Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Research Article(ISSN: 2637-4595)

To Study the Serviceability Properties of the Upholstery Fabrics Volume 2 - Issue 2

AK Choudhary* and Payal Bansal

- Department of Textile Technology, National Institute of Technology, Jalandhar, India

Received: May 22, 2018; Published: May 29, 2018

*Corresponding author: AK Choudhary, Department of Textile Technology, National Institute of Technology, Jalandhar, India

DOI: 10.32474/LTTFD.2018.02.000133

Abstract

Upholstery is the work of providing soft covering on chairs and seats that makes them more comfortable to sit on. Serviceability of upholstery fabric influences by various factors of fabric quality and manufacturing parameters. In this study, the effects of different GSM and weave/knit of upholstery fabric on abrasion, rubbing, tensile strength and flexural rigidity properties are studied. The test result revealed that woven fabrics with more float length show good flexural rigidity and good rubbing fastness. Fabrics where high binding points are there show good resistance to abrasion. The test result shows that for durability property woven fabrics should be best and whereas for aesthetics and comfort property knitted fabrics should be used.

Keywords: Fabric GSM; Fabric Structure; Abrasion; Rubbing; Tensile Strength; Flexural Rigidity

Introduction

The performance and durability of an upholstery fabric determines its serviceability, which will depend upon a number of factors, including the construction and use of the furniture, and its maintenance and care [1]. The fabric specifications for different end user requirements are different and the selection of an appropriate fabric is one of the most difficult jobs for upholstery manufacturer [2]. There are two basic methods of weaving upholstered fabrics as flat and pile. Fabric weaves are regarded as the structural pattern of different fabrics. How loose, decorative, tight, nubby or soft a certain fabric is, depends largely on the fabric weave. They can also cause a huge variance regarding the fabrics durability or strength. Fabric used to upholster commercial public seating needs to provide increased abrasion resistance due to the amount of traffic that the furniture encounters [3,4].

There are many kinds of fabric weave. The most common ones are twill, rib, plain, oxford, basket, satin, uncut pile, chenille weave, dobby, cut pile, double knit, leno, and jacquard. There are actually a lot of different fabric weaves that are initially made due to various purposes [5]. Also they can help in determining exactly how durable particular clothing is. Figuring out which type of weave works best for a specific type of clothing can prevent having an end product that easily becomes frayed. Pile weaves have cut or uncut loops that stand up on the surface of the fabric [6]. Plain, decorative and pile as some of the many categories of weaves commonly used to make upholstery fabrics. The plain weave is strong, versatile and appropriate for many different fibres and blends of fibres [7].

When any fibre or blend of fibres is woven together, the visual texture and pattern of the fabric is created. There are two basic methods of weaving upholstered fabrics: Flat and Pile. These two weaves are the beginning of all the furniture fabrics. Flat weaves are tweeds, twills and satins. They have no pile although they may be course and nubby; shantung, for example, because of the uneven size of yarns used. Pile weaves are velvet, plush, terry cloth, velour and corduroy. The pile weave is raised loops, cut inter lacing’s of double cloths and other erect yarns or fibres, deliberately produced on cloth forming the surface of the fabric [8,9].

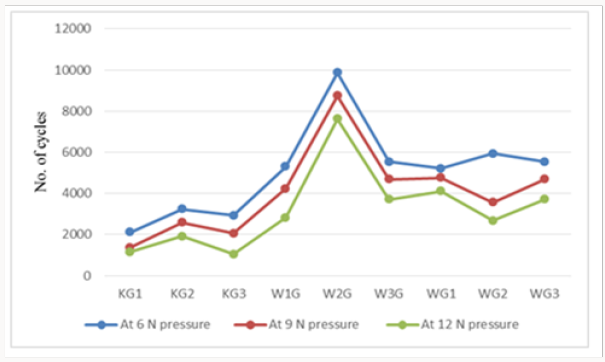

Experimental Material and Method

Testing Material

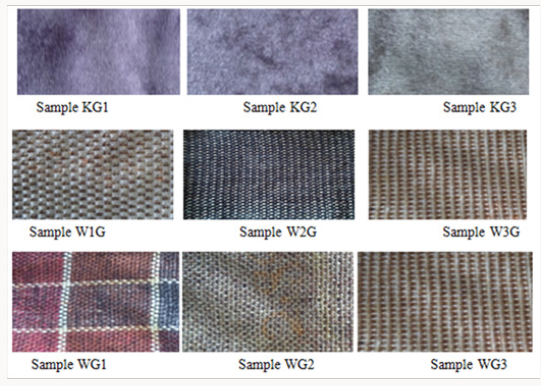

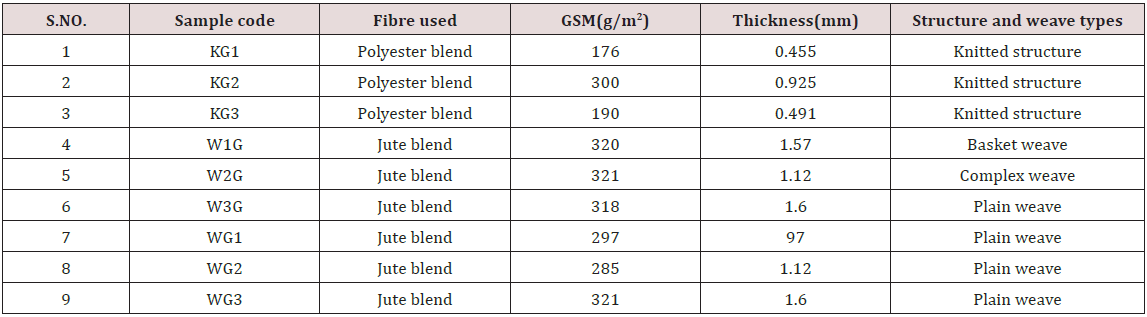

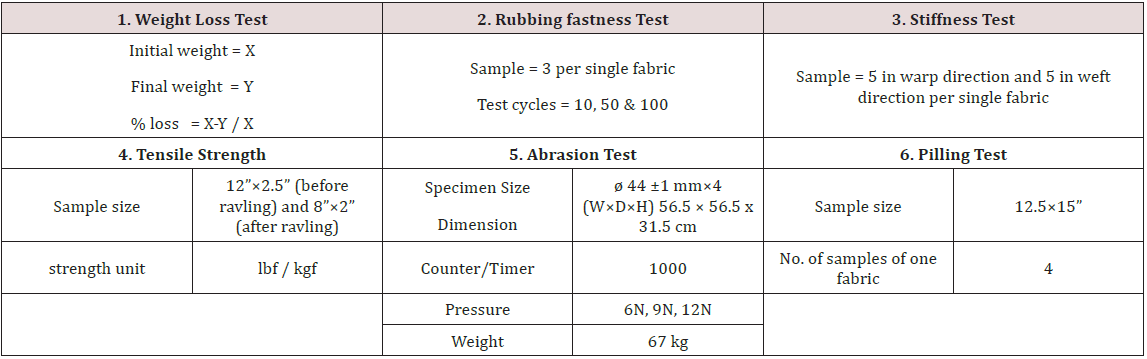

We have taken total 9 fabrics which have been divided in the group of 3-3 samples. First 3 fabrics are knitted structure with different GSM. These samples have same CPI and WPI. Next set of fabrics include same GSM with different weave and another set of samples include fabric with different GSM but with same weave as shown in Table 1. All 9 fabric samples are viewed under microscope to know about its structural parameters as shown in Figure 1. These are different kind of tests that can be performed on sofa fabrics like thickness, stiffness, rubbing, tensile strength, weight loss, abrasion and pilling test.

Result and discussion

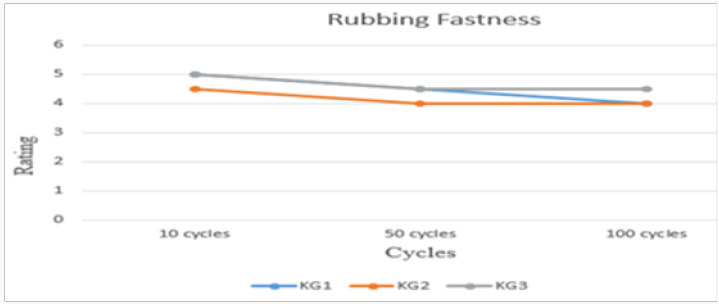

Influence of fabric structure, GSM and fabric weave on tensile strength

The tensile strength of all 9 samples is shown in Figure 1. The test results revealed that fabric structure i.e. woven and knitted structure of fabric affect the tensile properties. The tensile strength of knitted fabric is lower as compared to woven fabrics. In woven fabrics, load is being handled by fibres fully as they are straight not in loop forms. Whereas knitted samples show elongation as loops will be elongated first and then they show somewhat strength. Among this group of knitted fabric samples, sample KG2 show high strength as shown in Figure 2 because number of fibres in meter square is high so load will be bearded by high number of fibres which will prevent the fabric from being torn out. In other group, plain weave fabric (W3G) show high strength as fibres are straight and there is no float in fabric as in basket weave float. This is may be due to as fibres will provide cohesion to one another which leads to high tensile strength. Moreover, the number of binding points in plain weave is more. In this next group of fabrics all having same weave, so the effect of weave is nullified. In this sample WG3 show high tensile strength because of high GSM. Sample WG1 has high binding points as compared to Sample WG3 because of high ends per inches & picks per inches, but the number of fibres in sample WG3 is high which assist each other by providing cohesion and prevent breakage.

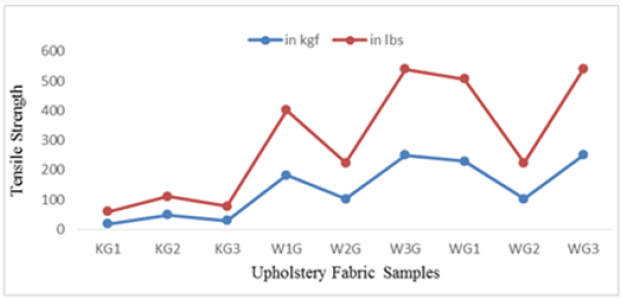

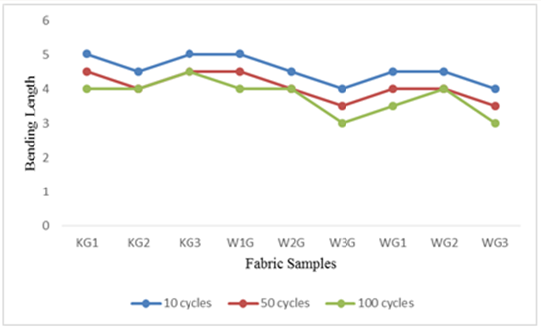

Influence of fabric structure, GSM and fabric weave on rubbing fastness

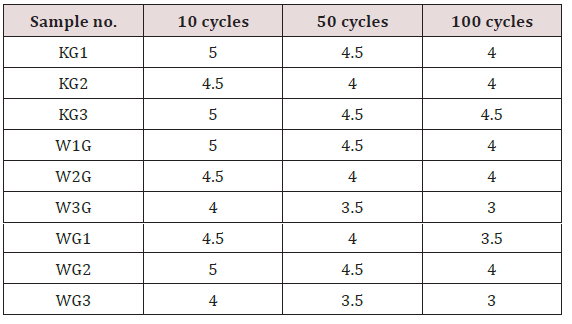

Rubbing fastness of all knitted and woven fabrics are testing using Crock meter. Three cycles 10, 50 and 100 are selected for effective rubbing of knitted and woven fabrics. Results are shown in Figure 3 and Tables 2 & 3. Rubbing fastness of knitted samples is high as compared to woven samples because in knitted samples dyed yarn is used which has high stability and fastness properties as compared to woven one’s where fabric dye is carried out. Sometimes dye May or may not be penetrated inside fabric, which can easily be removed when the fabric is being rubbed against certain abradant. Moreover, if the dye used in fabric is of red, black & blue colour, the rubbing fastness of these dye are very low. In woven fabrics, the yarns are present on surface as compared to knitted structure in which yarns are in loop stage which is not in direct contact with abradant but in woven fabrics, surface yarn are in direct contact with abradant which leads to removal of colour from fabric.

In this set of samples, sample KG2 show comparatively lower rubbing fastness as compared to remaining two, because of high GSM. High GSM leads to increase in number of fibres or yarns in particular area of fabric which leads to more contact points with abradant. Due to more contact points, rubbing fastness of sample KG2 is lower. At 100 cycles sample KG1 & sample KG2 show same rubbing fastness because of the increase in number of cycles, pressure of abradant will be same on both the samples. In other set of samples, plain weave show lowest rubbing fastness because there is no float in plain weave which leads to high contact of yarn with abradant leads to colour removal from this sample. In basket weave sample (W1G) where there is float of 2, 2 yarns are up and down continuously which prevent the contact of yarn with abradant. In this group of samples, all weaves are plain yet sample WG3 show lowest Rubbing Fastness because of high GSM in this group. Due to increase in GSM, there leads to increase in no. of fibres/ yarn which lead to more contact points with abradant, leads to low rubbing fastness. Sample WG2 has low GSM Test procedure tables. among these three which leads to high rubbing fastness which can be easily be seen from Table 2.

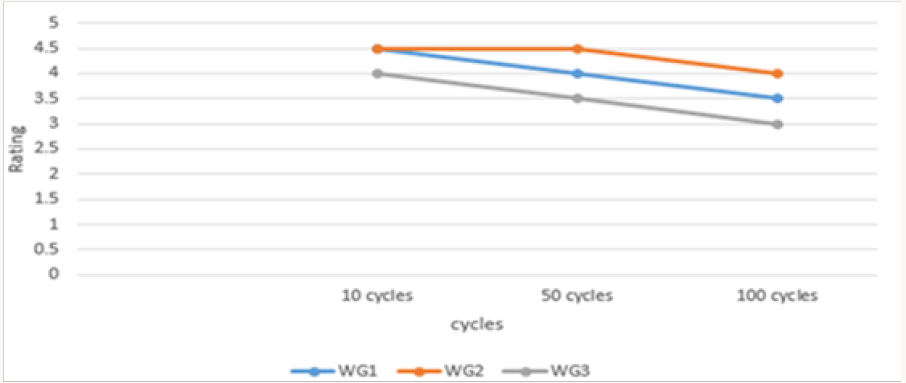

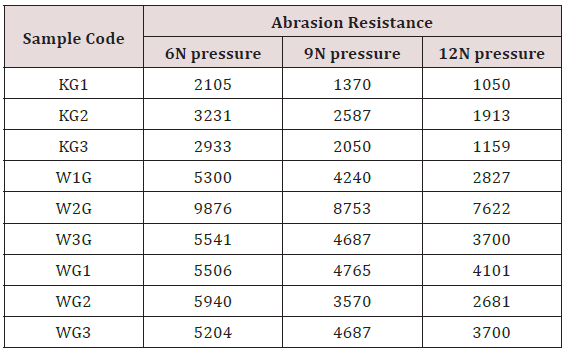

Influence of fabric structure, GSM and fabric weave on abrasion properties

Abrasion depends on number of binding points rather than GSM in case of woven fabrics, whereas in case of knitted fabric it depends on GSM as there are no binding points in knitted sample. Woven fabrics show high resistant as compared to knitted due to high inter fibre cohesion, which prevent breakage of threads and provide high resistant to abrasion. In woven fabrics binding points are there which helps to bind the fibres and load is being taken by group of fibres.

In the first group, sample KG1 show high abrasion resistant because of high GSM, as no. of fibres are more, so more cohesion will be there. More number of loops is there in these fabrics. As shown in Table 4 and Figures 4 & 5 test results shows that GSM is varied but the weave is same, sample WG1 show high abrasion resistant because of high GSM and High EPI & PPI. Due to increase of GSM, there is increase of fibres which lead to increase in inter-fibre cohesion. With increase in EPI & PPI, the binding points increased which provide high abrasion resistant. Sample WG3 show lowest abrasion resistant because of low EPI & PPI and low GSM of fabric. In the next set of fabrics, complex weave (W2G) will show highest abrasion resistant because of very high EPI and PPI which means more number of binding points are there as GSM of all samples are same. After that plain show high abrasion resistant as compared to basket weave as in basket weave there is float of 2 which leads to reduction in binding points which means low abrasion resistant.

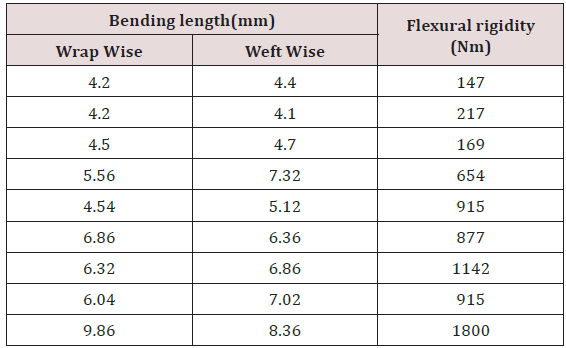

Influence of fabric structure, GSM and fabric weave on bending length

This parameter is necessary for cushioning effect and comfort characteristics. How well a fabric can take shape of cushions, it depends on drapability of fabrics. Knitted fabrics show higher drapability (As shown in Figure 6 and Table 5 and less stiffness, so they show better cushioning effect.

Conclusion

Following conclusions have been drawn from above experimental work:

a) The abrasion resistance of complex weave upholstery fabric is higher than plain and basket weave, due to high binding points in the fabric.

b) Upholstery fabric weight influences the abrasion resistance of upholstery fabrics. Increases the fabric weight increases the abrasion resistance.

c) Woven upholstery fabric shows high abrasion resistance as compared to knitted upholstery fabrics.

d) As fabric weight of upholstery fabric increases, decreases rubbing fastness in both woven and knitted upholstery fabrics.

e) Woven upholstery fabrics with longer floats show high rubbing fastness than with shorter floats.

f) When comparing woven and knitted, knitted structures show high rubbing fastness.

g) As increases fabric weight of upholstery fabrics, flexural rigidity increases in both woven and knitted fabrics.

h) In woven fabrics, weaves with longer floats shows lower flexural rigidity.

i) An upholstery fabric of knitted structure shows higher cushioning effect or comfort characteristics than woven fabrics.

References

- Tremblay KR, Williams K (2007) Selecting Upholstered Furniture for Your Home.

- Upholstery Basics (2009) Cowles Creative Publishing.

- Paek SL, Pilling (1989) Abrasion Tensile Properties of Fabrics from Open-End and Ring Spun Yarns, Textile Research Journal 59(10): 577- 583.

- Saville BP (2000) Physical Testing of Textiles (1st edn.), England: Wood head Publishing Limited.

- Pamuk G, Çeken F (2008) Comparative Study of the Abrasion Resistance of Automobile Seat Covers. Fibres & Textiles in Eastern Europe 16(4): 57-61.

- Hatice Kübra Kaynak, Mehmet Topalbekiroğlu (2008) Influence of Fabric Pattern on the Abrasion Resistance Property of Woven Fabrics. Fibres & Textiles in Eastern Europe 16(1): 54-56.

- Kalaoğlu T, Onder E, Ozipek B (2003) Influence of Varying Structural Parameters on Abrasion Characteristics of 50/50 Wool/Polyester Blended Fabrics. Textile Res J 73(11): 980-984.

- Marilyn Joan Levy, Rosalie Rosso King (1980) Pile upholstery fabricsconstruction characteristics and abrasion resistance. International Journal of Consumer Studies 4(2): 167-177.

- Kadir Bilisik, Gaye Yolacan (2009) Abrasion Properties of Upholstery Flocked Fabrics, First Published, TRJ 79(17): 1625-1632.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...