Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Review Article(ISSN: 2637-4595)

Bamboo in Textiles – An Ecological Perspective Volume 5 - Issue 1

Alka Madhukar Thakker* and Danmei Sun

- School of Textiles and Design, Heriot-Watt University, UK

Received:July 27, 2022 Published: August 19, 2022

*Corresponding author: Alka Madhukar Thakker, School of Textiles and Design, Heriot-Watt University, UK

DOI: 10.32474/LTTFD.2022.05.000205

Abstract

A viewpoint on bamboo in textiles explores significant studies that are conducted to emphasize the inherent properties of bamboo fibres for the greater good. Also, the perspective focuses on keeping the environment first by evidently limiting severe and elaborate processing and coatings, especially because the bamboo fabrics are naturally with outstanding qualities. Concurrently, opinions on the natural colouration, dye effluent treatment and plausibility of green laminates with bamboo fabrics are discussed. The scientific standpoint concludes by asserting that fast-growing and strong bamboo is one of the most sustainable fibres of the 21st century.

Applications of Bamboo with Environmental Viewpoint

Bamboo is a cellulosic grass and eco-crop. It requires less water, pesticides and labour as compared to cotton. In this, the logic is to promulgate a minimalistic approach that orients research and development on bamboo textiles towards less intrusive making and finishing treatments. Concomitantly, a pure bamboo fabric was microencapsulated with natural herbal materials namely Azadirachta indica, Centella asiatica, and Curcuma longa extracts. The constituted wound healing bamboo herbal fabrics demonstrated a maximum zone of inhibition of 22 mm against Staphylococcus aureus, Escherichia coli and Bacillus subtilis strains of bacteria commonly found to proliferate on wounds [1]. The dressing material exhibited no allergic reactions and only 20% degradation to lysozyme enzymes (An enzyme commonly found in wound fluids). Additionally, wounds of the Albino Wistar rats were completely healed in 15 days with the herbal bamboo dressing material [1]. Bamboo is inherently known to bear hypoallergenic and antibacterial properties [2]. Ecological technology of microencapsulation combined with biomaterials encourages an ecological perspective. Alongside, three species of spalting fungi such as Scytalidium cuboideum, Scytalidium ganodermophthorum, and Chlorociboria aeruginosa were experimented with for natural colouration of wood and textiles applications. Natural spalting of blue, red, and yellow colours was best observed with Scytalidium cuboideum [3]. On direct application, S. cuboideium and C. aeruginosa fungal pigments yielded surface colours on bamboo. For internal colouration direct inoculation of S. cuboideium was appropriate [3].

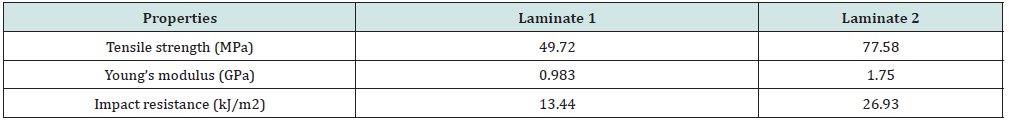

During bamboo manufacturing, lignin is derived as a byproduct. This bamboo-lignin as filter material could be utilised for the adsorption of violet dye wastewater. Even more, the chemically modified bamboo-lignin with Al3+ and Mn2+ resulted in greater adsorption of dye effluent [3]. For complete adsorption of dye effluent optimum temperature of 343 K and contact time of 30 minutes were noted. Similarly, the endothermic and spontaneous adsorption process demonstrated the Gibbs free energy ΔG is −1198.69 kJ mol−1 and enthalpy ΔH is +86.85 kJ mol−1. The adsorption system was concluded to be +98.11% efficient [4]. The point of upscale is devouring the dye effluent from the textile colouration units efficiently and saving the ecosystem. The granules of polylactic acid were formed into films at a high temperature of 200 ℃. The plain-woven bamboo fabric and the film were compressed under a pressure of 556.7 kPa at 160 ℃ to obtain composite laminate as shown in Figure 1. The laminate was constituted with film and fabric warp-weft in the same and opposite directions respectively [5]. It was noted that the tensile strength, young’s modulus, and impact resistance were greater for composite laminate with film and fabric warp-weft in opposite directions as compared to the composite laminate in the same direction. The values are presented in Table 1 [5]. An environmentally friendly character of the composite laminate was formulated comprising great strength for industrial purposes. The viewpoint here is that the part is saved by including natural bamboo hence making the resultant product more friendly to the natural world.

A bamboo fabric was treated with microencapsulated phase change materials (PCM) n-octadecane and poly methyl methacrylatebutyl acrylate-hydroxyethyl methacrylate polymer by dip and dry method to develop a thermo-regulating bamboo fabric. The latent heat and thermal storage capacity of the phase change materials were tested which was 110 J/g [6]. Likewise, the latent heat of the PCM-treated bamboo fabric was 20 J/g. The bamboo fabric and the phase change materials microcapsules exhibited exceptional wash fastness due to excellent bonding strength. Furthermore, 72% of PCM microcapsules remained on the treated bamboo fabric after 15 wash cycles [6]. The bamboo fabric is intrinsically known to be breathable with thermo-regulatory properties [7]. The idea would be to combine wool with bamboo fibres to elevate thermo-regulation properties so that the complex materials and methodologies could be overlooked. This is because both wool and bamboo are naturally fantastic as thermo-regulation materials. This way we do justice to both the pure value of the bamboo fabric and the atmosphere. The viewpoint is to accentuate the inherent properties with preferably sustainable materials for a higher-end good. In the same vein, the bamboo fabric was coloured with biomaterials namely sappan wood, pomegranate peels, onion skins, indigo, Indian rhubarb, night jasmine, marigold, annatto, madder roots, lac, and oak tree fruit gaining a wide range of colours such as pink, gold, yellow, blue, orange, and red [7]. China is the largest grower of bamboo trees and maker of bamboo textiles. Bamboo fibres are popular for their cashmere-like soft silky feel as shown in Figure 2. Additionally, bamboo fabric is naturally able to protect against harmful sun rays that have been used for UV protective clothing [8]. Having thus examined the various properties of bamboo textiles and the corroborating studies that accentuate the natural properties of bamboo fabrics we derive greater economic, environmental, and human health benefits. Keeping the environment first extensive and energy-intensive processing and coatings with petroleum based materials could be curtailed as bamboo is born tough with superb qualities. The perspective paper voices to highlight the true organic value of bamboo textiles rather than obscuring them with fossil-based toppings.

Conclusions

Though the manufacturing of bamboo yarns utilises sodium hydroxide and carbon disulphide as solvents in large proportions that are detrimental to environmental and human health [2], however, water recycling plants are installed, and closed-loop processing is adopted that recaptures and recycles 99% of the chemical solution [9]. Bamboo trees ought to be sustainably farmed just like how eucalyptus trees are farmed for producing lyocell fibres that have been awarded the ‘European award for the environment’ by the European Union. The bamboo fabric that is ecologically produced like lyocell is branded as Monocel [9]. Such accreditations could enable buyers to make a wise eco-friendly choice. We have to persuade bamboo textiles from start to finish and its R&D to adhere to Sustainable Development Goals of climate action by protecting life below water and abiding by responsible production and consumption.

References

- Ahmed, Sidhra Syed Zameer, Naresh Balu, Syed Zameer Ahmed Khader, Mohamed Raf Mahboob, et al. (2021) Fabrication and evaluation of bamboo fabric coated with extracts of Curcuma longa, Centella asiatica and Azadirachta indica as a wound dressing material. Advances in Traditional Medicine 21: 83-95.

- Hasan Mahedi (2021) Bamboo Fabric Manufacturing Process, Advantages with Disadvantages.

- Gutierrez Sarath Vega, Patriciaz Vega Gutierrez, Auna Godinez, Lauren Pittis, Megan Huber, et al. (2016) Feasibility of Coloring Bamboo with the Application of Natural and Extracted Fungal Pigments. Coatings 6(37): 1-11.

- Aniagor CO, MC Menkiti (2019) Synthesis, modification and use of lignified bamboo isolate for the renovation of crystal violet dye effluent 9(77): 1-9.

- Porras A, A Maranon (2012) Development and characterization of a laminate composite material from polylactic acid (PLA) and woven bamboo fabric. Composites Part B Engineering 43(7): 2782-2788.

- Zhang Guoqing, Changwei Cai, Yilai Wang, Guojin Liu, Lan Zhou, et al. (2019) Preparation and evaluation of thermo-regulating bamboo fabric treated by microencapsulated phase change materials. Textile Research Journal 89(16): 3387-3393.

- Chaudhary Kavita (2019) Exploration of Bamboo Fabrics with Natural Dyes for Sustainability. Intech Open.

- Simpson Chloe (2017) Bamboo: The facts behind this amazing fabric.

- Hymann Yvette (2020) Material Guide: Is Bamboo Fabric Sustainable? 7: 12.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...