Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6921

Research Article(ISSN: 2641-6921)

Microstructure And Composition Can Significantly Affect The Properties Of Tissue-Engineered Materials Containing Living Cells Volume 5 - Issue 1

Jianming Wang1*, Meng Li2, Zhizhong Shen2, Xiaorui Tian1 and Shengbo Sang2

- 1General Hospital of TISCO, North Street, Xinghualing District, China

- 2Taiyuan University of Technology, China

Received: January 15, 2022; Published: January 24, 2022

*Corresponding author: Jianming Wang, & Shengbo Sang, General Hospital of TISCO, North Street, Xinghualing District, Taiyuan 030024, China, Taiyuan University of Technology, Taiyuan 030024, China

DOI: 10.32474/MAMS.2022.05.000203

Opinion

Bioengineering synthetic materials to replace some specific human functions is the inevitable direction of development in the field of materials in the near future. Synthetic materials containing living cells will have a broad application prospect in skin replacement. For example, the market scale of wound repair (avoiding donor site injury, promoting healing, and improving healing quality), such as in vitro validation of beauty products will be 10 billion US dollars. Up to now, in the research of skin substitute materials, many research teams around the world have released a lot of research results, but they still have not fully developed an artificial composite material that can replace human skin. At the same time, they have not developed skin organ products that can solve wound coverage and skin function substitution. Our previous research combined with the research progress of other teams, found the material characteristics of other teams in simulating skin structure, and made improvements. Our research found that GelMA-PEGDA co-network hydrogel to prepare tissue-engineered skin with RRs structure. We have found that 10%GelMA-2%PEGDA hydrogels showed the adequate bioactivity, excellent structural support, suitable degradation rate and high mechanical stability mechanical stability [1]. The advantages of mold one-time forming gelma are low cost, low equipment requirements, low technical requirements, and fast manufacturing speed. It can simulate the net ridge structure between dermis and epidermis, so as to induce the close connection between them; [2].

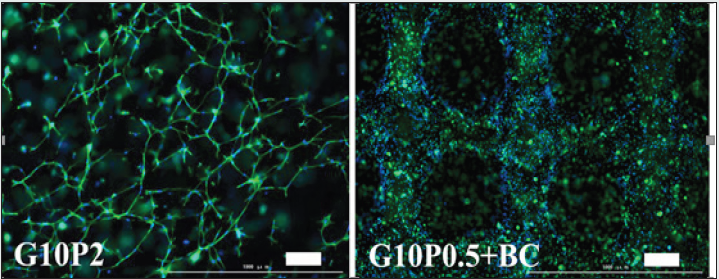

Figure 1: HSFs contained within G10P2 hydrogels and G10P0.5+BC at day 5 stained with DAPI for nuclei (blue) and FITCphalloidin for F-actin (green). Scale bar: 200 μm.

The disadvantage is that the looseness of the internal structure

of the material is completely formed by the cavity after crosslinking

and water loss after the material solidification, as shown in Figure

1 and a film layer with few pores will be formed on the material

surface due to molecular tension, which may partially lead to

unfavorable fluid exchange and cell migration and growth. The

current research of our team is based on the deficiencies found in

the previous study to further improve the appropriate raw material

ratio to make it suitable for biological ink as 3D biological printing.

The raw material ratio of biological ink in this study is 10%

gelma-0.5% pegda-0.1% BC (BC, bacterial cell). It uses 3D printing

technology to maintain the network ridge structure on the material

surface, The internal structure of the material is improved by

printing and forming, so that the internal structure is also a threedimensional

network structure, which can facilitate the liquid

exchange around the cells and the migration and growth of cells in

the three-dimensional space [3,4].

The preliminary research results suggest that the expected

effect has indeed been achieved. Its in vitro experiment shows that,

as shown in the figure, the statistical result of cell proliferation in

3D printing material is about three times higher than that of mold

forming material under the same cell inoculation density and

culture time. In vivo validation: We conducted in vivo experiments

after inoculation of material printing cells. The results showed that

the proliferation of two main cells constituting the skin, epidermal

cells and fibroblasts, was faster than that of mold forming

materials, and the wound healing speed was also faster. The key

was that the healing quality could be significantly different at the

time point of 2 weeks, The specific results will be introduced in

the next treatise. We all know that time is life in clinical rescue. If a

material can achieve in vitro proliferation in the shortest time and

meet the transplantation requirements, it will greatly increase its

practicability for clinical application, and has a very broad prospect

in clinical transformation application. The same cell inoculation

density has great differences in the proliferation rate of different

materials, which shows that the structure, composition, and ratio

of materials have a significant impact on the cell proliferation in

materials. The two materials currently developed by our team

have their own advantages and disadvantages. How to avoid the

disadvantages and combine the advantages of the two schemes will

be the problem to be solved in the next research.

References

- Zhizhong S, Yanyan C, Meng L, Yayun Y, Rong C , et al. (2021) Construction of tissue-engineered skin with rete ridges using co-network hydrogels of gelatin methacrylated and poly(ethylene glycol) diacrylate Mater Sci Eng C Mater Biol Appl 129: 112360.

- Clement AL, Moutinho Jr, Pins GD (2013) Micropatterned dermal-epidermal regeneration matrices create functional niches that enhance epidermal morphogenesis. Acta Biomater 912: 9474–9484,

- Zhou X, Tenaglio S, Esworthy T, Hann SY, Cui H, et al. (2020) Three-Dimensional Printing Biologically Inspired DNA-Based Gradient Scaffolds for Cartilage Tissue Regeneration. ACS Appl Mater Interfaces (29): 33219-33228.

- Vila A, Torras N, Castano AG, Garcia-Diaz M, Comelles J, et al. (2020) Hydrogel co-networks of gelatine methacrylate and poly (ethylene glycol) diacrylate sustain 3D functional in vitro models of intestinal mucosa. Bio fabrication 12(2): 025008.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...