal elements of the subject

and his relationship with the environment in which he operates.

It covers activities improving the quality of products, restructuring

the scope of manufactured products, related to the flattening

of organizational structures, with changes in human resource

management and ensuring the competitiveness of manufactured

products. The key concept of Lean Management is the added

value of the product or service for the recipient, while generating

profit for their producer. Obtaining it requires meeting at least the

following conditions:

a) The customer (in the case of health protection, individual

patient or institutional payer - public or private) is willing to

pay for the product,

b) The product (health service) has the value desired by the

customer (it is not defective, has utility value, corresponds to

the health need),

c) The manufacturer (medical entity) rationalizes the use of

production factors (labor input, expenditure on manufacturing

instrumentation, expenditure on infrastructure, proper

inventory rotation).

Understanding the Lean Management principle is a condition

to avoid misunderstanding its essence. Correct interpretation is

associated with its identification with activities aimed at eliminating

waste (from Japanese Muda), and not with austerity measures

consisting in limiting expenditures while providing value not fully

desired for the patient (e.g. limiting the employment of persons in

the positions of medical secretaries assisting the work of doctors

or people working in the registration of medical entities, resulting

in longer queues and patient waiting times, as well as employee

dissatisfaction due to excessive workload). [7]. The term Muda is

combined, among others with: production of defective products,

production of products with low utility and low efficiency for the

recipient, production of often unnecessary products, inefficient

organization of employees’ work resulting in so-called apparent

actions (not having a real purpose), lack of synchronization in

time and space of activities of individual employees or groups

of employees (downtime related to time not worked effectively,

resulting from non-delivery of products by the previous product

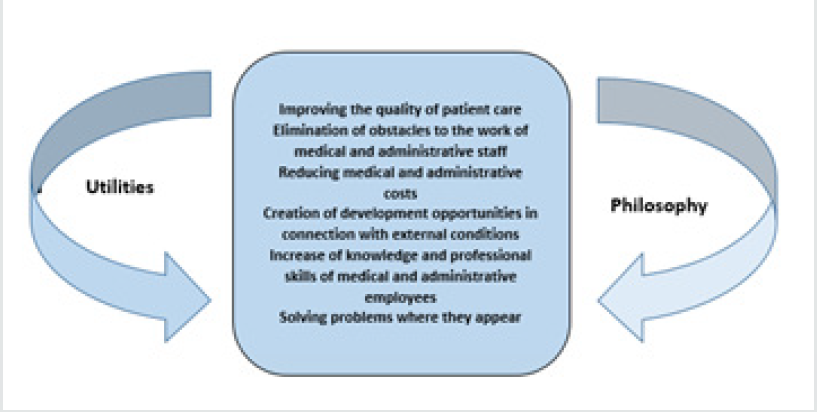

manufacturing links) Figure-1.

Source: Own study based on [2].

To sum up, it should be emphasized that the concept of

lean management, especially in the management of healthcare

organizations, should be clearly understood. Elimination of waste

(time, equipment and apparatus, money) should be distinguished

from economical and limiting resources of medical organizations

that cause disruptions in the course of medical processes, extending

patient waiting time, offering defective health services and

dissatisfaction of employees with work overload. Lean Management

as a concept supporting the implementation of changes is not a way

to generate profit at all costs, but is a way to reconcile the demand

side with the supply side through the transformation of assets, the

way of management, organization, relations with the environment

understood not only as a market of health services, but much more

widely (legislation, competition, outsourcing, general economic

factors).

Principles and Tools of Lean Management in the Aspect of Application in Healthcare Organizations

Creating patient value should be based on several principles of

Lean Management. The rules are as follows:

a) The products are free of defects (benefits having value

for the recipient; benefits not disputed by payers - in accordance

with technological standards, requirements set by payers as to the qualifications of personnel, medical equipment and apparatus,

infrastructure conditions; benefits corresponding to satisfying a

given health need; no loss of time and material; safe in terms of

health, technology and hygiene for all stakeholders),

b) Solving problems at the place of origin (employees’

readiness to redefine activities and redesign work),

c) Compliance of the performed health service with the

standard way of its performance (if it was developed), objectives,

conditions of implementation,

d) Transparency of relations between producers and

recipients of health services thanks to a properly designed and

constantly improved process of manufacturing and supplying

products; designing roles enabling the production of services

without defects [8].

e) Techniques leading to the elimination of losses and

adapting business results to external expectations should also

be adapted to the specifics of healthcare organization entities.

Selected techniques include, but are not limited to, techniques

that may prove particularly valuable from the perspective of the

effectiveness of implementing changes in healthcare organizations.

These are among others:

f) Just in Time or production on time - the use of this tool

allows you to eliminate the unjustified expectations of patients,

employees from the same or another organizational unit, recipients,

suppliers, and as a consequence prevents the loss of contracts and

income.

g) Kanban - is a system of signals used in undertaking

individual actions at various stages of product creation (at what

point in time the next health service for the patient is needed,

in which organizational part of the entity, which personal and

material resources are to be used). The condition of introducing

the signal system is to create an undisturbed system of relations

between individual groups of employees or organizational units

of the therapeutic entity leading to the development of principles

of close cooperation and a system of communication between

them. A particularly desirable approach to patient management is

treating the patient care path as an inseparable whole (successive

phases of value creation), which is a condition for determining

the cumulative value (final health effect) of individual services

(medical procedures) performed for the patient. The condition is

cooperation between individual organizational parts of the entity

and a departure from treating services performed by individual

organizational units as final or detached from the final effect for

the patient.

h) Elimination of waste - areas of waste can be: production

of health services that do not correspond to the reported demand,

breaks / downtime between the individual stages of the process of

creating value (the final health effect) for the recipient, unjustified

movement between the stages of creating value (transport of the

patient between parts of the hospital or between hospitals), the

appearance of defects in the manufacturing process or product

(making an incorrect diagnosis based on a faulty performance of

a diagnostic test), unjustified generation of inventory, unnecessary

movement of employees, equipment and apparatus, documentation

and an unfriendly way of delivering products to recipients (failure

to comply with the dates and hours of health service). For example

- obtaining incorrect results of a patient’s diagnostic examination

requires correction or repetition, i.e. the consumption of additional

material resources and workload, as well as additional control.

This, in turn, can cause “downtime” in other parts of the medical

organization.

i) 5 S (selection, systematics, cleaning, standardization,

self-discipline) - the use of this tool becomes possible to reduce

in-hospital infections, which may also result from irregularities

in waste storage, non-compliance with occupational hygiene,

movement between hospital departments without adequate

protection against exposure to infection biological agents.

j) Creating a value stream map (VSM) - the essence of VSM is

to analyze how to produce and deliver the product to the customer

and identify those activities that add value. The activity that creates

the value of a patient’s medical service is to conduct an interview

with the patient by a nurse, as opposed to providing no interview

with a patient waiting for direct contact with a doctor who only

after entering the office orders or conducts the interview himself.

k) Jidoka - is a way for employees to respond in the event

of problems during the product manufacturing process. Prevents

the penetration of the defective product or its parts into the

next stages of manufacture and subsequent positions, e.g. in the

event of incorrect preparation of the patient for a diagnostic test

or surgery, the employee should break the chain of subsequent

medical activities that may have a defective “effect” of the medical

procedure.

l) To sum up, it should be emphasized that the selection of

tools under the Lean Management concept and the way they are

used must take into account the specifics of a given activity, as well

as adapting them to a given type of therapeutic entity [9].

Using the principles of “lean” management in restructured healthcare organizations - Lean Healthcare

The principles of Lean management in health care were adopted

to be called Lean Healthcare. They have been introduced in many

healthcare organizations in numerous countries [10]. However,

experience shows that only part of the Lean Management tools

and methods have been used to improve selected areas of activity

of health care entities, especially hospitals. Given the specifics of

the healthcare sector and operations, Lean Healthcare has a specific

interpretation: a medical entity is an entity that produces specific

products - most often they are health services; health service is a

manufacturing process; the patient, together with the services

provided to him which bring specific health effects, is a product. The applications of Lean Healthcare in healthcare organizations

presented in the literature show that it is most often focused on

improving the quality of health care (increasing the value of the

product for the patient), improving access to health services,

improving organizational processes and rationalizing costs.

Improving access to healthcare understood as shortening the

waiting time for health services, streamlining internal processes

related to providing patients with services are the factors that allow

rationalization of the costs of medical procedures. By increasing

work efficiency, both in terms of health services and support

activities (patient registration, referring patients to appropriate

organizational units in the hospital) - there is the possibility of

shortening expectations for services and improving the economic

efficiency of entities. With the high effectiveness of implementing

changes, patient waiting times can be reduced by up to 42% [11].

Reducing patients’ waiting time for medical procedures is not the

only attribute of high-quality healthcare. It also depends on the

method of providing health services, especially in those entities

(mainly hospitals) that provide comprehensive care for a package

of medical services. Often, due to the nature of the disease, the

group of patients requires various activities not only within one

ward / hospital department. An example would be elderly patients

with chronic diseases. The experience of hospitals indicates that

ensuring higher quality of care may depend on the implementation

of so-called complex co-managed care depending on the patient’s

condition and medical procedures that he needs. This creates a

situation in which patients are not exposed to frequent movement

between different parts of the hospital (avoiding unnecessary

transport) and frequent changes of the staff who care for them. This

undoubtedly increases the sense of patient safety [12]. The problem

of many healthcare organizations in most health systems is the

strong bureaucracy of organizational structures. This is associated

with the loss of working time of medical workers, and from the point

of view of patients with prolonged paths and time from the moment

of issuing the diagnostic test order to its execution and obtaining

the test result. Often, the extension of the “path” is associated

either with errors in completing order cards or with errors in the

performance of the study itself. According to Canadian experience,

by optimizing the time spent on organizational processes or

activities related to medical diagnostics, hospitals can intensify

both human and apparatus work, and thus at the same time

provide more health services, which can translate into increased

accessibility them. An additional advantage is the implementation

of the same activity with the same measures [13]. The changes

inspired by the Lean Healthcare concept, which resulted in a

reduction of patients’ waiting time by 19-24%, were associated with

the creation of clear, understandable mechanisms of cooperation

between individual employees by defining their roles in the chain of

creating value for the patient, creating new principles of employee

communication, defining patterns procedures and work schedules,

scope of duties and ways of solving current problems. Adaptation

of Lean Healthcare in Swedish hospitals has resulted in improved

management due to the introduction of work standardization,

organizational connections of positions / people working in mutual

logical relationships, elimination of unnecessary and disruptive

medical procedures, introduction of employee motivation to

independently identify problems and overcome them [14].

The effectiveness of Lean Healthcare adaptation in strengthening

employee roles in the value creation chain may be conditioned

by transferring greater responsibility for the way the work is

performed and its effects to individual employees who perceive

it as an increased motivation to work [15]. Given the specifics of

the tasks performed, the manner of management in healthcare

organizations, and strong restrictions on their functioning, caused

by limited access to public funds, an approach that can bring

good results from the implementation of Lean principles is the

evolutionary approach [Nielsen, Improving Healthcare through

Lean Management: Experiences from the Danish healthcare

system].

In view of the international experience and conclusions

resulting from the implementation of Lean Healthcare in healthcare

entities and the conditions for the functioning of healthcare

organizations in Poland, an attempt can be made to indicate

directions for improving management in healthcare entities.

Particular attention will be focused on specialist hospitals. The

starting point for determining the areas of the entity’s operations

that should become subject to improvement / restructuring is the

diagnosis of the entity’s activities, including:

a) Analysis of the economic situation (basic economic values and

indicators as well as financial statements); in the conditions

of growing financial debt of hospitals in Poland, the scope of

analysis should include: financial efficiency ratios - receivables

turnover, liabilities turnover, inventory turnover; debt ratios

- total debt ratio, equity to liabilities ratio; productivity

indicators),

b) Analysis of the causes of the entity’s existing financial situation

(impact of system changes on the entity’s position),

c) Analysis of internal causes of organization and management

irregularities (scope and structure of resources, degree of

their adaptation to conducted activity, allocation of resources

in the entity, organization of work processes, mutual relations

between medical activities).

The conclusions made as a result of the diagnosis should

become the starting point for indicating the directions of improving

the management of the entity. However, creating a uniform list

of directions, or “path of change” for all hospitals is not justified

because existing profile, technological, organizational and financial

differences that generate other problems. Potentially they may

include:

a) Setting priority and other tasks in individual areas of

conducted activity (medical, scientific, didactic) and medical

specialties as well as individual activities constituting their

implementation;

b) Organizational changes, e.g. laboratory diagnostics

combined with a change in the location of diagnostic cells to

reduce costs; allocation of archived documents in one “place” in the

hospital building, which will allow faster access to information and

adaptation of vacant rooms for other purposes;

c) Functional changes - restructuring of hospital beds in

order to adjust the financing bed base (monitoring indicators of

average period of stay of patients, waiting time for admission to a

ward or clinic, the degree of bed use);

d) Resource changes: a combination of clinical units enabling

consistent policy to intensify the use of medical equipment and

apparatus; providing access to the departments’ facilities providing

health services as part of caring for the local population (eliminating

duplication of purchases of the same equipment and apparatus

as well as dispersion of equipment increasing operating costs);

centralization of the distribution of diagnostic base elements;

e) Changes in personal resources in the aspect of assigning

employees to diagnostic, hospitalization and outpatient tasks;

formal assignment of employees to consulting tasks not only within

one branch, but also for other organizational units;

f) Eliminating (by pooling) duplication of the same medical

procedures by several hospital organizational units to improve

resource management and eliminate unnecessary manufacturing

factors;

g) Determining the centers of responsibility for the

management of medical equipment and apparatus (taking over

supervision over the management of diagnostic equipment by a

separate department, plant, clinic or clinic);

h) Implementation of new medical technologies enabling

more efficient diagnosis of disease entities, which is associated with

shortening the waiting time for results and the time from diagnosis

to intervention;

i) Implementation of an integrated IT system facilitating

and accelerating the flow of information in the hospital (integrated

management of drugs, medical equipment, centralization of

material management),

j) Implementation of integrated management of medical

materials, medical consumables and medicines;

k) Establishment of cost responsibility centers to strengthen

supervision and eliminate waste;

l) Developing the principles of communication between

the management and employees in order to explain and motivate,

which allows reducing stress and social unrest associated with the

economic uncertainty of the entity;

m) Compliance with the precise implementation of contracts

with payers in order to eliminate any financial sanctions, including

the termination of contracts; particular attention should be focused

on the so-called over-limit benefits;

n) Property restructuring (e.g. when the hospital operates

in several different buildings / rooms distant from each other or

the infrastructure is not used due to poor technical condition) to

eliminate unnecessary usable space and unnecessary transport, to

rationalize maintenance costs and depreciation costs;

o) Outsourcing of non-medical services.

Summary

The effective functioning of medical entities depends not only

on the course of internal management processes, but also on the

flexible adjustment of their activities to the changing environment.

The emergence of new health technologies, changing health

exposures not yet occurring or occurring to a limited extent,

demographic and epidemiological changes in combination with

systemic factors force changes in which the use of “lean management”

may be particularly useful. The main directions of improving the

functioning of healthcare organizations should be: reducing the

time of access to health services by designing an efficient from the

point of view of direct recipients of the implementation of activities

preceding the performance of health services; this is associated

with a smooth transfer of information, e.g. about available places

in hospital wards; maximum focus on patients’ expectations,

while in the case of financing services from public funds - focus

on the implementation of obligations towards public payers

(National Health Fund, ministries, local governments), which

are related to the implementation of the principles of contracts

concluded (comprehensiveness and continuity of care, accuracy

of diagnoses , reliability of the use of diagnostic, therapeutic and

prophylactic methods, ensuring declared personnel, equipment

and infrastructure conditions, maintaining the assumed level

of costs and financial result). Ensuring good communication

between patients and the medical entity in the scope of providing

information at every stage of medical treatment with the patient.

Conducting constant analysis of work positions, activities of

individual organizational parts of the medical entity in order to

formulate current recommendations for employees assuming equal

treatment of medical employees and those indirectly involved in

the provision of medical services.

In addition, care for proper technological preparation, which

allows to avoid discouragement of employees and patients

as well as the increase of costs and losses, which result, e.g.

from poor-quality diagnostic tests results requiring repetition,

downtime, cancellations of medical services. It is also important

to increase the quality of tasks implemented, which contributes to

strengthening the relationship between hospitals and recipients

of their products (patients, payers, other medical entities) [16].

Even precise determination of directions of changes in health

care organizations may not prevent management staff from

implementing them incorrectly. The main risks associated with

the distortion of the Lean being are most often: identifying the

Lean concept with the economic or financial rationalization of the

medical entity’s economy, reducing financial liquidity, reducing the quality of services and bypassing legal provisions imposing specific

obligations on entities contracting benefits with payers, increasing

the level of employee stress and decrease in motivation to work,

rationalizing employment by simply limiting it, neglecting the

problems of employees with lower qualifications [17]. According

to prof. Zimniewicza [18], the need arises to consolidate the Lean

concept as a way of thinking.

References

- Niedziółka M, Piasek A (2014) Kaizen Costing by a modern method of cost management, Scientific Notebooks of the Podlasie University in Siedlce, Series: Administration and Management 81: 79-87.

- Graban M (2014) Lean hospitals - improving hospitals. Quality improvement, patient safety and staff satisfaction, ProdPublishing, Wrocław, Poland, p. 2.

- Lichtarski J (1997) Fundamentals of enterprise science, WAE, Wrocław, Poland, pp 224.

- Jones DT, Womack JP (2014) Slimming companies, CIM, Warsaw, Poland.

- Czerska J (2016) More than slimming, i.e. the essence of the concept of Lean management, Staff.

- Pedro José Martínez-Jurado, JoséMoyano-Fuentes (2014) Lean Management, Supply Chain Management and Sustainability 85 (15): 134-150.

- Cholewicka Goździk K (2014) LEAN method - process and product improvement, Quality Problems p. 21.

- Jimmerson C Weber D Sobek DK (2014) Reducing Waste and Errors: Piloting Lean Principles at IHC, Joint Commission Journal on Quality and Safety 1-22.

- Kubis N (2015) Lean management tools, Technical and Economic issues 50(2-3): 291-303.

- De Souza LB (2015) Trends and Approaches in Lean Healthcare, Leadership in Health Services 22 (2): 121-139.

- Bernatek A (2019) A profitable investment in Lean Healthcare.

- Greco A, Cascavilla L, Paris F, Addante F, Miscio L, et al. (2015) The nephro-geriatric unit in a lean-oriented in hospital model of care. J Nephrol 25(19): 16-19.

- Villeneuve C (2014) Fujitsu’s Lean Soution Group. Lean Healthcare in Canada. Fujitsu Sci Tech 47(1): 41-48.

- Mazzocato P, Holden RJ, Brommels M, Aronsson H, Bäckman U, et al. (2016) How does lean work in emergency care? A case study of a lean-inspired intervention at the Astrid Lindgren Children’s hospital, Stockholm. Sweden BMC Health Services Research 12: 28.

- Glossmann JP, Schliebusch O, Diehl V, Walshe R (2016) Lean management in hospitals: Potentials and limitations. Med Klin Munich 95(8): 470-473.

- Sobczak A, Rydlewska Liszkowska I (2016) Management of occupational medicine entities. The concept and application of lean management, Occupational Medicine 63(5): 599-606.

- Robbins A (2016) Lean Management I outsourcing. The road to success is to take massive, determined actions, Change management. POU Newsletter.

- Zimniewicz K (1999) Contemporary management concepts and methods, Polish Economic Publishing House, Warsaw, Poland, p. 63.

- Brännmark M, Halvarsson A, Lindskog P (2019) Implementing Lean in Swedish Municipalities and Hospitals.

- Der Shin Ke Overwork (2012) Stroke and Karoshi-death from Overwork. Acta Neurol Taiwan 21(2): 54-59.

- Encyklopedia Zarządzania (2019).

- Fijałkowska B (2019)

- Efficiency and restructuring of SPZOZ (2019).

- Izabela Rydlewska-Liszkowska, Lean Management-doskonalenie zarządzania pp. 289.

- Inoue K, Matsumoto M (2014) Suicide from overwork: A spreading occupational threat. Occup Environ Med 57(4): 284-285.

- Iwasaki K, Takahashi M, Nakata A (2016) Health problems due to long working hours in Japan: Working hours, workers compensation (Karoshi) and preventive measures. Ind Health 44(4): 537-540.

- Kawanishi Y (2016) Suicide by Overwork: Why Do Japanese Workers Work Themselves to Death?. Follow International Journal of Mental Health 37(1): 61-74.

- Nogalski B, Walentynowicz P (2016) Modern management concepts in production enterprises of the Pomeranian region - an attempt to evaluate, Scientific Papers of E. Kwiatkowski University of Administration and Business in Gdynia 7: 14-32.

- Nielsen AP (2019) Improving Healthcare through Lean Management: Experiences from the Danish healthcare system.

- Uchiyama S, Kurasawa T, Sekizawa T, Nakatsuka HJ (2015) Job strain and risk of cardiovascular events in treated hypertensive Japanese workers: hypertension follow-up group study. Occup Health 47(2): 102-111.

- Act of 15 April 2011 on medical activity, Journal of Laws 2011 No. 112: 654.

- Weathers C, North S (2015) Overtime Activists Take on Corporate Titans: Toyota, McDonald’s and Japan’s Work Hour Controversy. Pacific Affairs 82(4): 615-636.

- Zimniewicz K (1999) Contemporary management concepts and methods, Polish Economic Publishing House, Warsaw, Poland, p. 63.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...