Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Research Article(ISSN: 2637-4595)

Importance of Spindle Speed in Ring Frame Volume 3 - Issue 5

Redwanul Islam1*, Amit Chakrabortty1, Joyjit Ghosh1, Tareq Iqbal2 and Tanvir Hossen3

- 1Lecturer, Department of Textile Engineering, Ahsanullah University of Science and Technology(AUST), Bangladesh

- 2Lecturer, Department of Textile Engineering and Management, BGMEA University of Fashion and Technology, Bangladesh

- 3Lecturer, Department of Textile Engineering, Jashore University of Science and Technology (JUST), Bangladesh

Received: March 31, 2021 Published: April 14, 2021

*Corresponding author: Redwanul Islam, Lecturer, Department of Textile Engineering, Ahsanullah University of Science and Technology (AUST),Bangladesh

DOI: 10.32474/LTTFD.2021.03.000173

Abstract

We all know that in the spinning system the ring frame plays a vital role, so that we want to highlight the importance of the ring frame in this paper. There are many modern spinning systems but the product which we get from the ring frame is much better than other spinning systems. For making good quality yarn, we need to control the spindle speed because sometimes it is shown that the speed of spindle is changing for lack of maintenance and lack of monitoring. If we properly monitor them and control the spindle speed, then we get a proper resulted count. It is observed that when the spindle speed is 15000 rpm for average ring yarn it shows the optimum quality.

Keywords: Spindle; ring frame; RPM

Introduction

The productivity of ring frame is a major factor contributing to the profitability of a spinning mill and higher spindle speed has become necessary for higher productivity [1]. Problems encountered in spinning yarns at high spindle speeds include yarn breakage rate, hairiness, strength loss and fly generation [2]. Consequently, production of acceptable yarn is achieved only at relatively low speeds [3].The identification of natural frequencies of the spindle under rotating conditions is challenging, due to the low number of sensors and the presence of many harmonics in the measured signals. In order to overcome these issues and to extract the characteristics of the system, the spindle modes are determined through a 3-step procedure. First, spindle modes are highlighted using the Frequency Domain Decomposition (FDD) technique, with a new formulation at the considered rotating speed. These extracted modes are then analysed through the value of their respective damping ratios in order to separate the harmonics component from structural spindle natural frequencies. Finally, the stochastic properties of the modes are also investigated by considering the probability density of the retained modes. Results show a good correlation between numerical and experimentbased identified frequencies. The identified spindle-tool modal properties during machining allow the numerical model to be considered as representative of the real dynamic properties of the system [4]. Ring spinning which uses the Ring frame is the main spinning system is used by 7 in every 8 mills to produce cotton yarns for fabric production by knitting and weaving factories 3. The process of fibre to yarn conversion at the ring frame involves drafting, twisting roving of fibres and winding the spun yarn on the bobbin and is the costliest stage in the spinning process flow contributing 60% of the total cost of yarn production4. Mills therefore aim at maximizing the utilisation of ring Improvement of Ring Frame Spindle Utilization in Cotton Short Staple Spinning DOI: 10.9790/1684-1601035865 www.iosrjournals.org 59 | Page frame to reduce the overall cost of yarn production and improve competitiveness of the textile produce [5].

Research Methodology

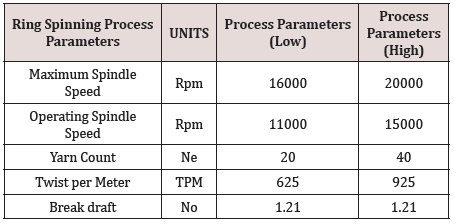

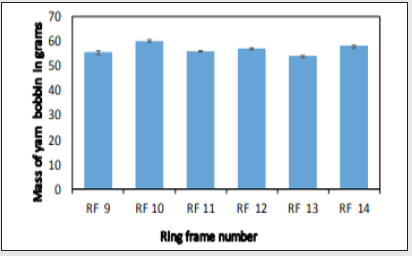

For this study we consider 1200 spindles and operate these and carefully monitor these for 7 days (Table 1).

Ring Spinning and Doffing Cycles

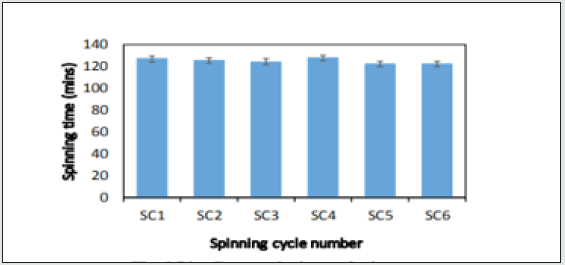

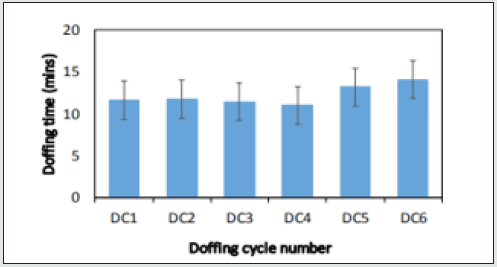

The spinning cycle was timed from the start of the running of the ring frame when yarn starts building up on the bobbin to the time when ring frame automatically stops due to bobbins get filled up with yarn. The doffing cycle was timed when the ring frame automatically stops up to the time when the machine was restarted for the next spinning cycle (SC). The Ring Frames automatically records the cycle process parameters such as spinning cycles (SC) and doffing cycles (DC) times automatically recorded were retrieved, recorded and analysed. The spinning and doffing cycles had a mean time of 125.05 and 12.1867 minutes respectively as shown in Figures 1 & 2. The mean weight of ring frame yarn bobbin in grams from 6 different ring frames spinning 20s was of 56.71525 grams representing a loss of 7.5847 grams per bobbin as shown in Figure 3. The low spindle utilization below the standard norm can be attributed to several factors such as stoppage of the entire ring frame for doffing full bobbins, idle spindles within the ring frame during running of the ring frame, end breakages and occasional stoppage of the ring frame for cleaning and maintenance of the ring frame [5].The analysis of yarn properties such as hairiness, imperfections, tenacity and elongation produced at two different spindle speed of the ring frame machine was done. From the analysis it is concluded that the hairiness and total imperfections in the ring yarn increased but there is remarkable decrease in the breaking extension was found as the spindle speed increased. Practically we will always try to achieve the optimum quality of yarn at higher production rate of ring frame [6]. Bangladesh is a developing country where the economy of Bangladesh depends on textile sector. There are 425 spinning mills established in Bangladesh which provide the raw materials yarn to the textile sector. The size of spinning determine by the number of spindle of a spinning mills. The total numbers of spindles are 12410000 in 425 spinning mills in Bangladesh [7]. The quality of ring spun yarn depends on many factors and the production of yarn depends on ring spindle speed. So, the effect of spindle speed of ring frame on yarn quality is very important. The aim of this research is to produce maximum yarn with high quality in optimum spindle speed. The productivity of ring frame is directly related to the profitability of a spinning mill and also the productivity of a spinning mills is depending on the spindle speed of ring frame. So, the profitability of a spinning mills depends on the spindle speed of ring frame [6]. But the higher spindle speed effect the quality of yarn as well as end breakage [8].

Figure 3: Shows Average Weight of Ring Frame Yarn Bobbin in Grams from 6 Different Rings Frames Spinning 20s.

Research Limitations

Data for the study was collected from Yasmin spinning mills Ltd. Another limitation is we didn’t monitor the spindle speed as well as the production in the night shift.

Conclusion

Excessive spindle speed will cause premature tool wear, breakages, and can cause tool chatter, all of which can lead to potentially dangerous conditions. Using the correct spindle speed for the material and tools will greatly enhance tool life and the quality of the surface finish. Here we want to highlight the importance of spindle speed for producing the good quality yarn.

References

- Grosberg P, Iype C (1999) Yarn Production, Theoretical Aspects, The Textile Institute: Manchester, UK pp. 99-113.

- Schlaf horst (1995) Preparation of Linen Fibres and Their Processing in Ring and Rotor Spinning, Manchengla batch, Germany pp. 33

- Lawal AS, Nkeonye PO, Anandjiwala RD (2011) Influence of spindle speed on yarn quality of Flax/Cotton blend. The Open Textile Journal 4(1): 7-12.

- Gagnol V, Le TP, Ray P (2011) Modal identification of spindle-tool unit in high-speed machining. Mechanical Systems and Signal Processing 25(7): 2388-2398.

- Musyoki JK, Muchiri PN, Keraita JN (2019) Improvement of Ring Frame Spindle Utilization in Cotton Short Staple Spinning: A Case Study of a Cotton Spinning Mill 16 (1): 58-65.

- Patil MJ, Kolte PP, Gulhane MS (2019) Effect of Spindle Speed of Ring frame on yarn quality. IPI 442(319): 232.

- Tanvir H (2018) Cotton and Products Annual_ Dhaka_Bangladesh. Global Agricultural Information Netwok (GAIN), Dhaka, Bangladesh.

- Chellamani KP, Gnanasekar K, Karthikeyan S (1995) Effect of spindle speed on end breakage and yarn quality while using lower package size. Indian Journal of Fibre & Textile Research 20: 83-85.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...