Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Research Article(ISSN: 2637-4595)

Baru Dye Applied to Fashion Accessories Volume 4 - Issue 2

Adriano Alves Passos1*, Ricardo Rodrigues Ramos Cecci1, Wanderson Ferraz do Valle1, Thales Calmon de Aguiar Neto1 and Joyce SQ Guillen2

- 1SENAI Innovation Institute for Biosynthetic and Fibers, SENAI CETIQT Rio de Janeiro, Brazil

- 2SENAI Innovation Institute for Biosynthetic and Fibers, SENAI CETIQT, Rio de Janeiro, Brazil

Received:July 24, 2021 Published: August 09, 2021

*Corresponding author: Adriano A Passos, SENAI Innovation Institute for Biosynthetic and Fibers, SENAI CETIQT, Rio de Janeiro, 20961-020, Brazil

DOI: 10.32474/LTTFD.2021.04.000184

Abstract

The synthetic dyes used in the textile segment, besides causing a relevant negative impact on the environment, it may also cause problems to human health, such as contact dermatitis. Natural dyes may be an alternative to those, some even presenting properties as UPF protection. Considering Brazilian biodiversity and world interest, this article aims to contribute to the development of a dye from Dipteryx alata Vogel, which besides its various health benefits, it may also be used as a natural dye in fashion accessories and photoprotection agent. The results obtained from the development of the dyeing method of textile substrates present interesting information. However, continuity in studies is required for further improvement and to reach new markets.

Keywords: Natural dye; Photoprotection; Textile; Eco-friendly

Introduction

The clothing industry is one of the most important in the world,

moving more than 1 trillion dollars annually, contributing to 7%

of the world’s exports, and employing approximately 25 million

people. It is also one of the most unsustainable industries, according

to the report “Fashioning Sustainability” released in 2007 by the

British NGO Forum for the Future and one of the most polluting,

according to a report by Deloitte, “Fashioning Sustainability

2013” [1]. According to the same Deloitte report, sustainability

has become an imperative strategic business. Consumers want

to relate to sustainable institutions and there is a high demand

for sustainable products in the textile and cosmetics sector [2].

Brazil is located between the tropic of Capricorn and Ecuador,

which is why it is a region that receives the greatest intensity of

solar radiation, making it the country with the largest intertropical

area. One of the ways in which sunlight can manifest its harmful

effects is through the generation of reactive oxygen species by

UV radiation, which has serious implications on human health,

affecting cellular material directly or through photosensitization

mechanisms [3]. Clothes that protect against solar radiation are

increasingly popular, and they receive a titanium oxides bath to

acquire this function, which is the same physical ingredient used in

sunscreens. Simple actions such as avoiding sun exposure at times

of greatest insolation and wearing sunscreen do not determine an

absolute protection for people whose skin is more sensitive to the

sun exposure. Only opaque protection guarantees such complete

skin protection [4]. This is possible with clothes treated for this

purpose, which generally protect against ultraviolet A (UVA) and

ultraviolet B (UVB) rays. The dyeing of plain or knitted textiles relies

on chemical products and dyes, which may contain heavy metals

(lead and mercury) and other carcinogens, which may represent a

risk to final consumers. Furthermore, the cost to treat the effluent

is something to be considered in terms of the final cost of the dyed

textile.

Aspects related to environmental, economic, and social

sustainability are being increasingly appreciated by the growing

number of concerned consumers. According to Araujo (2005),

natural dyes are substances extracted only by physical-chemical

processes (extraction, precipitation, etc.) or biochemical processes

(fermentation) from an animal or plant raw material, in which

those must be soluble in the liquid medium [5]. Although not

all natural dyes have characteristics that provide a more vivid

appearance of colors when compared to artificial ones, their use

is greatly beneficial to the environment. In fact, the use of natural

dyes is a major challenge for the fashion industry. Considering the

demand for sustainable alternatives, a study of the current global

scenario of natural dyes was carried out, through the analysis of

the PATENTSCOPE database, in which the keywords used were:

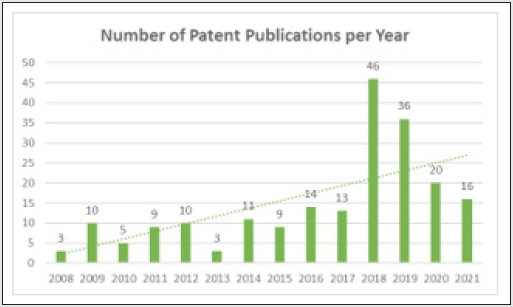

“natural dye” in the title and “textile” in the title or abstract. The growth of patents related to natural dyes is remarkable, as shown

in Graph 1. The years that show the highest number of filings are:

2018, in which there are forty-six patent filings, 2019 with thirty-six

filings, and 2020 with 20 filings. The trend indicates an increase in

the number of patents since the beginning of the last decade. From

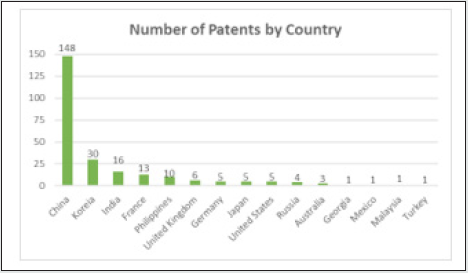

the publications cited in Graph 1, the countries which contribute

the most are identified in Graph 2. Based on Graph 2, it is possible to

conclude that China and Korea are, by far, more developed in their

technological production on this topic than other countries, since

their patent deposits represent 71.48% of the total deposits. To

better exploit Brazilian biodiversity and to meet the world market

trends, bark and endocarp of the species Dipteryx alata Vogel were

used, promoting a true combination between the Amazon and

Cerrado biomes. The parts used were waste from the production of

oils, meaning that, the pulp and nuts of the species are used, and the

peel and endocarp are usually discarded. The textile dyeing sector

has helped to promote a sustainable use of natural resources,

especially in terms of circular economy. Packaging prototypes were

obtained using the dyed material. Thus, the present investigation

aimed to develop an ecological dye with photoprotective and

modifying action, from species originated from Brazilian

biodiversity. In addition, the international competitiveness of the

Brazilian textile industry will be improved through the exportation

of the sustainable photoprotective fabric. Additionally, this work

reveals this new dyeing process prevents the fading of clothes and

is non-allergenic [6].

Methodology

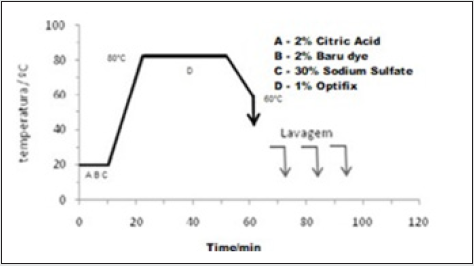

The plant species Dipteryx alata Vogel, known as baru, occurs in cerrado formations, mainly in Minas Gerais, Goiás, Distrito Federal, Mato Grosso and Mato Grosso do Sul, and is a soil nitrogenfixing plant, occurring in more fertile soils [7]. It was processed in accordance with patent BR 10 2013 013080 0 A2, filed by Biodiversité company, obtaining the baru in powder form, marketed for the cosmetics area and used for the manufacture of specific products for make-up, masks, exfoliants and foods, specifically food supplements and nutricosmetics. Solubility and chemical compatibility tests as a function of temperature were carried out to determine a dyeing method for the textile substrates. Empirical results allowed the determination of a dyeing method for the knitted cotton (CO) (after purge/bleached) substrates. The dyeing was carried out at different concentrations with recipes without the fixer and recipes with commercial Optifix CD (Clariant) fixer. Four dyeing procedures were carried out on textile substrates, as shown in Graph 3, with the following concentrations: 0.5%; 1.0%; 2.0% and 4.0% spm. The dyed substrates were analyzed by reflectance spectroscopy, using a Minolta model 2200d spectrophotometer in the visible region between 400 and 800 nm to determine the colorimetric coordinates in the CMC 2:1 system. The colorfastness to light, colorfastness to wash and the ultraviolet protection factor (UPF) were also quantitatively analyzed.

Graph 3: Baru dye application curve without fixer (ABC) and with fixer (D) process ‘All In”.

Source: Elaborated by the authors.

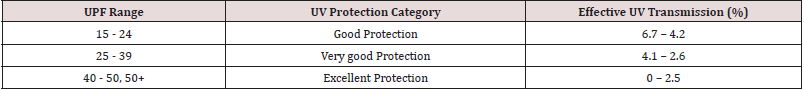

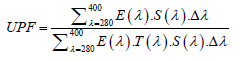

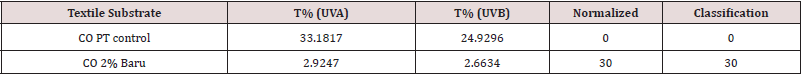

The ultraviolet protection factor (UPF) indicates the ability of a textile to photoprotect the user’s skin [8]. The UPF of the dyed fabric with the natural dyes were determined using a UV-VIS spectrophotometer (Lambda 800, Perkin Elmer), with a 150 mm integrating sphere from the Colorimetry Laboratory of SENAI CETIQT. All samples were analyzed dry and without tension, with the beam perpendicularly incident to the textile substrate. Eight measurements were performed for 4 specimens of each sample and the diffuse transmittance spectra were obtained with a step of 5nm in the spectrographic range from 400 to 290 cm-1 using the WinLab software, version 5.1.5. The temperature of 21.0 °C ± 2.0 °C and the relative humidity of 65% ± 5% of the measurements performed were controlled by a thermohygrometer, Hanna Instruments, model HI9564. The UPF values (average) were obtained statistically, according to AS/NZS Standard 4399:1996 [9], from the Equation 1 below, and then were normalized (Rated UPF) (Table 1).

Where S(λ) is the solar spectrum irradiance (W.m-2nm-1) (tabled value), E(λ) is the relative erythemal efficiency (tabled value), T(λ) is the measured spectral transmittance, Δλ is the range of measured wavelength (nm) and λ is the wavelength (nm). The solar spectrum used to calculate the protection factor was Melbourne, according to Table B2 of AS/NZS Standard 4399:1996 [9]. The UPF values determined for the functionalized textiles were classified according to the level of protection, according to Table 1. The colorfastness to wash tests were performed according to the ABNT NBR ISO 105-C06 standard in B1M condition, using a DW multifiber control fabric, steel balls, standard reference detergent WOB AATCC 1993 [10,11]. The colorfastness to light tests were carried out in accordance with the ABNT NBR ISO 105- B02 standard [12], in method 5 of the Weather Ometer equipment, with normal exposure, in a tempered zone, using a blue reference fabric, series 1-8, at the Black Panel temperature of 45 °C, with approximately 6000 kJ/m² of radiant energy, 42 W/m² of irradiance. For packages confection, the machinery of the Prototyping Laboratory was used (1 needle/straight stitch machines and 3-wire overlock). For the applications of accessories, it was used an Ultimaker 3D printer and then gold jets were applied with varnish (Figure 1).

Results and Discussion

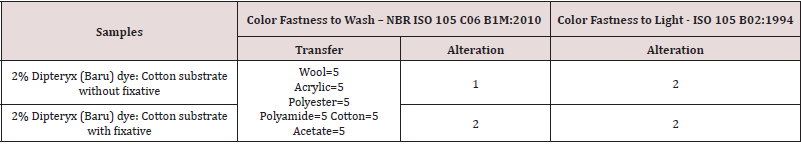

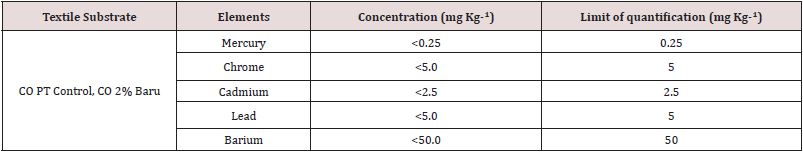

The development of the dyeing method for the baru dye was satisfactory due to the fixation and development of the color on cotton, reducing the dyeing time and temperature, as shown in Figure 2. It was possible to verify an increase in the wash fastness on cotton substrate, as shown in Table 2. This indicates that it is possible to work with other commercial and natural fixatives to improve the product, changing the quantities of fixatives and their chemicals characteristics. The assessment of UPF was carried out on substrates without application of baru dye and with application of 2% Baru, and the results are shown in Table 3. The dyeing with the plant species dyes, in addition to color, conferred UV protection to the treated fabric, compared to the untreated fabric, with 30 FPS. The results of blocking solar radiation in the UVA-UVB region of the photoprotective fabric are significant and reveal the potential for applicability in the weaving and manufacturing sector. Regarding the dyeing process, it is possible to compare the textile substrate before and after dyeing. Thus, heavy metals are evaluated using the NM-300-3 standard, as shown in Table 4, where it is possible to observe that the dyed textile substrates values were below those allowed [13]. These results corroborate the low toxicity claimed for such dyes. Figure 3 illustrates the prototypes made with the photoprotective fabric in different designs in order to assess its applicability for makeup packaging based on Baru’s pigment.

Table 2: Transfer System and Change of Color Fastness to Washing – NBR ISO 105 C06 B1M:2010 and Color Fastness to Light - ISO 105 B02:1994.

Table 3: Transmittance values (%) for the range of UVA (400 to 315nm) and UVB (315 to 290nm) of the analyzed sample. Calculations based on the formulas of Norm AS/NZS 4399:1996.

Table 4: Quantification of Metals by Atomic Absorption with Graphite Furnace and Hydride Generator, Digestion method. Heavy metal soluble in textile extraction standard NM-300-3.

Conclusions

It was presented a sustainable baru dye, used in a dyeing method at low temperature. The dye has a difference in its hue that differs from pastel tones (earth colors) presented by most natural dyes. The application of natural baru dye on cotton significantly increased the ultraviolet protection factor (UPF), from 0 to 30. Regarding color fastness to washing and light, depending on the market to which the textile is destined, studies with natural fixatives and metrological tests are recommended to better inform the final consumer. Besides all the benefits provided by the natural dye, such as ultraviolet protection and good colorfastness to wash, it was also possible to use the dyed textiles with baru dye in fashion accessories.

Acknowledgement

The authors would like to thank the Metrology Laboratory of the Textile Technology Institute of SENAI CETIQT (IST Textile – SENAI CETIQT), the partnership with SENAI Paraná (Londrina Unit) and the trust placed by the company Biodiversité in the team.

Declaration of Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Deloitte (2013) Fashioning Sustainability.

- Forum for the Future (2007) Fashioning Sustainability 2007.

- DE Jager TL, Cockrell AE, DU PLESSIS SS (2017) Ultraviolet Light Induced Generation of Reactive Oxygen Species. In: Ultraviolet Light in Human Health, Diseases and Environment. Springer Cham p. 15-23.

- Melo MM, Ribeiro CSC (2015) Novas Considerações sobre a Fotoproteção no Brasil: Revisão de Literatura/New Considerations on the Photoprotection in Brazil: Literature Review. Revista ciências em saúde 5(3): 80-96.

- Araujo MEM (2005) Corantes naturais para têxteis – da Antiguidade aos tempos modernos. Conservar Património Universidade de Lisboa 3(4).

- Carrazza LR, D’ÁVILA JCC (2010) Manual Tecnológico de Aproveitamento Integral do Fruto do Baru. Instituto Sociedade, População e Natureza (ISPN), Brasil.

- Rocha RB, Rocha MGB, Santana RC, Vieira AH (2009) Estimação de parâmetros genéticos e seleção de procedências e famílias de Dipteryx alata Vogel (BARU) utilizando metodologia de REML/BLUP e E(QM). Cerne 15: 331–338.

- Qi K, Wang X, Xin JH (2011) Photocatalytic self-cleaning textiles based on nanocrystalline titanium dioxide. Text Res J 81: 101–110.

- (1996) Standards Australia and Standards New Zealand. AS/NZS 4399–Sun Protective Clothing–Evaluation and Classification.

- (2006) Abnt Associação Brasileira de Normas Té ABNT-NBR-ISO 105-A02 Textile - Test for colour fastness. Part A02: Grey scale for assessing change in colour.

- (2006) ABNT Associação Brasileira de Normas Té ABNT-NBR-ISO 105-A03 - Textile - Test for colour fastness. Part A03: Grey scale for assessing staining.

- (2019) ABNT Associação Brasileira de Normas Té ABNT-NBR-ISO 105-B02 Textiles - Color Fastness to Artificial Light: Xenon Arc Fading Lamp Test.

- (2011) ABNT Associação Brasileira de Normas Técnicas. ABNT-NBR-NM 300-3 Safety of toys Part 3: Migration of certain elements.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...