Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Review Article(ISSN: 2637-4595)

Some Significant Trends in Conductive Textiles Volume 2 - Issue 3

N Gokarneshan1* and G Naren Srivatsav2

- 1 Department of Textile Technology, Park College of engineering and technology, Tamil Nadu, India

- 2 Department of Electrical and electronics engineering, Srivenkateswara College of engineering, Tamil Nadu, India

Received: June 14, 2018; Published: June 20, 2018

*Corresponding author: N Gokarneshan, Department of Textile Technology, Park College of engineering and technology, Tamil Nadu, India

DOI: 10.32474/LTTFD.2018.02.000136

Abstract

The article critically reviews some of the significant advances in conductive textile materials. Body motion signals indicate several pathological features of the human body, and a wearable human motion monitoring system can respond to human joint motion signal in real time, thereby enabling the prevention and treatment of some diseases. Because conductive fabrics can be well integrated with the garment, they are ideal as a sensing element of wearable human motion monitoring systems. In situ polymerization has been used for the preparation of poly pyrrole conductive fabric. Investigations have been carried out relating to the anisotropic property of the conductive fabric resistance, resistance-strain relationship, and the relationship between resistance and the human knee and elbow movements. In another development, a novel two-step method has been developed for fabricating silver plating cotton fabrics (SPCFs) with high electrical conductivity and excellent washing fastness. Cotton wrapped nichrome yarn, copper core conductive yarn, optical core conductive yarn POF of different diameters have been developed to produce, nichrome fabric, copper core conductive fabric, optical core conductive fabric and tele intimation fabric.

Keywords: Conductive Fabric; Polypyrrole; Silver Plated; Electromagnetic Shielding Effectiveness; Copper Core Yarn; Wearable Electronics; Smart Textiles

Introduction

In day to day life, textile materials are being used. In one instance they are used as garment to protect human body from heat or cold. As fabrics they are used for covering the surfaces of floors, or the upholstery of car seats. On the other hand electronic devices are spreading - but still some people do not have the knowledge to use them. So the next step to spread these electronics is to improve the user interfaces. Wearable Electronics could offer improved interfaces and make it easier for the user to accept electronic devices in everyday life. When textile materials are integrated with electronic sensors and actuators, they can prove useful in many end uses. Unfortunately, it is difficult to identify the needs without knowledge on the application in these fields. There is little interaction between the electronics-in-textiles community and respective industries. Currently the purpose of textile conductors for electronics in textiles have not been intended for transmitting energy or data but rather for the sake of anti-static and antibacterial functions. These threads need to be improved regarding conductance, process ability, reliability and signal transmission capability. Also isolation of textile integrated conductors has been neglected although it is required by most applications. Existing garments are primarily designed for protective functions, including protection from extreme cold, physiological monitoring for emergency conditions, and wearer GPS information for emergency intervention [1,2]. Smaller electrical devices that can be worn and carried have been made possible through the process of continuous miniaturization.

Measuring human movements is beneficial to rehabilitation, training, or exercises. A motion capture system, which consists of cameras, accelerometers, and flexible electro gonio meters, has been used to monitor human motion [3]. Despite the motion capture system being able to make accurate measurements, conventional sensors fixed on the cloth by strap or other techniques render them incapable for use owing to discomfort and inconvenience. During the flexion of a limb, the skin around the joint stretches, as does the surrounding clothing. In order to achieve general comfort from the fabric, it needs 25-30% stretchability, since the skin around the knee stretches lengthwise about 40% of its normal length [4]. Textile solutions are well suited for constructing a sensing system that is comfortable for the wearer, because it can integrate well with clothing.

Owing to the quick advances and large market prospectus relating to wearable electronics and smart textiles, conductive fabrics have been the focus of researchers [5,6]. Conductive fabrics can be applied to many fields, such as textile electrode [7], electromagnetic shielding [4-6], and heating fabrics [8]. A number of techniques are available for producing conductive fabrics which include coating metals, metallic salts films, and conducting polymers on the fabric surfaces. The term -Smart Textiles‖ refers to a broad field of studies and products that extend the functionality and usefulness of common fabrics. Textile materials like fibers and filaments, yarns together with woven, knitted or non-woven structures that can interact with the surroundings/user are termed as smart textiles. The convergence of textiles and electronics (e-textiles) can be relevant for the development of smart materials that are capable of accomplishing a wide spectrum of functions, found in rigid and non-flexible electronic products nowadays.

Conductive fabrics as wearable electronics

User friendly methods have been evolved by scientists for development of methods which enable e-textile technology to be available to crafters, students, and hobbyists [9]. Also possible to develop transmission lines structures screen-printed on fabrics [10] as well as photonic textile displays woven on a Jacquard loom. Wireless communication and wearable computers coupled with clothing forms a new approach to wearable computing [11,12]. ‘‘Tool Model’’ and ‘‘Clothing Model’’ describes the different usage models of wearable systems [13]. Steve Mann has carried out extensive work in the field of making computer systems wearable [14]. Probably the best-known example of smart clothing is a textile keyboard and a synthesizer embedded into a denim jacket [15]. Intelligence in the form of electrical components has also been embedded into other pieces of clothing, e.g. gloves [16], ties [17], undergarments [18] and footwear [19]. An organization has adopted a different approach in the development of smart clothes [20], active ventilation, heat transfer through garments, and reactive waterproof materials. Conducting polymers are a relatively new type of material in terms of understanding, syntheses, and applications [21-24]. Different kinds of yarn and methods of fabric production, modifications conducted in the conventional textile machines, problems encountered during the production processes and the solutions have been dealt with. The specialty yarns and fabrics can be utilized for developing wearable electronic products.

Today, the interaction of individual humans with electronic devices demands specific user skills. The crucial microelectronic functions prove economical enough to attract key technologies to take advantage of this aspect for social benefit [25]. Wearable Electronics are an emerging Tran’s disciplinary field, bringing together concepts and expertise from a variety of disciplines, ranging from materials science, through computer engineering to textile design. An emerging area of research which combines the strengths and capabilities of electronics and textiles in wearable electronics is highlighted. In these paper different types of yarn and fabric production techniques has been developed for wearable electronic products. In order to develop a heating garment, the cotton yarn wrapped by nichrome is integrated into knitted fabric. Copper core conductive yarn and Optical core conductive yarn were developed for the production of Communication Garment and POF integrated tele intimation fabric has been developed for Teleintimation Garment.

Electrical Properties of PPY Coated Conductive Fabrics

There are two ways to produce textile-based deformation sensors for wearable devices. One is by coating a thin layer of piezo resistive material on conventional fabrics, and the other is by knitting and weaving conductive yarns with nonconductive yarns. The technique permits continuous, long-term monitoring of a human joint, based on the stretch of the skin and the elastic fabric, where a conductive fiber [26] or conductive elastomer [27] is attached to the fabric. There is an increase in resistance of the conductive fibre due to increase in the length of wire between two terminals when bending of fibre occurs. If the conductive fabric is attached to clothes worn next to the skin, its resistance also increases during the bending process. Besides, in order to monitor the flexion angle of elbow and knee movements, elastic conductive webbing by conductive yarns and elastic yarns [28,29] has been designed and the elastic conductive webbing exhibits a linear response of resistance to the flexion angle. Conductive elastomer sensors have been directly integrated into lycra fabrics. This has been made possible by a combination of silicon rubber and graphite. These test devices can be worn for a long period and be used for monitoring without discomfort.

Recently, a great deal of investigation has been carried out relating to the technology for conductive fabric sensing elements from conductive polymers. These materials offer several advantages with respect to other sensors: lightness, large elasticity and resilience, resistance to corrosion, flexibility, and so on [30]. Polypyrrole (PPy), polyaniline, and polythiophene are some of typical types of conductive polymers that offer certain merits like high conductivity, good environmental stability, ease of synthesis, adhesion, nontoxicity, etc. Furthermore, polypyrole conductive fabric is generally used for wearable fabric sensors.

A high sensitivity in elongation has been observed in the case of the surface resistance of PPy conductive fabric [31]. The relation of strain-resistance relationship in the case of PPy coated lycra fabric and its strain sensitivity coefficient is up to 25 [32]. Thus, the sensor made from PPy conductive fabric can be used to detect knee joint movements.

Body joint motion was detected by monitoring the resistance change of the conductive fabric. The movement of the human joint is normally multidirectional, like the torsional flexion of an elbow joint. In this case, the fabric sensor around the joint is not only stretched along the axial direction of extremities, the sensor can also deform in the other direction, which is usually neglected in previous studies [33]. The resistance in all directions has to be monitored in order to characterize the joint movement. Hence, there is a need to understand the directional resistance distribution of the conductive fabric. Due to more or less anisotropic structure of the fabric, the PPy coated fabric will show to some extent anisotropic electrical resistance [34]. In such a regard, the dependence of the anisotropic resistance on fabric structure can be considered for study. The electrical conductivity of PPy woven fabric has been studied with respect to the surface resistance and its directional distribution, as well as the elongation-resistance relationship. Subsequently, the extension angle of the knee and elbow has been monitored by the PPy-coated conductive fabric. The relation between angle and resistance has been explained.

The conductive resistance of PPy coated woven fabric has been found to be anisotropic, and the anisotropy feature of PPy conductive fabric resistance is dependent on the structure of the fabric itself [35]. And the trend of PPy conductive woven fabric resistance distribution in each direction depends only on the orthogonality of the fabric sample structure, and the extremes occur in the direction that parallels the direction of the warp or the weft yarn. There is an upper limit for the change in the electrical resistance of PPy conductive fabric which is based on the structure of the fabric. Moreover, PPy conductive woven fabrics can be used to monitor the movement of human joints.

Innovative Method of Designing Silver Plated Cotton Fabrics

Many techniques like vacuum deposition, chemical plating, and composite plating by in situ polymerization have been applied to development of conductive fabrics [34-36].The chemical plating method has better industrial application prospect for fabricating conductive textiles due to operation simplification and high efficiency. Recently, owing to better electrochemical properties and good electrical conductivity of silver nano particles, the surface electro less silver plating has been utilized for surface metalizing of many of electrical insulating materials due to superior electrochemical properties and good electric conductivity of silver nano particles. Gout [37] obtained silver patterns onto flexible polymer surfaces at the micron and submicron scale using electro less metallization. Yu [38] prepared silver plating wool fabric using electro less silver plating. Lu [39] fabricated silver plating polyethylene terephthalate (PET) fabric by ultrasonic assisted electro less silver plating. However, silver plating fabrics have low washing fastness when silver plating is coated on surface of fabrics by electro less plating method. Hence, surface modification of substrate is of great importance for improvement of the adhesive force between the metal and the substrate [40]. Lee [41,42] reported that polydopamine films could be formed on the surface of materials by self-polymerization of dopamine and have a wide range surfaceadherent for all types of inorganic and organic materials, including noble metals, oxides, polymers, semiconductors, and ceramics. Further studies found that the self-polymerization of dopamine has secondary reaction and weak reducibility [43-48]. The process of polydopamine preparation is simple and environment-friendly. Lee [49] dissolved dopamine into the Tris buffer solution (pH = 8.5) and then formed a layer of polydopamine film under aerobic condition. In general, adhesion mechanism of polydopamine film shows that catechol and amino functional groups in polydopamine have the covalent and non covalent bonds combination with the inorganic or organic materials [50,51].

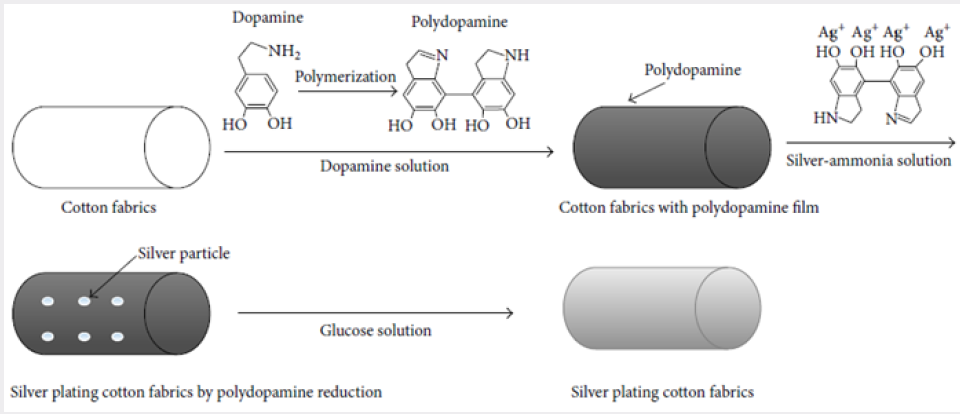

Xu [52-55] fabricated silver plating glass fibers by dopamine fictionalization and electro less plating. Wang [56-58] prepared surface silverized meta-aramid fibers by bio inspired functional polydopamine. Silver plating cotton fabrics (SPCFs) will be fabricated through polydopamine reduction and glucose reduction reaction. First, the silver nano particles will be reduced from silver nitrate by in situ reduction of polydopamine (PDA). Second, silver ions will be reduced by glucose, and silver nano particles were coated on the surface. The whole process is shown in Figure 1. This is followed by use of various techniques such as field emission scanning electron microscopy (FESEM), X-ray photoelectron spectroscopy (XPS) and thermo gravimetric analysis (TGA), etc, to carry out certain tests in order to achieve the properties of SPCFs. Silver plating fabrics can be applied in these fields such as antibacterial, intelligent textiles, smart garments, electromagnetic shielding, and flexible sensors.

A novel two-step method for fabricating the SPCF with high conductivity and excellent washing fastness has been developed. Polydopamine (PDA) film was coated on the surface of cotton fabrics by self-polymerization of dopamine, the silver ions in silver nitrate solution were reduced by the catechol groups of polydopamine, and silver nano particles were combined with polydopamine by covalent bond on surface of cotton fabrics. Subsequently, silver plating was coated on the surface by glucose reduction reaction [59]. With the increasing of silver-ammonia solution concentration or dopamine concentration, the surface resistivity of SPCFs all decreases and gradually stabilized. With the increasing of washing times, the surface resistivity increased. After 1st washing and 15th washing, the surface resistivity increased to 0.32 ± 0.01Ω and 0.8 ± 0.03Ω, respectively. The electromagnetic shielding effectiveness of SPCFs is in negative correlation with their surface resistivity when the structure and material of fabrics are identical. When the concentration of dopamine and silver-ammonia solution is, respectively, 6 g/L and 0.25mol/L, the surface resistivity of SPCF is the smallest (0.12 ± 0.02Ω), and the ESE is the best (in the range of 58.5 ± 4.5 dB). Silver plating fabrics can be widely applied in these fields, such as antibacterial, intelligent textiles, smart garments, electromagnetic shielding, and flexible sensors.

Wearable electronics and smart textiles

Smart Textiles will serve as a means of increasing social welfare and they might lead to important savings on welfare budget. They integrate a high level of intelligence and can be divided into three subgroups:

a) Passive smart textiles: only able to sense the environment/ user, based on sensors.

b) Active smart textiles: reactive sensing to stimuli from the environment, integrating an actuator function and a sensing device.

c) Very smart textiles: able to sense, react and adapt their behavior to the given circumstances.

Sensors provide a nervous system to detect signals, thus in a passive smart material, the existence of sensors is essential. The actuators act upon the detected signal either autonomously or from a central control unit [60]; together with the sensors, they are the essential element for active smart materials. Fabricbased sensing has been a large field of research in the biomedical and safety communities [61]. The fabric sensors can be used for electrocardiogram (ECG) [62], electromyography (EMG) [63], and electroencephalography (EEG) [64,65] sensing; fabrics incorporating thermocouples can be used for sensing temperature [66]; luminescent elements integrated in fabrics could be used for biophotonic sensing [67]; shape-sensitive fabrics can sense movement, and can be combined with EMG sensing to derive muscle fitness [68]. Carbon electrodes integrated into fabrics can be used to detect specific environmental or biomedical features such as oxygen, salinity, moisture, or contaminants [69,70].

Active functionality could include power generation or storage [71], human interface elements [72], radio frequency (RF) functionality, or assistive technology [73]. All electronic devices require power, and this is a significant design challenge for Smart Fabrics. Power generation can be achieved through piezoelectric [74] elements that harvest energy from motion or photovoltaic elements [75]. Human interfaces to active systems can be roughly grouped into two categories: input devices and annunciation or display devices. Input devices can include capacitive patches that function as pushbuttons [76], or shape-sensitive fabrics [77] that can record motion or flexing, pressure, and stretching or compression. Annunciation and display devices may include fabric speakers [78], electroluminescent yarns [79], or yarns that are processed to contain arrays of organic light emitting diodes (OLEDs) [80]. Fabrics can also include elements that provide bio-feedback [81] or simply vibrate. Fabric-based antennas are a relatively simple application of Smart Fabrics. Simple fabric antennas are merely conductive yarns of specific lengths that can be stitched or woven into non-conducting fabrics [82].

A study about intelligent textiles is at his first stage reduced to a study on smart materials. In a second phase, it is to be considered in which way these smart materials can be processed into a textile material. These smart materials are incorporated into the textile structure by different technologies. Among those we may list embroidering [83], sewing, non-woven textile, knitting [84], weaving [85], making a spinning [86], braiding [87], coating/ laminating [88], printing [89] and chemical treatments [90] that provide specific features such as controlled hydrophobic behavior. Innumerable combinations of these source materials result into a whole range of textiles but sometimes the commercial output is represented by garments that contain conventional cables, miniaturized electronic components and special connectors. As humans prefer to wear comfortable textiles rather than hard, rigid boxes, first efforts have been made to use the textiles themselves for electronic functions [91].

Smart Textiles present a challenge in several fields such as the medical, sport, and artistic communities, the military and aerospace. The early European Commission‘s 6th and 7th framework programs provided significant research and development funding for personal health monitoring through smart wearable systems and for projects targeting the integration of sensors, energy sources, processing, and communication inside the clothing. The list below shows the projects funded by the European Commission‘s 6th and 7th Framework programs that have focused on smart fabrics and interactive textiles [92].

Particular attention in this review is devoted to describing the materials and methodologies to develop smart textiles. Each scientific approach will be followed by a review of the related work carried out by companies, universities or research institutes. Textile materials can be suitable as wearable bio-sensors since they offer themselves as an attractive category of substrates. Electronic textiles, or smart textiles, describe the convergence of electronics and textiles into fabrics which are able to sense, compute, communicate and actuate. The versatility of a wearable system is enhanced with increasing number of varied electronic systems that can be connected to any clothing. Its appearance can be changed by the user based on environmental changes and personal choice. The vision of wearable computing describes future electronic systems as an integral part of our everyday clothing serving as intelligent personal assistants. Hence, these wearable sensors should maintain their sensing capabilities based on the requirements of normal wear. This could cause serious mechanical deformation of the underlying garment/substrate.

One promising approach to reduce the rigidity of electronic textiles and enhance its wearability is to replace PCBs by flexible electronics. Attempt has been made to describe the possibility of development of a smart textile material. Some methods show advantages with respect to others, but in our opinion and in according to the consulting company Smart Garment People (Lancashire, UK), while some manufacturers are well exposed to electronics and others are well versed with textiles, only some are able to deal in both effectively. Current advances in textile technologies, new materials, nanotechnology and miniaturized electronics are making wearable systems more feasible but the final key factor for user acceptance of wearable devices is the fit comfort. It looks certain that this goal can only be achieved by addressing mechanical resistance, and durability of the materials in what is recognized to be a harsh environment for electronics: the human body and society. Lastly, it is accepted that the development of smart textiles needs a multidisciplinary skill relating to an understanding of circuit design, smart materials, micro-electronics and chemistry which are basically integrated with a thorough knowledge of textile fabrication.

Conclusion

Because conductive fabrics can be well integrated with the garment, they are ideal as a sensing element of wearable human motion monitoring systems. Polypyrrole conductive fabric has been prepared by in situ polymerization, and the anisotropic property of the conductive fabric resistance, resistance-strain relationship, and the relationship between resistance and the human knee and elbow movements have been discussed. First, polydopamine (PDA) film was coated on the surface of cotton fabrics by in situ polymerization of dopamine, the silver ions in silver nitrate solution were reduced by the catechol groups of polydopamine, and silver nanoparticles were combined with polydopamine by covalent bond on the surface of cotton fabrics. Second, silver ions were reduced by glucose, and silver plating was coated on the surface. Subsequently, the properties of SPCFs were characterized by field emission scanning electron microscopy (FESEM), X-ray photoelectron spectroscopy (XPS) and thermo gravimetric analysis (TGA), and so forth. With the increasing of silver-ammonia solution concentration or dopamine concentration, the surface resistivity of SPCFs decreases and gradually stabilized.

The SPCFs can attain value of surface resistivity around 0.12 ± 0.02Ω, while value of electromagnetic shielding effectiveness (ESE) can attain to around 58.5 ± 4.5 dB. Conductive fabrics have wide application prospect in many of fields, such as antibacterial, intelligent textiles, smart garments, electromagnetic shielding, and flexible sensors. Depending on the extent of integration, electronics coupled with textiles can be categorized into wearable electronics, textronics and fibertronics. The development of cotton wrapped nichrome yarn, copper core conductive yarn, optical core conductive yarn POF of different diameters has been done to produce, nichrome fabric, copper core conductive fabric, optical core conductive fabric and teleintimation fabric. A test rig has been specifically developed for the testing of the yarn and the fabrics. A platform has been provided for the methodology of developing conductive yarns and fabric for the wearable electronics product development to progress on the issue of user acceptability.

Electronic Textiles represent fabrics which comprise electronics and interconnections woven into them, exhibiting physical flexibility and typical size that are not matched by other existing electronic manufacturing methods. Components and interconnections are intrinsic to the fabric and thus are less visible and not susceptible of becoming tangled or snagged by surrounding objects. E-textiles can also more easily adapt to fast changes in the computational and sensing requirements of any specific application, this one representing a useful feature for power management and context awareness. Wearable computing provides a future insight into electronic systems as a critical component in our day to day outfits. These electronic devices should satisfy particular needs relating to wearability. Wearable systems will be characterized by their ability to automatically recognize the activity and the behavioral status of their own user as well as of the situation around her/him, and to use this information to adjust the systems configuration and functionality. The recent advances in the field of smart textiles have been reviewed and pay particular attention to the materials and their manufacturing process. Each method offers its merits and demerits and the focus is directed towards striking a balance between flexibility, ergonomics, low power consumption, integration and eventually autonomy.

References

- Rantanen J, HaoNnnikaoNinen (2005) Data transfer for smart clothing: Requirements and Potential technologies. In Tao X (Eds.), Wearable electronics and photonics Wood head Publishing in Textiles.

- Sensatex, Inc. Smart Shirt physiological monitoring device.

- Dunne LE, Walsh P, Smyth B, Caulfield B (2006) Design and evaluation of a wearable optical sensor for monitoring seated spinal posture. 2006 10th IEEE International Symposium on Wearable Computers.

- Corbman BP (1983) Textiles. Fiber to fabric. Gregg/McGraw-Hill Marketing Series; McGraw-Hill. Gregg Division.

- M Stoppa, A Chiolerio (2014) Wearable electronics and smart textiles: a critical review. Sensors 14(7): 11957-11992.

- Y Huang, H Hu, Y Huang (2015) From industrially weavable and knittable highly conductive yarns to large wearable energy storage textiles. ACS Nano 9(5): 4766-4775.

- Y Zhou, X Ding, J Zhang, Y Duan, J Hu, et al. (2014) Fabrication of conductive fabric as textile electrode for ECG monitoring. Fibers and Polymers 15(11): 2260-2264.

- D Duran, H. Kadoglu (2015) Electromagnetic shielding characterization of conductive woven fabrics produced with silver containing yarns. Textile Research Journal 85(10): 1009-1021.

- Buechley L, Eisenberg L (2007) Fabric PCBs, electronic sequins, and socket buttons techniques for e-textile craf.

- Locher I, Troster G (2007) Screen-printed Textile Transm ission Lines. Textile Research Journal 77(11): 837-842.

- Troster G , Kirstein T, Lukowicz P (2003) Wearable Computing: Packaging In Textiles And Clothes Wearable Computing Lab 14th European Microelectronics and Packaging Conference & Exhibition Friedrichshafen Germany.

- Yao J, Schmitz R, Warren S A (2005) Wearable point-of-care system for home use that incorporates plug-and-play and wireless standards. IEEE Trans. Inf. Technol. Biomed 9(3): 363-371.

- Mizell D (1999) Message from the Chair, Proceedings of the 3rd International Symposium on Wearable Computers. San Francisco CA, USA.

- Mann S (1997) An historical account of the `WearComp’ and `WearCam’ inventions developed for applications in Personal Imaging. First International Symposium on Wearable Computers.

- Post ER, Orth M (2000) E-broidery: Design and fabrication of textilebased computing. IBM Systems Journal 39: 840-860.

- Perng JK, Fisher B, Hollar S, Pister KSJ (1999) Acceleration sensing glove. Proceedings of the 3rd International Symposium on Wearable Computers. San Francisco CA, USA.

- Schmidt A, Gellersen HW, Beigl MA (1999) Wearable context-awareness component. Proceedings of the 3rd International Symposium on Wearable Computers. San Francisco CA, USA.

- Mann S (1996) Smart clothing: The shift to wearable computing. Communications of the ACM 39: 23-24.

- Paradiso J, Feldmeier M (2005) A Compact, Wireless, Self-Powered Pushbutton Controller. Ubicomp 2001: Ubiquitous Computing, LNCS 2201, Springer-Verlag pp. 229-304.

- Russell DA, Elton SF, Squire J, Staples R, Wilson N (2000) First experience with shape memory material in functional clothing. Proceedings of the Avantex, International Symposium for High-Tech Apparel Textiles and Fashion Engineering with Innovation-Forum. Frankfurt-am-Main, Germany.

- Elton SF (2000) Ten new developments for high-tech fabrics & garments invented or adapted by the research & technical group of the defense clothing and textile agency; Proceedings of the Avantex International Symposium for High-Tech Apparel Textiles and Fashion Engineering with Innovation-Forum Frankfurt-am- Main Germany.

- Sayed I, Berzowska J, Skorobogatiy M (2010) Jacquard-Woven Photonic Bandgap Fiber Displays. Research Journal of Textile & Apparel 14(4): 97-105.

- Ala O, Fan Q (2009) Applications of Conducting Polymers in Electronic Textiles. Research Journal of Textile & Apparel 13(4): 51-68.

- Ashok Kumar L, Vigneshwaran C (2010) Design and Development of Signal Sensing Equipment for Measuring Light Transmission Efficiency of POF Fabrics. Indian Journal of Fibre & Textile Research 35: 317-323.

- Ashok Kumar L (2015) Study on Different Techniques of Fabricating Conductive Fabrics for Developing Wearable Electronics Garments. J Textile Sci Eng 5: 212.

- Gibbs PT, Asada HH (2005) Wearable conductive fiber sensors for multiaxis human joint angle measurements. Journal of neuro engineering and rehabilitation 2(1): 7.

- Tognetti A, Lorussi F, Mura GD, Crbonaro N, Pacelli M, et al. (2014) New generation of wearable goniometers for motion capture systems. Journal of NeuroEngineering and Rehabilitation 11(1): 56.

- Shyr TW, Shie JW, Jiang CH, Li JJ (2014) A Textile-Based Wearable Sensing Device Designed for Monitoring the Flexion Angle of Elbow and Knee Movements. Sensors 14(3): 4050-4059.

- Tognetti A, Lorussi F, Bartalesi R (2005) Wearable kinesthetic system for capturing and classifying upper limb gesture in post-stroke rehabilitation. Journal of Neuro Engineering and Rehabilitation 2(1): 8.

- Scilingo EP, Lorussi F, Mazzoldi A, De Rossi D (2003) Strain sensing fabrics for wearable kin aesthetic-like systems. Ieee Sensors Journal 3(4): 460-467.

- Li Y, Cheng XY, Leung MY, Tsang J, Tao XM, et al. (2005) A flexible strain sensor from poly pyrrole-coated fabrics. Synthetic Metals 155(1): 89-94.

- Wu J, Zhou D, Too CO, Wallace GG (2005) Conducting polymer coated lycra. Synthetic Metals 155(3): 698-701.

- Hu J, Zhang X, Li G, Yang X, Ding X (2016) AUTEX Research Journal 16(1).

- R Pawlak, E Korzeniewska, M Frydrysiak (2012) Using vacuum deposition technology for the manufacturing of electro conductive layers on the surface of textiles, Fibres & Textiles in Eastern Europe 91(2): 68-72.

- EG Han, EA Kim, KW Oh (2001) Electromagnetic interference shielding effectiveness of electrolessCu-plated PET fabrics, Synthetic Metals 123(3): 469-476.

- YK Hong, CY Lee, CK Jeong (2001) Electromagnetic interference shielding characteristics of fabric complexes coated with conductive polypyrrole and thermally evaporated Ag, Current Applied Physics 1(6): 439-442.

- S Gout, J Coulm, D Leonard, F Bessueille (2014) Silver localization on polyimide using microcontact printing and electroless metallization, Applied Surface Science 307: 716-723.

- D Yu, W Tian, B Sun, Y Li, W Wang, et al. (2015) Preparation of silverplated wool .fabric with antibacterial and antimould properties, Materials Letters 151: 1-4.

- YX Lu, SH Jiang, YG Huang (2010) Ultrasonic-assisted electroless deposition of Ag on PET fabric with low silver content for EMI shielding, Surface and Coatings Technology 204(16-17): 2829-2833

- LA Burzio, JH Waite (2000) Cross-linking in adhesive quinoproteins: studies with model decapeptides, Biochemistry 39(36): 11147-11153.

- H Lee, SM Dellatore, WM Miller, PB Messersmith (2007) Mussel-inspired surface chemistry for multifunctional coatings, Science 318(5849): 426- 430.

- H Lee, NF Scherer, PB Messersmith (2006) Single-molecule mechanics of mussel adhesion, Proceedings of the National Academy of Sciences of the United States of America 103(35): 12999-13003.

- J Xu, M Li, L Wu, Yong S, Ligen Z, et al. (2014) A flexible polypyrrolecoated fabric counter electrode for dye-sensitized solar cells, Journal of Power Sources 257: 230-236.

- CH Xu, M Tian, L Liu, H Zou, L Zhang, et al. (2012) Fabrication and properties of silverized glass fiber by dopamine functionalization and electroless plating, Journal of the Electrochemical Society 159(4): D217-D224.

- WC Wang, RU Li, M Tian (2013) Surface silverized meta -aramid fibers prepared by bio-inspired poly(dopamine) functionalization, ACS Applied Materials and Interfaces 5(6): 2062-2069.

- Hao L, Lili Z, Jie X, Lei H, Jin L, et al. (2016) A Novel Two-Step Method for Fabricating Silver Plating Cotton Fabrics, Journal of nano materials 1.

- R Pawlak, E Korzeniewska, M Frydrysiak, Zieba Z, Gniotek K, et al. (2012) Using vacuum deposition technology for the manufacturing of electroconductive layers on the surface of textiles, Fibres & Textiles in Eastern Europe 91(2): 68-72.

- EG Han, EA Kim, KW Oh (2001) Electromagnetic interference shielding effectiveness of electrolessCu-plated PET fabrics, Synthetic Metals 123(3): 469-476.

- YK Hong, CY Lee, CK Jeong, JH Sim, K Kim, et al. (2001) Electromagnetic interference shielding characteristics of fabric complexes coated with conductive polypyrrole and thermally evaporated Ag. Current Applied Physics 1(6): 439-442.

- S Gout, J Coulm, D Leonard, F Bessueille (2014) Silver localization on polyimide using microcontact printing and electroless metallization. Applied Surface Science 307: 716-723.

- D Yu, W Tian, B Sun, Y Li, W Wang, et al. (2015) Preparation of silverplated wool fabric with antibacterial and antimould properties. Materials Letters 151: 1-4.

- YX Lu, SH Jiang, and YG Huang (2010) Ultrasonic-assisted electroless deposition of Ag on PET fabric with low silver content for EMI shielding. Surface and Coatings Technology 204(16-17): 2829-2833.

- LA Burzio, JH Waite (2000) Cross-linking in adhesive quino proteins: studies with model Decapeptides. Biochemistry 39(36): 11147-11153.

- H Lee, SM Dellatore, WM Miller, PB Messersmith (2007) Mussel-inspired surface chemistry for multifunctional coatings. Science 318(5849): 426- 430.

- H Lee, NF Scherer, PB Messersmith (2006) Single-molecule mechanics of mussel adhesion. Proceedings of the National Academy of Sciences of the United States of America 103(35): 12999-13003.

- J Xu, M Li, L Wu (2014) A flexible polypyrrole-coated fabric counter electrode for dye-sensitized solar cells. Journal of Power Sources 257: 230-236.

- CH Xu, M Tian, L Liu, H Zou, L Zhang, et al. (2012) Fabrication and properties of silverized glass fiber by dopamine functionalization and electroless plating. Journal of the Electrochemical Society 159(4): 217- 224.

- W C Wang, RU Li, M Tian (2013) Surface silverized meta -aramid fibers prepared by bio-inspired poly (dopamine) functionalization. ACS Applied Materials and Interfaces 5(6): 2062-2069.

- Hao L, Lili Z, Jie X, Lei H, Jin L, et al. (2016) A Novel Two-Step Method for fabricating silver plating cotton Fabrics. Journal of nano materials p. 11.

- Langereis GR, Bouwstra S, Chen W (2012) Sensors, Actuators and Computing Architecture Systems for Smart Textiles. In Smart Textiles for Protection. Chapman R, Ed Woodhead Publishing: Cambridge, UK (1): 190-213.

- Custodio V, Herrera FJ, López G, Moreno JI (2012) A review on architectures and communications technologies for wearable healthmonitoring systems. Sensors 12(10): 13907-13946.

- Coosemans J, Hermans B, Puers R (2006) Integrating wireless ECG monitoring in textiles. Sens. Actuators A Phys (130-131): 48-53.

- Linz T, Gourmelon L, Langereis G (2007) Contactless EMG sensors embroidered onto textile. In Proceedings of the 4th International Workshop on Wearable and Implantable Body Sensor Networks, Aachen, German, Europe 13: 29-34.

- Lofhede J, Seoane F, Thordstein M (2010) Soft textile electrodes for EEG monitoring. In Proceedings of 10th IEEE International Conference on Information Technology and Applications in Biomedicine (ITAB), Corfu, Greece p. 1-4.

- Löfhede J, Seoane F, Thordstein M (2012) Textile electrodes for EEG recording-A pilot study. Sensors 12(12): 16907-16919.

- Sibinski M, Jakubowska M, Sloma M (2010) Flexible temperature sensors on fibers. Sensors 10(9): 7934-7946.

- Omenetto F, Kaplan D, Amsden J, Dal Negro L (2013) Silk Based Biophotonic Sensors. Patent US.

- Meyer J, Lukowicz P, Tröster G (2006) Textile Pressure Sensor for Muscle Activity and Motion Detection. In Proceeding of the 10th IEEE International Symposium on Wearable Computers, Montreux, Switzerland.

- Coyle S, Lau KT, Moyna N, O’Gorman D, Diamond D, et al. (2010) BIOTEXBiosensing textiles for personalised healthcare management. IEEE Trans Inf Technol Biomed 14(2): 364-370.

- Zadeh E (2006) Flexible biochemical sensor array for laboratory-on-chip applications. In Proceeding of the International Workshop on Computer Architecture for Machine Perception and Sensing Montreal QC, Canada, USA p. 65-66.

- Vatansever D, Siores E, Hadimani R, Shah T (2011) Smart Woven Fabrics in Renewable Energy Generation. In Advances in Modern Woven Fabrics Technology; Vassiliadis S, Ed InTech: Rijeka, Croatia p. 23-38.

- Baurley S (2004) Interactive and experiential design in smart textile products and applications. Pers Ubiquitous Comput 8(3-4): 274-281.

- Black S (2007) Trends in Smart Medical Textiles. In Smart Textiles for Medicine and Healthcare: Materials, Systems and Applications; Van Langenhove L, Ed University of Ghent: Ghent, Belgium 1: 3-26.

- Edmison J, Jones M, Nakad Z, Martin T (2002) Using piezoelectric materials for wearable electronic textiles. In Proceedings of the 6th International Symposium on Wearable Computers (ISWC), Seattle, WA, USA p. 41-48.

- Bedeloglu A, Demir A, Bozkurt Y, Sariciftci NS (2009) A Photovoltaic Fiber Design for Smart Textiles. Text Res J 80(11): 1065-1074.

- (2014) How to Get What You Want?

- Pacelli M, Loriga G, Taccini N, Paradiso R (2007) Sensing Fabrics for Monitoring Physiological and Biomechanical Variables: E-textile solutions. In Proceeding of the IEEE/EMBS International Summer School on Medical Devices and Biosensors, St Catharine’s College, Cambridge, UK p. 1-4.

- Dias T (2012) Development and Analysis of Novel Electroluminescent Yarns and Fabrics for Localised Automotive Interior Illumination: El Yarns and Fabrics. Text Res J 82(11): 1164-1176.

- Janietz S, Gruber B, Schattauer S, Schulze K (2012) Integration of OLEDs in Textiles. Adv Sci Technol 80: 14-21.

- Munro BJ, Steele JR, Campbell TE, Wallace GG (2005) Wearable Textile Biofeedback Systems: Are They too Intelligent for the Wearer. In Wearable eHealth Systems for Personalised Health Management: State of the Art and Future Challenges; Lymberis A, De Rossi D, Eds IOS Press- STM Publishing House: Amsterdam, The Netherlands 108: 271-277.

- Salonen P, Hurme L (2003) A novel fabric WLAN antenna for wearable applications. In Proceeding of IEEE International Symposium on Antennas and Propagation Society, Columbus, OH, USA 2: 700-703.

- (2014) Popular Embroidery Techniques Used to Decorate Fabrics. Creative Sewing.

- (2014) Loominous.

- (2011) Cornell University-Fabrics of Our Livelihoods.

- (2014) CMI.

- (2013) Textile Innovation Knowledge Platform.

- (2014) Custom Fabric Printing.

- (2014)Durable water repellent.

- Post ER, Orth M, Russo PR, Gershenfeld N (2000) E-broidery: Design and fabrication of textile-based computing. IBM Syst J 39: 840-860.

- (2013) Systenx Project.

- (2013) Proetex Project.

- Matteo S, Alessandro C (2014) Wearable Electronics and Smart Textiles: A Critical Review. Sensors 14(7): 11957-11992.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...