Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-6921

Research Article(ISSN: 2641-6921)

Compressive And Flexural Strength of Non- Hydraulic Lime Mortar with Metakaolin Pozzolan Volume 5 - Issue 1

Ash Ahmed1*, Georgie Haslam2, Charlotte Sutherland2, Colin Yates3, Lee Yates3 and Hafiz Nadir2

- 1Reader ( Associate Professor) Civil Engineering Group, Leeds Beckett University, UK

- 2Leeds Beckett University, UK

- 3Conserv Lime Products, UK

Received: December 17, 2021; Published: January 17, 2022

*Corresponding author: Ash Ahmed, Civil Engineering Group, Leeds Beckett University, UK

DOI: 10.32474/MAMS.2022.05.000202

Abstract

Mortar for masonry is important because it provides the linkage between masonry units so enabling the composite to behave as a single material. The type of mortar used determines the flexural and compressive strength of the masonry. Nowadays most mortars used in construction are cement based. However, due to the heavy energy-intensive processes that are involved in its production the cement industry is responsible for up to 10% of global CO2 emissions; therefore, there are serious environmental implications with the usage and application of cement mortars. A sustainable alternative are lime mortars which have 30% less embodied CO2. Lime mortars confer benefits in comparison to cement based mortars such as accommodating a greater degree of wall movement and improved damp resistance. The main disadvantage with lime mortars is the longer setting time which can take up to 91 days in addition to the low strength. A way to overcome this is to add cement replacements e.g pozzolans. This paper investigates the properties of non-hydraulic (lime putty) lime mortar containing metakaolin (MK). Findings show a minimal amount of MK addition of 2% increases the mortar strength to 2 MPa within 28 days with an eventual strength of over 17 MPa achieved with 10% MK. Strengths satisfying minimum requirements for all four mortar designations were achieved with between 2-8% MK addition, mostly within 28 days ageing. Therefore, non-hydraulic lime mortars with MK offer a more sustainable alternative to cement based mortars without compromising setting time or strength whilst offering improved flexibility and breathability.

Keywords: Mortar; Non-hydraulic Lime Mortar; Lime Putty; Metakaolin; Calcined Clay; Pozzolan

Introduction and Background

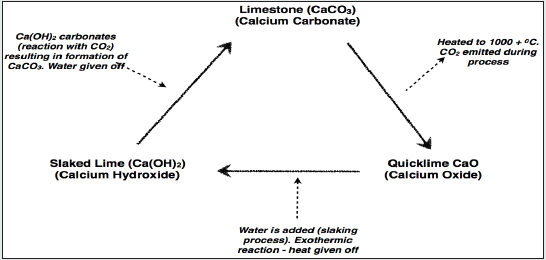

Mortar is a very important material in civil engineering as it bonds together bricks and blocks in dwellings. Traditionally there are two different types of mortars: lime and cement based. Lime mortar is the oldest type and has been used for centuries. This was the preferred type of mortar until cement mortars were developed. There are essentially three different types of lime, hydrated, nonhydraulic and hydraulic [1]. Figure 1 shows the lime cycle; lime is made by first burning chalk or limestone to form quick lime (calcium oxide or CaO) and then slaking the quicklime with water forming calcium hydroxide (Ca (OH2). If no clay is present in the original limestone or chalk, the resulting lime is said to be ‘non-hydraulic’. Lime putty usually contains calcium hydroxide (approx. 90%) and calcium oxide (approx. 10%); it stiffens and eventually hardens by reacting with carbon dioxide which is present in air to form calcium carbonate once again; a process known as carbonation. Non-hydraulic lime is usually used in the saturated form known as lime putty. Lime putty is produced by slaking quicklime with an excess of water for a period of several weeks until a creamy texture is produced. Alternatively, it can be made by stirring hydrated lime into water, followed by conditioning for at least 24 hours. Lime putty, often mixed with sand is used directly as a pure lime mortar, particularly in restoration and conservation work. It sets, not by reaction with sand and water, but only by carbonation and is therefore described as non- hydraulic. The carbonation process is very slow and therefore the mortar remains weak and vulnerable to damage for a significantly long period of time. A hydraulic lime or natural hydraulic lime (NHL) sets by hydration so it can set underwater [1,2]. For the NHL mortars, the lime is obtained from limestone which naturally contains an adequate percentage of silicates and/or aluminates in addition to calcium hydroxide. The process involves the burning of argillaceous or siliceous limestones followed by reduction to powder by slaking, with or without grinding. NHL comes in three European grades, NHL 2, NHL 3.5 and NHL 5; the numbers refer to the minimum compressive strength at 28 days as specified in EN 459 [2]. The NHL grades 2, 3.5 and 5 are also referred to as being feebly, moderately and eminently hydraulic, respectively. Both hydraulic and non-hydraulic lime mortars are breathable; hydraulic mortars have a quicker setting speed, however, non-hydraulic mortars can accommodate greater wall movement. The disadvantage with lime mortars is that they generally have longer setting times, this can delay construction time which can confer negative economic implications. The main advantage with cement based mortars is that maximum strength is achieved within 28 days. There are four different designations of cement mortars as shown in Table 1.

Table 1: Different designations of cement based mortars and respective mean and minimum compressive strength at 28 days, as per BS 5628.

With decreasing strength, there is increased flexibility, i.e.,

designation (iv) has the greatest flexibility. Typically, designations

(iii) and (iv) are used with bricks and low density blockwork

in construction [3]. However, cement is deemed to have a

considerably high carbon footprint, contributing immensely to

global anthropogenic CO2 [4]. Climate change is suggested to be a

phenomenon that can bring about a rise in global temperatures due

to the presence of excessive carbon dioxide (CO2) in the atmosphere,

and is cumulative and irreversible over timescales of centuries [5,6].

The burning of fossil fuels, in this case for the production of cement

contributes to the greenhouse gas effect, which is a major cause of

climate change [7]. As a result, the cement industry accounts for up

to 10% of the total global CO2 emissions, a considerably high level

when compared to 3% total global CO2 emissions attributed to the

aviation industry [8-10]. However, energy efficiency can be achieved

by reducing on the amount of clinker and utilising Supplementary

Cementitious Materials (SCMs), which require less process heating

and emit fewer levels of CO2 [8].

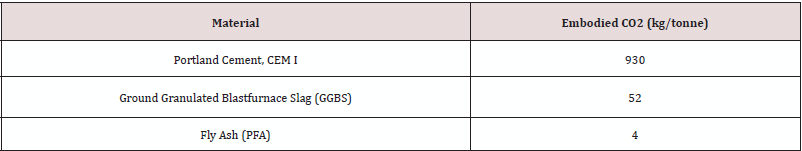

Established SCMs include PFA (also known as fly ash), ground

Granulated Blast Furnace Slag (GGBS), Metakaolin (MK) and Silica

Fume (SF). There are also novel / less established ones such as Rice

Husk Ash (RHA) from agricultural waste. PFA, GGBS, MK, SF & RHA

are known as pozzolans as they require a reaction with calcium

hydroxide to impart cementitious properties. Whereas GGBS is a

direct cement replacement as chemically it is very similar to cement

[11]. Table 2 shows the embodied CO2 values for cement (CEM I),

PFA and GGBS. Clearly, the embodied CO2 for both PFA and GGBS

is substantially less than CEM I, given most PCRs are either from

industrial waste or not an energy intensive process. When cement

reacts with water, Calcium Silicate Hydrates (CSH) form which is

the major contributor to strength in mortars and concrete. Most

pozzolans are silica rich (SiO2) which reacts with calcium hydroxide

to form the strength forming C-S-H. Therefore, it is possible to

increase the setting time and strength of lime mortars by adding

a pozzolan or GGBS. This paper reports the findings of a study

undertaken to verify the mechanical properties of non-hydraulic lime mortar containing MK as this can potentially reduce the curing

time and facilitate in alleviating a disadvantage associated with

lime mortars. Metakaolin (MK) is a dehydroxylated form of the clay

mineral kaolinite. It is obtained from manufacture of porcelain.

China clay (mineral kaolin) is heated up to a temperature between

600-800°C to manufacture MK. This pozzolan was used for the first

time in1960s in Brazil for construction of large dams. Originally, its

use in concrete started in order to repair any damage caused by

Alkali-Silica Reaction (ASR) [12]. Subsequent research has shown

MK to be a very effective pozzolan in concrete; used as a cement

replacement between 5-20% results in an increase in strength and

improvement in durability properties. Indeed, unlike GGBS and PFA,

MK concrete has impressive early age strengths. Furthermore, when

lime is manufactured, it produces less CO2 than the manufacture

of cement because it is being burnt at low temperatures which

saves fuel consumption and emissions of pollution and greenhouse

gasses. The embodied CO2 is therefore approximately 30% lower

than cement manufacture [13] ensuring it is more sustainable and

eco-friendlier as opposed to cement. Thus, a lime based mortar

incorporating MK can potentially overcome the slow rate of

strength development and become a more robust and sustainable

alternative to cement based mortars.

Materials & Methods

Experimental work was undertaken to establish the mechanical properties of non-hydraulic lime mortar containing a specified amount of MK content. A series of tests were carried out to evaluate the cube compressive and flexural strengths. Sample preparation and testing were carried out in accordance with appropriate standards as documented in this paper.

Test Materials

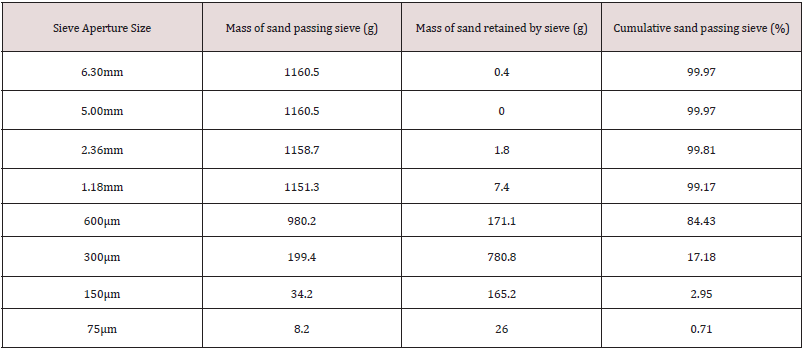

High calcium, fat lime putty (class A) matured for at least 120 days in accordance with BS EN 459 was used [2]. X-Ray Diffraction (XRD) analysis was conducted to elucidate the chemical constituents. Soft building sand was used. The particle size distribution of the sand is given in Table 3 and schematically shown plotted in Figure 2. Tests were carried out in accordance with BS 1200 [14] and the results indicate that the sand used complies with the requirements of the BS 1200 [14].

Specimen Preparation

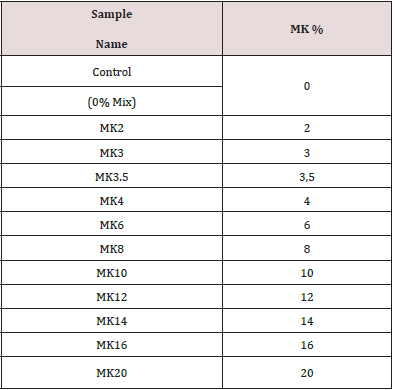

Mortar samples of the non-hydraulic lime mortar were produced to establish fresh and mechanical properties. Water was added so that the workability was consistent and corresponded to an approximate 10mm penetration of the dropping ball test as suggested in BS 5628 [3]. EN 1015: Part 3 [15] and BS 4551 [16]. Table 4 shows the mixes prepared which were in accordance with EN 998-2 [17]. The mix ratio was the standard 1:3 of lime putty: sand by weight. The MK was added as a percentage of the total weight e.g, with a 1:3 ratio, if ‘X’ kg of lime putty is used, the amount of sand = 3X kg. Hence, total amount of lime and sand = 4X (X+3X). For 10% metakaolin addition, the amount would be 4X ÷ 10 (kg); this amount woud be added to the lime + sand mix.

Properties Examined

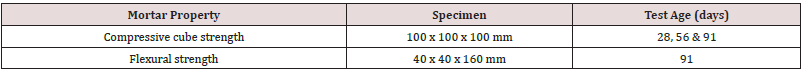

A range of properties were examined during experimental work as shown in Table 5. In all testing, three specimens were broken at each test age Table 4. Tests were carried out in accordance with EN 1015: Part 11 [18]. Test specimens were demoulded after 24 hours of casting and then stored in a laboratory where a constant temperature of 20°C was maintained throughout.

Results & Discussion

XRD Analysis

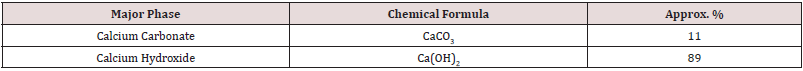

Table 6 shows the analysis on lime putty. As can be seen there are two phases present, calcium carbonate (11%) and the predominant constituent, calcium hydroxide (89%). Lime putty is manufactured by slaking quicklime in clean water then leaving it to mature [1]. i.e., CaO reacts with H2O to form Ca (OH)2 (calcium hydroxide).

Workability

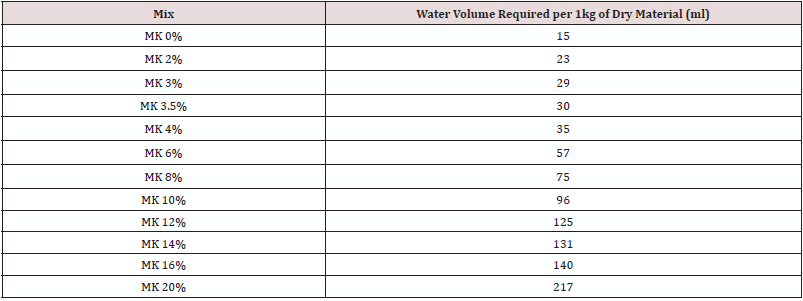

Table 7 shows the workability details for the mixes. The workability of a mortar, also referred to as its consistency, can be defined as how easy it is to handle, its provision of a sufficient bond and a smooth surface finish. The water content of a mortar determines its consistency, typically more water added leads to a more workable mix. The ease of use whilst wet, directly effects the speed and accuracy with which the mortar can be used. The water content also has an effect of the properties of the hardened mortar, such as strength and durability. A higher water content will also have an adverse effect on durability as a higher water content leads to larger capillary pores in the hardened mortar, which when exposed to elements such as frost or chemicals will allow ingress and hence reduce the durability of the structure [13]. Although the higher MK mixes have a greater water demand, findings have shown that MK addition to concrete significantly improves the durability properties, e.g., many concrete dam structures contain MK [12]. For each mix, water was added to obtain a standard 10mm drop ball consistency. The results show the required amount of water per 1kg of dry material. There is a discernible trend showing a direct correlation between water demand and increase in MK content. This is in accordance with workability behaviour in concrete [12]. Whereas PFA and GGBS addition increases the workability of mortar and concrete [7], MK has the opposite effect which needs to be taken into account for design mixes.

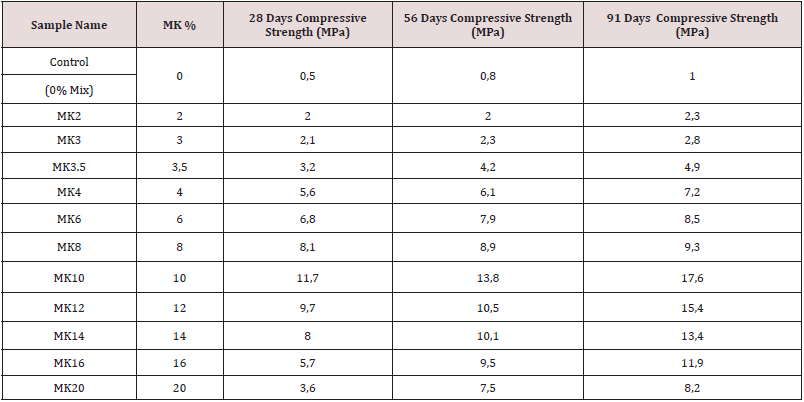

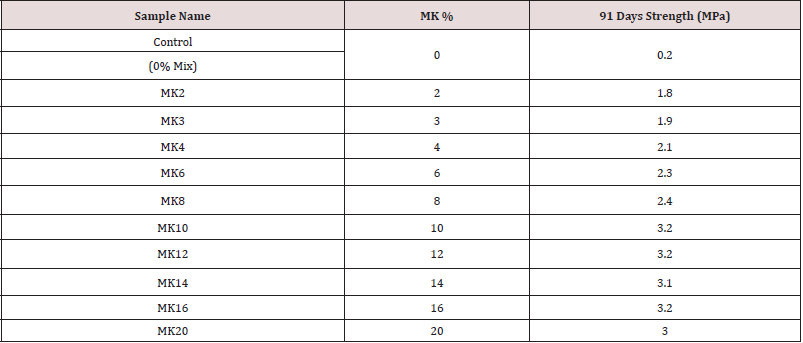

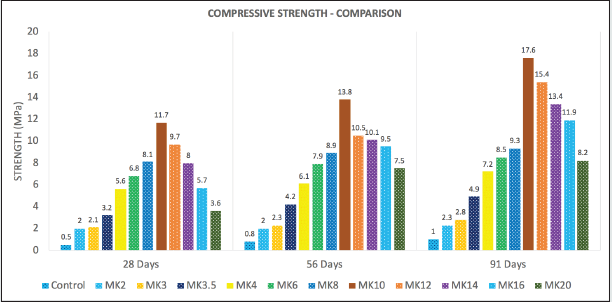

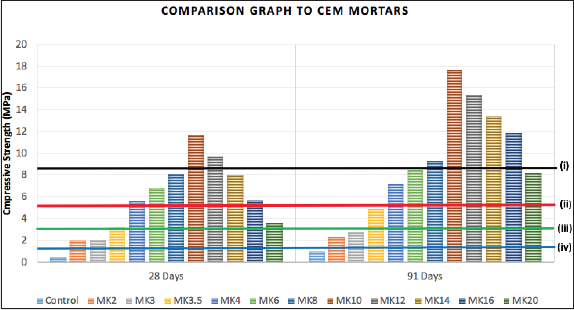

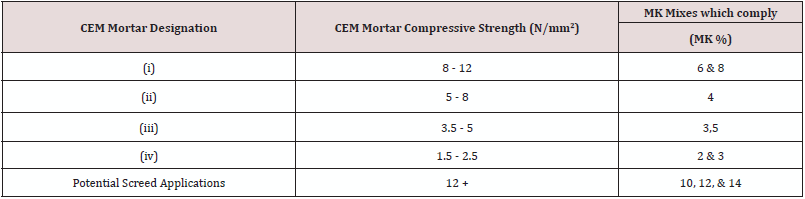

Table 8 show the compressive strength results of the mortar mixes with Figure 3 illustrating the compressive strength trends up to 91 days. Table 9 and Figure 4 show a comparison and classification of the MK mortars with cement (CEM) based mortars as per BS 5628 [3]. Table 10 shows the flexural strength of the MK mortar mixes after 91 days curing. The control mix as expected has a slow rate of strength gain. Non hydraulic lime mortars are generally very weak mortars which require several weeks to gain working strengths and months or even years to gain maximum strength [13]. This is due to the fact that lime putty mortars, unlike cement and hydraulic limes which set hydraulically with the addition of water, gain strength (or cure) by absorbing carbon dioxide from the air. This process, known as carbonation, is a very lengthy process with most lime putty mortars reaching a strength of about 1.5 MPa after 365 days. This is a clear disadvantage as it can slow progress on a construction site and furthermore, the lime putty mixes can be more prone to failure caused by frost damage during the winter months, e.g., the water in the lime putty mortar mixes can freeze and exert an internal tensile force leading to delamination of the mortar bed, cracking and eventual failure. Therefore, it is highly desirable to accelerate the curing time. Just a small addition of MK significantly reduces the curing time and increases strength; 2% MK addition increases the compressive strength at 28 days to 2 MPa, this is highly desirable especially for frost resistance. Table 8 and Figure 3 show up to 10% MK addition results in a substantial increase in strength, with 10% MK reaching over 17 MPa after 91 days. Figure 4 and Table 9 show how each MK mix can be classified in accordance (or a sustainable alternative) to CEM designation mortars, i.e., MKs 2 - 8% range all fall within the Designations (i) - (iv) as specified in BS 5628. 10% MK has potential application as a screed in construction, similarly also for MKs 12 & 14, although beyond 10% MK addition results in a subsequent decrease in strength. The flexural strengths (Table 10) compare favourably to cement based mortars [20]. The increase in strength for the lime putty mortar can be attributed to the pozzolanic reaction between CaOH2 and MK, is shown below [11,12].

Table 9: Classification of lime putty mortar with MK in comparison to cement based mortars as per BS 5628 (at 91 days).

Calcium Hydroxide + Metakaolin ---> Calcium Silicate Hydrate (CSH). The calcium silicate hydrate (CSH) phase is the major contributor to strength in concrete and cementitious materials [11]. Therefore, even with a minimal addition of the MK pozzolan of 2% is sufficient to initiate the pozzolanic reaction and thus resulting in increased strength. It should also be borne in mind in masonry, the strength of the mortar should not be greater than the brick or block. The properties of all the lime putty mortars with up to 8% MK (Figure 4 and Table 9) are in accordance as specified in BS 5628 [3], in fact the range of compressive strengths fall within all designations (i), (ii), (iii) and (iv). Therefore, lime putty (non-hydraulic lime mortars) with MK addition can be used in construction projects as a viable alternative to cement based mortars. The major benefit would be sustainability; as mentioned in the Introduction section, the cement industry emits three times more CO2 than the aviation sector, therefore, there are serious implications regarding the use of cement based materials. As lime based materials have a 30% lower embodied CO2 than cement [1,11]. They offer a greener, more environmentally friendly option. Furthermore, lime based mortars have the added benefit of being able to accommodate greater wall movement and improved damp resistance in comparison to cement based mortars.

Conclusion

a) Historically lime based materials have been used in

construction for centuries. However, over the past 50 years

cement based mortars are increasingly the preferred choice in

the construction due to their quicker setting times.

b) As the cement industry emits up to 10% of the global CO2

emissions which is three times greater than the aviation sector,

there are serious environmental implications regarding the

use of cement based products.

c) Lime based mortars have 30% lower embodied CO2 in

comparison to cement mortars, they also offer greater

flexibility and improved damp resistance.

d) The main drawback with lime based mortars is the slow setting

time, however, this can be overcome by adding MK pozzolan.

e) Non-hydraulic lime (putty) mortar with as little as upto 2% MK

addition (by weight) significantly accelerates the setting time

with strengths comparable to designations (iv) mortar. A 3.5%

MK addition increases the strength to designation (iii) level.

f) The strengths achieved for all lime putty mortars with up to

8% MK addition are in accordance with the minimum strength

specified for all designation mortars as specified in BS 5628:

Part 1.

g) Non-hydraulic lime mortars with MK offer a more sustainable

alternative to cement based mortars with lower embodied CO2.

Acknowledgement

The authors would like to acknowledge the assistance of Kev Smith and Andy Brannan, Leeds Beckett University. Gratitude also to Zahra BP for her support.

References

- Conserv Lime Products mortar-guide.

- BS EN 459, Building lime. Definitions, specifications, and conformity criteria.

- BS 5628-1:1992 - Code of practice for use of masonry - Part 1: Structural Use of Un-reinforced Masonry.

- Brien EJO, Dixon AS, Sheils E (2012) Reinforced and Prestressed Concrete Design to EC2: The Complete Process: Spon Press.

- Akinboboye F, Ogunfayo I, Dawodu H (2012) Assessment of the severity of CO2 emission from anthill soils used as replacement for shale in cement manufacture.

- Cline WR (1992) The Economics of Global Warming: Peterson Institute.

- Yerramala A, Desai B (2012) Influence of fly ash replacement on strength properties of cement mortar. International Journal of Engineering Science and Technology p. 4.

- Gambhir, Concrete Technology 4e: Tata McGraw-Hill Education 2009.

- Mehta PK (2001) Reducing the environmental impact of concrete, Concrete International, 23, 61-66.

- Johnson ME, Gonzalez A (2013) Estimating cost savings for aviation fuel and CO2 emission reductions strategies, Collegiate Aviation Review 1.

- Ahmed A, Kamau J, Pone J, Hyndman F, Fitriani H (2019) Chemical Reactions in Pozzolanic Concrete, Modern Approaches on Materials Science 1 (4): 128 -133.

- Aiswarya S, Prince G, Dilip CA (2013) Review on use of Metakaolin in Concrete, IRACST – Engineering Science and Technology: An International Journal (ESTIJ) 3: 3.

- Ahmed A, Davies M (2016) Sustainable High Performance Lime Mortar using Pozzolans, Lambert Academic Publishing ISBN 978-3-330-02520-2.

- BS 1200:1976 - Specifications for Building Sands from Natural Resources.

- BS EN 1015-3:1999 -Methods of Test for Mortar for Masonry - Part 3: Determination of consistence of fresh mortar (by flow table).

- BS 4551, Mortar - Methods of test for mortar and screed - Chemical analysis and physical testing.

- BS EN 998-2:2003 - Specification for mortar for masonry. Masonry mortar.

- BS EN 1015-11:1999 - Methods of Test for Mortar for Masonry. Determination of Flexural and Compressive Strength.

- MPA Mortar, Screeds Data Sheet.

- Ahmed A (2014) Comparison of Properties of Conventional Cement and Thin Layer Mortars, International Conference on Construction Materials and Structures. ICCMATS Johannesburg, South Africa.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...