Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6921

Review Article(ISSN: 2641-6921)

High-Power Laser Radiation Driving Material Applications Volume 4 - Issue 2

Bahman Zohuri1,2,3*

- 1Golden Gate University, Ageno School of Business, San Francisco, California

- 2International Technological University, ECE Department Santa Clara, California

- 3Galaxy Advanced Engineering, a Consulting Firm, Albuquerque, New Mexico

Received:April 26, 2021; Published: May 12, 2021

*Corresponding author: Adjunct Professor, Business Analytics School, Computer Science and Electrical, Computer Engineering, Galaxy Advanced Engineering, Albuquerque, New Mexico

DOI: 10.32474/MAMS.2021.04.000182

Abstract

With recent attention to high power energy and its interaction with materials of different type, both in industry and military application, this paper covers a short review into subject of materials response in respect to such high-power energy lasers. In this paper, we are covering laser interaction with matter and different stages that matter goes through, sheet of metal that has transition from solid to melt and vapor and finally plasma stage driven by longer time interaction of such high-power laser with target of interest. We have also covered other industrial application of these type of laser in the field of medical as well as cosmetology and briefly have touched their military applications.

Keywords:Laser and Laser radiation; Heat Transfer and Heat Radiation; Laser Interaction with Matter; Lase Application and Metallurgy; Laser Applications in Biology and Medical Fields; Military usage of High-Power Lasers

Introduction

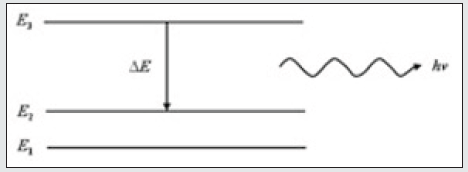

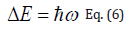

As we have learned from our college physics, the word LASER, of course, is an acronym for “Light Amplification by the Stimulated Emission of Radiation,” but that is not terribly enlightening. More correctly described a laser is a device for producing light that is almost totally coherent. It works in principle like this: An atom emits a photon of light when it decays from an excited energy state to a lower state; the difference in energy between the two states determines frequency according to Equation (1) as:

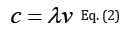

where is Planck’s constant and its value is given as = 6.62606957 x 10-34 J.s = 4.135667516 x 10-15 eV.s. Equation (1) in term of energy level is depicted below as (Figure 1). If we assume the wavelength of emitted photon light designated with symbol and speed of light with , then relationship between wavelength and speed of light can be written as:

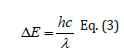

Substitution of Equation-2 into Equation 7-1 for frequency, we get a new expression for the Plank-Einstein relationship as:

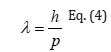

The above equation leads to another relationship involving Plank’s constant. Given for the linear momentum of a particle (not only a photon, but other particles as well), the de Broglie wavelength of the particle is given by:

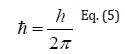

In some applications where it makes sense to use the angular frequency, where the frequency is expressed in terms of radians per second instead of rotation per second or Hertz, it is customary to absorb a factor of into the Planck constant. The resulting constant is called Reduced Plank Constant or Dirac Constant. It is equal to the Plank constant divided by and is denoted as and pronounced h-bar.

Therefore, the energy of photon with angular frequency, where , is given as

The reduced Plank’s constant is the quantum of angular momentum in quantum mechanics. The numerical value of reduced Plank constant is given as = 1.054571726 x 10-34 J.s = 6.58211928 x 10-16 eV.s. With recent past few decades, laser technology has triviid tremendously and its application can be found in both industry and military in form of high-power energy and many other industries such as filed of biology and medicine, etching, welding annealing, metallurgy, and almost more than decade ago, we can see its application in generating electricity driven by Inertial Confinement Fusion (ICF) under National Ignition Fusion (NIF) program led by Lawrence Livermore National Laboratory (LLNL) as well [1]. Military also in past decade under Star Wars or Strategic Defense Initiative (SDI) during President Ronald Reagan took the advantage of such High Energy Laser (HEL) by building three type of lasers as a Weapon of Directed Energy and they are namely known as: [2]

a. Space Based Laser (SBL).

b. Airborne Based Laser (ABL).

c. Ground Based Laser (GBL).

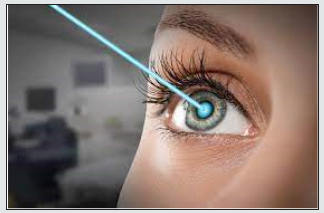

Where either Neodymium-yttrium aluminum Garnet (Nd-Yag) laser, or Hydrogen Fluoride (HF), or Carbon Dioxide (CO2) or Popup X-Ray lasers, were under consideration for the above three purpose as Directed Energy Weapons (DEWs). In field of medicine blue-green laser can be used for eye treatment such as cataracts or glaucoma. Laser driven ophthalmology and optometry past decade is another growing area of laser interaction with matter, where LASIK eye surgery is way to go for your vision correction providing one is the right candidate for this enhancement treatment accordingly as illustrated in (Figure 2) In cosmetology for the purpose of cosmetic surgy, where two basic types of lasers are used, mainly: [3]

1. Ablative,

2. Nonablative.

Ablative lasers actually vaporize the top layers of damaged skin, while non-ablative lasers work deeper in the skin without removing or otherwise damaging the top layers. For this reason, there is no real patient downtime associated with cosmetic procedures that employ solely nonablative laser technology. Few examples of these types of treatments can be seen i.e., skin resurfacing peels as its shown in (Figure 3) and Tattoo Removal as illustrated in (Figure 4) in dermatology and cosmetology is in Acne Scars or a none-surgical face lifts as a noninvasive approach as well removing excessive fat from body locally. There more other medical applications of laser such as:

a. Skin Health due to Sun Age,

b. Fraxel Procedure,

c. Toenail Fungus laser Treatment,

d. Skin Tumor Removal,

e. Keloid Treatment and Prevention

f. Hair removal or Facial

Are few that are also can be named. In metallurgy driven by laser interference, patterning of high-resolution features on largearea metallic substrates are getting performed by utilization of mentioned above techniques. This is due to coherency and intensity distribution of laser interference pattern that allows to heat the material surface locally and periodically to temperatures higher than the melting point with a long-range order. Also, by combining laser and powder Processing, laser Metal Deposition (LMD) enables the manufacture of high precision near-net shape components from powders, so enhancing materials utilization. There are many more applications exist in industry that are driven by laser beam, but it is beyond scop of this paper to cover them all, so we refer our reader to internet for their quests.

How Lasers Work

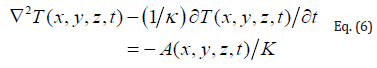

Lasers offer a new type of high-power light source, capable of producing interesting and useful effects. The shower of sparks blasted from a metallic surface by a focused laser beam has by now become very familiar. Investigations of the effects of laser beams have multiplied over the last few years; work on laser effects represent an important technology within the growing laser field. What we mean by laser effects in this article, we mean the interactions between high-power laser beams and matter, which includes items such as heating, melting, vaporization, and plasma production that in general is governed by Equation (6) here inform a Partial Differential Equation (PDE) for heat flow in a semi-infinite slab of material with a boundary at the plane on which radiation is incident as:

where is the temperature as a function of position and time , is the thermal diffusivity, the thermal conductivity, and is the heat production per unit volume per unit time as a function of position and time. The initial condition is that i.e., ). The boundary conditions are that the temperature approaches zero ( ) as approaches infinity ( ) and that there is no heat flux across the surface. In addition, there is sufficient material on the related areas of laser properties, measurement techniques, and safety aspects to make the book self-contained. Specifically excluded are such items as nonlinear optical effects, parametric interaction, and scattering processes such as the stimulated Raman effect. These phenomena, which likewise can involve an interaction of a high-power laser beam, are indeed sometimes called laser effects, but they shall be outside the definition of “laser effects” as we are employing here. Lasers are monochromatic (mono means one and chromo refers to color), which means that a given laser emits light of only one wavelength (or color) of light. Lasers with their today’s applications are found to be interesting and useful and the reason for this is that the radiation emitted by lasers has unusual properties that separate it from ordinary source of light. Due to unusual properties and consequently behavior of laser, many applications are possible, ranging from distance measurements or in case of measuring speed through Laser Radar (LADAR) to holography to angular rotation rate sensing to nonlinear optics.

For purpose of this article, these properties make it easy to produce spectacular effects when the beam strikes a target and make the laser useful in such areas as melting, vaporization, and heating, in order to deal with the effects produced by interaction of high-power laser beams with matter. These high-power effects include heating, melting, and vaporization of solid materials, emission of charged particles and plasmas, electrical discharges in gases, and applications of these effects in such areas as materials processing. Moreover, the Lasers that are working in cosmetic applications through a process called “selective photo-thermolysis” [4]. When broken down, this very fancy word means that it modulates the frequency of light (photo) to produce heat (thermo) in the specific area of the corresponding thing you wish to destroy (lysis). To do this, the wavelength of the light beam must be in sync with the color of the target, which is to be addressed, whether that be brown spots, unsightly red broken capillaries, or some other undesirable skin condition.

Laser Properties

It is necessary to describe properties of lasers insofar as they have a special relevance to the field of laser effects. This section and the next are meant to provide enough background material about lasers and measurement techniques to make the book selfcontained. It is because laser light has unusual properties that laser beams can produce effects that are scientifically interesting and that have practical applications. We first consider what the properties are and how they are relevant to the topic of laser effects. The main properties of interest that are different in laser radiation as compared to radiation from conventional light sources are as follows for the laser radiation:

a. The Intensity,

b. Th Directionality,

c. The Monochromaticity, and

d. The Coherence.

Each of the above uniqueness of the laser radiation are described in a holistic form below.

The intensity

The Intensity of laser is a hallmark of laser light unique property and this uniqueness is very well known in any laser light in particular the high-power energy one. The ability to produce very-high-power beams is the facet of lasers that has most caught the public imagination. The shower of sparks and flash of light from a metallic surface struck by a laser beam has become familiar. With today’s laser technologies generation of short-duration pulses of red or infrared laser light with power of the order of millions of watts in a simple case to several billions to trillions of watts in lasers driven military applications have been obtained as well. Such highpower pulses of laser radiation can vaporize metallic and refractory surfaces in a fraction of a second. It is these effects that we shall be dealing with to a large extent. Continuous powers available from lasers are more modest, but with the recent advent of the C02 laser, continuous powers have been increasing until several kilowatts are now available in a C02 laser system [5],. More details can be found in Ready, J. F. and Duley, W. W., books about the subject as well [5-6].

The directionality

The next property of laser radiation that is of interest in effects work is the directionality of the beam. Laser radiation is confined to a narrow cone of angles. Typically, for a gas laser system, the spreading angle is of the order of a few tenths of a milliradian, and for solid state lasers it is of the order of a few milliradians. Because of the narrow divergence angle of the laser radiation, it is easy to collect all the radiation with a simple lens system. The narrow beam angle also allows focusing of the laser light to a small spot. Therefore, the directionality of the radiation is an important factor in the ability of lasers to deliver high irradiances to a target and therefore to produce interesting effects.

The monochromaticity

The third property is the monochromaticity of laser radiation. This simply means that the laser light does not cover a wide range of frequencies as ordinary light does. To be sure, the frequency spread is not infinitesimally small, but in a gas laser it is fairly simple to obtain a frequency stability of one part in 1010.

In specialized models even higher frequency stabilities have been obtained. For solid state lasers, the frequency spreads are typically of the order of several megahertz. This is not so good as with a gas laser, but it is still very impressive. The monochromaticity as such generally plays very little role in producing laser effects. For vaporization of a metal surface, for example, it makes little difference whether the radiation is monochromatic or covers a broad band so long as a specified number of watts per square centimeter is brought to the surface. However, monochromaticity does make focusing easier in that chromatic aberration of the lens is unimportant. Moreover, in case of military applications, where High Energy Laser (HEL) that they have to travel through atmospheric environment would encounter a phenomenon known as “Thermal Blooming” monochromaticity and coherency (see next section) of dueling with target of interest play a very important roles to overcome adverse effect of thermal blooming issue [2].

The coherence

Finally, let us consider coherence briefly. This is a property that is of great interest in potential communication applications of lasers but is only of secondary interest in producing laser effects. Coherence is related to the narrowness of the beam divergence angle. An incoherent source can be focused to a small area only with a large sacrifice in the total power of the source, so that coherence properties are indirectly related to the ability of the laser to produce high irradiance. However, the coherence of the laser beam is not of primary concern. Generally, once a certain number of watts per square centimeter is delivered to a surface, the effect will be much the same whether the radiation is coherent or not.

Laser radiation absorption at opaque material surfaces

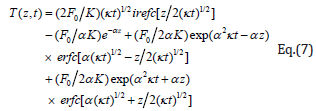

Application of high-power lasers in metallurgy, raises a most interesting phenomena associated with lasers involve the effects produced, when a high-power laser beam is absorbed by a metal with an opaque surface. The most noticeable effects can be observed, when absorption effect is involved with change of phase of absorbing materials; for example, the luminous cloud of vaporized material blasted from a metallic surface and often accompanied by a shower of sparks. However, in many cases, heating with no change of phase is also of interest, for example, in studies of thermionic emission and in thermomagnetic writing. Taking the simplest case under consideration in a one-dimensional case (i.e., z -direction), when there are no phase changes in material during the heating of the surface of the material and give methods to calculate the temperature rise produced when a beam of laser radiation is absorbed, in conjunction with a found solution for governing Equation (6). Details of how to solve the Equation (6), using Laplace Transform method is beyond the scope of this paper, yet the granular methodology can be found in a book by Zohuri [7]. Other aspects of phase absorption in metal such as transition from Solid, to Melting/Liquid and vaporization to Plasma stages also could be dealt with, but it is beyond scope of this paper as well and we refer the reader to References by Ready [5], Duley [6), Zohuri [7], and finally Carslaw & Jaeger [8] for more mathematical derivation steps of these different cases. However, generally speaking the solution for governing Equation (6) in One-Dimensional case with no phase changes of material during the heating surface of it with laser provides the following answer as:

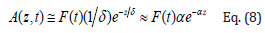

In this case, we have assumed that A(x, y, z,t) is the heat production per unit volume per unit time as a function of position and time and for one-dimensional case is presented by Equation (8) here as:

In above case, we assumed that F(t) is (1− R) times the irradiance incident on the surface (with R the reflectivity), and the spatial pulse shape is uniform with an infinite extent in the x − y plane. With this form we may consider many simple cases, such as the one, where the absorption coefficient α is relatively small and we are interested in the temperature at depths z of the order of 1 α The temporal pulse shape is flat, i.e., 0 F(t) = F = const for t ≥ 0 . Under these conditions, in a material of thermal conductivity K and thermal diffusivity κ , the solution to the heat flow equation is given by Equation (7). In this equation, erfc and ierfc denote the complimentary error function and its integral. This equation may be evaluated to give profiles in depth and time for the temperature rise produced by the laser pulse with the indicated properties. Note that other cases are also studied and can be found in references [5- 8].

Laser drilling

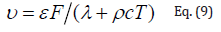

The rate at which material is removed in the vicinity of the laser focus becomes significant only when the incident flux and the duration of the pulse are such that the temperature can be brought to the boiling temperature of the material in a time shorter than the pulse length. When these conditions are satisfied, then a vaporization front is established, which has as its limiting speed as Equation (8).

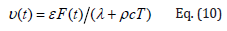

where F is the incident intensity (W/cm2), the of vaporization (J/cm3), p the density (g/cm3), c the specific heat (J/g 0C), T the vaporization temperature, and e the emissivity at laser wavelength. This equation assumes that flux F is incident uniformly over the free surface of a semi-infinite sheet and that all material vaporized is completely removed from the solid. In practice, Eq. (9) can also be used to describe the vaporization that occurs in drilling with a focused laser on a finite slab, provided the pulse length is less than the smallest thermal time constant for a particular set of boundary conditions. It can also usually be assumed that a vaporization equilibrium is reached in a time short compared with any fluctuations in the absorbed intensity and therefore that the speed of the vaporization front follows the time-varying absorbed intensity through Eq. (9). Thus, usually to a good approximation,

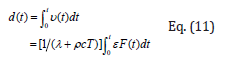

and

where dt is the depth of penetration of the vaporization front at time t .

This distance can be equated to the drilling depth. As we will discuss below, the temperature T is also a function of F(t) and tends to rise as F(t) increases. When convective and radiative losses are neglected, the use of available energy is divided between bulk heating of the material and vaporization of material below the focal spot. If drilling is to be done with relatively low intensities, long irradiation times are needed and the fraction of available energy used for bulk heating is very significant, especially when drilling metals. If short, high-power pulses are to be used, then a large fraction of the available energy can be used in the actual drilling process. More details about this matter can be found in book by Duley [6].

Metallurgy and laser hardening

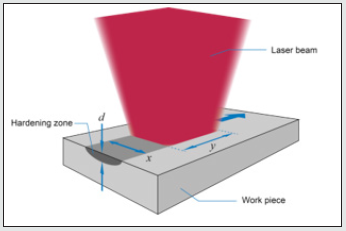

Laser hardening is the perfect solution for processing highly stressed, complex components. This is because there is practically no warping of the component during processing due to targeted heat input that is confined to local areas. You can even open up applications that would not be possible with conventional hardening methods such as induction or flame hardening using the non-contact laser process. Since the machining process can be controlled precisely, even geometrically complex and delicate components can be hardened. The result is surfaces that can be strongly stressed mechanically and chemically; they produce significant benefits in tool making, the automotive industry, and in agricultural technology. This a process of annealing that can take place on a precise spot on the target and annealing as we know is a process that by heating metal or glass and allowing it to cool slowly, in order to remove internal stresses and toughen it.

As (Figure 5), illustrates Laser hardening is an alternative to furnace or flame hardening for heat treatable metals. Some stainless and carbon steels, nickel alloys, and other materials can undergo structural changes when heat is applied for a specific time and temperature. These changes typically cause the material to become harder, and, because the transformation happens from the surface where the heat is applied, the internal portions of a heat-treated component can remain softer and more ductile. The metal hardening process and method, holistically described here with its goal in mind. The goal of all metal hardening processes is to ensure a structural transformation of steel and cast-iron materials with greater strength. First, the original ferritic-perlitic material structure is austenitized by heating, and then transformed into hard martensite by quenching. Here, hardening with high-power diode lasers has the decisive advantage of making an exclusive locally heat input at stressed areas possible. By this, at complex components, a partial hardening can be realized, while in other zones the ductility of the initial structure can be maintained. With induction hardening, such a local treatment is not possible in many cases and thus has disadvantages compared to laser hardening.

As the workpiece is only heated near the surface with a low hardening depth at laser brazing and the heat is discharged very efficiently over the neighboring material, in most cases there is no need for an additional quenching media, which keeps costs low. As the warpage is compared to other hardening techniques in quite a minimal way, additional methods to correct the material deformations can mostly be omitted. Type of laser used in this application is typically diode lasers that are used in hardening material surfaces. The processes of surface hardening with laser are generally usable for all materials at which classical hardening methods can be used due to the adequate carbon content. At laser hardening, only the especially stressed areas of the components are locally hardened, e.g., at steels and cast iron in tool manufacturing. The thermal treatment of wear or cyclical stressed component areas [9].

Conclusion

As we can observe by reading the above sections and content, there it goes a lot into interaction of laser with matter bot militarily and industrial-wise, which we barely scratched the surface of this technology. However, we have provided enough ground for the readers to start their own investigations if they need more information and move on with the subject of their own interest.

References

- Zohuri B (2017) Inertial Confinement Fusion Driven Thermonuclear Energy. 1st Edition, Springer Publishing Company New York.

- Zohuri B (2018) Directed Energy Weapons: Physics of High Energy Lasers (HEL). 1st Edition, Springer Publishing Company New York.

- (2016) American Board of Cosmetic Surgery. Laser skin resurfacing: top 8 things you need to know.

- https://www.verywellhealth.com/what-is-selective-photothermolysis-2710175

- Ready JF (1971) Effects of High-Power Laser Radiation. 1st (Edn) Academic Press, Publishing company, NY, USA.

- Duley WW (1976) CO2 Lasers Effects and Applications. 1st (Edn) Academic Press, New York, USA.

- Zohuri B (2021) Thermal Effects of High-Power Laser Energy on Materials. Springer Publishing Company, New Your, USA.

- Carslaw ΗS, Jaeger JC (1959) Conduction of Heat in Solids. 2nd (Edn) Oxford Univ. Press, London, and New York.

- https://www.laserline.com/en-int/laser-hardening/

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...