Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6921

Review Article(ISSN: 2641-6921)

Heat Pipe Driven Off Grid Hydroponic Heat System with Artificial Intelligence Assist Volume 4 - Issue 3

George Tannous1,2 and Bahman Zohuri3,4,5*

- 1Computer Science and Electrical, Computer Engineering, Chairman, International Technological University, San Jose, California

- 2Chief Executive Officer and Founder, Evolution Solar, Incorporation

- 3Galaxy Advanced Engineering, a Consulting Firm, Albuquerque, New Mexico

- 4Computer Science and Electrical, Computer Engineering, Adjunct Professor, International Technological University, California

- 5Golden Gate University, Ageno School of Business, Business Analytics School, USA

Received:June 14, 2021; Published: June 25, 2021

*Corresponding author:Bahman Zohuri, Computer Science and Electrical, Computer Engineering, Adjunct Professor, International Technological University, San Jose, California, USA

DOI: 10.32474/MAMS.2021.04.000187

Abstract

- Abstract

- Introduction

- Hydroponic Benefits

- Hydroponic System Components

- Light Source and Photovoltaic (PV) System

- Solar Collector Panels

- What is Heat Pipe and How It Works

- Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Artificial Intelligence Augmenting Hydroponic Control System

- Conclusion

- References

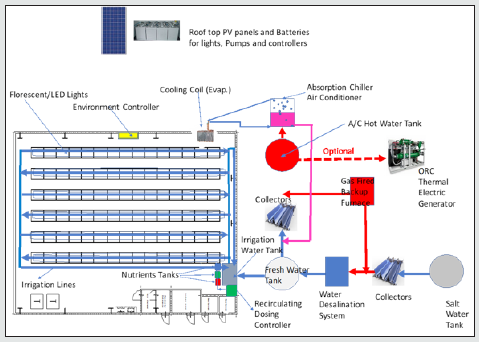

This is a patent pending solar energy powered (Thermal and Photo Voltage (PV)) hydroponic system that can be installed anywhere in the world. The system consists of scalable hydroponic technology, solar water purification system that provides clean water for the plants and advanced solar thermal collectors, based on Heat Pipe Technology, used to provide up to 400°F hot water supply. The hot water is used in an innovative air-conditioning system that uses an absorption chiller to replace the compressor in traditional air-conditioning systems and operates on heat source without electricity, except for the pumps that is powered by the photovoltaic panels’ arrays. The solar collectors are also used for water purification or even desalination, if necessary. The Light Emission Diode (LED) lights provides the necessary light for the plants, the low power pumps as well as the control systems are fully powered by the solar PV during daylight and solar-generated energy storage at night. Today widespread application of energy-saving equipment based on heat pipes makes a significant contribution to the task of resources saving. Using the heat pipes as heat transfer and heat exchange design elements allows creating new effective equipment generation for solar energy systems. Heat pipes are widely used both to improve the outdated equipment, increase its efficiency, reliability, and lifetime and in the creation of new high-quality and economic technology samples. Up to the present day there are the following systems and solar energy equipment where heat pipes are widely used: photovoltaic-thermal solar collectors, solar thermal collectors, concentrating photovoltaic and concentrating solar plant. The article presents an analysis of the current state and prospects of heat pipes used in solar energy systems

Keywords:Hydroponic System; Heat Pipe; Cost Effective; Artificial Intelligence; Machine Learning; Deep Learning; Price Optimization; Data Analytics and Predictive; Common Separated Value (CSV) Data

Introduction

- Abstract

- Introduction

- Hydroponic Benefits

- Hydroponic System Components

- Light Source and Photovoltaic (PV) System

- Solar Collector Panels

- What is Heat Pipe and How It Works

- Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Artificial Intelligence Augmenting Hydroponic Control System

- Conclusion

- References

In the past decade, technology has advanced drastically in many areas. Most technology investments were focused on the digital space, both hardware and software. While the digital market enjoyed a great adaptation of several technologies, such as new smart phones every few months, technology adaptation in other areas was lagging. Agriculture and environment fields could greatly benefit from new technologies in terms of food quality and availability, energy consumption, environmental pollution, water utilization and overall cost reduction. Hydroponics is an industry which is fast growing and has yet to reach its full potential. The use of hydroponics broadens the ability to garden in small spaces where adequate land is scarce and in arid or barren conditions not conducive to propagation. See (Figure 1) Though the benefits of hydroponic gardening are numerous and well documented, the commercial hydroponics industry has not hit the mainstream. The reason could be attributed to the initial capital cost of the hydroponic facility. As time passes, environmental concerns and a decline in arable lands will inevitably foster a global awareness of the advantages of hydroponics for farmers and home vegetable gardeners alike. Hydroponics is gardening without soil. In hydroponic gardening systems, plants are placed in a growing medium, water stream, or suspended in air and nutrients are provided directly to the roots. Many people are surprised plants do not require soil to live, but soil can sometimes be a very inefficient growing medium. Plants expend a great deal of energy growing root systems so they can search the soil for the water and nutrients they need to survive. By providing constant and readily available nutrition, hydroponics allows plants to grow up to 50% faster than they do in soil.

Hydroponic Benefits

- Abstract

- Introduction

- Hydroponic Benefits

- Hydroponic System Components

- Light Source and Photovoltaic (PV) System

- Solar Collector Panels

- What is Heat Pipe and How It Works

- Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Artificial Intelligence Augmenting Hydroponic Control System

- Conclusion

- References

Hydroponics Offers Many Benefits:

a. Nutrients - Complete control over nutrient balance.

b. No Yard Needed - Create a hydroponic garden in any indoor space.

c. Water-Saving - Hydroponic gardens use up to 90% less water.

d. Affordable - Get started on a very low budget and save on any size of project.

e. Higher Yields - Hydroponic gardens are far more productive for their size.

f. Better Results - Hydroponics produces better tasting, more nutritional results.

g. Year-Round Growing - With hydroponics, you control the season.

h. Enjoyment - Your success is all but assured with hydroponics.

i. Relaxing - All gardeners tell you the same thing, it is a relaxing hobby.

One of the heralded benefits of hydroponic gardening is how it can alleviate poverty while simultaneously easing strains on the environment. Hydroponic gardening systems can be set up to recycle water and nutrients, greatly reducing the resources necessary to grow food. Recycling hydroponic systems use as little as 10% of the water that traditional hydroponics and Organics systems require, a tremendous benefit in areas entirely dependent on irrigation. Hydroponic gardening virtually eliminates the need for herbicides and pesticides, and hydroponic gardeners need only use about 1/4 the fertilizer that traditional gardeners require. Off course one most important aspect of being Off-Grid System of Hydroponic is that being self-sustained and does rely on source of electrical energy coming from any network of electricity nationally or globally, yet via its own built in Solar Photovoltaic (PV) as illustrated in (Figure 2) here, allows such system to produce its own renewable source of energy for its own internal consumption. As the amount of arable land continues to decrease (over 10 million hectares per year are lost), another environmental benefit of hydroponic gardening will gain attention: Hydroponic gardens can produce the same yield as soil gardens in about 1/5 the space. And because artificially lit hydroponic gardens are not dependent on growing seasons, they can produce yields several times a year rather than just once. It has even been speculated that in decades to come, hydroponics will become a significant food source for over-populated urban regions, with people growing food on rooftops and/or in basements. As global warming becomes a bigger issue for the average citizen, consumers and government leaders are always looking for better ways to cut down on carbon dioxide emissions and help the environment. Perhaps one of the greatest ways countries can cut back on harmful greenhouse gasses is through examining how they produce and distribute their food supply. Hydroponic growing has numerous possibilities to not only produce, larger, better tasting vegetables, but also help the environment. Hydroponic growing may be the way to “go green” in the future. Here is why:

Hydroponic Growing Uses Less Land

It is estimated that approximately 10 million hectares of arable land is lost every year for a variety of reasons. With farmers being increasingly pinched on the amount of land that can be used for traditional soil gardening, hydroponics may prove to be the solution. Because every element of this style of growing can be closely controlled, it can produce larger yields, making the same amount of vegetables in just 1/5th of the space.

Hydroponics Can Grow Vegetables Anywhere

This is important because it cuts down on the distance that food may have to travel to reach its destination. Whenever a vegetable is out of season in one part of the world, it is in season in another part. So, these vegetables are often crated and shipped to those areas where they are not in season and the scarcity can drive up prices. The transportation of food requires a great deal of fossil fuel to move it to distant locations. With hydroponics, vegetables can grow virtually in any season in any part of the world, therefore, vegetables can be grown closer to their point of sale and hence, less fuel is used. Vegetables usually taste better too, because the shorter distance they travel means vegetables can be picked when they are ready or ripe.

Hydroponics Uses Less Water

When watering a typical soil garden, much of the water used gets lost in the soil, which means a lot more water needs to be used. In a hydroponic garden, the water is recycled, which means less water and stress on the increasingly strained water supplies.

Less Land Erosion

Traditional farming requires tilting the land, which can contribute to land erosion. Since hydroponics uses no soil, no land titling is required and therefore land erosion problems can be completely averted.

Fewer Pesticides

While pests are by no means completely absent in hydroponics systems, the closed, controlled environment can eliminate many of pesticides that are often necessary to keep bugs from destroying traditional crops. This means the plants are not much exposed to chemicals which could be less harmful to human consumption as well as to the environment. These factors, plus the improved taste resulting from this style of growing has made hydroponics the choice of many large-scale greenhouses. In fact, about 90% of the greenhouses in British Columbia use hydroponic growing at this time. As the benefits of hydroponics become more obvious over time, more greenhouses are sure to follow suit.

Hydroponic System Components

- Abstract

- Introduction

- Hydroponic Benefits

- Hydroponic System Components

- Light Source and Photovoltaic (PV) System

- Solar Collector Panels

- What is Heat Pipe and How It Works

- Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Artificial Intelligence Augmenting Hydroponic Control System

- Conclusion

- References

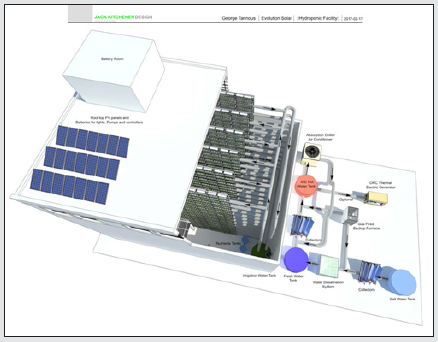

The details of system and components that is involved in it are left behind since suggested overall system offered by Dr. George Tannous is awaiting patent to be issued, while is in process. However, we have revealed enough information for our readers here to be acquainted enough with this suggested Off-Grid Hydroponic System so they can see, where components such as Heat Pipe technology and absorption chillers can be integrated as part of selfsustained renewable sour of energy and how Artificial Intelligence (AI) along with its sub-system such as Machine Learning (ML) and Deep Learning (DL) as explained below in this article play into overall of the system of hydroponic. The existing suggested design system components by Evolution Solar, are consisted of several states of the art components as follows and illustrated in (Figure 2) and (Figure 3) as well:

a. Building (facility).

b. Hydroponic racking system.

c. Water recirculation.

d. Water purification system.

e. Light Emission Diode (LED) lights.

f. Solar PV.

g. Solar hot water collector.

h. Water tank.

i. Water pump.

j. Solar Thermal Air Conditioning system.

k. Nutrient monitoring and control system.

Off-Grid Hydroponic System configuration are described as illustrated in (Figure 4 & Figure 5) as below. The hydroponic facility consists of a racking system and water channels that houses the seeds and the plants, LED lighting to provide the photons for the plants, the water tank, and the water pump. Bear in mind that, Many regions in the world cannot grow their own produce due to weather, soil quality, and water availability. Our hydroponic technology achieves high produce quality without dependence on soil and uses much lower water, in any climate. Our hydroponic facilities are based on a patented technology that achieves over 40% cost reduction in a 100% organic process. The hydroponic system uses patent pending technologies to grow vegetables in soil free and pesticides free vertical configuration. It is a perfect way to use the latest technology for the basic human needs. The hydroponic system has many advantages over traditional agriculture practices.

a. Vegetables can be grown at any location regardless of the soil or weather conditions.

b. All types of vegetable can be grown at any time of the year.

c. Much shorter time for seed to harvest (28 days for most greenleaf vegetables and 45 days for other vegetables and fruits such as cucumbers and tomatoes). Hence, much higher quantities and revenue.

d. Since the vegetables are grown in an indoor confined and conditioned environment, it is free of soil contamination, air contamination, and pests and insect contamination.

e. Vertical agriculture density (plant/square meter) is very high and therefore can be located in urban populated area and close to consumers. This minimizes the transportation cost and the time from harvest to consumption for fresh vegetables (from farm to dinner table).

f. Using organic minerals in the circulated water will produce 100% organic vegetables.

g. Circulated water system uses a fraction (10 to 15 percent) of the water used in traditional agriculture per plant (No wasted water in the ground).

h. Vertical agriculture requires much less labor and easier work in a comfortably air-conditioned environment.

There are many key benefits involved with implementation of Evolution Solar Off-Grid Hydroponic System designed by co-author Dr. George Tannous founder of the company and readers should reach out to him for more details and implementation discussions. However, some of them are listed here, which shows system optimization for faster organic vegetable growth even in remote areas:

i. Controlled Photosynthesis system (*Patented by Evolution Solar).

ii. Highest productivity.

iii. Environmentally friendly concept.

iv. Few moving parts.

v. Lower Equipment and Operating Costs.

vi. Standard hydroponic planting process

vii. Patented wave technology enhances natural ability to absorb nutrition into the roots.

viii. Produce grows faster and with more uniform and higher quality consistency and taste:

ix. 80% CAPEX reduction

x. 75% reduction of operating cost

Light Source and Photovoltaic (PV) System

- Abstract

- Introduction

- Hydroponic Benefits

- Hydroponic System Components

- Light Source and Photovoltaic (PV) System

- Solar Collector Panels

- What is Heat Pipe and How It Works

- Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Artificial Intelligence Augmenting Hydroponic Control System

- Conclusion

- References

Our system uses Florescent or LED light source to provide the right light frequency for the plants. The light source is powered by the solar PV panels that provide the DC power to the light source with very high efficiency without having to convert solar DC power to AC power. Additionally, the system uses a set of batteries for night use charged during the daylight using the PV solar panels.

Solar Collector Panels

- Abstract

- Introduction

- Hydroponic Benefits

- Hydroponic System Components

- Light Source and Photovoltaic (PV) System

- Solar Collector Panels

- What is Heat Pipe and How It Works

- Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Artificial Intelligence Augmenting Hydroponic Control System

- Conclusion

- References

Evolution Solar system uses Fluorescent or Light Emission Diode (LED) light source that need to tab to self-sustained renewable source of energy from sun radiation as demonstrated in Figure 2 in above to provide the right light frequency for the plants. The light source is powered by the solar PV panels that provide the DC power to the light source with very high efficiency without having to convert solar Direct Current (DC) power to Alternate Current (AC) power. Additionally, the system uses a set of batteries for night use charged during the daylight using the PV solar panels. This is an area the augmentation of heat pipe is shining as additional enhancement to production of renewable source of energy in a very efficient way, where helps to reduce the Total Cost of Ownership (TOC) and Return On Investment (ROT). As illustrated in (Figure 6), heat pipes can be integrated behind the solar collector panel as a means of passive heat exchangers. Design and efficient heat pipes are a tricky business that requires an optimum design of these heat pipes do not freeze nor burned out during their normal operation task depending on the environment where the combination of these heat pipes and hydroponic system are implemented as a whole. For more detailed design of heat pipes reader should refer to first author of this article Dr. Bahman Zohuri [1]. In summary, the Heat Pipe Technology as illustrated in (Figure 7) is a Revolutionary Collector for Industrial Process heat, desalination, solar Air-conditioning/Refrigeration and ORC Power Generation that the results in high efficacy solar energy collection without costly systems. Low-cost technology for temperatures up to 200 ˚C.

The heat pipe technology could prove to be the greatest advancement in solar heating in over 100-years. Low cost, solar energy collector technology that can be applied in any weather environment. Heat Pipe high temperature solar heating collector solves the heating needs of the enormous, yet underserved, commercial and industrial heating market. The market for high temperature Industrial Process Heat (IPH) includes such diverse applications as:

a. Absorption Cooling & Refrigeration

b. Drying.

c. Pasteurization, and sterilization.

d. Dehumidification.

e. Thermo-chemical treatment.

f. Waste treatment.

g. Laundries & Water Heating.

What is Heat Pipe and How It Works

- Abstract

- Introduction

- Hydroponic Benefits

- Hydroponic System Components

- Light Source and Photovoltaic (PV) System

- Solar Collector Panels

- What is Heat Pipe and How It Works

- Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Artificial Intelligence Augmenting Hydroponic Control System

- Conclusion

- References

The principle of the heat pipe is very simple. Phenomena involved are surface tension and the latent heat of the working fluid. There are no moving parts. Its effective thermal conductivity is hundreds of times more than conventional solid heat conductors. Substantial research in this field did not begin until the 1960s. Already there have been efforts made to employ heat pipes in various areas. Government agencies such as the NAVY can benefit from the useful characteristics of heat pipes. Several potential naval applications are discussed in the paper. More and more opportunities for the employment of the heat pipes could be realized as time goes on. Heat pipe technology may play a decisive role in improving the overall economics, and public perception on nuclear desalination, specifically on seawater desalination. When coupled to the Low-Temperature Multi-Effect Distillation process, heat pipes could effectively harness most of the waste heat generated in various types of nuclear power reactors. Indeed, the potential application of heat pipes could be seen as a viable option to nuclear seawater desalination where the efficiency to harness waste heat might not only be enhanced to produce larger quantities of potable water, but also to reduce the environmental impact of nuclear desalination process. Furthermore, the use of heat pipebased heat recovery systems in desalination plant may improve the overall thermodynamics of the desalination process, as well as help to ensure that the product water is free from any contamination which occur under normal process, thus preventing operational failure occurrences as this would add an extra loop preventing direct contact between radiation and the produced water. In this paper, a new concept for nuclear desalination system based on heat pipe technology is introduced and the anticipated reduction in the tritium level resulting from the use of heat pipe systems is discussed.

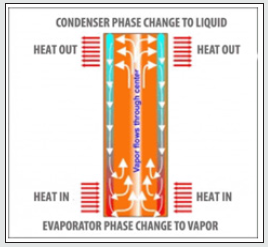

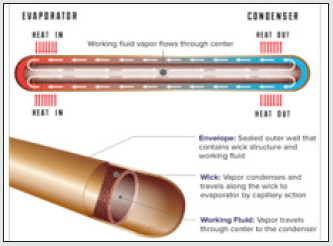

In summary, a heat pipe is a two-phase heat transfer device with a very high effective thermal conductivity. It is a vacuum tight device consisting of an envelope, a working fluid, and a wick structure. As shown in (Figure 7), the heat input vaporizes the liquid working fluid inside the wick in the evaporator section. The saturated vapor, carrying the latent heat of vaporization, flows towards the colder condenser section. In the condenser, the vapor condenses and gives up its latent heat. The condensed liquid returns to the evaporator through the wick structure by capillary action. The phase change processes and two- phase flow circulation continues as long as the temperature gradient between the evaporator and condenser are maintained. Heat pipes function by absorbing heat at the evaporator end of the cylinder, boiling and converting the fluid to vapor. The vapor travels to the condenser end, rejects the heat, and condenses to liquid. The condensed liquid flows back to the evaporator, aided by gravity. This phase change cycle continues as long as there is heat (i.e., warm outside air) at the evaporator end of the heat pipe. This process occurs passively and there is no external electrical energy required. At the hot interface of a heat pipe a liquid in contact with a thermally conductive solid surface turns into a vapor by absorbing heat from that surface. The vapor then travels along the heat pipe to the cold interface and condenses back into a liquid – releasing the latent heat. The liquid then returns to the hot interface through either capillary action, centrifugal force, or gravity, and the cycle repeats. Due to the very high heat transfer coefficients for boiling and condensation, heat pipes are highly effective thermal conductors. The effective thermal conductivity varies with heat pipe length and can approach 100 kW/(m·K) for long heat pipes, in comparison with approximately 0.4 kW/(m·K) for copper.

Heat pipes employ evaporative cooling to transfer thermal energy from one point to another by the evaporation and condensation of a working fluid or coolant. Heat pipes rely on a temperature difference between the ends of the pipe and cannot lower temperatures at either end below the ambient temperature (hence they tend to equalize the temperature within the pipe) (Figure 8). Heat pipes have an envelope, a wick, and a working fluid. Heat pipes are designed for very long-term operation with no maintenance, so the heat pipe wall and wick must be compatible with the working fluid. Some material/working fluids pairs that appear to be compatible are not. For example, water in an aluminum envelope will develop large amounts of non-condensable gas over a few hours or days, preventing normal operation of the heat pipe. Since heat pipes were rediscovered by George Grover in 1963, extensive life tests have been conducted to determine compatible envelope/fluid pairs, some going on for decades. In a heat pipe life test, heat pipes are operated for long periods of time, and monitored for problems such as non-condensable gas generation, material transport, and corrosion [1]. In addition to standard, Constant Conductance Heat Pipes (CCHPs), there are a number of other types of heat pipes, including:

1. Vapor Chambers (planar heat pipes), which are used for heat flux transformation, and is thermalization of surfaces.

2. Variable Conductance Heat Pipes (VCHPs), which use a Non- Condensable Gas (NCG) to change the heat pipe effective thermal conductivity as power or the heat sink conditions change

3. Pressure Controlled Heat Pipes (PCHPs), which are a VCHP where the volume of the reservoir, or the NCG mass can be changed, to give more precise temperature control

4. Diode Heat Pipes, which have a high thermal conductivity in the forward direction, and a low thermal conductivity in the reverse direction

5. Thermosyphons, which are heat pipes where the liquid is returned to the evaporator by gravitational/acceleration forces,

6. Rotating heat pipes, where the liquid is returned to the evaporator by centrifugal forces

Additionally, benefits of the heat pipe augmentation are listed below as overall systems:

A. High Thermal Conductivity (10,000 to 100,000 W/m K)

B. Isothermal

C. Passive

D. Low Cost

E. Shock/Vibration tolerant

F. Freeze/thaw tolerant

The followings are limitation of heat pipes in general as: a. Heat pipes must be tuned to particular cooling conditions. The choice of pipe material, size and coolant all have an effect on the optimal temperatures at which heat pipes work. b. When used outside of its design heat range, the heat pipe’s thermal conductivity is effectively reduced to the heat conduction properties of its solid metal casing alone - in the case of a copper casing, around 1/80 of the original flux. This is because below the intended temperature range the working fluid will not undergo phase change; and above it, all of the working fluid in the heat pipe vaporizes and the condensation process ceases.

c. Most manufacturers cannot make a traditional heat pipe smaller than 3 mm in diameter due to material limitations.

In conclusion, we may state that, Overall, a heat pipe is a heat-transfer device that combines the principles of both thermal conductivity and phase transition to effectively transfer heat between two solid interfaces. (Figure 9). Phase-change processes and the two-phase flow circulation in the Heat Pipe (HP) will continue as long as there is a large enough temperature difference between the evaporator and condenser sections. The fluid stops moving if the overall temperature is uniform but starts back up again as soon as a temperature difference exists. No power source (other than heat) is needed. In some cases, when the heated section is below the cooled section, gravity is used to return the liquid to the evaporator. However, a wick is required when the evaporator is above the condenser on earth. A wick is also used for liquid return if there is no gravity, such as in NASA’s micro-gravity applications

Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Abstract

- Introduction

- Hydroponic Benefits

- Hydroponic System Components

- Light Source and Photovoltaic (PV) System

- Solar Collector Panels

- What is Heat Pipe and How It Works

- Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Artificial Intelligence Augmenting Hydroponic Control System

- Conclusion

- References

Today widespread application of energy-saving equipment based on heat pipes makes a significant contribution to the task of resources saving. Using the heat pipes as heat transfer and heat exchange design elements allows creating new effective equipment generation for solar energy systems. Heat pipes are widely used both to improve the outdated equipment, increase its efficiency, reliability, and lifetime and in the creation of new high-quality and economic technology samples. Up to the present day there are the following systems and solar energy equipment where heat pipes are widely used: photovoltaic-thermal solar collectors, solar thermal collectors, concentrating photovoltaic and concentrating solar plant. The article presents an analysis of the current state and prospects of heat pipes using in solar energy systems. Utilizes heat pipes inside vacuum sealed glass tubes with a reflector also used to further increase the ability to absorb radiation. The collector operates by vapor rising to the heat exchanger shown on the left of Figure 7, where heat is then transferred to the systems primary circuit and condensed fluid flows back down the heat pipe. Choosing the correct collector can depend on the temperature of hot water required in the system and the climate where the system is installed. The suitability of a collector to a system therefore depends on the rated efficiency of the panel and suitability to the application. The vacuum envelopes in evacuated tube collectors reduce conduction and convection losses, which enables the collectors to operate at higher temperatures than flat plate collectors. This advantage means that these collectors are always used for high temperature applications. They also have the ability to absorb both direct and diffuse radiation like flat plate collectors but at lower incident angles their efficiency is greater. This effect tends to give Evacuated Tube Collectors an advantage over Flat Plate Collectors in day-long performance [2,3].

Artificial Intelligence Augmenting Hydroponic Control System

- Abstract

- Introduction

- Hydroponic Benefits

- Hydroponic System Components

- Light Source and Photovoltaic (PV) System

- Solar Collector Panels

- What is Heat Pipe and How It Works

- Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Artificial Intelligence Augmenting Hydroponic Control System

- Conclusion

- References

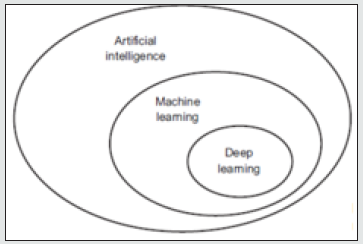

In the past decade or so, Artificial Intelligence (AI) has become known to us as a technology powered with capabilities at par with human intelligence. With advanced technological approaches such as Machine Learning (ML) and Deep Learning (DL) as integrated sub-systems to AI, combined, provide an excellent augmentation to make our daily lives and business operations more efficient. The rise of Artificial Intelligence (AI) with its large-scale adoption is pressing businesses to adopt AI applications. Sufficient conditions as Big Data and Machine Learning and consequently Deep Learning (DL) (i.e., see (Figure 10) are having an impact on most aspects of our modern life, from entertainment, commerce, banking, sports, cybersecurity, energy both renewable and non-renewable, and healthcare. Due to the capabilities and functionality of an integrated system of AI, ML, and DL as a whole (i.e., See(Figure 1), AI powered system and sub-systems have penetrated and been utilized across every industry. With the help of AI, enterprises including medical institutions are effectively dealing with sheer data for analysis [4]. In the medical field, research is important to find more effective ways to treat patients. AI capabilities help medical institutions not only in collecting important information but also in building models for effective diagnosis and decision making. With the augmentation of AI system and sub-systems of ML and DL, companies like Netflix know which movies and series people prefer to watch. Based on the data collection they build catalogs based upon the watching habits and behaviors of the consumers. Amazon knows which items people like to buy when and where, and Google knows various patterns of our web searches such as which health symptoms and conditions people are searching for. AI, along with ML and DL sub-system boosts the search engine such as Google and, drive its Data Analytics (DA) and consequently Predictive Analytics (PA), as effective as it can be. All this data can be used for very detailed personal profiling, which may be of great value for behavioral understanding and targeting and can predict trends in different, multiple areas. There is great optimism that the application of artificial intelligence (AI) can provide substantial improvements in all areas of economy including commerce, banking, multi-tier organization, with multi-tier operations, such as airline industry, as well as healthcare, from diagnostics to treatment. It is generally believed that AI tools will facilitate and enhance human work and not replace the work of physicians and other healthcare staff as such. There is great optimism that the application of Artificial Intelligence (AI) can provide substantial improvements in all areas of healthcare, from diagnostics to treatment [5].

It is generally believed that AI tools will facilitate and enhance human work and not replace the work of physicians and other healthcare staff as such. AI is ready to support healthcare personnel with various tasks from administrative workflow to clinical documentation and patient outreach and specialized support such as image analysis, medical device automation, and patient monitoring [5]. AI applications are growing at fast pace and dominating almost every industry by making their operations efficient and effective. Airline industry is no exception. They need to focus on adopting AI powered machine learning and deep learning technologies to achieve their profit and revenue goals especially during the time of crisis. Utilization of AI, ML and DL as system in any automated control system is very imperative and has been known for a quote long time. As matter of fact one can find such system in modern electrical grid control room, where artificial intelligence works as standalone and unsupervised system. Similarly, control system within suggested Evolution Solar for hydroponic system as illustrated in the right-hand-side of Figure-4, can use such AI system for all the controlling events that takes place in that location such, heat control system, electrical usage, air condition, etc. As a modern system of hydroponic as a whole, we are in process of implementing such a capability within our system by apply an appropriate algorithm of Python that our AI system relies upon it and can be used as modern control system, where it does apply. Most of the control systems today are working based on digital infrastructure implementing Fuzzy Logic (FL) first type such as the one you may find on your thermostat for your central HAVC in our homes or offices. By integrating AI systems combined we can introduce more modern and up to date approach via ML and DL as sub-system of AI.

Conclusion

- Abstract

- Introduction

- Hydroponic Benefits

- Hydroponic System Components

- Light Source and Photovoltaic (PV) System

- Solar Collector Panels

- What is Heat Pipe and How It Works

- Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Artificial Intelligence Augmenting Hydroponic Control System

- Conclusion

- References

Idea of gardening and growing vegetable or any other produce without presents of soil is nothing new, however methodology that can be used in order to make more efficient and yet independent of external man-made source of electricity is different. Our system relies on a natural renewable source of energy for production of electricity that system requires to use, thus it can operate off the grids, and off course that allows the system to operate in any remote area including Artic or Antarctic with its revolutionary suggest components as they were described within the content of this article. As we stated, hydroponics is a form of gardening that uses no soil, but instead grows plants in a solution of water and nutrients. A hydroponic system can grow plants and vegetables faster than growing outdoors in soil, and hydroponic systems can be used year-round. Plants grown hydroponically often yield more, require less space, and use less water than with conventional gardening. A hydroponic system also can be an ideal solution for apartment dwellers and urbanites who do not have an outdoor gardening plot. Four systems are suitable for beginners getting started with hydroponic growing: wick, water culture, and ebb and flow. More advanced systems include the nutrient film technique and the aeroponic system. The easiest plants to start with are greens like lettuce, spinach, Swiss chard, and kale; herbs like basil, parsley, oregano, cilantro, and mint; and fruiting plants like tomatoes, strawberries, and hot peppers. Our advanced system will bring to you a complete self-sustained system and operational one to you as whole. For more detailed information contact the authors of this article.

References

- Abstract

- Introduction

- Hydroponic Benefits

- Hydroponic System Components

- Light Source and Photovoltaic (PV) System

- Solar Collector Panels

- What is Heat Pipe and How It Works

- Heat Pipe Integration Driven Hydroponic Renewable Energy Source

- Artificial Intelligence Augmenting Hydroponic Control System

- Conclusion

- References

- Zohuri B (2016) Heat Pipe Design and Technology: Modern Applications for Practical Thermal Management. 2nd 2016 Edition, Springer Publishing Company, New York.

- Sivakumar K, Krishna N Mohan, B Sivaraman (2005) Performance analysis of elliptical heat pipe solar collector. Indian Journal of Science and Technology 4(1): 4-7.

- Ong KS, Tong WL, Sheriwati, Low K (2011) System Performance of Heat Pipe Solar Water Heaters. 10th

- Zohuri B, Zadeh S (2020) Artificial Intelligence Driven by Machine Learning and Deep Learning, Nova Science Pub Inc first edition.

- Bohr A, Memarzadeh K (2020) The rise of artificial intelligence in healthcare applications. Artificial Intelligence in Healthcare p. 25-60.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...