Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Research Article(ISSN: 2637-4595)

Bamboo/Cotton Knitted Fabric for Thermal Comfort Volume 3 - Issue 5

Gopalakrishnan M1*, Satheesh Kumar D2 and Saravanan K3

- 1Department of Textile Technology, Bannari Amman Institute of Technology, India

- 2Research Scholar, Bannari Amman Institute of Technology, India

- 3Department of Fashion Technology, Bannari Amman Institute of Technology, India

Received: March 03, 2021 Published: March 17, 2021

*Corresponding author: Gopalakrishnan M, Department of Textile Technology, Bannari Amman Institute of Technology, India

DOI: 10.32474/LTTFD.2021.03.000172

Abstract

In this article, the aim was to analyses the impact of different bamboo/cotton blend proportions on thermal comfort properties of knitted jersey fabrics. When the portion of bamboo fibre is increased in the blend either in yarn form or fabric form, it improves the thermal comfort properties. Since 100% bamboo knitted jersey is having high drape and not stable for many applications, various blend proportions of bamboo with cotton are used to make knitted jersey in this study. Knitted jersey fabrics made out of bamboo blends are less thick and lower in GSM than made out of fabrics using 100% cotton. Thermal conductivity of cotton is more than bamboo, so the blends of bamboo with cotton not only gives a better fabric for commercial use, but it also gives the required right value of thermal conductivity when used in gym, physical activities and sports applications. When proportion of bamboo is increased in the blend, both water vapor permeability and air permeability values are also increased in the fabric. The analysis also reveals that result received are remarkable for thermal comfort properties of 30s Ne Count bamboo/cotton blended knitted jersey fabrics.

Keywords: Bamboo; cotton; blend proportion; thermal comfort; air permeability; water vapour permeability

Introduction

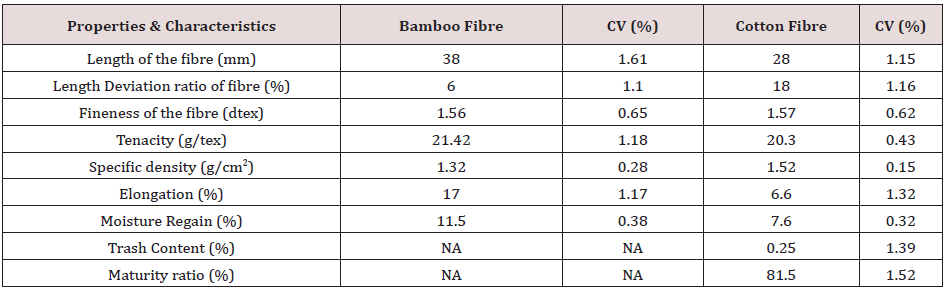

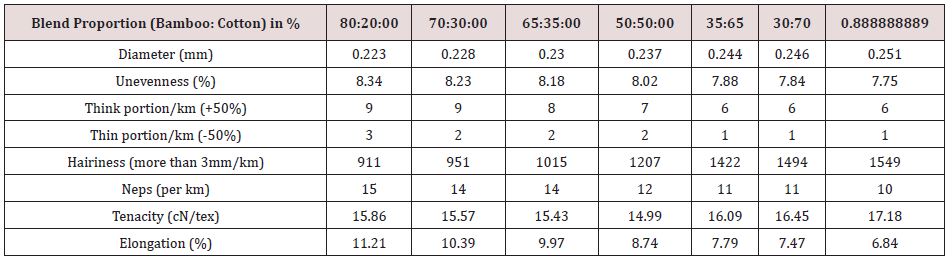

In the aspects of clothing, comfort is a highly important feature. Comfort is expressed in many ways like it is our body’s temperature regulation and it is influenced by the physiological reaction of the wearing person. It is also the absence of unpleasantness or discomfort. By and large it is a state of enjoyable physical, nonphysical and harmony between the wearer and the environment etc. These three features are equally crucial, since wearer feel uncomfortable if even one of them is missing. To understand the characteristics of comfort of any specific clothing or fabric, it is needed to find out the different properties of fabric which effects the comfort property directly. Thermo-physiological character, sensorial / tactile character, physiological character and comfort on fitting are the four primary parts of comfortable clothing. Comfort on thermo-physiological says about the moisture and heat transmission aspects through clothing, i.e., heat transmission, air transmission, and moisture transmission (liquid and vapour). How a person feels next to skin when he / she try wearing a fabric or garment is said as comfort of sensorial / tactile i.e., mechanical contact of fabric or garment with skin. These feels are like fabric handle or feel, soft, prick, itch, full, warm touch, cool touch, generation of static charge etc. [1]. Also wear circumstances indicates the comfort, which involves both thermal and non-thermal elements written clearly by Bhat and Bhonde [2]. Combinations of attire, weather and physical activity depends on individual’s thermal comfort. Thermal comfort condition which expresses delight with the thermal surroundings said in ISO 7330. Majumdar, Mukhopadhyay and Yadav [3] reported that thermal comfort properties of fabrics are highly governed by fibres, yarn and fabric properties in it. There is a thickness increase in the material and air entrapment in fabric with a shoot up in water vapour resistance and heat, a statement by Havenith [4] showed it. Karunakaran Chinnasamy K and Chidambaram P [5] investigated the thermal comfort properties of the fabrics and said that it depends on content of the fibre and linear density of the component yarns. Jordeva, et al. [6] indicated after analysis that against the content of raw material, the comfort on thermophysiological property of jersey fabrics has major effect on structural characteristics. Work about the relationship between thermal comfort and textile properties were done by Bedek, et al. [7]. They suggested that fibre type affects the properties on related to comfort of fabrics, combined with the regain of moisture and characters of knitted structures. Bivaintye A, et al. [8] investigated the knitted fabrics air permeability and water vapour permeability, they found that structural characteristics of knits, i.e., loop length, compactness on structure and type of structure, had an important effect on air permeability. The material composition of knitted fabrics has the most important impact on the water permeability. Now-a-days, any blends with cotton have become very viable for production and also people started liking the end products made out of these blends instead of 100% cotton and 100% of any other fibers. In many technicalities, 100% Bamboo is having little disadvantages over blended Bamboo. So, many knitted fabric manufacturers are attempting to make cotton bamboo blends instead of 100% Bamboo. Fibers for this study, bamboo (imported) and cotton (MCU7 variety) were procured from Indian agents with the technical parameters given in the below Tables 1 & 2.

Cotton: Bamboo spun yarn with blend proportion of 80:20, 70:30, 65:35, 50:50, 35:65, 30:70, 20:80 was made. RX300 high speed ring frame machines were used to spin Ne 30s/1 with same TM of 3.4 for all different blends of yarn. Process route from Manual Opening -> Mixing -> Blow room -> Carding -> Draw frame -> Speed frame -> Ring Spinning was followed to produce the yarn.

Materials and Methods

Samples of knitted single jersey fabric was knitted on a plain single jersey knitting machine (Pai Lung) 28gg 34 Inch Diameter for finding the thermal comfort behaviour. Sample fabric were made with a knit loop length 3.0mm. After knitting process, the fabric sample was dyed in medium shade using soft flow machine, dried using relax dryer and compaction was done in open width compacting machine. Once fabric sample was in-house, it was relaxed for 48 hours in a lab room. A standard atmospheric temperature of 21 °C and relative humidity of 65% were set in the lab room. Then the fabric was cut into 1.25-meter panel length and sent for cut panel wash to control shrinkage. In sample washing machine, the fabric samples were washed in water with 0.06 grams per liter of wetting agent, with temperature of water set at 40 °C and run for 25 mins. Then bits were hydro extracted to remove excess water and dried using tumble dryer at 70°C for 40 mins. After washing, the fabric samples were taken back to standard conditions again of 21 °C and relative humidity of 65% for 24 hours, to make it relax. GSM (mass per unit area) and fabric thickness were evaluated to understand the fabric structural and physical properties. GSM of the fabric was taken as per ASTM D3776-96 using precise commercial GSM cutter. 5 GSM samples were cut in and the mean value was arrived. Using ASTM D1777-07, mean value of fabric thickness was arrived at 10 different spots in each fabric sample. Sample fabric porosity was found using the formula given below [9]. Porosity P% = 100 x [1 – (M/L ρm)] where M is GSM (grams per sq. metre), L is the thickness of the fabric and ρm is the density of the fibre. To find the air permeability of the fabric, TF164B Test ex air permeability tester was used complying ASTM D737 at 100 Pa pressure. SKZ175B (SKZ Industrial) Physiological thermal and water-vapour resistance Tester was used to measure both water vapour permeability and thermal conductivity & resistance complying ISO 11092 under standard atmospheric conditions of 21°C temperature and 65% RH as mentioned in ASTM D1776. Mean calculated with 10 sample readings taken for each of the sample jersey fabrics.

Results and Discussion

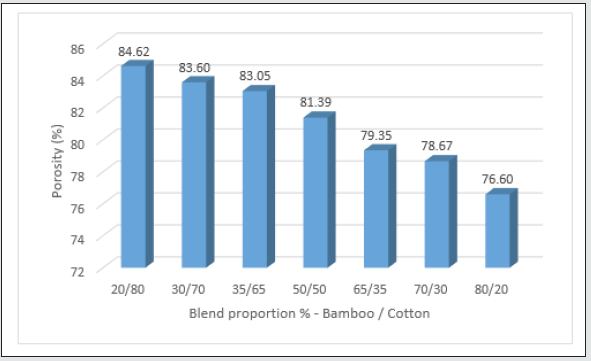

It can be noticed from Table 3 that when bamboo content is less and cotton content is more i.e., from 20/80, the fabric thickness is decreasing when bamboo content is increasing. It is because the bending rigidity of bamboo is lesser than cotton, so that in jersey structure the packing closely the knitting loops are possible, which ultimately reduces the fabric thickness. As analysed and reported by Kane et al. [10], the values resulted reflect that the fabric thickness is hang on properties like linear density of the yarn, structure of the fabric and loop length maintained to knit. Figure 1 shows the relationship between different blend proportion and porosity %. When cotton content is more in the yarn, the porosity is also more due to more hairiness in cotton which doesn’t allow more compactness to the structure and thickness of the fabric is also high. Vive-versa when bamboo content in the yarn is increased, the porosity is also decreased due to less hairiness in yarn and more compact structure is achieved.

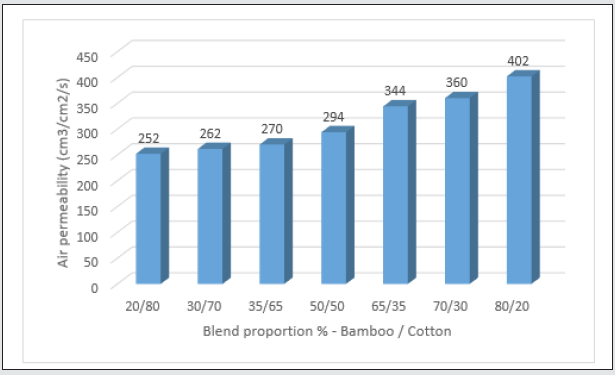

Air permeability

The relation between blend proportion and air permeability values of bamboo/cotton knitted jersey fabrics are shown in Figure 2. It shows very clearly that when cotton is more the air permeability value is less and when bamboo content is increasing the air permeability value is also increasing. Micro gaps in bamboo fibre structure gives more air to pass on knitted fabric. Study by Xu Y, et al. [11] states that cracks on bamboo fibre surface with many void spaces which can be seen in cross-section of the fibre enhances the air permeability values when proportion of bamboo is increased in the blend. Also, when fabric thickness increases due to higher cotton proportion, the air permeability value is decreased (Figure 3).

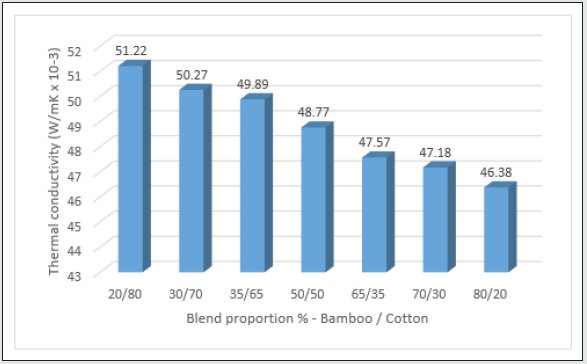

Thermal conductivity

When increase in the content of bamboo fibre, the tested results of knitted jersey fabrics shows that there is a decrease in the values of thermal conductivity. In another investigation by Pac MJ, et al. [12], it is stated that there may be an impact on heat transfer though the fabrics are made with same fibre type but if the varieties are different. As per the analysis by Chidambaram, et al. [13], the increase in the level of air spaces there will be increase in the values of thermal conductivity. Also, the test findings are showing that thermal conductivity decreases when fabric thickness and GSM is also decreased.

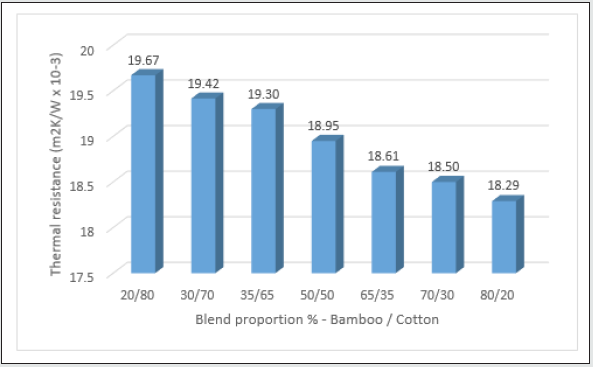

Thermal resistance

Like thermal conductivity even thermal resistance value decreased when bamboo content was increased in the tested knitted jersey fabrics. In Figure 4, we can understand very clearly from the test results that when bamboo proportion get increased, the yarn becomes finer, and thickness of the fabric is also reduced. This is an important factor which reduces the thermal resistance of the fabric. Hoge, et al. [14] stated that thickness of the fabric determines the thermal lagging of the fabric through their analysis. Generally, we have studied that there will be an inverse relationship between thermal conductivity and thermal resistance. But the tested results in this study shows that both thermal conductivity and thermal resistance were decreasing when bamboo percentage is increased. Though same loop length to knit the fabric is considered, low thermal resistance is shown due to finer yarns.

Water vapour permeability

Fabric thickness and GSM plays a major role in the water vapour permeability. From Figure 5, we can see that values of water vapour permeability gradually increases when the fabric thickness and mass per unit area is reduced. It is easy for the water vapour to penetrate through the less thick fabric. Also, when the content of bamboo is increased in the fabric samples it is noticed that the water vapour permeability is increased. Even moisture regain of both cotton and bamboo to be considered here. Bamboo has higher moisture regain than cotton, due to which the diffusion of water vapour through the higher bamboo content fabric may increase the water vapour permeability. When the value of higher bamboo content fabric is seen, air permeability is close to double than the water vapour permeability, which shows lower vapour transfer rate when there is more presence of cotton. Asta, et al. [8] concluded that values of air permeability and water vapour permeability cannot be directly correlated. The rate at which the value of air permeability increased were not seen in the rate of increase in water vapour permeability in our investigation also.

Conclusion

Knitted jersey fabrics made from higher content of bamboo has lesser fabric thickness and lower GSM for the same loop length. Air permeability value is lower if the presence of cotton is more in the yarn than bamboo. Value increase is due to micro gaps in the bamboo fibre structure. If is found that thermal conductivity is based bamboo fibre proportion in the blend of yarn. Tested values shows that knitted jersey fabrics made has decrease in thermal conductivity values when there is increase in content of bamboo. Likewise, it is observed that thermal resistance is also significantly affected by the fibre composition ratio. Thermal resistance is decreased when bamboo proportion is increased in yarn blend. Water vapour permeability increases when the fabric thickness and mass per unit area is reduced, basically by increase in the proportion of bamboo content in yarn blend.

References

- Apurba Das, R Alagirusamy (2010) Science in Clothing Comfort, Woodhead Publishing India Pvt Ltd, New Delhi, India p. 4.

- Bhat P, Bhonde HU (2006) Comfortable clothing for defense personnel. Asian Textile Journal 11(2): 73-77.

- Majumdar A, Mukhopadhyay S, Yadav R (2010) Thermal properties of knitted fabrics made from cotton & regenerated bamboo cellulosic fibres. International Journal of Thermal Sciences 49(10): 2042-2048.

- Havenith G (2002) The Interaction of Clothing and Thermoregulation. Exogenous Dermatology 1(5): 221-230.

- Kadapalayam Chinnasamy K, Chidambaram P (2017) Influence of the Bamboo/Cotton Fibre Blend Proportion on the Thermal Comfort Properties of Single Jersey Knitted Fabrics. Fibres & Textiles in Eastern Europe 6(126): 53-57.

- Jordeva S, Kjortoseva S, Kalojanov N (2012) Release of Thermo-physiological Comfort of Single Jersey Knitted Structures with Method of Thermo-Vision Analysis. Proceeding of the Fourth International Scientific-Professional Conference Textile Science and Economy p. 35-48.

- Bedek G, Salaun F, Martinkovska Z, Devaux E, Dupont D (2011) Evaluation of thermal and moisture management properties on knitted fabrics and comparison with a physiological model in warm conditions. Applied ergonomics 42(6): 792-800.

- Bavainyte A, Micucoiniene D (2011) Investigation on the air and water permeability of double layered weft knitted fabrics. Fibres & Textiles in Eastern Europe19(3): 69–73.

- Muhammad Owais Raza Siddiqui, Danmei Sun (2015) Porosity Prediction of Plain Weft Knitted Fabrics. Fibers 3: 1-11.

- Kane CD, Patil UJ, Sudhakar P (2007) Studies of the influence of knit structure and stitch length on ring and compact yarn single jersey fabric properties. Textile Research Journal 77(8): 572-582.

- Xu Y, Lu Z, Tang R (2007) Structure and thermal properties of bamboo, viscose, tencel and conventional viscose fiber. Journal of thermal analysis and calorimetry 89(1): 197-201.

- Pac MJ, Bueno MA, Remer M (2001) Warm Cool Feeling Relative to Trilogical Properties of Fabrics. Textile Research Journal 71(9): 806-812.

- Chidambaram P, Govindan R (2012) Influence of blend ratio on thermal properties of bamboo/cotton blended woven fabrics. Silpakorn University Science and Technology Journal 6(2): 49-55.

- Hoge H J, Fonseca GF (1964) The thermal conductivity of a multilayer sample of underwear material under a variety of experimental conditions. Textile Research Journal 34(5): 401-410.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...