Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Research Article(ISSN: 2637-4595)

Cement Slabs and Pavers with Incorporation of Waste Selective Collection the City of Blumenau, SC Volume 3 - Issue 4

João Marcos Bosi Mendonça de Moura1, Rafael Reis2, Samantha May2* and Ivone Gohr Pinheiro1

- 1Department of Graduate Program in Environmental Engineering, Regional University Foundation of Blumenau, Brazil

- 2Department of Civil Engineering Course, Regional University Foundation of Blumenau, Brazil

Received: September 29, 2019; Published: October 31, 2019

*Corresponding author: Samantha May, Department of Civil Engineering Course, Regional University Foundation of Blumenau, Brazil

DOI: 10.32474/LTTFD.2019.03.000168

Abstract

This project analyzed the physical-mechanical performance of plates and pavers with the incorporation of waste originated from the sorting process in the city of Blumenau, SC, Brazil. The waste consisted of organic waste, polymers, paper, glass and textile materials which were reduced in size (2.4mm to 19.0mm) and then used to replace natural aggregate at different ratios: 5%, 10%, 20% and 30%. The consistency of the fresh mortar and the physical-mechanical indices, the apparent specific gravity, water absorption and compressive strength of the hardened mortar were determined. Scanning electron microscopy analysis and flexural strength tests were also conducted. The bulk density of the plates and pavers ranged from 0.8 to 1.6g.cm-3 and 1.78 to 1.84g.cm-3 respectively. In the case of low incorporation of waste, both materials presented water absorption results that meet the requirements of correlated standards. The plates presented compressive strength values ranging from 4.7MPa to 14.6MPa. Flexural strength results reached values between 0.1MPa and 1.8MPa. The pavers achieved compressive strength values between 10.8MPa and 18.7MPa. Pavers with 5% incorporation of waste aggregates could be used in sidewalks and curbs, as long as future studies are able to demonstrate their durability.

Summary

Analisou the physical-mechanical performance of slabs and pavers with the incorporation of tailings from the selective collection of the municipality of Blumenau, SC. Such tailings are composed of organics, polymers, papers, glass and textiles, which have been reduced in size (2.4mm to 19.0mm) and have replaced the natural fine aggregate by 5%, 10%, 20% and 30%. %. For the composite in the fresh state the consistency index was verified, and in the hardened state apparent specific mass, water absorption and compressive strength were determined. The plates were subjected to flexural strength testing and scanning electron microscopy analysis. The apparent specific mass of the plates ranged from 0.8 to 1.6g.cm-3 and the pavers from 1.78 to 1.84g.cm-3. For smaller amounts of incorporated tailings, both materials presented water absorption rates that meet the requirements of related standards. The plates presented compressive strength values ranging from 4.7 MPa to 14.6MPa. In flexion, the values reached were from 0.1MPa to 1.8MPa. The pavers achieved compressive strength values between 10.8MPa and 18.7MPa. Pavers with 5% incorporation of tailings aggregates would be applicable to sidewalks and curbs as long as future studies guarantee their durability.

Keywords: Recycling; Waste building materials; Waste Construction materials

Introduction

The challenges in solid waste management, despite all the

advances, are still present, and among them, we can highlight

the goal of expanding the selective collection and, consequently,

the incentive for recycling, reuse and recovery of municipal solid

waste [1]. However, this expansion is not always accompanied

by structures capable of absorbing potentially (re) usable

materials and an environmental awareness of the population as

to what should effectively be directed to selective collection. Not

infrequently, these situations generate a significant amount of

waste in the selective collection of Brazilian municipalities, that

is, a large amount of waste that, after exhausting all treatment

and recovery possibilities, presents no other possibility than the

final disposal [2,3], for example, noted that in Blumenau, Santa Catarina, the municipality’s Association of Recyclable Materials

Workers (Reciblu) rejected from December 2014 to November

2015 approximately 345t.

In this context, technological alternatives that promote the

inclusion of tailings in a production chain can mitigate the use of

natural resources and reduce public spending on final disposal.

Studies recognize that the incorporation of these wastes and

tailings in cementitious materials can reduce costs and promote

environmental benefits [4-6]. Thus, what is observed in the

scientific literature is a significant amount of studies with concretes

and incorporation of polymeric residues. Recyclable waste (PET, PP,

EPS, paper and glass) was incorporated into cementitious slabs by

[7]. In this study, the flexural strength for plates composed by the

ratio 1:2, 1:3 and 1:4 (residue: mortar) was determined, resulting

in 1.0, 1.4 and 1.7MPa, respectively.

In the compressive strength tests, composites with recyclable

waste from selective collection were tested by applying NBR 5739

(ABNT, 2007). The study identified, for a ratio of 1:2, 1:3 and 1:4

(residues: mortar), values of 4.02, 3.55 and 4.36MPa respectively.

By comparing the contents of products already sold in the market,

the authors concluded that the plates could be applied to vertical

and horizontal seals (liners) residences [8], when studying the

mechanical behavior of concrete with recycled polyethylene

terephthalate (PET), used water-cement ratios in the range of 0.5

to 0.6. The results indicated a relationship between PET volume

and particle size with physical and mechanical parameters. As the

presence of PET increased, the workability of the composite was

reduced, as well as mechanical parameters such as compressive

strength, tensile strength, flexural strength and modulus of

elasticity. In contrast, water absorption increased due to the

increased porosity that the residue provided.

Similarly, [9] studied the effects of replacing the aggregate

with recycled PET. Properties of fresh concrete as well as hardened

concrete were evaluated. The results showed that fresh concrete

with PET particles has lower workability and specific mass.

Ultrasonic tests revealed a relatively more porous structure for

concrete containing PET particles. These PET particles can impair

the adhesion between cementitious paste and aggregates, causing

a decrease in the mechanical performance of composites [10]. Also,

according to Sharma and Bansal [11], most studies that work with

cement composites observed that the addition of polymers reduces

the compressive strength. However, some studies report that

incorporation of fiber-shaped polymers has resulted in increased

compressive strength when added in relatively small amounts

[12,13].

Moreover, it is emphasized that the influence of these residues

occurs in different degrees for different mechanical efforts. For

example, studies show a greater negative impact on compressive

strength than flexural strength when incorporating waste in place

of the natural fine aggregate [13,14]. Considering these aspects,

the objective of this article was to evaluate the performance of

two construction materials with the incorporation of selective

waste collection that have different mechanical efforts; the first

is cementitious slabs, for which flexural strength is a major factor

for their adequate mechanical performance; and the second, the

pavers, whose compressive efforts are decisive for their viability.

Methodology

The natural fine aggregate used in cement seal boards and pavers was replaced by tailings aggregates from the selective collection of Blumenau, SC. Once collected, the tailings aggregates were treated (ground) to reduce their size. The following describes the characterization of the tailings aggregates used, composites production traces and procedures, and the physical and mechanical tests performed.

Tailings Aggregates

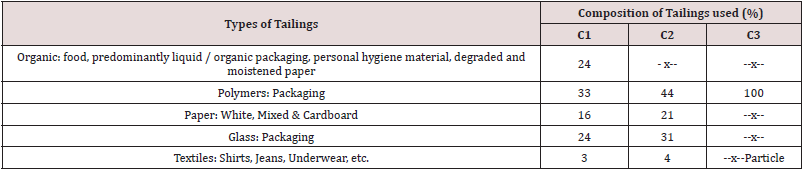

The tailings used and resulting from the process of segregation of solid waste from blumenauense selective collection were organic (food, packaging with predominance of liquid / organic material, personal hygiene material, degraded and moistened papers), polymers (packaging), paper , glass (packaging) and textiles (shirts, jeans, underwear, etc.). These categories represent on average 78.3% of the selective waste collection in Blumenau, SC [3]. The compositions of the tailings aggregates are expressed in Table 1. They were determined from the study by [3] which performed eight analyzes, totaling a sample of 400kg of tailings in January 2015. It was generated the gravimetric composition with 17 categories, among which 5 were selected to be incorporated into the materials.

Three tailings mixtures were applied. The first composition

(C1) covered the maximum categories that are judged prior to be

viablein corporated: organic, polymers, papers, glass and textiles,

and was named C1. Composition 2 (C2) included all classes

of composition C1, but without the presence of organics, and

composition 3 (C3) contained only the discarded polymers from selective collection. The tailings used were mixed with the others

and were segregated at RECIBLU in different months (March, April

and May 2015).

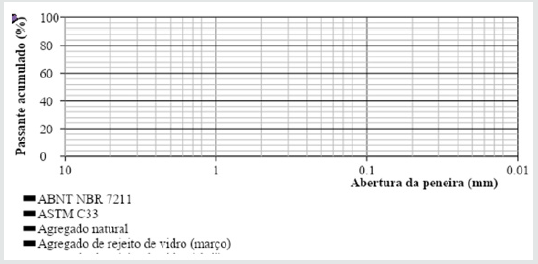

It was decided to reduce the volume of glass waste in the

machine Los Angeles considering the studies by Moura and Matos

[14] and Oliveira, Brito and Veiga [15]. The size reduction process

was carried out with abrasive loads (12 steel balls) over a period

of 10min to 45min (depending on the desired grain size of the

sand) and at 24rpm rotation. Once the glass waste was transformed

into glass waste aggregate, it and natural sand were subjected

to determination of particle size distribution (Figure 1), which

was within the ranges recommended by NBR 7211 (ABNT, 2009)

and ASTM C33 [16]. The non-vitreous tailings aggregates (those

classified as “organic”, “polymers”, “papers” and “textiles”) were

ground in a knife mill. In this way, particle size tailings between

2.4mm and 19.0mm were obtained (Figure 2). Non-vitreous tailings

were subjected to the loose state unit mass test determined by NBR

NM 45 (ABNT, 2006a).

Figure 2:Non-vitreousafter grinding: C1 without glass (organics, polymers, papers and textiles), C2 without glass (polymers, papers and textiles) and C3 (polymers).

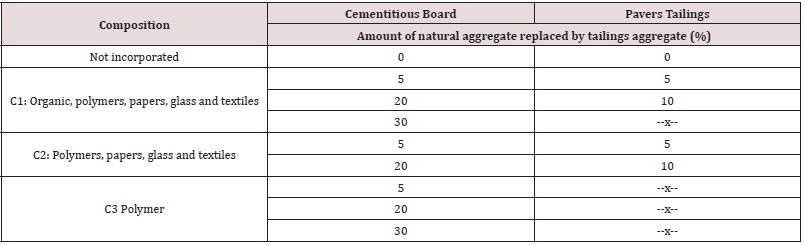

Traces

In Table 2 it is possible to see a synthesis of the percentage of substitution of natural fine aggregate (sand) by tailings aggregate in each construction material worked. The cementitious plate with and without incorporated tailings aggregate was performed in 1: 1 ratio (cement: aggregate) by mass. The pavers without incorporation reject aggregate were manufactured in the ratio 1: 3 and the incorporation ratio of 1: 1 (cement: aggregate) by mass. The CP V-ARI type cement and the water / cement factor of 0.5 were used in both composites, based on studies by Albano et al. [16] and Rahmani et al. [17], who researched cementitious materials with incorporation of polymeric waste.

Production of Composite

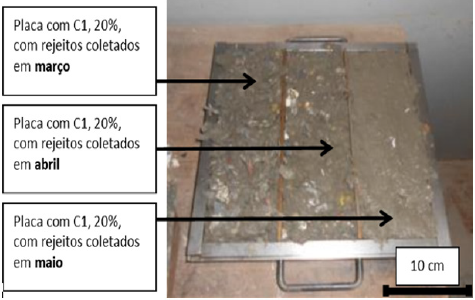

Cement plates

The cement plates and cylindrical specimens were prepared in a mechanical mixer. For each trait were made plates with dimensions of 330x100x12,5mm, as also worked Moura and Matos [7]. Cylindrical specimens with a diameter of 50mm and a height of 100mm [18] were used. In all 30 plates and cylindrical specimens were made to contemplate the three tailings compositions (C1, C2 and C3) and the incorporation percentages (0%, 5%, 20% and 30%). The tailings used for the same trait were collected in different months, March, April and May 2015, generating a triplicate experiment to ensure reproducibility (Figure 3).

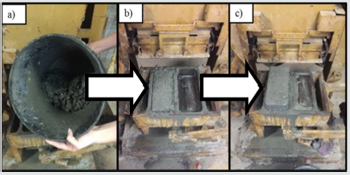

pavers

The mixture of components pavers was first made placing the natural fine aggregate, cement and mixing water being added after the aggregates tailings, mixing the grout until homogeneous present. The pieces were made in a single layer, with commercial dimensions of 220x110x60mm. The dosage material was placed in the steel form of the apparatus, greased with a thin layer of vegetable oil, and then compressed. After pressing (Figure 4), they were removed from the machine and subjected to dry curing, as well as the cementitious plates.

Figure 4: Manufacturing process Paver: (a) composite after mixing all components; (b) seated composite (precast); and (c) pressed and demolded composite (demold).

Tests

\In the fresh state, the consistency index of the cementitious

plates was determined (ABNT, 2005b).

In the hardened state the plate andimmersion water absorption

test paver was performed using three specimens for each of the

compositions on the 26th and 25th day of cure respectively. The

procedures were adopted as defined in NBR 9778 (ABNT, 2005a)

with adaptation regarding the temperature inside the greenhouse.

In this case, the temperature was reduced due to the presence of

the tailings. Thus, the boards and pavers were oven dried at 70 °C.

Water absorption was determined on the plates and the saturated

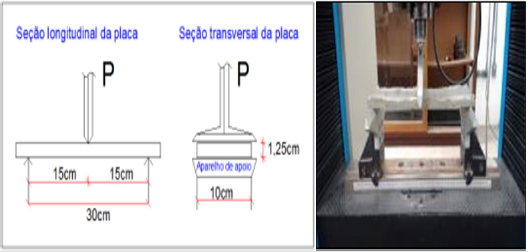

flexural strength test was performed at 28 days of cure. In this test

a displacement speed of 1.3mm / min was applied. The bearing and

load application points are illustrated in Figure 5, and the resistance

calculation was based on ASMT procedures [18].

Results and Discussion

Unitary mass in loose state - non-vitreous aggregates

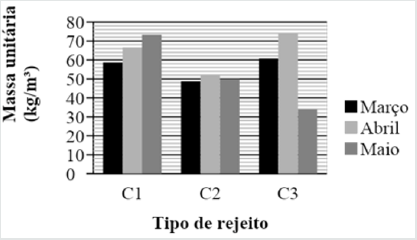

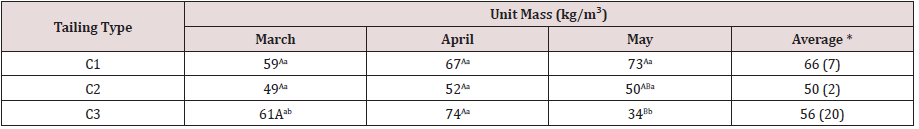

On average the unit masses found from tailings C1, C2 and C3 were 66kg/m3, 50kg/m3 and 56kg/m3 respectively (Figure 6). The results of the loose mass unit mass of non-vitreous tailings aggregates showed a significant difference between C1 and C3 for May (Figure 6). In the remaining months, the unit masses did not present statistically significant difference. C3 polymers showed a significant difference between April and May (Figure 6), indicating different types of polymeric tailings from one month to another.

Figure 6. Unit mass in the loose state of incorporated non-vitreous tailings collected at different months Note: Caption:

Consistency Index consistency

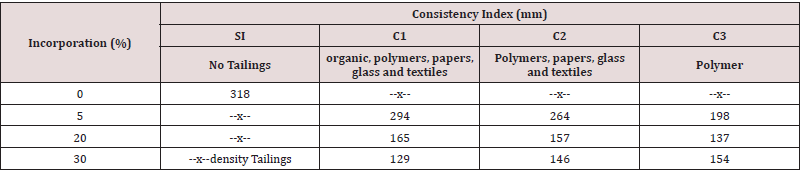

The index is expressed as the means of each composition (C1, C2 and C3) versus the percentage of tailings incorporation in the cementitious plates (Table 3). There is an important change regarding the mortar consistency index, noting that it decreases as the incorporation of tailings in the composite increases, approaching the center value. Such phenomenon indicates loss of mortar consistency as tailings are incorporated, which corroborates the results of Albano et al. [8], Rahmani et al. [9] and Saikia &Brito [19].

Table 3: Consistency index versus percentage of tailings incorporation-results of composites used in cementitious slabs with different tailings compositions (C1, C2 and C3) Tailings.

There was a decrease between 8% and 59%, 17% and 54% and 38% and 52% for mortars with C1, C2 and C3 respectively. According to NBR 13276 (ABNT, 2005b), a standard coating mortar has a consistency index of 255±10mm. These values were achieved in mortar with 5% incorporation of type C2 tailings aggregate, which achieved the highest compressive strength in the test pavers.

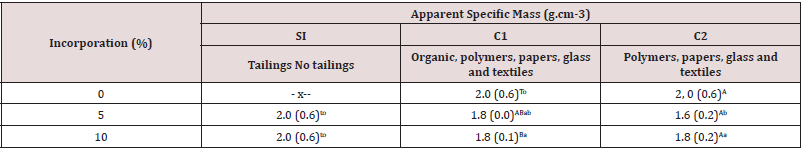

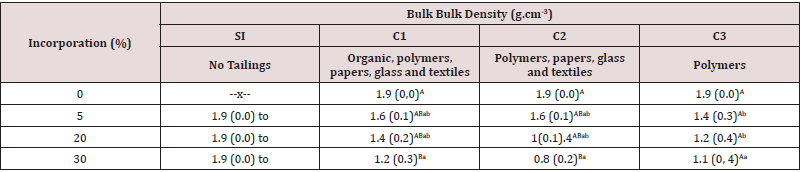

Apparent specific apparent specific

The mass of the tailings incorporation plates decreases significantly compared to those without tailings incorporation (SI) (Table 4). Such behavior is due to the fact that the tailings have a specific mass smaller than the substituted natural minute aggregate (sand). This decrease in specific mass ranged between 16% and 58% in relation to the plates without incorporation of tailings. There was a statistical difference in the specific mass when the type of tailings (C1, C2, C3) was changed to the same amount incorporated (5% and 20%). All composites with incorporation had an apparent specific mass below 1.7g.cm-3 of the cement-based cementitious slabs marketed in the national market [20,21]. The average apparent specific mass of pavers without tailings aggregates was 2.00g.cm-3, while pavers composed of type C1 tailings (organic, polymers, papers, glass and textiles) and C2 (polymers, papers, glass) and textiles) varied with averages between 1.84g.cm-3 and 1.78g.cm-3 and 1.81g.cm-3 and 1.78g.cm-3 respectively (Table 5). A significant decrease was observed between the trait without incorporation and traits with 10% tailings of composition C1.

Table 4: Bulk cement bulk.

Note: Legend:

*mean (standard deviation); and

**capital letters inform about the incorporated amount of tailings. Lower case letters indicate the different types of tailings. Equal

letters indicate no significant difference (p <0.05).

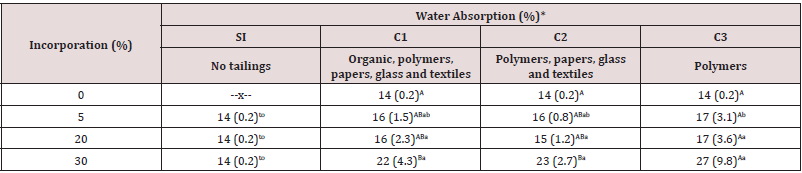

Water Absorption by Immersion

In the water absorption test performed on the plate the traces with 5% and 20% of tailings aggregate incorporated in substitution to the natural aggregate met the limit specification given by NBR 15498 (ABNT, 2007) for fiber cement plates. without asbestos (Table 6). Plates with 30% C1 and C2 tailings showed significantly higher absorption than plates without tailings aggregate. Their average results were approximately double that of the plate without tailings aggregate (SI) (Table 6). No significant differences were observed between the first incorporations (0%, 5% and 20%). Albano et al. [8], who studied concretes with PET, also observed that water absorption is lower in composite with less waste. Waste reduction promotes lower porosity. Moreover, according to the same study, polymer particle sizes influence water absorption values, so that the larger their dimensions, the greater the water absorption. Porrero et al. [22] state that these results are caused because waste / tailings, when crushed, acquire a relatively longer and flatter shape, which promotes the emergence of voids. In this case also a reduction in the volume of tailings aggregates may decrease porosity and water absorption.

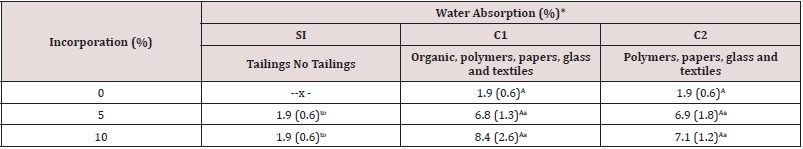

In the case of pavers it is observed that there was no significant increase as the amount of tailings aggregate (A) or the type of tailings aggregate (a) changes (Table 7). For the trait with C1, for incorporations of both 5% and 10%, as the percentage of incorporated tailings increased, there was an increase in the average value of water absorption of 6.8%. to 8.4%. In the trace with C2, for 5% and 10% of tailings incorporation, the values were close, resulting in 6.9% and 7.1% of water absorbed respectively. Costa Gumieri & Brandão [23], when analyzing mortar blocks with the incorporation of iron ore tailings, observed that the water absorption of the traces produced with the tailings showed absorption rates very close to the reference blocks at 28 days of age. used in your search. They found that continuous particle size with lower voids consequently leads to lower absorption. In the present research, discontinuous distribution and increased presence of tailings did not significantly influence water absorption rates.

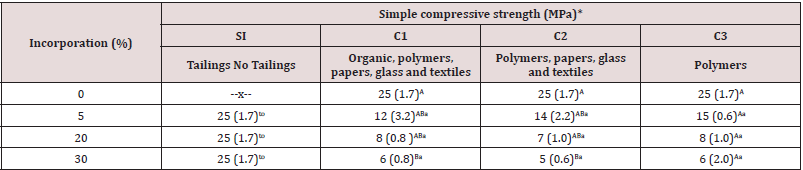

Simple Compressive Strength

Table 8 shows the average simple compressive strength of

cylindrical specimens composed of the same mortar used in the

cementitious plate. Significant reduction in simple compressive

strength was observed between composites without tailings and

composites with 30% tailings of composition C1 and C2. For the

same incorporation percentage, the change of tailings type did not

generate significant difference between the results. Moura & Matos

[7], by applying the same test on mortars with recyclable waste

from selective collection (PET, PP, EPS, paper and glass), reached

values of 4.36MPa for a ratio of 1: 4 (residues: mortar). In this sense,

the plate with 30% of sand replaced by tailings has an equivalent

ratio of 1: 5.6 (tailings: mortar) and therefore achieved a superior

compressive strength of 6.3MPa, 4.7MPa and 6.1MPa. for composite

with tailings type C1, C2 and C3 respectively.

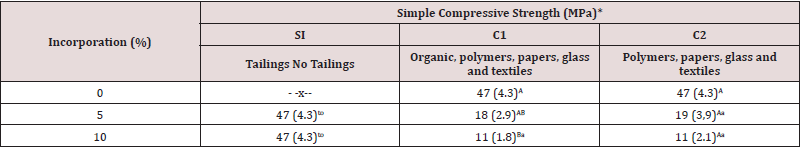

The average compressive strength results of pavers tailings

compared to the paver tailings show a reduction of 62% to 76%

in pavers type C1 tailing sand from 60% to 77% in pavers. tailings

aggregate type C2 (Table 9).

There was a significant difference between the traits without tailings and with 10% tailings of composition C1. Two important observations can be drawn from these results: (a) in the case of pavers C1 tailings the incorporation of tailings decreased the compressive strength; and b) the traits with tailings incorporation stand out the one with the lowest tailings content (5%), whose specimens presented resistance values of 18.03±2.9 MPa (w/C1 tailings) and 18.73±3.9MPa (w/C2 tail). Note that these values are lower than those recommended by NBR 9780 (ABNT, 2013), of 35.0MPa, for use in line commercial vehicle traffic areas. However, there is a potential use of these pavers with the resistance below this limit, given that some studies and municipalities have accepted sidewalks and curbs with characteristic resistance of 15MPa [24,25].

In this context, the composite developed with 5% incorporation is applicable to sidewalks and curbs, with the exception that the resistance does not meet the limit of NBR 9780 (ABNT, 2013). Durability aspects should be considered, but not within the scope of this study. Another aspect that can be observed about composites was related to their behavior when submitted to compression rupture. It was observed that during load application the breakage of pavers without tailings aggregates was characterized by the appearance of cracks and composite disintegration, whereas this was not the case with pavers with tailings aggregates. This corroborates the observations of Moura & Matos [7], who state that polymeric and fibrous materials tend to decrease composites brittleness and increase ductility.

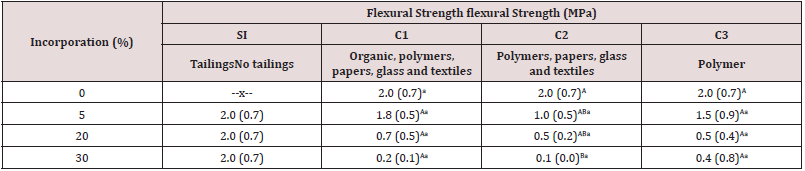

Flexural strength - cement plates

In cementitious plate the results of the flexural strength test decrease as the tailings are incorporated. Values below 1 MPa are noted from the 20% replacement of sand by tailings (Table 10). It is noted that the reference plate (SI) reached 2.0MPa. For the plate without tailings incorporation, the average strength reductions ranged from 10% to 90% for C1 tailings composites, from 50% to 95% for C2 tailings composites and from 25% to 80% for C3 tailings composites. Significant differences were observed between the results of the 30% C2 tailings plates and those of the 0% tailings plates. For plates with different types of tailings but equal incorporation rates, no significant differences in flexural strength were observed.

Studies such as Albano et al. [18], who researched concrete

plates with incorporation of PET bottle particles (average size of

1.14cm), obtained flexural strength equal to 1.5MPa for the same

w/c ratio of the present study (0.5) and with 11% incorporation

of PET in relation to the aggregate mass. Thus, the traits with 5%

incorporation achieved similar resistance, even without natural

large aggregates. It is also a benefit to not only use PET, whose use

technologies are already consolidated. Nevertheless, selective waste

is used, which does not necessarily have available and economically

viable recycling techniques.

Comparing the results obtained with 5% incorporation of

tailings aggregates for slabs and pavers, it is observed that the

reductions in the flexural strength test are relatively smaller than

the differences observed between the composites with and without

tailings in the resistance test. compression. Such behavior is

corroborated by other studies [25,26]. Batayneh Marie & Asi [14]

also state that incorporations of polymeric and vitreous residues in

cementitious matrix composites negatively impact flexural strength

less than compressive strength. This indicates a tendency to use

composites with tailings aggregates in structures that mainly need

to ensure resistance to bending stresses [27-36].

Scanning electron microscope

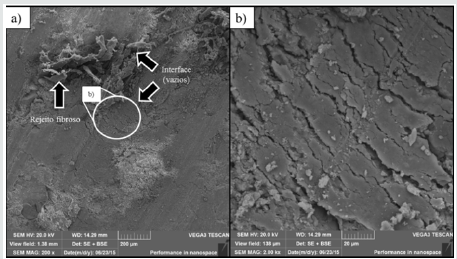

Figure 7: (a) C1 tailings composite (100x); and (b) interface between fibrous tailings and cementitious paste (1000x).

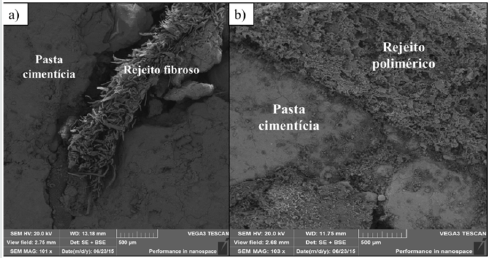

Analysis SEM analysis showed that at the interface between the cement paste and the fibrous tail there is the appearance of cracks (Figure 7), which may influence the decrease of the flexural strength of the plates [37-40]. Opening voids can also cause a significant increase in water absorption if these cracks generate water permeable pores [10]. It is also observed that the bonding relationship between cementitious paste and fibrous waste does not appear to be uniform among the different types of materials [41-43]. Observing Figure 8, it was again found that in fibrous particles (Figure 8A) the adhesion appears to be more fragile due to the reduced contact between the tailings aggregate and the cementitious paste. However, between the paste and the polymeric waste there is greater contact (Figure 8B). This behavior of cement paste on fibrous residues and polymers has also been studied by Moura & Matos [15], which corroborate these results.

Figure 8: Interface between the cementitious paste and tailings: (a) fibrous composite with C2 tailings incorporation (50x); and (b) polymeric composite with C3 tailings incorporation (50x)

Conclusion and Recommendations

A reduction in the apparent specific mass of was observed pavers as the incorporation of waste from selective collection was increased. This behavior is linked to the specific mass of the tailings, which is smaller than that of sand. Regarding the absorption of water by immersion, there was a tendency to increase as the percentage of incorporated tailings increased. This may indicate reduced material durability as the tailings are incorporated (Figure 9). From a mechanical point of view, pavers can be applied to sidewalks and curbs. Nevertheless, further studies are recommended to continue the evaluation of pavers, reducing the size of tailings aggregates and addressing durability aspects. In the plates it was observed that the negative impact of tailings aggregates is greater in compressive strength than in flexural strength [44]. This behavior indicates that it would be advisable for tailings aggregate composites to be used in vertical/horizontal seals, where compression stresses are not predominant. In the scanning electron microscopy analysis, it was observed that in the transition zone the fibrous tailings aggregates have less adherence with the cement paste (Table 11). These types of tailings may be responsible for significant reductions in mechanical parameters [45,46]. Future research is recommended to reduce the incorporated tailings volume as well as its size, thus making it possible to optimize mechanical indexes and material durability.

Figure 9:simple compressive strength in cylindrical specimens

Note: Legend:

* mean (standard deviation); and

** capital letters inform about the incorporated amount of tailings. Lower case letters indicate the different types of tailings.

Equal letters indicate no significant difference (p <0.05).

Table 11: Unit mass in the loose state of incorporated non-vitreous tailings collected at different months.

Acknowledgments

We thank the Coordination for the Improvement of Higher Education Personnel (Capes), for the master’s scholarship of the first author, and to the Municipal Autonomous Water and Sewer Service (Samae) of Blumenau, SC, for supporting the research through an agreement signed with the Regional University Foundation of Blumenau (Furb). We also thank the volunteer undergraduate researcher Juan Peres de Oliveira for his help in the laboratory.

References

- Brazil (2015) National Plan of Solid Waste. Brasí

- Brazil (2014) National Policy on Solid Waste. Brasí

- Moura (2016) JMBM Refuse Collection Waste from the Municipality of Blumenau-SC: gravimetric composition and incorporation of building materials. 106 f. Dissertation (Master in Environmental Engineering) - Blumenau Regional University Foundation, Blumenau, Brazil.

- Saikia N, Brito J (2014) Mechanical Properties and Abrasion Behavior of Concrete Containing Shredded Pet Bottle Waste As A Partial Substitution of Natural Aggregate. Construction and Building Materials 52: 236-244.

- Tonet Kg, Gorninski JP (2013) Polymer Concrete with Recycled Pet: The Influence of The Addition of Industrial Waste on Flammability. Construction and Building Materials 40: 378-389.

- Frigione M (2010) Recycling of Pet Bottles As Fine Aggregate In Concrete. Waste Management 30(6): 1101-1106.

- Moura, Jmbm, Matos (2015) LFS Home Solid Waste Cementitious Plates. Journal of Environmental Studies 17(1): 54-63.

- Albano C, Camacho N, Hernández M, Matheus A, Gutiérrez A (2009) Influence of Content and Particle Size of Pet Waste Bottles on Concrete Behavior at Different W / C Ratios. Waste Manag 29(10): 2707-2716.

- Rahmani E, Dehestani M, Beygi MHA, Allahyari H, Nikbin IM (2013) On the Mechanical Properties of Concrete Containing Waste PET Particles. Construction and Building Materials 47: 1302-1308.

- Raju Sharma, Bansal P (2016) Use of Different Forms of Waste Plastic in Concrete: a review. Journal of Cleaner Production 112(1): 473-482.

- Prahallada MC, Parkash KB (2013) Effect of Different Aspect Ratio of Waste Plastic Fibers on the Properties of Fiber Reinforced Concrete and an Experimental Investigation. International Journal of Advanced Research in IT and Engineering 2: 1-13.

- Ramadevi K, Manju R (2012) Experimental Investigation on the Properties of Concrete with Plastic PET (Bottle) Fibers as Fine Aggregates. International Journal of Emerging Technology and Advanced Engineering 2(6): 2250-2459.

- Malagaveli V (2011) Strength Characteristics of Concrete Using Solid Waste in Experimental Investigation. International Journal of Earth Sciences and Engineering 4: 937-940.

- Batayneh M, Marie I, Asi I (2007) Use of Select Waste Materials in Concrete Mixes. Waste Management, 27: 1870-1876.

- Oliveira R, Brito J, Veiga R (2013) Incorporation of Fine Glass Aggregates in Mortars. Theory and Practice in Civil Engineering 44: 329–341.

- American Society for Testing and Materials (2003) ASTM C 33: standard specification for concrete aggregates. West Conshohocken, USA.

- Test the simple compressive strength determination test for the composite of the plate was performed using cylindrical specimens (ABNT, 1997). In the case of pavers, after being subjected to the water absorption test on the 25th day and run capping on both sides, the pavers were tested in compression at 28 days of curing (ABNT, 1997). Results were generated from three samples for each trait.

- American Society for Testing and Materials (1999) ASTM C674: standard test methods for flexural properties of ceramic whiteware materia astm international. West Conshohocken, USA.

- Saikia N, Brito J (2012) Use of Plastic Waste as Aggregate in Cement Mortar and Concrete Preparation: a review. Construction and Building Materials 34: 385-401.

- Cement Boards (2015)

- Decorlit Cement Boards (2015)

- Porrero J (2004) Manual of Structural Concrete. Caracas: Sidetur.

- Costa AV, Gumieri AG, Black PRG (2014) Interlocking Concrete Blocks Produced with Sinter Feed Tailings. Ibracon Journal of Structures and Materials 7(2): 228-259.

- Martins CH (2015) Pozzolanic Activity Analysis of Sugarcane Bagasse Light Ash and Its Application in Pavers Production. Technological Journal 24(1): 53-64.

- Urban Development Company of the Port of Rio De Janeiro Region. Standards for the Execution of Works, Repairs and Services in AEIU Ports of Porto Maravilha.

- Hannawi K, Prince W, Kamali-Bernard S (2010) Effect of Thermoplastic Aggregates Incorporation on Physical Mechanical and Transfer Behavior of Cementitious Materials. Waste Biomass Value 1: 251-259

- The apparent specific mass was also determined for each plate and specimen paver by the total hardened mass ratio (prior to the immersion water absorption test) and its total volume.

- Scanning Electron Microscopy - SEM

- A microstructural analysis was performed on samples taken from the cementitious plates using a Tescan scanning electron microscope, model Vega 3 LMH / LMU. The objective was to verify the porosity of the composite and the arrangement of the tailings with the cement paste. The plates analyzed were composed of 5% tailings in compositions C1, C2 and C3 (collected in March). The composites were sawn and reduced to an approximate volume of 1cm³.

- Statistical analyzes.

- All the results obtained were subjected to statistical treatment, initially testing the normality of the data (Shapiro-Wilk test) and applying statistical differentiation tests - ANOVA (for parametric data) or Kruskal-Wallis (for non- parametric). Analyzes

- ACTION (2015) Statistical analysis.

- Brazilian association of technical standards (2007) Nbr 15498: Asbestos-free fiber cement plate: requirements and test methods. Rio de Janeiro.

- Brazilian association of technical standards (2009) Nbr 7211: aggregates for concrete: specification. Rio de Janeiro.

- Brazilian association of technical standards (1997) Nbr 7215: Portland cement: determination of compressive strength. Rio de Janeiro.

- Brazilian association of technical standards (2005) Nbr 9778: hardened mortar and concrete: determination of water absorption, voids index and specific mass. Rio de Janeiro.

- Brazilian association of technical standards (2013) Nbr 9780: paving concrete parts determination of compressive strength: test method. Rio de Janeiro.

- Brazilian Association of Technical Standards (2006) Nbr nm 45: aggregates determination of unit mass and void volume. Rio de Janeiro.

- Frigione M (2010) Recycling of Pet Bottles as Fine Aggregate in Concrete. Waste Management 30(6): 1101-1106.

- Bela Vista City Council (2016) Descriptive Memorial: technical specifications.

- Municipal Prefecture of Belt Pinto (2011) Tancredo Neves Street Asphalt Repaving and Lighting Project: descriptive memorial.

- Hall of Indaial (2013) Engineering Project for Interlocking Paving with Concrete Blocks: volume I: descriptive memorial. Greide Engineering.

- Hall of Maraba (2016) Sidewalk Construction Services.

- Hall of São Vicente (2016) Basic Guide Construction and Maintenance of Sidewalks.

- Practical Guide to Building Sidewalks (2nd edn) Union of the Construction Industry of Matogrosso do Sul, (2009) University of The Civil Construction University of Mato Grosso Do Sul. Brazil.

- Tonet, KG, Gorninski JP (2013) Polymer Concrete with Recycled PET: the influence of the addition of industrial waste on flammability. Construction and Building Materials 40: 378-389.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...