Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Research Article(ISSN: 2637-4595)

Green Dyeing On Cotton Fabric Demodulated From Diospyros Malabarica and Camellia Sinensis with Green Mordanting Agent Volume 2 - Issue 2

Md Anowar Hossain1* and AK Samanta2

- 1Department of Textile Engineering, City University, Bangladesh

- 2Department of Jute and Fiber Technology, University of Calcutta, India

Received: May 03, 2018; Published: May 09, 2018

*Corresponding author: Md Anowar Hossain, Department of Textile Engineering, City University, Dhaka, Bangladesh

DOI: 10.32474/LTTFD.2018.02.000132

Abstract

A combined green dyeing and mordanting method was applied on cotton fabric in which natural coloring agents were extracted from Diospyros malabarica (Green Gaub fruit) and Camellia sinensis (Green Tea Leaf) wherever green lemon juice had been used as green mordanting agent and there is no artificial chemical was used during demodulation process of coloring agent, dyeing and mordanting. Both the treated and untreated fabric samples were tested for their mechanical properties (color fastness to washing and rubbing) and dyeing performance in terms of color fastness properties (light fastness) and color strength, K/S value. For dyeing with green gaub fruit, color fastness to wash and rubbing = Very excellent, color fastness to light = good and for dyeing with green tea leaf, color fastness to wash= very excellent, color fastness to rubbing = excellent, color fastness to light = good. An improved color strength, K/S value had been found for both dyeing with green gaub fruit and green tea leaf while mordanting was applied with green lemon juice.

Abbrevations: RSW: Red Sandal Wood; MJ: Manjistha; JFW: Jack Fruit Wood; MG: Mari Gold; SW: Sappan Wood; BL: Babool; OWG: Optimum on Weight Goods; OWF: On Weigh Fiber

Introduction

Natural dyes are being called as green dyes which can be prepared from natural dye bearing plants like leaves, stem, barks, seeds, flowers, roots etc collected from completely natural sources and have no negative effect to environment as well as no harmful for the aquatic life. There are many trees available in Bangladesh and India which can be used as the major sources of natural dyes. For example: (green gaub fruit), Diospyros malabarica (green gaub fruit), Camellia sinensis (green tea leaf) etc. Natural dye has a great demand in the national and international market due to increasing rate of conscious person related to health and environment. Due to the current economic and environmental consciousness, research in this front should be titled towards the use of natural dyes for dyeing textile materials. Today, people around the globe are rediscovering color through the use of renewable and non-toxic natural sources. For successful commercial use of natural dyes for any particular fibers, the appropriate scientific standardized techniques/procedures are to be derived. Thus, relevant scientific studies and its output on standardization of dyeing methods, dyeing process variables, dyeing kinetics and test of compatibility of selective natural dyes and natural mordant have become very important. Lemon juice, Tamarind is also selected as the most important natural mordant to standardize the dyeing effect.

Literature Review

Growing consciousness for eco-friendly textile products has caused more interest on cotton fiber based natural dyeing and finishing. Productions of synthetic dyes are dependent on the petrochemical source and some of the synthetic dyes contain toxic/ carcinogenic amines and are not eco-friendly. Contrary to this, most of the natural dyes as well as natural finish with few exceptions are based on vegetable/ animal origin and are renewable, biodegradable, energy-efficient and eco-friendly [1,2]. Single and binary mixtures of aqueous extracts of red sandalwood (RSW) with aqueous extract of other natural dyes like manjistha (MJ), jackfruit wood (JFW), marigold (MG), sappan wood (SW) and babool (BL) in different proportions are applied on bleached jute fabric for its dyeing after double pre-mordanted with myrobolan and aluminum sulphate applied in sequence under optimized conditions of mordanting with effects of use of different proportions of binary mixture of selective natural dyes on colour strength and other colour where good fastness properties were observed [3]. Bleached cotton fabric (after sequential pre-mordanting with myrobolan and then with aluminum sulfate applied in sequence) had been dyed with a pre-fixed concentration of purified binary mixtures of jackfruit wood (JFW) and other natural dyes, like manjistha (MJ), red sandalwood (RSW), Marie gold (MG), sappan wood (SW) and babool (BL) in different proportions to obtain a variety of compound shades wherever color strength (K/S values), washing and color fastness properties were improved [4].

Natural extracted dyes, manjistha was applied on cotton fabric and observed the improvement of wash and light fastness properties [5]. Myobolan (Harda) and metallic salts (Potash alum and aluminum sulphate) as mordents and aqueous extract of Tesu (Palash flower petals) as dyeing agent was used and found improved wash and light fatness [6]. Myrobolan (harda) and other mordents (metallic salts) followed by dyeing with aqueous extract of Jackfruit and found good color fastness properties [7]. Yasashri Ranganath Bark of Swietenia macrophylla (Mahogany) is a valuable natural dye source for textile. 1% alkaline solution was used for the extraction of the dye from the finely crushed bark at 90 Celcius. Optimum dye extraction was obtained at 2 hours and optimum on weight goods (OWG) ratio for extraction was 1:6. Usually a salt of Al, Fe, Cr, Cu, or Ti has to be used as the mordant to enhance the affinity of the nature dye to the fabric. In order to test the best mordant for this dye, 4% on weigh fiber (OWF) solution of Al2 (SO4)3, MgCl2, FeSO4 were applied. MgCl2 showed the best uniform dyeing, thus it was used as the optimized mordant for dyeing experiments. Adsorption of extracted mahogany dye to the cotton fabric and adsorption capacities are significantly affected by pH, initial dye concentration and temperature of the dye bath. In the current study the dye bath was maintained at pH=10 and temperature at 90 Celcius for 2 hours and 1:50 metal to liquor ratio of the mordent was used. Amount of dye adsorption reached to the saturation when dye concentration was at 200ppm.

Dye adsorption data at 90 Celcius were analyzed using Langmuir and Frendlich isotherms and CIE Lab colour values was measured [8]. Rakesh Kumar and YC Tripathi were studied Atharveda carries description of natural dyes. Bhrigu Samhita is written using natural dyes. Colour formed a basis to the various economic activities. Kautilya’s Arthasastra dating back to 298 BC bears account of durations (days) allowed for various types of colouration and wages to be provided to the then professional artisans. Archaeological evidences shows that the dyeing was a widespread industrial enterprise in Egypt, Indiana and Mesopotamia around third millennium BC. The art of dyeing was as old as human civilization. From the historical records it is learnt that natural colorants were available to people during Greco-Roman periods [9]. KH Prabhu* and Aniket S Bhute were studied that Natural dyes, which were pushed during the last sixty years into the background by synthetic dyes, are recently again becoming object of consumer interests. This is due to the awareness of possible risks during production of synthetic dyes which involve use of petrochemical based raw materials and the violent chemical reactions for their synthesis. The manufacture of such dyes is energy intensive with adverse impact on environment adding to its pollution. Many of these dyes, especially the azo- based ones, are found to be carcinogenic. In this background, a brief review of natural colourant from plant sources, their classification, chemical constituents responsible for producing different colours, its activities and effect of different mordents on the hue is discussed. Different classes of mordents employed for fixation of natural colouration on textiles substrate, its mechanism and plant sources are also discussed [10].

V Narayana Swamy, Ninge Gowda K N were studied that Ecofriendly natural dye extracted from Swietenia mahogany leaves, has been used as eco-friendly dye to cotton and silk fabrics. The dyeing was carried out with and without the use of mordents and0 the fastness properties of the fabrics were determined. Colour values in terms of K/S and L* a* b* C and h colour coordinates were examined. A wide range of shades were obtained by using various mordents and mordanting techniques. Dye was tested for some eco-parameters using atomic absorption spectrophotometer and GC/MS. The effluent disposed at the end of the processing was also tested in some cases. The test results were compared with set standards to determine the eco-friendliness of natural dye, show that their concentrations are much below the stipulated limits. Narayana Swamy*, K.N. Ninge Gowda and R. Sudhakar were studied that extracted from Swietenia mahogany leaves, has been used as eco-friendly dye to cotton and silk fabrics. The dyeing was carried out with and without the use of mordents and the fastness properties of the fabrics were determined. Colour values in terms of K/S and L* a* b* C and h colour coordinates were examined. A wide range of shades were obtained by using various mordents and mordanting techniques. Dye was tested for some eco-parameters using atomic absorption spectrophotometer and GC/MS. The effluent disposed at the end of the processing was also tested in some cases. The test results were compared with set standards to determine the eco-friendliness of natural dye, show that their concentrations are much below the stipulated limits [11].

M. Kumaresan Fastness properties of the flower of Spathodea campanulata and Cordia sebestena dyed cotton fabric have been studied using different combination (1:3,1:1 and 3:1) of various mordents, such as myrobolan: nickel sulphate, myrobolan: aluminum sulphate, myrobolan: potassium dichromate, myrobolan: ferrous sulphate and myrobolan: stannous chloride. The wash, rub, light and perspiration fastness of the dyed samples have been evaluated. Comparing the fastness properties and colour strength of flower of Spathodea campanulata and Cordia sebestena dyed cotton by using combination of mordents. In the comparative study of fastness properties and colour strength of the dyed cotton samples Spathodea campanulata in simultaneous mordanting method with 1: 3 mordant combinations gives better results than using flower of Cordia sebestena [12]. Ploysai Ohama, Nattida Tumpat were studied that Natural dye extracted from Caesalpinia sappan Linn was applied to a cotton fabric and silk yarn by dyeing process. The dyestuff component of Caesalpinia sappan Linn was extracted using water and ethanol. Analytical studies such as UV–VIS spectrophotometer and gravimetric analysis were performed on the extracts. Brazilein, the major dyestuff component of Caesalpinia sappan Linn was confirmed in both aqueous and ethanolic extracts by UV–VIS spectrum. The color of each dyed material was investigated in terms of the CIELAB (L*, a* and b*) and K/S values. Cotton fabric dyed without mordant had a shade of reddish-brown, while those post-mordanted with aluminum potassium sulfate, ferrous sulfate and copper sulfate produced a variety of wine red to dark purple color shades. Cotton fabric and silk yarn dyeing was studied using aluminum potassium sulfate as a mordant. The observed color strength was enhanced with increase in mordant concentration [13].

Materials and Experimental Works

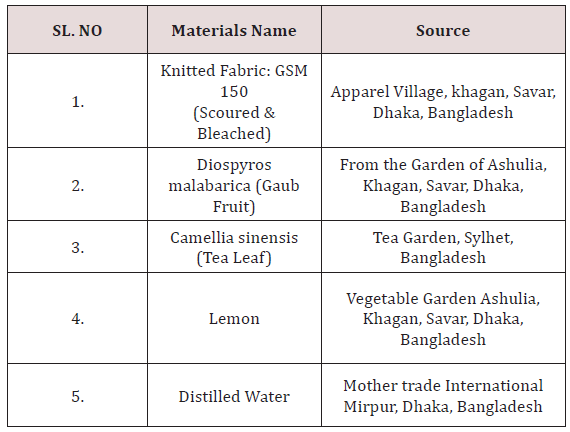

Materials Used

Experiment 01: First we collected Gaub Fruit from garden and split by knife and took 2.13gm. After that we took 100cc water and heated up to 70 0c for 30 min. Then we filtered the total solution of Gaub fruit and got the dye solution. After that we dyed the specific fabric with 1.72gm weight in 700c for 30 min. Then we dyed the total fabric. Temperature checked by thermometer and finished with padding and drying method (Table 1).

Dyeing and Finishing with Natural Dyes Extracted from Gaub Fruit:

Diospyros malabarica 2.13gm ↓ Distilled water (100cc) ↓ Heat (70 0c×30min) ↓ Filtering with very fine meshed fabric ↓ Add Fabric 1.72gm ↓ Dyeing ↓ (700c×30min) ↓ Padding and natural Drying

Experiment 02: First we collected Gaub Fruit from garden and split by knife and smashed it. We got 6gm powder. After that we took 200cc water and heated up to 70 0c for 30min. Then we filtered the total solution of Gaub fruit and got the dye solution. Then we added 45cc green lemon juice. After that we dyed the specific fabric with 10gm weight in 70 0c for 30min. Then we dyed the total fabric. Temperature checked by thermometer and finished with padding and drying method.

Combined Dyeing with Natural Dyes Extracted from Diospyros Malabarica and Natural Mordanting Agent Extracted from Green Lemon:

Diospyros malabarica 6gm ↓ Distilled water (200cc) ↓ Heat (70 0c×30min) ↓ Filtering with very fine meshed fabric ↓ Added green Lemon juice (45cc) ↓ Mixer with automatic blending machine ↓ Add Fabric 10gm ↓ Dyeing ↓ (70 0c×30min) Padding Drying

Experiment 03: First we collected Tea Leaf from bazaar and took 5gm. weight. After that we took 200cc water and heated up to 70 0c for 30 min. Then we filtered the total solution of tea leaf and got the dye solution. After that we dyed the specific fabric with 10gm weight in 70 0c for 30min. Then we dyed the total fabric. Temperature checked by thermometer and finished with padding and drying method.

Dyeing with Natural Dyes Extracted from Tea Leaf and Natural Mordanting Agent Extracted from Green Lemon:

Tea leaf 5gm ↓ Distilled water (200cc) ↓ Heat (70 0c×30min) ↓ Filtering with very fine meshed fabric ↓ Add Fabric 10gm ↓ Dyeing ↓ (700c×30min) padding drying

Experiment 04: First we collected Tea Leaf from bazaar and took 5gm. weight. After that we took 200cc water and heated up to 70 0c for 30 min. Then we filtered the total solution of tea leaf and got the dye solution. After that we dyed the specific fabric with 10gm weight in 70 0c for 30 min. Then we dyed the total fabric. Temperature checked by thermometer and finished with padding and drying method.

Testing Methods

Color fastness to wash was tested ISO 105-A05, Textiles - Tests for color fastness - Part A05: Instrumental assessment of change in color for determination of grey scale rating with Launder-o-Meter.

Dyeing with Natural Dyes Extracted from Green Tea Leaf and Natural Mordanting Agent Extracted from Green Lemon:

Tea leaf 5gm ↓ Distilled water (200cc) ↓ Heat (700c×30min) ↓ Filtering with very fine meshed fabric ↓ Added green Lemon juice (35cc) ↓ Mixer with automatic blending machine ↓ Add Fabric 10gm ↓ Dyeing ↓ (700c×30min) padding drying

Testing Methods

a) Color fastness to wash was tested ISO 105-A05, Textiles - Tests for color fastness - Part A05: Instrumental assessment of change in color for determination of grey scale rating with Launder-o-Meter.

b) Light fastness to wash was tested by AATCC TM16 in Q-SUN XE-2 Xenon Test chamber against blue wool standards (BS -1006-B01-1978.

c) Color fastness to Rubbing was tested ISO 105-X12:2001(E) which finger and force were used in the test. Whether dry or wet rubbing was performed along with the percentage of soak the numerical rating for staining for each test specimen. The staining of the cotton rubbing cloths with the grey scale for staining 4.4 under suitable illumination.

d) Color strength (K/S value) was measured by measuring surface reflectance value where Computer color measuring instrument (Macbeth 2020 plus spectrophotometer). Color strength of untreated and treated cotton fabric samples is measured from the reflectance value at maximum wave length from which surface color strength (K/S value) can be determined by kubelka- munk equation:

K/S=(1-Rλmax)/2Rλmax αCD

Where, K = coefficient of absorption, S = coefficient of scattering.

Rλmax = reflectance of the substrate at maximum absorbance wavelength.

CD = concentration of dye.

Result & Discussion

Diospyros malabarica (Green Gaub fruit) and Camellia sinensis (Green Tea Leaf) were extracted wherever green lemon juice had been used as green mordanting agent. Both the treated and untreated fabric samples were tested for their mechanical properties (color fastness to washing and rubbing) and dyeing performance in terms of color fastness properties (light fastness) and color strength, K/S value. For dyeing with green gaub fruit, color fastness to wash and rubbing = Very excellent, color fastness to light = good and for dyeing with green tea leaf, color fastness to wash= very excellent, color fastness to rubbing = excellent, color fastness to light = good. An improved color strength, K/S value had been found for both dyeing with green gaub fruit and green tea leaf while mordanting was applied with green lemon juice.

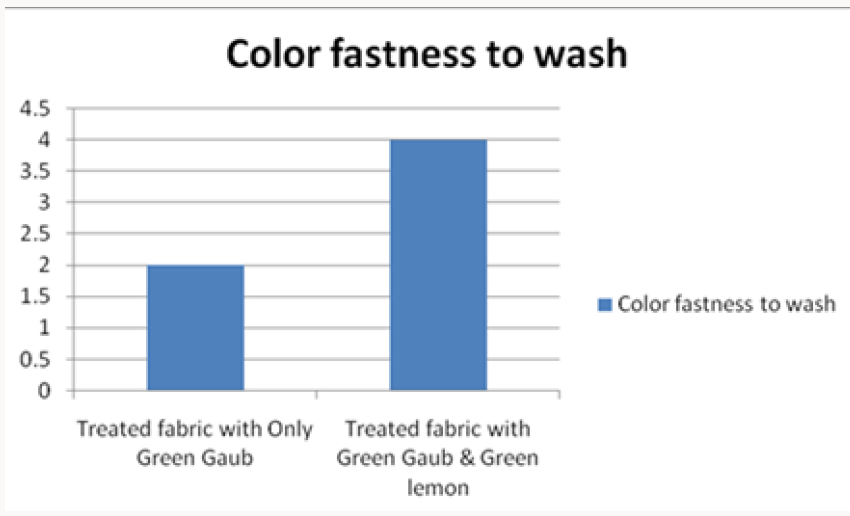

Color Fastness to Wash for Green Gaub Fruit

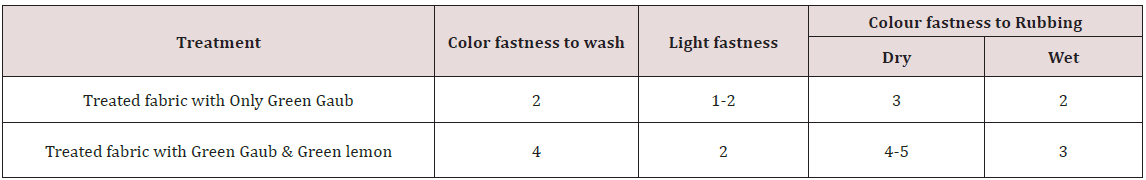

For Gaub, the color fastness to wash tabulated in the result table shows in graph that the mordanted sample gaub with lemon have excellent color fastness.

For Green Gaub Fruit: (Table 2) (Figure 1)

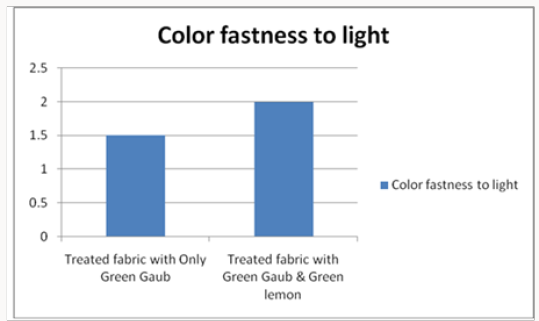

a) Color Fastness to Light: The colorfastness to light tabulated in result table shows in graph that the mordanted samples of gaub with lemon had observed good light fastness property (Figure 2).

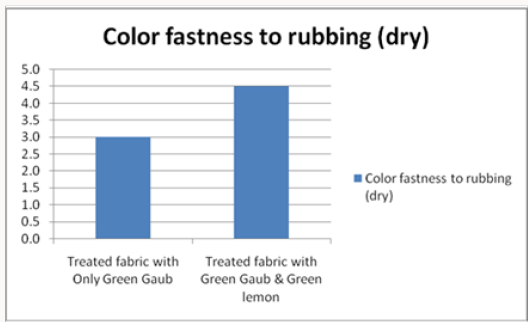

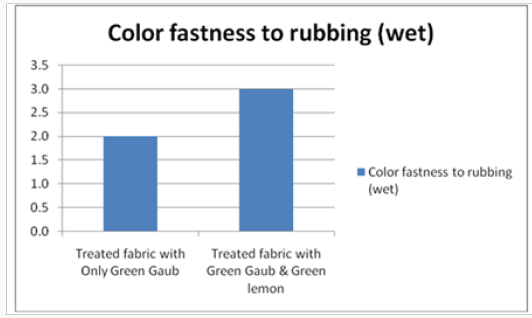

b) Color Fastness to Rubbing: Rub Fastness from result table it can be understood that mordanted samples were better than unmordanted samples exhibited better rub fastness under dry and wet conditions. The mordanted samples had good fastness under both crocking conditions. We can say that the mordanted samples are good color fastness to provide here in Dry and Wet conditions (Figures 3 & 4).

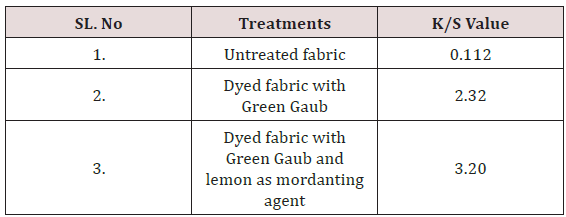

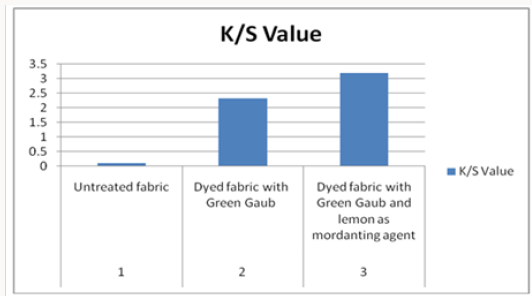

Study on K/S value for Green Gaub Fruit:

Improved K/S value had been found due to mordanting with lemon while extracted solution of green gaub fruit was used as natural coloring agent (Table 3) (Figure 5).

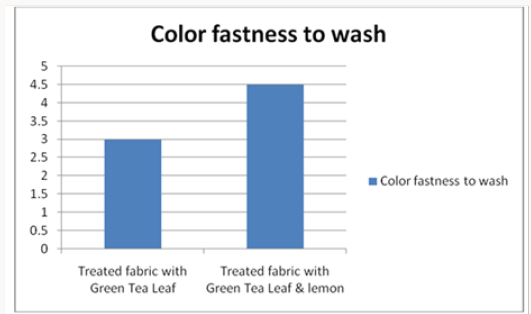

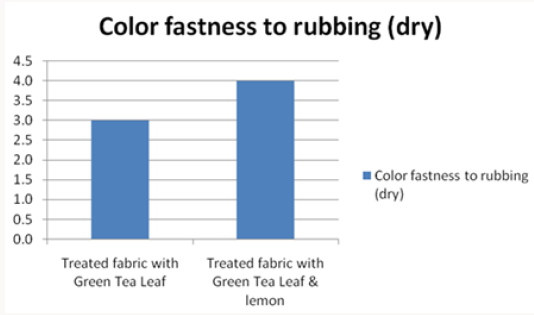

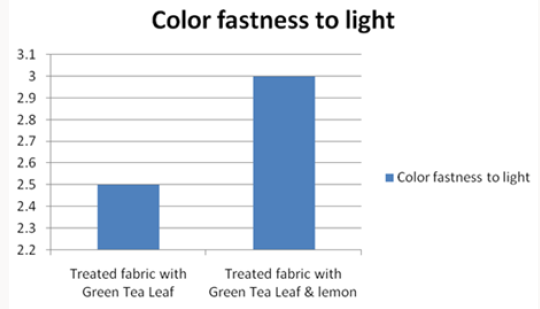

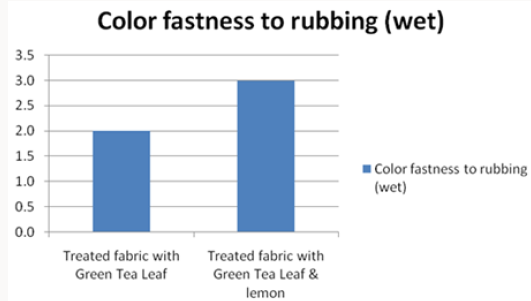

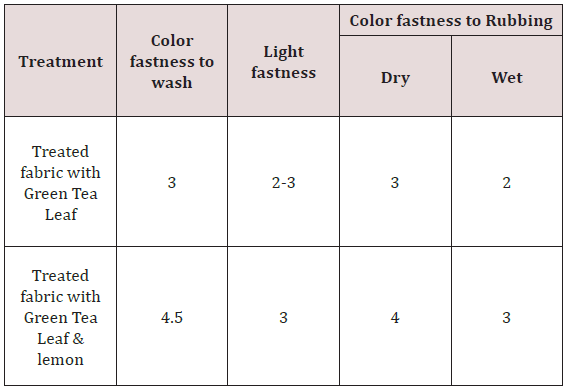

For Tea Leaf

a) Color Fastness to Wash: Mordanted sample treated with green tea leaf and lemon showed excellent color fastness to wash comparing to sample where no mardanting agent was used (Figure 6).

b) Color Fastness to Light: Sample treated with green tea leaf and lemon showed excellent color fastness to light comparing to sample where no mordanting agent were used (Figure 7).

c) Color Fastness to Rubbing: Rub Fastness from the result table it can be understood that samples exhibited better rub fastness under dry and wet conditions. We can say that the unmordanted and mordanted both are good color fastness to provide here in dry and wet conditions (Figures 8 & 9).

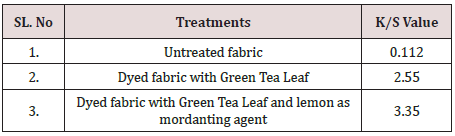

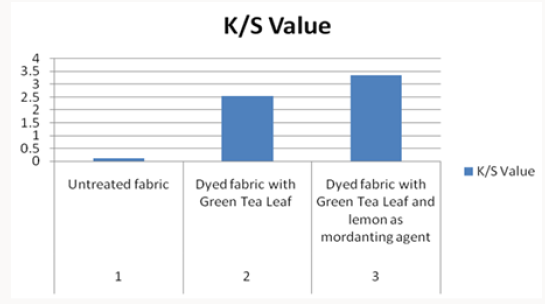

Improved K/S value had been found due to mordanting with lemon while extracted solution of green tea leaf was used as natural coloring agent (Tables 4 & 5) (Figure 10).

Conclusion

In favor of both dyeing with green gaub fruit and green tea leaf and mordanting with green lemon have been found excellent color fastness to wash and rubbing but color fastness to light had been found slightly less which can be established with further study of chemistry based reaction in presence of light, but both dyed fabric showed improved result of color strength, k/s value with very even distribution of color on the surface of fabric which may be ascertained in the corner of green dyeing of textile substrate and it will not only influence to create the green scenario of environment but also it will highly minimize the coloration cost if it can be further studied to put into practice in industrial based dyeing under great thinking of commercialization considering all negative effect of synthetic dyeing on textile substrate and availability of green sources of natural dyes mainly in Asian country like Bangladesh and India.

References

- Samanta AK, Singhee Deepali, Sethia Mitu (2003) Application of Single and Mixture of Selected natural dyes on Cotton Fabrics-A Scientific Approach 50(10): 29-42.

- Dedhia EM (1998) Natural Dyes, Colourage p. 16.

- Ashis Kumar Samanta, Priti Agarwal, Deepali Singhee, Siddhartha Datta (2009) Application of single and mixtures of red sandalwood and other natural dyes for dyeing of jute fabric: studies on colour parameters/ colour fastness and compatibility. The Journal of textile institute 100(7): 565-587.

- AK Samanta Studies on Color Interaction Parameters and Color Fastness Properties for Dyeing of Cotton Fabrics with Binary Mixtures of Jackfruit Wood and other Natural Dyes. Journal of natural fiber 6(2): 171-190.

- Ashis Kumar Samanta (2010) Effect of different Mordents, Extraction Conditions and Dyeing Process Variables on colour interaction Parameters and Colour Fastness properties in dyeing of Jute Fabric with Manjistha, a Natural Dye. Journal of Institution of Engineers (India)- Textile Engg 91: 7-15.

- Ashis Kumar Samanta (2011) Dyeing of Jute fabric with Tesu extract: part 1-effects of different mordents and dying process variables. Indian Journal of Fiber and Textile Research 36: 63-73.

- Ashis Kumar Samanta (2007) Dyeing of Jute and Cotton fabrics using Jackfruit wood extract: part 1-effects of mordanting and dying process variable on color yield and color fastness properties. Indian Journal of Fiber and Textile Research 32: 466-476.

- Yasashri Ranganath Institute of Chemistry Ceylon.

- Rakesh Kumar, YC Tripathi Chemistry Division, India Natural dye from forest biomass, Training Manual on Extraction Technology of Natural Dyes & Aroma Therapy and Cultivation Value Addition of Medicinal Plants. Forest Research Institute, Dehra Dun, India.

- KH Prabhu, Aniket S Bhute Department of Textile Chemical and Colour, Plant based natural dyes and mordents: A Review. Wool Research Association, Kolshet Road, Maharashtra, India.

- V Narayana Swamy, Ninge Gowda KN (2015)

- M Kumaresan (2015) Department of Chemistry, Erode Sengunthar Engineering College, Thudupathi, Erode, Tamilnadu Scholars Research Library Der Pharma Chemica 7(4): 257-260.

- Ploysai Ohama, Nattida Tumpat (2014) Textile Dyeing with Natural Dye from Sappan Tree (Caesalpinia sappan Linn.) Extract World Academy of Science, Engineering and Technology International. Journal of Materials and Textile Engineering 8: 5.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...