Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Research Article(ISSN: 2637-4595)

Mathematical Substantiation of the Rational Package (Bag) of Fully-Formed Fur ArticlesWith Content of Polymer Composition Volume 2 - Issue 3

ZA Sobirova* and SSh Tashpulatov

- Doctor of technical sciences, Tashkent Institute of Textile and Light Industry, Uzbekistan

Received: June 19, 2018; Published: June 27, 2018

*Corresponding author: Hamidovich KMV, Tashkent Institute of Textile and Light Industry Tashkent, Uzbekistan

DOI: 10.32474/LTTFD.2018.02.000139

Annotation

The article presents the results of experimental studies on the mathematical substantiation of the use of polymer compositions, which provides the specified form stability and reliability, meeting the modern requirements of industrial production, the efficiency of their use in production conditions. In this case, the processing of all-seamed details of garments made from natural fur with the subsequent obtaining of a given shape by using the deformation properties of natural raw materials. Also, studies were carried out on the rational location of local areas of application of the polymer composition, taking into account the deformation features of the fur semi-finished product. As a result of the research, recommendations were given on the use of the proposed reinforcement options and the methods of the all-molded package of the product using a polymer composition, which makes it possible to improve the quality and shape stability of the garment components and the economic efficiency of production.

Keywords: Polymer Compositions; Deformation Properties; Shape Stability; Natural Fur; Whole-Molded Products; Relaxation; Reliability of Results; Resource-Saving

Introduction

Improving the mechanisms of shaping and molding in order to achieve a high quality of manufacturing garments by increasing their form stability is the need to evaluate the technological conditions for the formation of the package [1-3]. Insufficient stability of the form of parts of clothing after the technological process can be the result of a number of reasons. Some of them are: incomplete consideration of the strain relaxation in the material and the package; when determining the technological conditions for shaping; the failure to comply with technological regimes; ignoring the location of materials or applying the polymer composition in a package of parts; disturbing the mechanism of formation; and the lack of mechanisms for the formation of a rational package [4-7].

Objects and Methods of Research

The increase in the quality of molding, apart from the last of the above reasons, depends mainly, primarily on the skilled work of the performers. Elimination of the same disadvantages inherent in the method of shaping is associated with the modernization or development of new equipment. It is known [2,8] that it may be sufficient to study the physical-mechanical and technological properties of a package with a polymer composition in order to study the shape stability of parts of garments, in this case headdresses, from the effect of external-force systems and the mechanism of compound deformation (change in shape) consisting of several chemical components.

The purpose of the experimental studies is to determine the rational package for the manufacture of clothing parts of increased form stability, taking into account the deformation properties of the material. The complexity of evaluating and predicting the shape stability of parts from deforming materials during the manufacture of garments is related to the fact that they are determined not only by the composition of the fibers, the kind and structure of the materials, which have heterogeneity of the deformation properties of the raw materials in different directions, but also they are determined by the structural component of the package, reinforcing substances and its densities in the package.

Results and Discussion

The relaxation value of the testing package of the garment parts is determines by measuring the deflection bend of the sample segment after obtaining a three-dimensional shape. The measurements carried out for 24 hours. Variants of the package samples originally designed at different angles for the arrangement of the applied polymer composition in the package relative to the nominal axis of the semi-finished product (from 00 to 1800 with a 150-variation step). Five selected for further work from all the options considered: with angles α = 00, 300, 450, 600and 900 to the nominal axis.

The results of the studies on these samples allow us to estimate the nature of the change in the magnitude of the relaxation of the deformation of the bulk shells over the entire range of theoretically considered variants. According to the results of experimental studies, it is establishes that the samples manufactured according to the third (450) version have increased form stability. The results obtained allow us to conclude that the shape of shells of the third variant is sufficiently stable. It is advisable to increase the amount of relaxation to ensure the specified shape of the shells, while designing the segment configuring the specified shape of the operating devices of the equipment. It is advisable to apply the reinforcing strip of the polymer composition to the semi-finished parts in such a way that they are located at an angle of 450 to the nominal axis of the semi-finished product to obtain a stable volumetric shape of the headgear (headdress) segment.

It is reveals that the relative changes in the deflection boom are in the range of 8-12%from the analysis of the obtained data, depending on the size of the segment boom and the application of the polymer composition in the package, and is describes by the regression equation:

Y=61,4+2,79x1+1,116x2+1,8x3-0,7x1x2+0,43x1x3-0,14x2x3-1,161x1x2x3

Further verification of the reliability of the results obtained during testing of various versions of the package of parts is carrying out. Five different variants of packet formation selected to study the physical and mechanical properties. Ten series of test sis carryout. The purpose of the experiments is to show the advantage of some variants of packages over others. It is necessary to limit the possible number of trials while ensuring sufficient reliability of the difference in the experiments (at a given level of significance).

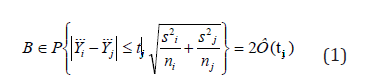

First, it is necessary to make sure that the results of the experiments between the different variants of the packet samples differ significantly. Taking into account the small number of experiments and the natural error in the observations, the statistical in homogeneity of the observation arrays verified. To do this, consider each series of experiments as a sample from the general aggregate. The volume R of the samples n1, n2, nR, thepartial averages of Y1, Y2, YR and sample variances ,S12,S22...SR2.. . Provide that the samples are independent and belong to the same normally distributed aggregatefor any other samples I and γ

Where Ô (tij )-is the Laplace integral function?

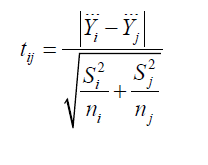

We calculate

i, j = 1,2,...,R

i ≠ j

The values tij , are compares with the table values of homogeneity tα , where 2 Ô(åα ) = 1− α is the confidence probability.

If the minimum sample size ni islessthan30, then we use the S-distribution and compare tij с tx hi-1 with the Student’s distribution table.

If the general aggregate is homogeneous, then in (1 - α) 100% of samples will take place

tij <tα (3)

And for the samplesα · 100

tij≥ tα (4)

If the calculated criterion valuem tij satisfies condition (3), then at the significance level α homogeneity hypothesis is adopts. Ifis tij satisfies (4), then the hypothesis at the significance level α is rejects.

When analyzing the correctness of the hypothesis put forward, there may be errors of the first and second kind. The errors of the first kind are those in which the hypothesis is true, but it is rejects, i.e. the criterion fell into the critical area. The probability of this error is α.

The errors of the second kind are those for which the wrong hypothesis is accepted. The probability of this error is 1-α, i.e. the smaller the probability of the first kind, the greater the probability of an error of the second kind. In the experiments carried out, the hypothesis of difference - heterogeneity of the results is advanced, therefore, in order to avoid errors of the first kind, we take α = 0.05, i.e. 5% level of significance.

Ten experiments were done in two series of tests of packages of parts. Therefore, to determine the criterion α t we use the Student’s quantile distributiont (n −1) α , which for n =10 are equal to t5(9) = 2,260.

Thus, the hypothesis of the heterogeneity of the results of the experiments is accepts, if tij ≥ 2,260.

An analysis of the experimental results shows a significant difference in the results of the experiments of all the series. Samplepackage№3has a difference with the rest of the samples, even at 1% significance level of t1(9) = 3,250.

Conclusion

Thus, the check on the statistical homogeneity of samples during the tests of the physical and mechanical properties of the packets made it possible to reveal a significant difference in the results of most experiments of all series in different directions of application of the polymer composition relative to the nominal axis of the packet samples. The results of the experiments provide a basis for choosing the most rational version of the package for the manufacture of clothing items of a given range.

References

- Melikov E Kh (1986) Working out and research of methods of forming of details of clothes: the author’s abstract. Dis Doct Sciences p. 42.

- S Sh Tashpulatov (2008) Development of highly effective resourcesaving technology for the manufacture of garments: Abstract of thesis. Dis Doct tech Sciences p. 42.

- Cherunova IV (2008) Theoretical bases of complex designing of special clothes: the author’s abstract. Dis Doct tech Sciences Mines: YURGUES p. 42.

- Tashpulatov S Sh, Cherunova IV, Nutfullaeva LN (2015) The study of the form-stability of three-dimensional details of garments: Journal Student Scientific Forum pp. 129-131.

- Tashpulatov S Sh, Nutfullaeva LN, Cherunova IV, Stenkina MP (2015) Hygienic assessment of the conditions of reinforcement of textile material of collagen-containing composition: Journal International Journal of Experimental Education, Moscow 11: pp. 415.

- Tashpulatov S Sh, Nutfullaeva LN, Cherunova IV, Stefanova EB (2015) Substantiation of the dimensions of the reinforcement of the textile material surface with a collagen-containing polymer composition: Journal. International Journal of Experimental Education, Moscow 11: pp. 451-452.

- Cherunova IV, Milutina GR Investigation of the development of nano structured materials and compositions for human life safety. Fundamental research 9-10: p. 2153-2156.

- Sobirova ZA (2017) Geometric characteristics and change bulk form part of the product impregnated with the polymer composition based on collagen. International Journal of the European Science Review pp. 236-237.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...