Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2641-1652

Review Article(ISSN: 2641-1652)

Herbally Treated Electro Spun Nano Fibrous Membranes for Medical Applicatons* Volume 3 - Issue 2

N Gokarneshan*, PG Anandha Krishnan, D Haritha, Navya Sudheer and Fousul Inaya

- Department of Fashion Design and Arts, Hindustan Institute of Technology and Science, Chennai, India.

Received:February 01, 2022 Published: February 18, 2022

*Corresponding author: N Gokarneshan, Department of Fashion Design and Arts, Hindustan Institute of Technology and Science, Chennai, India

DOI: 10.32474/CTGH.2022.03.000165

Abstract

Curcumin is a naturally occurring hydrophobic polyphenol compound. It exhibits a wide range of biological activities such as antibacterial, anti-inflammatory, anti-carcinogenic, antifungal, anti-HIV, and antimicrobial activity. In this research work, antimicrobial curcumin nanofibrous membranes are produce by an electrospinning technique using the Eudragit RS 100 (C19H34ClNO6) polymer solution enriched with curcumin. The morphology and chemistry of the membrane are analyzed using scanning electron microscopy (SEM) and Fourier transform infrared (FTIR) spectroscopy. Kirby Bauer disk diffusion tests are carried out to examine the antibacterial effectiveness of the membrane. Experimental results show that the nano fibers produced are of uniform thickness morphology and curcumin is successfully incorporated into the nanofibrous mat, while no chemical bonding was observed between curcumin and the polymer. The antimicrobial curcumin nanofibrous membranes can be effectively applied as antimicrobial barrier in a wide variety of medical applications such as wound healing, scaffolds, and tissue engineering.

Keywords:Antimicrobial Nano Fibrous Membrane; Curcumin; Electro Spinning; SEM; FTIR; Kirby Bauer Disk Diffusion Test

Introduction

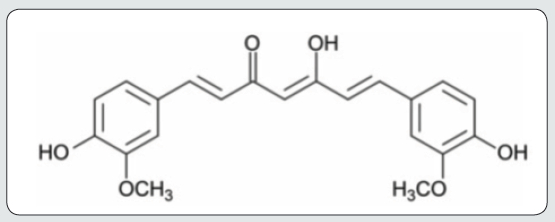

Nanofibers have emerged as exciting new class of materials, useful for many applications owing to their thickness (100 nm) and large surface-to-volume ratio [1]. Depending on polymer type, attainable fiber assembly, production rate, and cost, several techniques have been developed to produce nanofibers. Among these are electrospinning, melt-blowing, template synthesis, self-assembly, multi-component spinning, flash spinning, and nanolithography [2-8]. It is recognized that electro spinning is the most versatile fabrication process that can produce nano fibers from a wide range of polymeric materials at high production rate and low cost. Electro spinning is a process of applying high voltage between a polymer solution contained in a syringe with a capillary tip and a collector. Electro spun fibers are collected at the collector during the fabrication process in the form of membranes. The properties of nanofibers can be customized by regulating the voltage, concentration and viscosity of the polymer solution, and solvent composition [9]. Till the recent past, electrospinning of more than 100 varieties of natural and synthetic polymers, composites and ceramics into ultra-fine nano fibers have been demonstrated. Nano fibers can also be functionalized by mixing with functional additives or surface modification [10,11]. Electro spun nano fibrous membranes have found a wide range of applications in health care, energy storage, environment engineering and biotechnology due to their relatively light weight, high surface area, and interconnected porous structure.10 Recent developments in the field of nanostructures have opened up exciting opportunities for new materials design, such as nanofibrous membranes with antimicrobial properties for medical applications such as wound dressings [12,13]. Conventional wound dressings provide basic environments for wounds with regards to barrier to evaporation and protection from outside bodies. However, the biologically functional electro spun antimicrobial nanofibrous membranes encourage healing, and also compensate the functions of conventional wound dressing [14]. Antimicrobial agents inhibit the growth of microorganisms by bacteriostatic and bactericidal responses (they can, however, also be harmful in the case of specific allergies) [15]. Compared with synthetic alternatives, natural antimicrobial agents are less harmful, biocompatible, economically viable and readily available. Natural antimicrobial agents are the major chemical constituents of some common plants such as turmeric, aloe vera, basil and neem, etc. Turmeric was used in ancient times to promote wound healing because of one of its major chemical components, curcumin. Figure 1 shows the structure of the curcumin molecule. Curcumin is an anti-oxidant, anti-inflammatory, anti-cancer molecule used to reduce pain and accelerate the process of wound healing [16,17]. Curcumin dissolves in organic solvents such as ethanol, acetone and dimethyl formamide (DMF), and its anticoagulant property makes it suitable for drug-eluting stents [18]. Several researchers have successfully incorporated curcumin into biomaterials and observed its medical efficacy. Nguyen et al. produced curcumin loaded poly-lactic acid (PLA) nano fibers and reported its potential antimicrobial effectiveness. Xie et al. fabricated curcumin-loaded silk fibroin nanofibrous membranes and suggested that the drugloaded nano fibrous membranes can be useful as biomaterials with antimicrobial and antitumor function [19].

A wide range of natural (collagen, gelatin, chitosan, elastin, silk fibroin and alginate) and synthetic (PGA, PLGA, PCL, PLLA-CL, PEO and PVA) polymers are used to produce nanofibrous membranes for biomedical applications [20-22]. Natural polysaccharide polymers are biocompatible and biodegradable compared with synthetic polymers, and they display improved structural properties. In return, they have inferior mechanical properties. Consequently, copolymers of natural and synthetic polymers are sometimes mixed to enhance the functional properties of membrane [23]. Among the synthetic copolymers, Eudragit RS 100 (C19H34ClNO6) is greatly appreciated for biomedical applications because of its exceptional permeability and swelling properties [24]. For the first time, an economical and effective antimicrobial nano fibrous membrane is fabricated by applying an electro spinning technique on the Eudragit RS 100 polymer solution enriched with curcumin (a natural antimicrobial agent). Surface morphology and chemical composition of the nanofibrous membrane are studied using scanning electron microscopy (SEM) and Fourier transform infrared spectroscopy (FTIR), respectively. To evaluate application in the medical field, Kirby Bauer disk diffusion tests are carried out to examine the antibacterial effectiveness of the antimicrobial curcumin- loaded nano fibrous membranes. Based on the performance properties of the fabricated antimicrobial scaffold, its use is recommended in industrial applications such as tissue engineering, medical devices and wound care dressings.

Properties of polymer solution

The viscosity, surface tension and conductivity of the prepared polymer solutions for electrospinning of nanofibrous membranes were measured at 0 wt%, 1 wt%, 5wt% and 9wt% curcumin concentrations. The results from studies show a decreasing trend in viscosity and surface tension of the polymer solution with the increase in curcumin concentration. In order to achieve uniform and beadless nano fibers, the concentration of the electrospinning polymer solution should be above entanglement concentration (Ce), which is the minimum concentration required to develop nanofiber [25]. Lower viscosity of the polymer solution may cause electro spraying instead of electro spinning, while lower surface tension of the polymer solution leads to bead-free nanofibers production in electrospinning [26]. The addition of curcumin to the polymer solution was kept to the level to keep the viscosity above the entanglement concentration (Ce) threshold; therefore, at the attained viscosity, the workable range of polymer solution is expanded. A higher conductivity was observed when the concentration of curcumin was increased in the polymer solution. Wang et al. also reported the increase in conductivity with the addition of curcumin to the polymer solution and observed that the enhanced electrical conductivity favors the electrical drawing effect on the jet fluid and decreases the fiber fineness.

Morphology

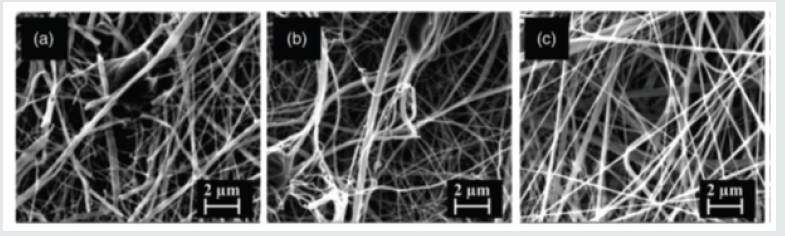

The SEM studies images showing the morphology of the electro spun nano fibrous membranes. The results evidence that the nano fibers are apparently produced with uniform thickness, and no accumulation of polymer mass in the form of beads was observed across the fibrous membrane. Researchers in the recent past reported that there are several electro spinning process parameters such as polymer concentration, applied voltage, type of solvent system, solution fed rate, type of collector and rotation speed that can affect the morphology of the nanofibers [27,28]. In this study, for all the specimens prepared, the electro spinning process parameters were first optimized and then kept identical during the series of experiments. As a direct consequence, diameter, layer thickness and distribution were found to be uniform in all nano fiber sheets.

The absence of bead formation and apparently even distribution of nanofibers in the nano fibers cluster shows the uniform dispersion of curcumin in the polymer and in the membrane. A relative discontinuity of nano fibers was noticed. However, uniform and continuous nano fibers were observed when the curcumin content in the polymer solution was increased to 9 wt%. The relative discontinuity noticed in Figure 2, can be ascribed to the lower capacity of these two polymer solutions to carry charges in comparison with the 9 wt% polymer solution. The latter seems to be the best doping concentration to obtain continuous and uniform thickness electro spun nano fibers at the designated optimized electro spinning conditions.

FTIR analysis

FTIR spectra of the polymer (Eudragit RS 100), antimicrobial agent (Curcumin) and the electro spun curcumin-loaded (9 wt %) nanofibrous membrane have been reported. The FTIR spectrum of the polymer reveals the presence of methyl band at 2930 cm-1, ester C-O band at 1724 cm-1 and C–O band at 1160 cm-1. Similar observations are reported in the literature by other researchers [29,30]. The FTIR spectrum of the antibacterial agent used in this study, The presence of hydroxyl, methyl, carbonyl and C-C bands have been evidenced at 3307 cm-1, 2950 cm-1, 1640 cm-1 and 1560 cm-1 bands, respectively. The observations are supported by the findings reported by Rohman et al. and Siregar et al. while working on curcumin-based drugs for medicinal applications [31,32]. Curcumin-loaded electro spun nanofibrous membrane FTIR spectrum, Figure 2, indicates the peaks for the constituents of polymer and curcumin such as at 3310 cm-1 (phenolic OH), at 1740 cm-1 (C=O ketone), at 2970 cm-1 (alkane CH3 stretching), at 1550 cm-1 (C=C) and at 1160 cm-1 (C–O). These results confirm the incorporation of antimicrobial agent (curcumin) into the nano fibrous membrane, while no apparent chemical linkages between the antimicrobial agent and polymer are observed.

Kirby Bauer disk diffusion test results

Inhibition zones were measured around the nano fibrous membrane without curcumin and 9wt% curcumin- loaded nanofibrous membrane disks in the agar plate. For the ease of comparison, the black arrows, visible in the pictures, identify the specimens loaded with antimicrobial agents. Studies have made it evident that the curcumin spreads into the agar and stops the growth of bacteria in the indicated zones compared with the zones having disks of nano fibrous membrane without curcumin. It is thus possible to conclude that the bacteria were totally killed after the incubation process and antibacterial activity of the nano fibrous membranes lasts even after 7 days. In order to avoid the spread of bacteria, different antimicrobial liquids were used on hand gloves during the material handling in the antimicrobial experiments. The lids look differently because the writing was erased during the experiment, and it was replaced. The inhibition of bacterial growth is confirmed by several researchers. Xie et al. exhibited the drug release properties of SF/PEG nano fibrous membranes loaded with curcumin. Nguyen et al. reported higher closure rates of wounds treated with curcumin-loaded PLA nanofibers. Wang et al. proposed that PVP nano fibers loaded with curcumin display enhanced bioavailability and effective anti-cancer effect. Hussain et al. proposed that alginate containing natural polyphenol based antimicrobial agents can be a potential candidate for wound care [33]. The current results show promising properties for the development of curcumin-based antimicrobial membranes for medical applications.

Conclusion

An economical and readily available natural antimicrobial agent, curcumin, extracted from a turmeric plant is successfully incorporated into a nano fibrous membrane using the electro spinning technique for medical applications. The nano fibrous membranes were characterized for morphology, chemistry and antimicrobial effectiveness. The SEM results show the formation of smooth, uniform and beadles nano fibers, clustered in a fibrous mat/ membrane when the concentration of curcumin was 9 wt%. The FTIR analysis confirmed the incorporation of antimicrobial agent curcumin into the nanofibrous membrane without chemical linkages between the antimicrobial agent and the polymer. The Kirby Bauer disk diffusion test results verified the antimicrobial effectiveness of the fabricated curcumin-loaded nano fibrous membranes. Future work in progress is in the direction of incorporating several other naturally occurring antimicrobial agents such as aloe vera, neem and basil, and their blends, into the nano fibrous membranes for high-end medical applications at lower cost.

References

- Kenry and Lim CT (2017) Nanofiber technology: Current status and emerging developments. Prog Polym Sci 70: 1-17.

- Ahmed FE, Lalia BS and Hashaikeh R (2015) A review on electrospinning for membrane fabrication: Challenges and applications. Desalination 356: 15-30.

- Zhang H, Zhen Q, Liu Y, Liu R, Zhang Y 2019 One-step melt blowing process for PP/PEG micro-nanofiber filters with branch networks. Results Phys 12: 1421-1428.

- Kim T, Naoki W, Miyawaki J, Park J, Lee C, et al. (2019) Synthesis of surface replicated ultra-thin silica hollow nanofibers using structurally different carbon nanofibers as templates. J Solid State Chem 272: 21-26.

- Mendes AC, Strohmenger T, Goycoolea F, Chronakis I (2017) Electrostatic self-assembly of polysaccharides into nanofibers. Colloids Surfaces. A Physicochem Eng Asp 531: 182-188.

- Yu DG, Gao LD, White K, White CB, Lu WY, et al. (2010) Multicomponent amorphous nanofibers electro spun from hot aqueous solutions of a poorly soluble drug. Pharm Res 27: 2466-2477.

- Nayak R, Padhye R, Kyratzis IL, Troung YB, Arnold L (2012) Recent advances in nanofibre fabrication techniques. Text Res J 82(2): 129-147.

- Ye Z, Nain AS and Behkam B (2016) Spun-wrapped aligned nanofiber (SWAN) lithography for fabrication of micro/nanostructures on 3D objects. Nanoscale 8: 12780-12786.

- Khil M, Cha D, Kim H, Kim I, Bhattarai N (2003) Electro spun nanofibrous polyurethane membrane as wound dressing. J Biomed Mater Res 67B: 675-679.

- Wang X and Hsiao BS (2016) Electro spun nanofiber membranes. Curr Opin Chem Eng 12: 62-81.

- Feng C, Khulbe KC, Matsuura T, Tabe S, Ismail A (2013) Preparation and characterization of electro-spun nanofiber membranes and their possible applications in water treatment. Sep Purif Technol 102: 118-135.

- Chen JP, Chang GY and Chen JK (2008) Electro spun collagen/chitosan nanofibrous membrane as wound dressing. Colloids Surfaces A Physicochem Eng Asp 313-314: 183-188.

- Jiang S, Ma BC, Reinholz J, Li Q, Wang J, et al. (2016) Efficient nanofibrous membranes for antibacterial wound dressing and UV protection. ACS Appl Mater Interfaces 8: 29915-29922.

- Seda Tig˘ li Aydın R, Erog˘lu AN, Karakecili A, Calimli A (2016) Designing double-layered nanofibrous membranes as a wound dressing material. Fibers Polym 17(11): 1765-1775.

- Ocampo PS, La´za´r V, Papp B, Arnoldini M, Wiesch PAZ, et al. (2014) Antagonism between bacteriostatic and bactericidal antibiotics is prevalent. Antimicrob Agents Chemother 58(8): 4573-4582.

- Nguyen TTT, Ghosh C, Hwang SG, Tran LD, Park JS (2013) Characteristics of curcumin-loaded poly (lactic acid) nanofibers for wound healing. J Mater Sci 48: 7125-7133.

- Wang C, Ma C, Wu Z, Liang H, Yan P, et al. (2015) Enhanced bioavailability and anticancer effect of curcumin-loaded electro spun nanofiber: In vitro and in vivo study. Nanoscale Res Lett 10: 439.

- Xie M, Fan D, Zhao Z, Li Z, Li G, et al. (2015) Nano-curcumin prepared via supercritical: Improved anti-bacterial, antioxidant and anti-cancer efficacy. Int J Pharm 496(2): 732-740.

- Xie X, Yu J, Zhao Z, Zheng Z, Xie M, et al. (2019) Fabrication and drug release properties of curcumin-loaded silk fibroin nano fibrous membranes. Adsorpt Sci Technol 37(5-6): 412-424.

- Bazbouz MB, Liang H and Tronci G (2018) A UV-cured nano fibrous membrane of vinyl benzylated gelatin-poly (ɛ - caprolactone) dimethacrylate co-network by scalable free surface electrospinning. Mater Sci Eng C 91: 541-555.

- Silva SS, Caridade SG, Mano JF, Reis RL (2013) Effect of crosslinking in chitosan/aloevera-based membranes for biomedical applications. Carbohydr Polym 98(1): 581-588.

- Li M, Mondrinos MJ, Chen X, Lelkes PI (2005) Electro spun blends of natural and synthetic polymers as scaffolds for tissue engineering. Annu Int Conf IEEE Eng Med Biol - Proc 7: 5858-5861.

- Bhattarai DP, Aguilar LE, Park CH, Kim CS (2018) A review on properties of natural and synthetic based electro spun fibrous materials for bone tissue engineering. Membranes 8(3): 62.

- Abhijit S and Amrish C (2013) Comprehensive review on Edragit polymers. Int Res J Pharm 4(5): 71-74.

- Tiwari SK and Venkatraman SS (2012) Importance of viscosity parameters in electrospinning: Of monolithic and coreshell fibers. Mater Sci Eng C 32(5): 1037-1042.

- Abutaleb A, Lolla D, Aljuhani A, Shin HU, Rajala JW, et al. (2017) Effects of surfactants on the morphology and properties of electro spun polyetherimide fibers. Fibers 5(3): 33-47.

- Gu SY and Ren J (2005) Process optimization and empirical modeling for electrospun poly (D, L-lactide) fibers using 1484 Textile Research Journal 91(13-14) response surface methodology. Macromol Mater Eng 290(11): 1097-1105.

- Sencadas V, Ribeiro C, Nunes-Pereira J, Correia V, Mendez SL, (2012) Fiber average size and distribution dependence on the electro spinning parameters of poly (vinylidene fluoride-trifluoroethylene) membranes for biomedical applications. Appl Phys A Mater Sci Process 109: 685-691.

- Reddy D, Dhachinamoorthi D, Sekhar KB (2013) Formulation and in vitro evaluation of antineoplastic drug loaded nanoparticles as drug delivery system. African J Pharm Pharmacol 7(23): 1592-1604.

- Verma P, Gupta RN, Jha AK, Pandey R (2013) Development, in vitro and in vivo characterization of Eudragit RL 100 nanoparticles for improved ocular bioavailability of acetazolamide. Drug Deliv 20(7): 269-276.

- Rohman A, Sudjadi, Devi, Ramadhani D, Nugroho A (2015) Analysis of curcumin in Curcuma longa and Curcuma xanthorriza using FTIR spectroscopy and chemometrics. Res J Med Plant 9(4): 179-186.

- Siregar C, Martono S and Rohman A (2018) Application of Fourier transform infrared (FTIR) spectroscopy coupled with multivariate calibration for quantitative analysis of curcuminoid in tablet dosage form. J Appl Pharm Sci 8(8): 151-156.

- Hussain F, Khurshid MF, Masood R, Ibrahim W (2017) Developing antimicrobial calcium alginate fibres from neem and papaya leaves extract. J Wound Care 26(12): 778-783.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...