Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Review Article(ISSN: 2637-4595)

Design of E Textile Mats for Bedridden Patients Volume 5 - Issue 1

Gokarneshan N1*, CSS Renukha Parameshwari1 and C Kayalvizhi2

- 1Department of Fashion Design and Arts, Hindustan Institute of Technology and Science, India

- 2Department of Textile Technology, RVS College of Engineering and Technology, India

Received:May 02, 2022 Published: May 24, 2022

*Corresponding author: Gokarneshan N, Department of Fashion Design and Arts, Hindustan Institute of Technology and Science, India

DOI: 10.32474/LTTFD.2022.05.000201

Abstract

An e-textile mat with capacitive textile sensors was designed and manufactured to monitor body position and prevent decubitus ulcers in the case of bedridden people. The sensors were incorporated through a process of machine embroidery with electrically conductive threads. A new production method for the conductive threads is still expected to be developed, resulting in good conductive properties, high wear resistance and durability. Samples of five variants of motifs without cross-stitching were studied, and the capacity and electrical resistance were determined experimentally. A prototype of the e-textile mat was made with a motif showing the best ratio between the inserted thread and the measured capacity. A hardware solution and a software application for collecting, processing and visualizing the received information were developed. Tests were performed in real conditions, which clearly showed that the designed e-textile mat could be successfully applied for non-invasive and continuous control of the position of the human body in a supine position to prevent decubitus ulcers.

Keywords: e-textiles; health care; multifunctional textiles; bedridden persons; decubitus ulcers; human comfort; body position; textile sensors; conductive threads; monitoring system

Introduction

Decubitus ulcers are a severe medical problem that is difficult to treat. They are usually the result of some tissue nutrition disorder; the most common cause is lying sick for a long time. In places of contact of the body with a hard pad (mattress), the perfusion with the tissue’s blood worsens. As a result, its nutrition hampers, leading to the appearance of necrosis and concomitant wound [1]. The main principle for avoiding decubitus ulcers is prevention, which is expressed in frequent changes in the body position of a bedridden patient or the use of an anti-decubitus mattress. The firmness of the mattress, temperature and humidity are the main physicomechanical and physiological factors that affect the quality of sleep and the comfort of the body lying in bed [2]. The use of e-textiles with sensors to monitor body pressure on the mattress has been investigated in [3,4]. However, the pressure sensors were used to provide information on the areas with the most active wear for each person, depending on the weight, gender and sleeping position as well as for the improvement of the mattress’ ergonomics and sleeping quality. At present, there are many examples of developed textile sensors [5-13], but few are used to monitor the distribution of pressure and, respectively, hardness, in the process of operation. In [5], some commercially available systems and devices for beds and cushions were discussed. It should be mentioned, however, that the price impedes the large-scale application of these products. The authors of [10] presented technology for smart jacket production. In [12], the possibility of measuring the sitting posture via textile pressure sensors was investigated. A new resistive pressure sensing principle was applied in [6].

The authors used conductive yarns and different technologies, such as embroidery, hand sewing, and weaving, for textile sensor production. Textile capacitive pressure sensors were developed in [7,8]. In [7], foam was used as a layer between the electrodes. In [8], the 3D compressible spacer fabric of Mueller Textil, Germany, was applied, the compressibility of which affected the sensor’s performance. Some examples for smart textiles production using the embroidery technique are described in [9]. Detailed analyses of the methods for obtaining textile pressure control sensors are presented in [14,15]. Various technologies are used to produce e-textiles with sensors, one of which is machine embroidery of electrically conductive threads [16]. The main advantage of this technology is that it can change the functionality of a finished traditional textile product in a less expensive, labour-consuming and time-consuming process. Our study was dedicated to designing and developing an e-textile mat with textile sensors, incorporated by embroidery, applied for the movement monitoring of bedridden people. The continuous data from sensors would give information about the period of immobility of the individual parts of the body. As a result, the position of a bedridden person could be regularly changed in situations where a caregiver is not necessarily present at the bedside or when the medical staff shifts. Communications and programs are also built to collect and process the data from the sensors and provoke reactions. The designed e-textile mat could have a great social impact.

The Design Idea

The design idea was to incorporate textile capacitive sensors in a thin mat, which ought to be set under the body of the bedridden person. The sensors should have the ability to register the movement of the body. The designed mat does not involve the zone of the head, as, usually, there is a pillow under the head. The selection of the structure of the e-textile mat was carried out in three main directions:

a) Selection of the sensors and measuring system.

b) Selection of the textile system.

c) Embedding of the sensors in the textile system through embroidery.

Sensors and Measuring System

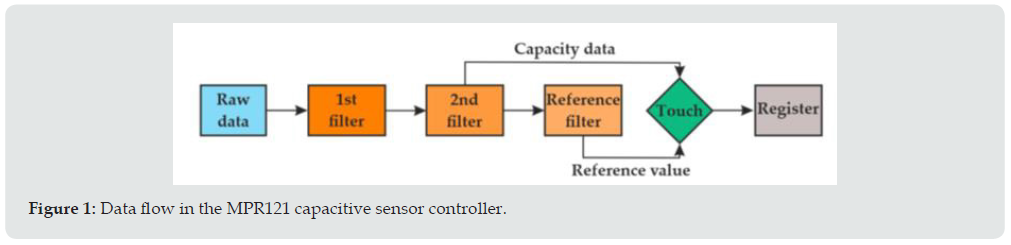

Of the three possible options for choosing the type of textile, sensor-resistive, capacitive, and piezo-resistive–capacitive sensors have been found to be the most suitable for the design of the e-textile. The capacitive sensors have low power consumption, high accuracy and a lack of requirements for special equipment and operating conditions. At the same time, the capacitive sensors are affected by environmental conditions: temperature and humidity. That is why the MPR121 controller of the capacitive sensors was chosen. The controller allows continuous and independent calibration of the inputs of each electrode, i.e., the current data obtained are compared with a base value that changes based on the variation of the background capacity. In addition, the data sampling rate was 64 ms, and its sensitivity was high, which significantly improves the capabilities of the filter system. It is possible to separate each electrode’s touch and release thresholds, which ensures independence from hysteresis. Figure 1 illustrates the data flow in the MPR121 capacitive sensors controller. The raw data outputs run through 3 levels of digital filtering to remove the encountered high- and low-frequency noises. After the first and second filtering, the result was the immediate capacitance of each sensing input. The reference value represents the capacitance variation over a long period caused by environmental changes such as atmospheric moisture and dirt.

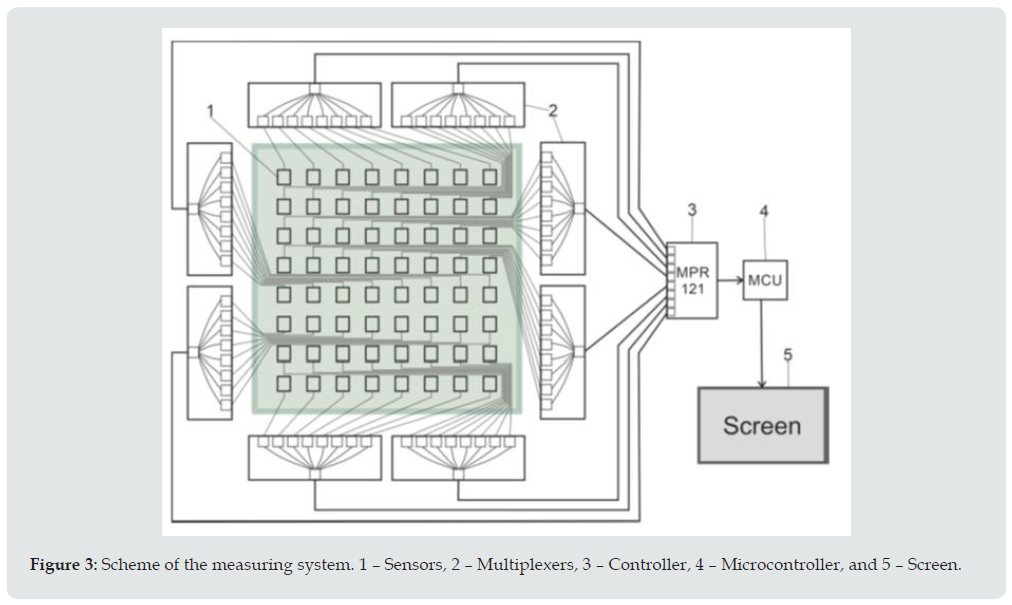

The data from the 2nd filter and the reference value were compared, and then theme asured value was presented (Figure 1) [16]. The number and location of the sensors were determined according to the critical areas of the human body where decubitus ulcers occur. They are found in the neck, shoulders, elbow, pelvis, thigh, legs and heel [17]. Therefore, when designing the sensor array, it was not necessary to fill the entire area of mat regularly. The location of the sensors could be tailored to the anatomical features of the human body. Three zones were built in the designed e‐textile mat following this strategy and the sizes of the most common human figures (Figure 2). The first two zones contained three rows of sensors, and the third‐two rows. Thus, the designed prototype could be used by individuals with a different build. The zones with three rows of sensors were located along the lines of the back and hips. The zone with two rows was along the line of the calves. The width of the e‐textile was 700 mm, which can be used in a single bed. Figure 3 shows a diagram of the designed measuring system, which consisted of textile sensors multiplexers, a controller, a microcontroller, and a screen. The need to include multiplexers was due to the large group of sensors which have data that must be collected and processed simultaneously in real time. The multiplexer has several inputs and one output. It acts as a circuit breaker, where the connection is not mechanical but is made through an integrated semiconductor circuit. Connecting a display to the minicomputer makes it easier for the user to monitor the results of the measuring system and is also compatible. The other aspects include the textile phase, embedding of the sensors, that involve machine embroidering, and electrical resistance and capacitance measuring [18,19].

Figure 3: Scheme of the measuring system. 1 – Sensors, 2 – Multiplexers, 3 – Controller, 4 – Microcontroller, and 5 – Screen.

The findings

Selection of the Textile Sensors

When incorporating sensors using embroidery with conductive threads, it is crucial to follow specific rules:

a. Avoid overlapping stitches.

b. Minimum thread length.

c. Making the motif without breaking/cutting the threads.

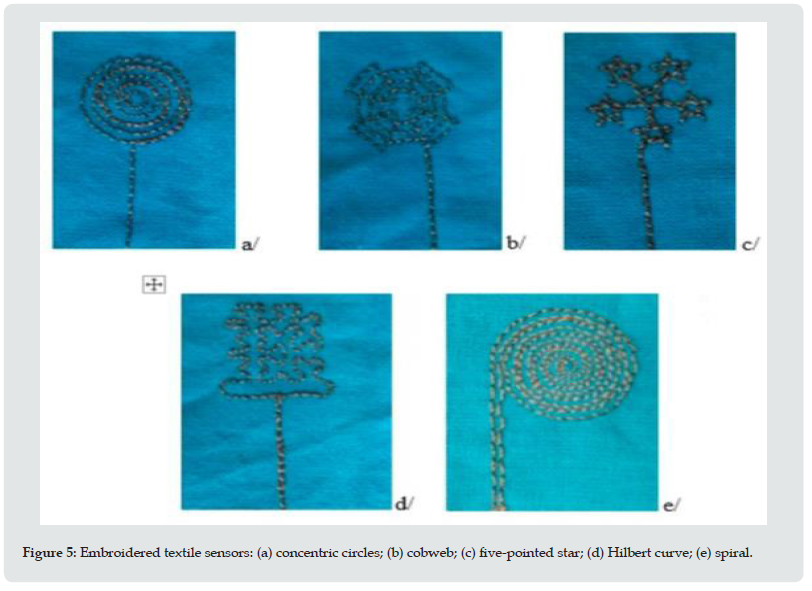

Five motifs were developed to incorporate the sensors in the textile systems: concentric circles, cobweb, spiral, five‐pointed star and Hilbert curve. They were designed based on known mathematical functions and fractals and observed work conditions with conductive threads. These variants have not been proposed in the literature yet. The sensor designs were made with 3D modelling software, after which the embroideries were created with Digitizer MB V 3.0 (Figure 4). All motifs were designed with the same overall size of 20 mm, which is in full accordance with the literature. Straight double‐sided stitch line, which consumes less thread. All motifs were designed with the same overall size of 20 mm, which is in full accordance with literature. Straight double sided stitch line which consumes less thread length, was used, with a stitch step of 2 mm. The produced samples with the sensors, are presented in Figure 5. It resulted that only the motif with concentric circles cannot be made without overlapping the stitches, which is undesirable. The results of the measurement of the sensors’ electrical resistance and capacitance in different patterns have been determined. The cobweb and five-pointed star were the motifs with the lowest electrical resistance. The spiral and cobweb motifs showed the highest capacitance, approximately 20 pF. Since the cobweb motif had a lower electrical resistance and a lower conductive thread consumption, it was selected for the e-textile mat design.

Figure 4: Design of the sensor patterns: (a) concentric circles; (b) cobweb; (c) five-pointed star; (d) spiral; (e) Hilbert curve.

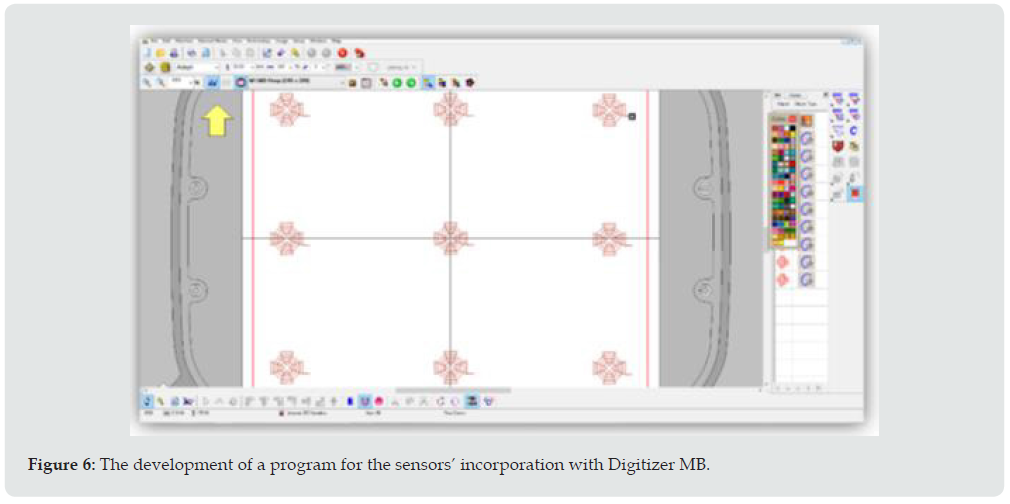

Production of the Textile Sensors

The sensors’ incorporation through embroidery required marking the lines on the fabric along which the sensors would be located. Thus, it was possible to centre the textile system in the embroidery frame. With the application of an embroidery frame with the largest dimensions, it was possible to digitize and produce a total of nine sensors simultaneously. The group of nine sensors had to be centre relative to the zero in the x and y-directions (Figure 6). Figure 7 presents the embroidered textile sensors for body position. Because the photo was taken at an angle, the rows of embroidered image sensors seem to be located at an angle, resulting in image distortion. When incorporating the sensors, a certain length of the upper thread (approximately 15–20 cm) was left free to be connected with the flat ribbon cable passing from the reverse side of the mat. The ribbon cable passed through the entire width of the product, ensuring that an equal length of conductive thread was used for each sensor. Figure 8 shows an image of the connected sensors with the flat ribbon cable using a cable lug. The width of the ribbon cable was consistent with the number of sensors in the three groups. The application of a second layer in the mat ensured the preservation of the comfort and stability of the product (to avoid the mat’s wrinkle when the body turns) during operation.

Figure 5: Embroidered textile sensors: (a) concentric circles; (b) cobweb; (c) five-pointed star; (d) Hilbert curve; (e) spiral.

The Software Connection

Part of the project was developing specific software (application) for control of the multiplexers, collecting the data from the controller of the capacitive sensors and sending them in a protocol on a serial port. The application was created in the processing environment for visualization of the results. A more straightforward interface was offered to simplify the data reading by the user. A mesh of the sensors) was used, which changed from black for the passive sensors to light green for the active. The depth of the green colour varied according to the change in the capacitance, which represented the pressure that the person exerted on the sensors. Therefore, it shows that the air gap between the body and the sensors decreased, or the overlapping area increased. This way, the user (caregiver, medical staff) could be informed about the bedridden person’s position, which had not been changed. To verify the data obtained from the sensors, experimental studies were performed with an individual in two postures, essential for the human body in a supine position: posture one, on the back (Figure 9), and posture two, in a sideways pose. The sensor readings were displayed on the screen of the minicomputer. The squares with the darkest colour corresponded to the passive sensors, and those with lighter ones to the activated ones. The motives that were obtained in the two postures of the human body are presented in Figure 9. The sensor readings were displayed on the screen of the Raspberry Pi 4 minicomputer. The squares with the darkest colour corresponded to the passive sensors, and those with lighter ones to the activated ones. The motives that were obtained in the two postures of the human body are presented in Figure 10. The software makes it possible to set a time interval for which the sensors move from one shade to another. Thus, the user could determine whether the bedridden person has performed movements of the torso and lower and upper limbs. At this stage, it is impossible to accurately determine the pressure values in the separate zones, as the capacitive sensors are influenced not only by the hardness of the mattress used for the test but also by the environmental conditions. However, the presence of reference values of the sensor controller before each measurement eliminates the influence of the environment.

Conclusion

The design and development of a prototype of an e-textile mat with textile sensors for avoiding decubitus ulcers in bedridden persons were presented. The developed monitoring system and software allowed real-time monitoring of the body position. The sensor was produced with silver-coated conductive thread, which has a good suability. Five variants of the pattern for the textile sensor were developed, and their capacitance was measured. The best performance had the design with cobweb, with a capacitance of 19.28 pF, and it was used for the smart mat production. Future work in this direction could be expanded by including a group of sensors (at least two rows of three sensors each) in the head area. It is also possible to look for other software solutions for visualization of the results It is hoped that the study would encourage the development of similar devices in the field, which would increase the comfort of the bedridden persons and help their caregivers’ performance.

References

- Vgontzas AN, Chrousos GP (2002) Sleep, the hypothalamic-pituitary-adrenal axis, and cytokines: Multiple interactions and disturbances in sleep disorders. Endocrinol Metab Clin 31: 15-36.

- Bansal C, Scott R, Stewart D, Cockerell CJ (2005) Decubitus ulcers: A review of the literature. Int J Dermatol 44: 805-810.

- Buckle P, Fernandes A (1998) Mattress evaluation-Assessment of contact pressure, comfort and discomfort. Appl Ergon 29: 35-39.

- Chen YX, Shen LM, Guo Y, Shao TT, Fang F, et al. (2012) Relationship between mattress comfort and sleep quality. J Anhui Agric Univ 3: 115-120.

- Orcioni S, Conti M, Martínez Madrid N, Gaiduk M, Seepold R (2018) A review of health monitoring systems using sensors on bed or cushion. In Proceedings of the InternationalWorkshop “Smart-Future-Living-Bodensee”, Konstanz, Germany, 24 November 2017; HTWG: Konstanz, Germany pp. 45-48.

- Parzer P, Perteneder F, Probst K, Rendl C, Leong J, et al. (2018) RESi: A Highly Flexible, Pressure-Sensitive, Imperceptible Textile Interface Based on Resistive Yarns. In Proceedings of the 31st Annual ACM Symposium on User Interface Software and Technology, Berlin Germany pp. 745-756.

- Sergio M, Manaresi N, Tartagni M, Guerrieri R, Canegallo R (2002) A textile based capacitive pressure sensor. In Proceedings of the SENSORS, 2002 IEEE, Orlando, FL, USA 2: 1625-1630.

- Meyer J, Arnrich B, Schumm J, Troster G (2010) Design and modeling of a textile pressure sensor for sitting posture classification. IEEE Sens J 10: 1391-1398.

- Post ER, Orth M, Russo PR, Gershenfeld N (2000) E-broidery: Design and fabrication of textile-based computing. IBM Syst J 39: 840-860.

- Poupyrev I, Gong NW, Fukuhara S, Karagozler ME, Schwesig C, et al. (2016) Project Jacquard: Interactive digital textiles at scale. In Proceedings of the 2016 CHI Conference on Human Factors in Computing Systems, San Jose, CA, USA pp. 4216-4227.

- Rofouei M, Xu W, Sarrafzadeh M (2010) Computing with uncertainty in a smart textile surface for object recognition. In Proceedings of the 2010 IEEE Conference on Multisensor Fusion and Integration, Salt Lake City, UT, USA pp. 174-179.

- Xu W, Huang MC, Amini N, He L, Sarrafzadeh M (2013) e Cushion: A textile pressure sensor array design and calibration for sitting posture analysis. IEEE Sens J 13: 3926-3934.

- Aigner R, Pointner A, Preindl T, Parzer P, Haller M (2020) Embroidered resistive pressure sensors: A novel approach for textile interfaces. In Proceedings of the 2020 CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA pp. 1-13.

- Sofronova D (2020) Application and technologies for textile sensors production used in pressure distribution measurement-a critical review. E3S Web Conf 207: 03001.

- Orth M (2002) Defining flexibility and sewability in conductive yarns. MRS Online Proc Libr (OPL) pp. 736.

- Sofronova D, Angelova RA (2021) Embedding Sensors by E-embroidery: Practical Steps for Smart Textiles Production. In Proceedings of the 2021 6th International Symposium on Environment-Friendly Energies and Applications (EFEA), Sofia, Bulgaria pp. 1-5.

- Angelova RA, Sofronova D (2021) E-textile for non-invasive control of the body movement of bedridden patients. IOP Conf Ser Mater Sci Eng 1031: 012029.

- Briedis U, Valisevskis A, Ziemele I, Abele I (2019) Study of Durability of Conductive Threads Used for Integration of Electronics into Smart Clothing. Key Eng Mater 800: 320-325.

- Daniela S, Radostina A, Angelova, Yavor S (2021) Design and Development of an E-Textile Mat for Assuring the Comfort of Bedridden Persons. Materials 14: 5437.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...