Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Research Article(ISSN: 2637-4595)

Low Cost Biodegradable Arecahusk Fibre for the Removal of Direct Dye from Effluent Volume 3 - Issue 4

S Kavitha*, J Srinivasan and GTV Prabu

- Department of Fashion Technology, Kumara guru College of Technology, India

Received:June 20, 2019; Published: July 03, 2019

*Corresponding author:S Kavitha, Assistant Professor, Department of Fashion Technology, Kumara guru College of Technology, India

DOI: 10.32474/LTTFD.2019.03.000166

Abstract

As treatment of dye plant effluent is becoming a mandatory requirement, search for cheap and best technology is progressing. Different treatment methods like filtration, flocculation, chemical precipitation, ion exchange, membrane separation and adsorption are being used in Industry. The adsorption process is one of the efficient methods to remove the contaminant from the effluent. New approaches based on the use of natural, inexpensive sorbent materials for effluent treatment are reported often. Areca husk fibre, a commonly available agriculture waste, is predominantly composed of hemicellulose. Dye solutions of different concentrations were prepared and a known amount of areca fiber as adsorbent was added to study the effect of concentration of dye solution and effect of the amount of adsorbent on the percentage of removal of direct dyes.

Keywords: Areca fiber; Adsorption; Direct dye; Effluent treatment; Hemicellulose

Introduction

Textile industry consumes huge volumes of water and chemicals like acids, alkalis, colors, surfactants, dispersing agents, soap and metals are contained in effluent wastewater with high BOD/COD concentration. Most textile wastewaters generated from textile dyeing industries are highly colored because they are on average released with a dye contents in the range of 10-200mg/L, and many dyes are noticeable in water at concentrations as low as 1mg/L. There are many types of dye that vary in chemical structure such as: acid, basic, direct, reactive, disperse, azo, diazo, sulfur-based, mordant, Vat and metal complexes and pigments. Many of them are chemically stable so that they are difficult to decolorize due to their complex structure and synthetic origin. Various effluent treatment alternatives have been reported in laboratory level research as well as full scale commercial, including physical, chemical, biological, Advanced Oxidation Process (AOP) and a combination of them. Most of the treatment methods used are based on different chemical principles which includes chemical precipitation, filtration, flocculation, ion exchange, membrane separation, and adsorption. New methods based on the use of natural, inexpensive materials for effluent treatment are in now demand. The adsorption process is one of the efficient methods to remove contaminant from effluent due to its sludge free clean operation and complete removal of dye even from dilute solutions. It is noted that a huge quantity of areca fiber is found unutilized and wasted or simply used as fuel once the nut is separated. About 1.5laks tones of dry husk can be estimated annually in India. Areca nut (Betel nut) husk is the outer cover of areca fruit, similar to Coir fiber. Areca nut is the kernel obtained from the fruit of the areca palm tree. The nut is of commercial importance and is separated by dehiscing machine whereas the husk of the fruit is removed, and it has no other traditional use (Figures 1a- 1d).

Materials and Methods Preparation of Adsorbents

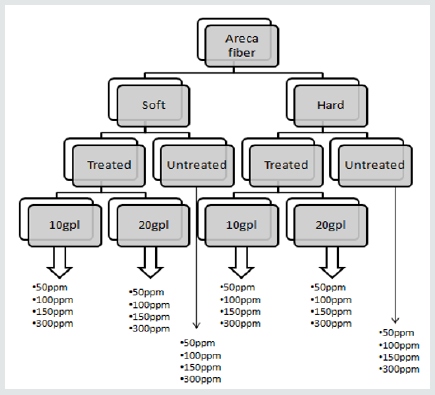

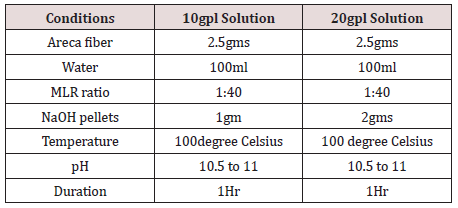

Areca husk was obtained from local farm, after removal of areca nut. Using special areca husk extraction machine fabricated in pilot scale, areca husk was beaten by the machine. The hard and soft fibers were separated using screening machine (Figure 2). Soft and hard fibers were treated with two different types of sodium hydroxide concentrations as 10gpl and 20gpl. The 5gms of soft and hard fiber was first separated into equal parts. These separated parts were treated with sodium hydroxide pellets to improve its absorbency property (Table 1). Direct dyes are so-called because they color cellulose ‘directly’, which benefits the environment by eliminating the need for a mordant. They are popular because they are cheap, easy to apply, very light fast, and available in a wide range of bright colors. However, the process requires salts for exhaustion and lot of energy is needed to heat the dye bath to boiling point. The wastewater from this process contains salt, dye fixing agents and between 5% to 20% of the original added amount of dyestuff. For this study, direct blue dye was sourced from Indo Col chem Limited with empirical Formula (Hill notation) C40H28N7 NaO13S4, Molecular Weight 965.94 and Color Index Number 34140 [1-3].

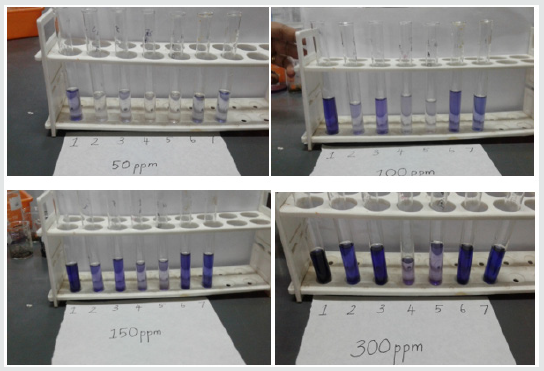

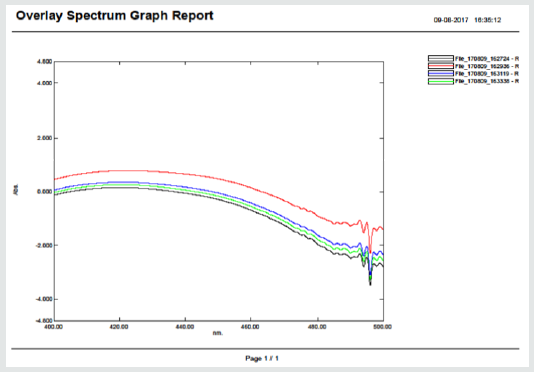

The dye structure is shown in Figure 3. A stock solution of the direct dye was prepared by dissolving 0.25 gram of dye in 250 ml distilled water to make a stock solution of 250 mg/l. The solution used for experiment was prepared by diluting definite volume of the stock solution to get the required concentration. For the preparation of 50ppm solution from stock solution, the stock solution is diluted by 20 times i.e. 15 ml of stock solution is diluted to 300 ml. Similarly, 100ppm, 150ppm and 300ppm of solutions were prepared. The bottles were shaken physically and then followed by mechanical shaking using a mechanical shaker for about 2 hours and was let still for few hours. A small quantity of solution was taken from the respective bottles and then was centrifuged at 3000 rpm for about 10 min. Then these samples and original solution were analysed for concentration of dye contents using UV-Spectrophotometer at 507nm. The respective value gives the study for effect of concentration of pre-treatment solution and the effect of amount of adsorbent for untreated and treated areca husk [4].

Results and Discussion

The following seven different solutions were taken for analysis of amount of dye adsorbed by the treated and untreated fibers in different dye concentrations.

a) Standard solution

b) Soft fiber treated at 10 gal

c) Soft fiber treated at 20 gal

d) Hard fiber treated at 10 gal

e) Hard fiber treated at 20 gal

f) Untreated soft fiber

g) Untreated hard fiber

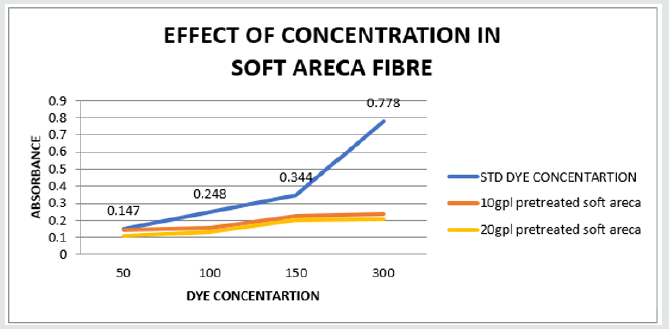

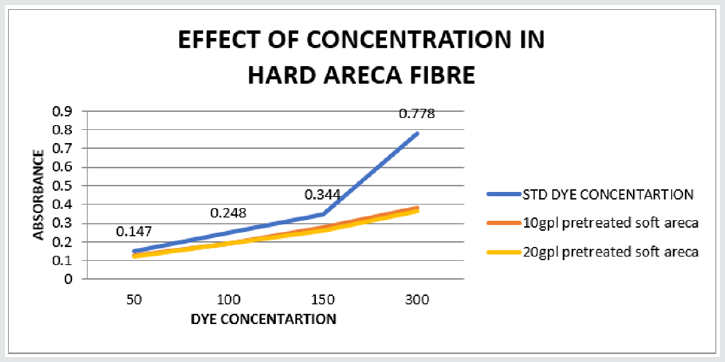

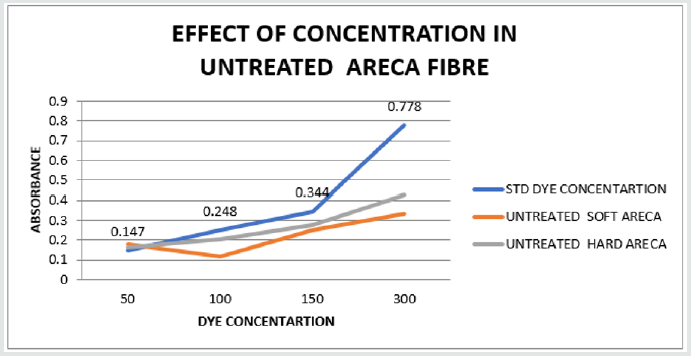

The results obtained from the present investigation revealed the ability of areca husk in absorbing the direct dye. The Figures 4-8 shows the absorbance spectrum obtained in the UV Spectrophotometer for different concentrations. The absorbency values of soft fibers and hard fibers were shown in Figure 9 and Figure 10 and the absorbency values for untreated fibers were shown in Figure 11. The values of the absorbance from the UV-VIS Spectrophotometer for all the study bottles were plotted in the graph that shows the amount of colour removed by the respective adsorbent and its amount. It infers that the treated areca husk removes more colour compared to the untreated Areca husk. This is because of more effective adsorptive capacity for the treated areca husk compared to the untreated Areca husk. It is also identified from the above graphs that [5-7].

a) Absorbency of soft areca fiber is more compared to hard areca fibers

b) Fiber were pretreated with 10gpl and 20gpl. Fibers treated with 20gpl has more absorbency irrespective of soft or hard fiber

c) Thus, soft fibers treated with 20gpl NaOH has good dye absorbing capacity

d) Untreated fiber also absorbs equally or more than treated fibers up to 150 ppm

e) Above 150 ppm, treatment of fiber is required to increase the absorbency.

Conclusion

It was found that adsorption is highly dependent on the contact time, adsorbent dose and dye concentration. Consequently, safety can point to the use of this natural material due to abundance and very cheap biomass. This leads to its superiority as a potential sorbent in removal of some coloured dyes from waste waters. Thus, from the above conducted experiment it can be concluded that the Areca husk can be used as a very effective absorbent in both treated and untreated form.

References

- Lata H, Garg VK, Gupta RK (2007) Removal of a basic dye from aqueous solution by adsorption using Parthenium hysterophorus: an agricultural waste Dyes and pigments. 74(3): 653-658.

- V M Sivakumar, M Thirumarimurugan, A M Xavier, A Sivalingam, T Kannadasan (2012) Colour Removal of Direct Red Dye Effluent by Adsorption Process Using Rice Husk. International Journal of Bioscience, Biochemistry and Bioinformatics 2(6): 377-380.

- R Nagaraja, B R Gurumurthy, M B Shivanna (2014) Bio Softening of Arecanut Waste Areca Husk, Leaf And Leaf Sheath For Value Added Compost. International Journal of Research in Applied, Natural and Social Sciences 2(9): 2347-4580.

- D Antoni, Mirko, Iracà F, Romero Marianna (2017) Abstract review on: Current treatment technologies and practical approaches on textile wastewater Dyes Removal.

- Binoj JS, Raj RE, Sreenivasan VS, Thusnavis GR (2016) Morphological, physical, mechanical, chemical and thermal characterization of sustainable indian areca fruit husk fibers (areca catechu l.) as potential alternate for hazardous synthetic fibers. Journal of Bionic Engineering 13(1): 156-165.

- Zheng JX, Li ZH, Yuan LJ, Zhong HY (2006) Review on the physiological effects of areca nut use. Food Science and Technology 9: 111.

- Nayak S, Mohanty JR (2018) Influence of chemical treatment on tensile strength, water absorption, surface morphology, and thermal analysis of areca sheath fibers. Journal of Natural Fibers 16(4): 589-599.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...