Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Research Article(ISSN: 2637-4595)

Analysis of Deformation for Active Sports Wears Volume 3 - Issue 5

Ashok Kumar A1 , Thirumurugan V1, Gopalakrishnan M1* and Priyalatha S2

- 1Assistant professor, Department of Textile Technology, Bannari Amman Institute of Technology, India

- 2Assistant professor, Sona College of Technology, Salem

Received: April 14, 2021 Published: May 05, 2021

*Corresponding author: Gopalakrishnan M, Assistant professor, Department of Textile Technology, Bannari Amman Institute of Technology, India

DOI: 10.32474/LTTFD.2021.03.000175

Abstract

When an athlete’s practices their body would have many changes Physically, Mentally and physiologically when compared with the normal static pose. To make them to feel comfortable with the environment and to manage their physical health and mental comfort. Running wear plays an important role in achieving their excellence. During each sports movement the garment worn by the player will undergo various movements like contraction and extensions. The purpose of the paper is to elucidate the extension and contraction of the sportswear was developed in the combination of Lycra and Micro polyester. The first phase of the study involves the anthropometric study of the human body in different motion state of running [1]. In the second phase the static block pattern has been created according to the wearer’s measurement and the tight fit (skin fit) garment has been constructed to make the further study. In the third phase the physical changes happening during running has been captured using Camera to find the deformation in various parts of the body. The photos and videos are taken for the further study. The deformations are found using the Image J Software and the maximum and minimum contraction and extensions are found for the biometric poses of running. As the result of the study, it was found that after the analysis the maximum extension was found about 84%, and the minimum contraction found was 0%, Thus micro polyester and lycra can be used in the construction of sportswear in future [2].

Introduction

This project deals with finding deviations that occurs in human body during different motions like cycling and running. People are becoming increasingly health conscious and realize the importance of participating in sports and exercises to maintain a healthy lifestyle. Sportswear includes different categories such as outwear, top trousers and footwear. Different specialized clothing products are designed for outdoor expedition or specific activities. In sportswear product design, aesthetic and functional design are the most important considerations which determine the wearing comfort [3-6]. Aesthetic design comprises of the style, color, accessory and material used in the sportswear products. Functional design requires that the sportswear properties should meet the body mechanical and physiological requirements in exercise. A good functional design can prevent athletes from injury by keeping the correct body postures in exercise and it also provides excellent thermal comfort by effectively transmitting excess body heat and moisture out of the body [7-10].

Deformation

Deformation refers to any changes in the shape or size of an object due toa)

An applied force (the deformation energy in this case is transferred through work)

b) A change in temperature (the deformation energy in this case is transferred through heat).

Applications

The study of biomechanics ranges from the inner workings of a cell to the movement and development of limbs, to the mechanical properties of soft tissue, and bones. Some simple examples of biomechanics research include the investigation of the forces that act on limbs, the aerodynamics of bird and insect flight, the hydrodynamics of swimming in fish, and locomotion in general across all forms of life, from individual cells to whole organisms. With growing understanding of the physiological behavior of living tissues, researchers are able to advance the field of tissue engineering, as well as develop improved treatment for a wide array of pathologies [10-15]. Biomechanics is also applied to studying human musculoskeletal systems. Such research utilizes force platforms to study human ground reaction forces and infrared video graphy to capture the trajectories of markers attached to the human body to study human 3D motion. Research also applies electromyography to study muscle activation, investigating muscle responses to external forces and perturbations. Biomechanics is widely used in orthopedic industry to design orthopedic implants for human joints, dental parts, external fixations and other medical purposes.

Sports

Sports are an incredibly important contributor to human nature in our pacified society. They lack responsibility and risk-taking swells to the point where people avoid any kind of competitive activity because of the inherent risk of failure [16-20]. Participating in sport at any level will replace the necessary competitive edge in an individual and kindle the fire of dedication, hard work, and almost reckless intensity; Individuals or groups participating in a sanctioned competition that has a standard set of rules for achieving victory. The competitors exhibit physicality.

Sports Wear

Sportswear or active wear is clothing, including footwear, worn for sport or physical exercise. Sport-specific clothing is worn for most sports and physical exercise, for practical, comfort or safety reasons. Typical sport-specific garments include Shorts, Tracksuits, T-shirt, and polo shirts. Specialized garments include swimsuits (for swimming), wet suits (for diving or surfing), ski suits (for skiing) and leotards (for gymnastics).Sports footwear include trainers, football boots, riding boots, and ice skates. Sportswear also includes bikini and some undergarments, such as the jockstrap and sports bra [21]. Sportswear is also at times worn as casual fashion clothing. For most sports the athletes wear a combination of different items of clothing, e.g., sport shoes, pants and shirts. In some sports, protective gear may need to be worn, such as helmets or American football body armour. Sports fabrics are technical materials which help to keep the wearer comfortable during exercise. The type of fabric required will depend upon the intensity of the exercise and the activity. Yoga clothing should use fabrics with good stretch ability for easy movement which will likely require the fabric to be of a knitted construction. Apparel for long distance running will keep the wearer in good comfort if it has excellent moisture wicking properties to enable sweat to transfer from the inside to the outside for the garment. Performance clothing for outdoor sports in the winter or snow sports ought to use breathable fabrics with very good insulating properties [22].

Materials and Methodology

Fabric: Fabrics are manufactured from various raw materials which are available from nature or artificially generated or mix of both. Fabrics can be classified based on the origin of fibers and its processes or its end usage.

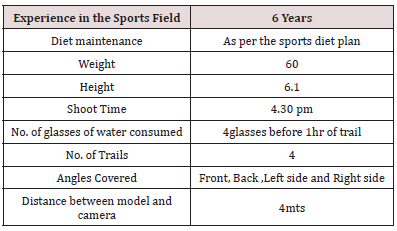

Selection of sports person: We selected the person who has his aim to become an Athletic figure, He is making his life to have a fit lifestyle. He just waited to have a right opportunity, we made and analyzed about his medical reports, He has been trained by the right agency and trainers. And have the right physique and appearance to help with our projects so this is how we selected the sports model.

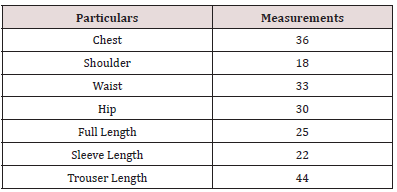

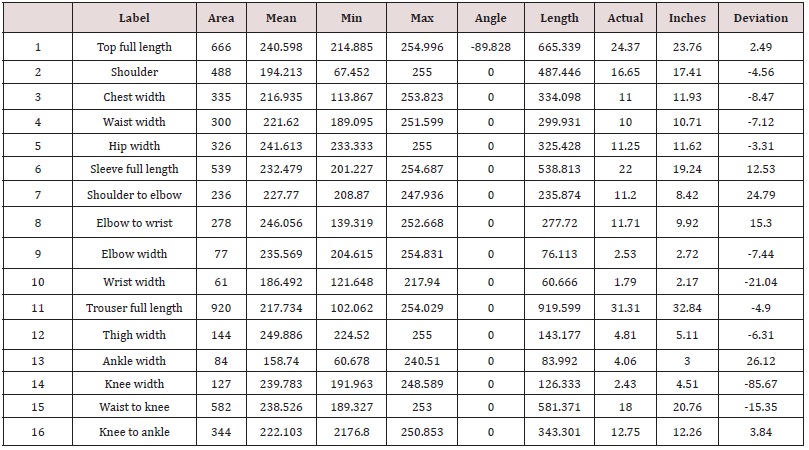

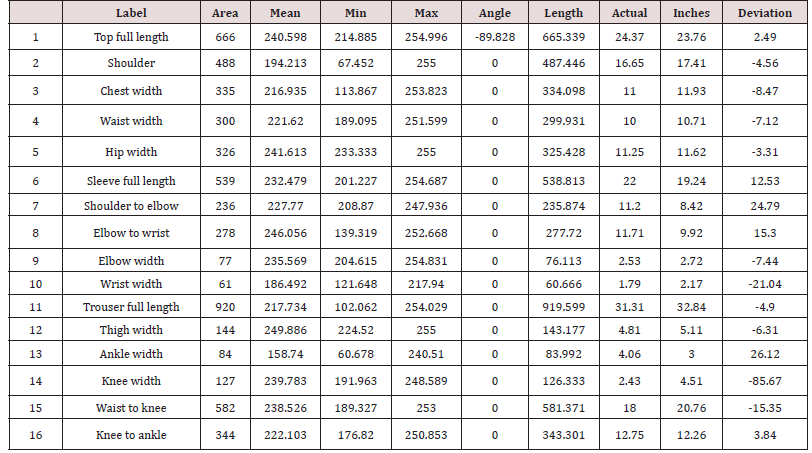

Measuring body dimensions: To Stitch the garment and to check his physical fitness we have measured his physique, starting from shoulder to leg his measurements are listed below (Table 1).

Fabric sourcing: The fabric has been sourced according to the requirement from Pranera textiles, Tirupur. The fabric has been custom made according to our Specifications.

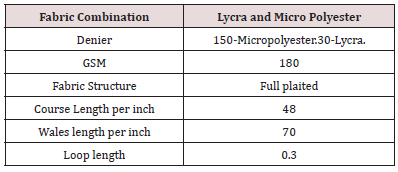

Fabric details: See in Table 2

Relaxing the fabric

Knitted fabrics tend to change dimensions in width and length after being taken off the machine, even without yarn shrinkage, indicating a change of loop shape rather than o. During knitting, the loop structure is subjected to a tension of approximately 15-25 grams per needle from sources such as the takedown mechanism and, in the case of fabric machines, the width stretcher board. Unless the structure is allowed to relax from its strained and distorted state at some time during manufacture, the more favorable conditions for fabric relaxation provided during washing and wearing will result in a change of dimensions, leading to customer dissatisfaction. We relaxed the fabric for about 3days and 3night-72hours

Marking in the fabric

The markings are made in the fabric to have the perfect fit in the garment, the markings are made horizontally and vertically from top to bottom.2X2 inches are because to find the perfect deviating factors and calculations. The deviations may happen in shoulder, leg, armhole, chest and other parts so in order to measure that the fabric is marked with horizontal and vertical lines with the distance of 2x2 inches.

Stitching

The patterns are cut according to the actual measurements of the wearer. Types of machine used

a) Three thread over lock

b) Flat lock

Sewing Procedure

A. Upper Garment

\a) Front and back shoulders are attached –using over lock machine.

b) Rib attached to the neck part -using over lock machine

c) Sleeve hemming – using flat lock machine.

d) Sleeve attaching to the armhole – using over lock machine.

e) Side seam is finished – using over lock machine.

f) Bottom hemming – using flat lock machine.

B. Lower Garment

a) Attaching Crotch -using over lock machine.

b) Attaching Side seam -using Over lock machine.

c) Attaching Inseam -using Over lock machine.

d) Making Bottom Hem -using flat lock machine.

e) Attaching Waistband Elastic –using Overlook machine. Wear fit trial

To confirm the Fit of the garment the fit trials are made, then we confirmed the fit of the garment, then made the wearer to stretch then and now to make sure that the garment has been fitted properly. The warmups are made in order to have proper fit, only after confirming the fitness we moved to the next step of making Video and photo shoot.

Video and Photo shoot

The Video and Photo shoot are made in order to find the deviations from the pictures collected. Poses captured:

a) Warm up poses

b) Stretch poses

c) Video of Running

i. Front view

ii. Side view

iii. Back view

iv. Horizontally and Vertically.

Finding deformation Using Image J software The deformation happened in the Garment is recorded using the Camera, then it is made as the separate frames using the Km player software, then by using the image J software the Deformations are found.

a) Video Editor: The player handles a wide range of audio, video and subtitles formats and allows one to capture audio, video and screenshots. It provides both internal and external filters with a fully controlled environment of connections to other splitters, decoders, audio/video transform filters and renderers without grappling with the DirectShow merit system (a system of selecting and prioritizing codes across the entire Windows operating system). Internal filters are not registered into the system’s registry in order to prevent the operating system from confusing system filters with K-Multimedia Player’s filters.

The user can set many audio and video effects, slow down or increase playback speed, select parts of a video as favorites, do various A-B repeats, remap the keys of remote interface for HTPC including overlay screen controls, and change a skin dynamically depending on the media type.

b) Image J software: Image J can display, edit, analyze, process, save, and print 8-bit color and grayscale, 16-bit integer, and 32-bit floating point images. It can read many image file formats, including TIFF, PNG, GIF, JPEG, BMP, DICOM, and FITS, as well as raw formats. Image J supports image stacks, a series of images that share a single window, and it is multithreaded, so time-consuming operations can be performed in parallel on multi- CPU hardware. Image J can calculate area and pixel value statistics of user-defined selections and intensity- threshold objects. It can measure distances and angles. It can create density histograms and line profile plots. It supports standard image processing functions such as logical and arithmetical operations between images, contrast manipulation, convolution, Fourier analysis, sharpening, smoothing, edge detection, and median filtering. It does geometric transformations such as scaling, rotation, and flips. The program supports any number of images simultaneously, limited only by available memory.

Results and Discussion

By the above analysis we have found the six phases of running and made the detailed study about the deformation happening in the garment by the numerical method. 6 phases of running are,

a. Initial Contact.

b. Mid stance stage.

c. Propulsive state.

d. Initial Swing.

e. Mid Swing.

f. Terminal Swing.

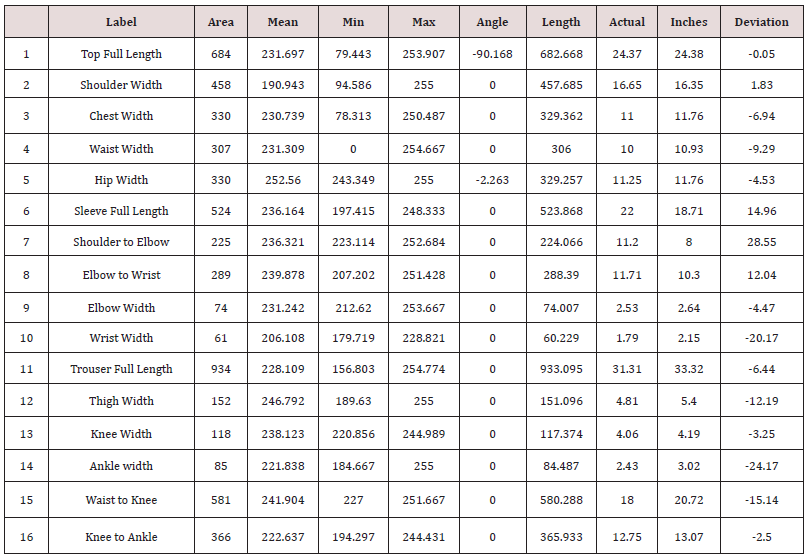

Then For each stage the video is recorded, and it is divided into several frame using the video editor, then according to the Deformation happening the numerical data are noted. Then by using the image j software the deformation percentage has been analyzed and then noted and the difference and deviations are graphed to find the maximum and minimum contraction and elongation and only based upon that analysis the final results are made.

Findings Regarding Models Routine

Then using the photos and videos shot the deformed areas are found (Table 3). The parameters found using the photos are

a. Extension

b. Contraction

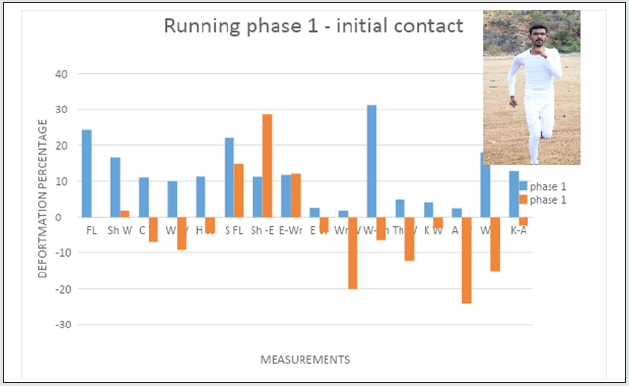

Running phase1 – Initial contact

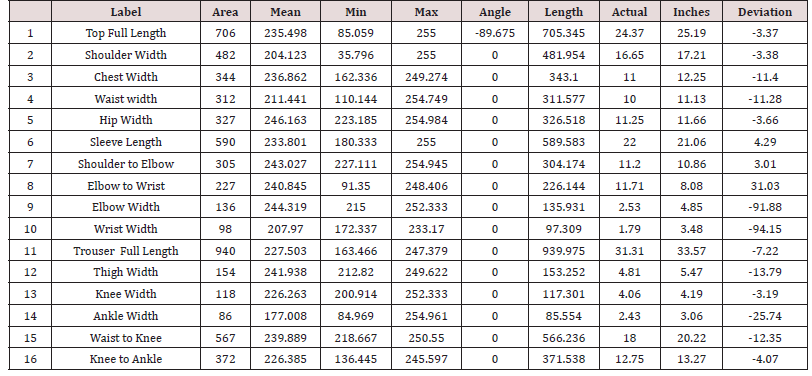

(Table 4 & Figure 1) There is 1% contraction in full length since is left leg is lifted up ,in shoulder width there is 2% contraction because the left shoulder is lifted up along with the left arm ,In the chest width there is extension of about 8% since the hands are moving in to and fro movement, there is extension of about 9% in the hip because of the left leg is raised, In sleeve full length there is contraction of about 15% because of the movement of hands ,There is contraction of about in Shoulder and elbow since the hands are moved up and down during running. There is a contraction of about 11% in Elbow and wrist because the left hand is folded, and it is in upward direction. There is extension of about 5% in elbow width because it gets folded during running. There is extension of about 20%in the wrist width since the hand is raised up. There is extension of about 5% in trouser full length because legs are lifted. In thigh width there is extension of about 12% because it gets expanded while running. In knee width it gets extension of about 4%.The Ankle width Extended up to 27% since there is no more change happening in ankle. There is extension of about 15% in waist to knee since there is more deformation and body stretch occurring in the waist

Deviations in each segments

Extension

a. The maximum extension is happening in Knee to angle of about 3%.

b. The minimum extension is happening in Ankle width of about 23%.

Contraction

a. The Maximum contraction is happening in Shoulder to elbow of about 28%.

b. The Minimum contraction is happening in Full length of about 1%.

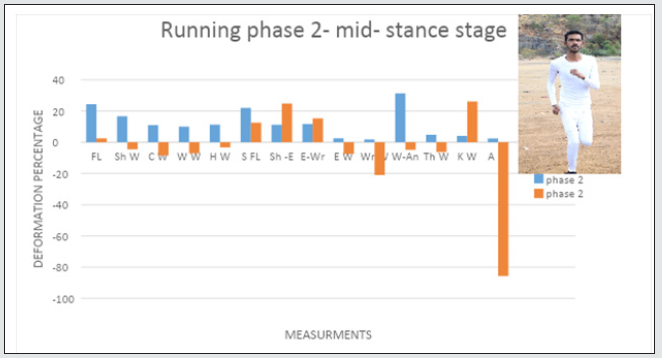

Running Phase 2 Mid - Stance Stage

(Table 5 & Figure 2) There is 2% contraction in full length since is left leg is lifted up, in shoulder width there is 5% Extension because the left shoulder is lifted up along with the left arm ,In the chest width there is extension of about 10% since the hands are moving in to and fro movement, in, there is extension of about -4% in the hip because of the left leg is raised, In sleeve full length there is contraction of about 15% because of the movement of hands ,There is contraction of about 25% in Shoulder and elbow since the hands are moved up and down during running. There is a contraction of about 16% in Elbow and wrist because the left hand is folded, and it is in upward direction. There is extension of about 10% in elbow width because it gets folded during running. There is extension of about 20%in the wrist width since the hand is raised up. There is extension of about 4% in trouser full length because legs are lifted. In thigh width there is extension of about 5% because it gets expanded while running. In knee width it gets Contraction of about 25%.The Ankle width Extended up to 84% since there is no more change happening in ankle .There is extension of about 4% in waist to knee since there is more deformation and body stretch occurring in the waist.

Deviations in each segments

Extension

a. The Minimum extension is happening in hip Width of about 2%.

b. The Maximum extension is happening in ankle Width of about 83%.

Contraction

a. The Maximum contraction is happening in Knee Width of about+ 24%.

b. The Minimum contraction is happening in Full length of about +2%.

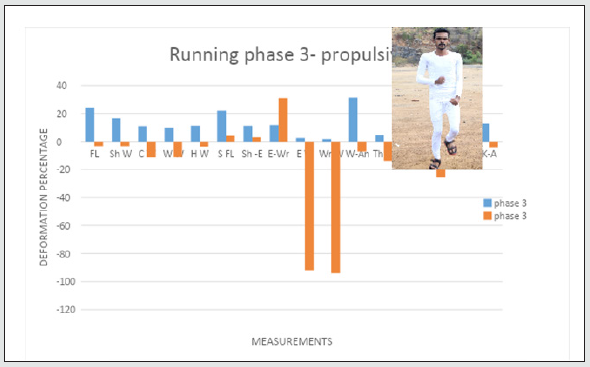

Running Phase 3- Propulsive Stage

There is 3% Extension in full length since is left leg is lifted up slightly in shoulder width there is 3% Extension because the hands are about to come to the rest. In the chest width there is extension of about 12% since the hands are moving in to and fro movement, there is extension of about 4% in the Hip Width because of the left leg is raised, in sleeve full length there is contraction of about 5% because of the movement of hands, there is contraction of about 3% in Shoulder and elbow since the hands are moved up and down during running (Table 6 & Figure 3). There is a contraction of about 26% in Elbow and wrist because the left hand is folded, and it is in upward direction. There is extension of about 94% in elbow width because it gets folded during running. There is extension of about 69%in the wrist width since the hand is raised up. There is extension of about 6% in trouser full length because legs are lifted. In thigh width there is extension of about 18% because it gets expanded while running. In knee width it gets Extension of about 3%.The Ankle width Extended up to 24% since there is no more change happening in ankle. There is extension of about 12% in waist to knee since there is more deformation and body stretch occurring in the waist.

Deviations in each segment Extension

a. The maximum extension is happening in knee Width of about -2%.

b. The minimum extension is happening in elbow Width of about -87%.

Contraction

a. The Maximum contraction is happening in Elbow to Wrist of about+ 26%.

b. The Minimum contraction is happening in Shoulder to Elbow of about +2%.

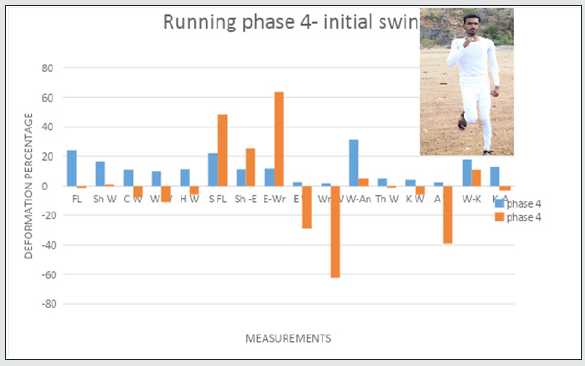

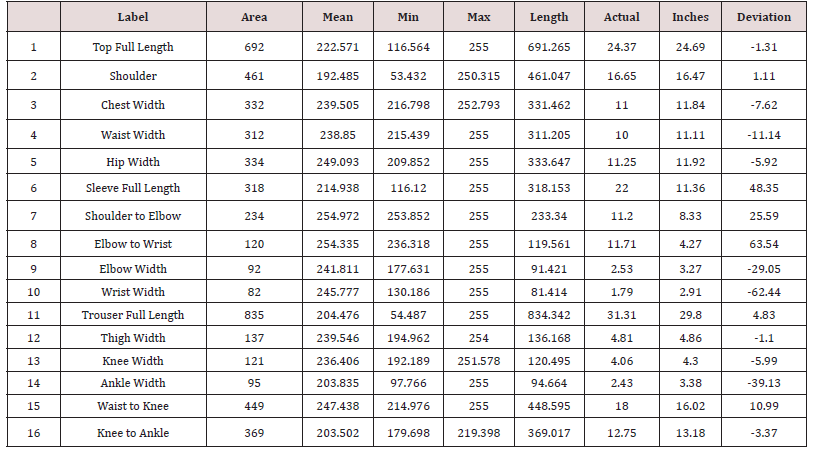

Running Phase 4- Initial Swing

There is 1% Extension in full length since is left leg is lifted up, in shoulder width there is 1% Contraction because the left shoulder is lifted up along with the left arm In the chest width there is Extension of about 9% since the hands are moving in to and fro movement, in, there is Extension of about 7% in the Hip Width because of the left leg is raised, In sleeve full length there is contraction of about 50% because of the movement of hands, there is contraction of about 26% in Shoulder and elbow since the hands are moved up and down during running (Table 7 & Figure 4). There is a contraction of about 64% in Elbow and wrist because the left hand is folded, and it is in upward direction. There is Extension of about 30% in elbow width because it gets folded during running. There is Extension of about 62%in the wrist width since the hand is raised up. There is Contraction of about 5% in trouser full length because legs are lifted. In thigh width there is Extension of about 1% because it gets expanded while running. In knee width it gets Extension of about 6%.The Ankle width Extended upto 36% since there is no more change happening in ankle. There is extension of about 12% in waist to knee since there is more deformation and body stretch occurring in the waist

Deviations in each segments

Extension

a. The Minimum extension is happening in full length and thigh Width of about 1%.

b. The Maximum extension is happening in Wrist Width of about 61%.

Contraction

a. The Maximum contraction is happening in Elbow to Wrist of about 61%.

b. The Minimum contraction is happening in Shoulder Width of about 0% (Table 8 & Figure 5).

There is 1% Contraction in full length since is right leg is lifted up, in shoulder width there is 5% Extension because the left shoulder is lifted up along with the left arm ,In the chest width there is Extension of about 14% since the hands are moving to and fro movement. There is Extension of about 9% in the Hip Width because of the left leg is raised, in sleeve full length there is contraction of about 38% because of the movement of hands, there is contraction of about 24% in Shoulder and elbow since the hands are moved up and down during running. There is a contraction of about 48% in Elbow and wrist because the the left hand is folded, and it is in upward direction. There is Extension of about 30% in elbow width because it gets folded during running. There is Extension of about 46%in the wrist width since the hand is raised up. There is Contraction of about 6% in trouser full length because legs are lifted. In thigh width there is Extension of about 7% because it gets expanded while running. In knee width it gets Contraction of about 14%.The Ankle width Extended upto 16% since there is no more change happening in ankle .There is Contraction of about 18% in waist to knee since there is more deformation and body stretch occurring in the waist

Deviations in each segments

Extension

a. The maximum Extension is happening in Shoulder Width of about 5%

b. The minimum extension is happening in Wrist Width of about 45%.

c. There is no extension in full length.

Contraction

a. The Maximum contraction is happening in Elbow to Wrist of about+ 50%.

b. The Minimum contraction is happening in Shoulder Width of about 2%.

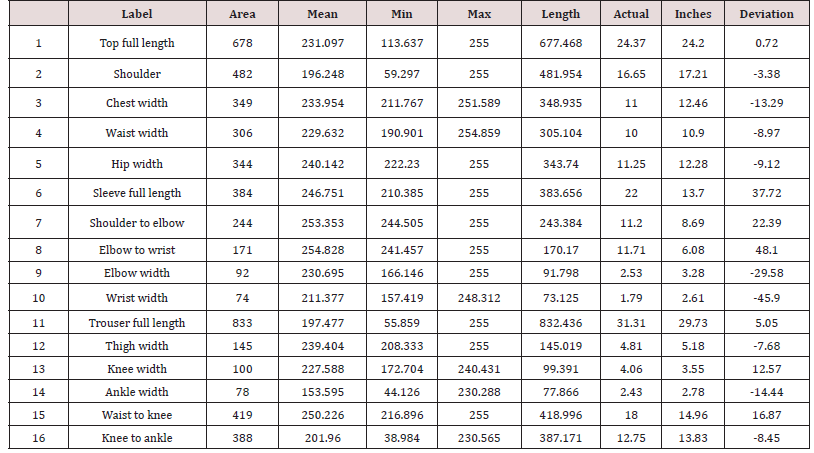

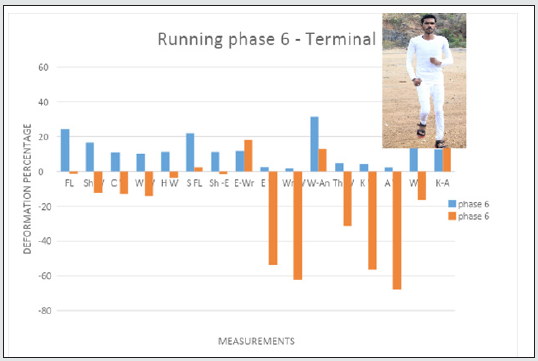

Running Phase 6- Terminal Swing

(Table 9 & Figure 6) There is 2% Extension in full length since is right leg is lifted up. In shoulder width there is 12% Extension because the left shoulder is lifted up along with the left arm ,In the chest width there is Extension of about 15% since the hands are moving in to and fro movement, There is Extension of about 5% in the Hip Width because of the right leg is raised, In sleeve full length there is Contraction of about 3% because of the movement of hands there is Extension of about 2% in Shoulder and elbow since the hands are moved up and down during running. There is a contraction of about 18% in Elbow and wrist because the right hand is folded, and it is in upward direction. There is Extension of about 56% in elbow width because it gets folded during running. There is Extension of about 2%in the wrist width since the hand is raised up. There is Contraction of about 16% in trouser full length because legs are lifted. In thigh width there is Extension of about 32% because it gets expanded while running. In knee width it gets Extension of about 58%.The Ankle width Extended up to 68% since there is no more change happening in ankle .There is Contraction of about 18% in waist to knee since there is more deformation and body stretch occurring in the waist.

Deviations in each segments

Extension

a. The maximum extension is happening in full length of about -1%.

b. The minimum extension is happening in ankle width of about -66%.

Contraction

a. The Maximum contraction is happening in Knee to Ankle of about + 52%.

b. The Minimum contraction is happening in Sleeve Full Length of about +4%.

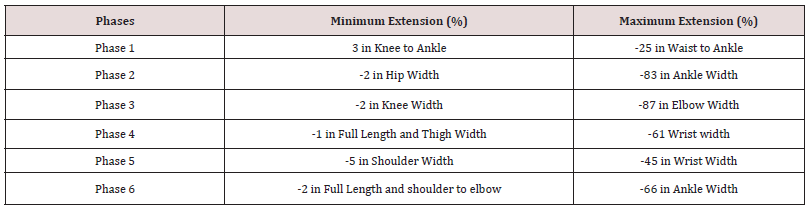

Extension

(Table 10) Thus, by the analysis, Maximum extension is happening in Phase 3 Propulsive stage of about -87 in Elbow width. Minimum extension is happening in Phase 4 Initial Swing of about -1 in Full length and thigh width.

Maximum Contraction is happening in Phase 4 Initial Swing of about +61 in Elbow to wrist. Minimum Contraction is happening in Phase 4 Initial Swing of about 0 in Shoulder width. Thus, by the analysis, The Combination of lycra and micro polyester fabric in sports wear gives maximum stretch

Conclusion

a. The project was started with an aim of finding the deformation in the sports wear while running. The deviations are found using the video recorded.

b. Then the maximum stretch and contraction are found,

c. It gives the maximum stretch of about 87% and minimum contraction of about 0%.

We have concluded with the simple and effective work and found the lycra and micro polyester gives the wearer more stretch ability than the normal sportswear.

References

- Voyce J, Dafniotis P, Towlson S (2005) Elastic Textiles, Textiles in Sport. Wood Head Publications, Cambridge, UK.

- Kirk Jr, Ibrahim SM (1996) Fundamental Relationship of Fabric Extensibility to Anthropometric Requirements and Garment Performance. Textile Research Journal.

- Li Yi, Anthony SW, Wong (2006) Clothing Biosensory Engineering.

- Bardhan MK, Sule AD (2001) Anatomy of Sportswear and Leisurewear: Scope for Spandex Fibres.

- Rozelle Walter N (1993) Spandex: Miracle Fiber Now Coming into its Own.

- Moncrieff RW (1970) Man-Made Fibres, WileyInterscience Publication, Edition 5, John EL Stretch Challenge, USA.

- Senthilkumar M, Anbumani N, Mario de Araujo (2011) Elastic Properties of Spandex Plated Cotton Knitted Fabric. Textile Engineering Division 92: 9-13.

- Donna Sajn Gorjanc, Vili Bukosek (2008) The Behaviour of Fabric with Elastane Yarn during Stretching. Fibres & Textiles in eastern Europe 16(3): 68.

- Arnold M Hansen, Hazel M Fletcher (1946) Elastic Recovery in Cotton Knitted Fabrics. Textile Research Journal.

- Kawabata S, Postle R, Masako N (1991) Objective Specification of Fabric Quality, Mechanical Properties and Performance. International Journal of Clothing Science and Technology 3(1).

- Peter Popper (1966) The Theoretical Behavior of a Knitted Fabric Subjected to Biaxial Stresses. Textile Research Journal 36(2): 148-157.

- http://www.elaspan.com/about3.html

- Senthilkumar M, Anbumani N (2011) Dynamics of Elastic Knitted Fabrics for Sportswear. Journal of Industrial Textiles 41(1): 13-24.

- Bayazit Marmarali A (2003) Dimensional and Physical Properties of Cotton/Spandex Single Jersey Fabrics. Textile Research Journal 73(1): 11-14.

- https://www.jeffjournal.org/papers/Volume9/V9I1.11.S.Mani.pdf

- R Sadek, AM El-Hossini, AS Eldeeb, AA Yassen (2012) Effect of lycra extension percent on single jersey knitted fabric properties. Journal of Engineered Fibres and Fabrics 7(2): 11-16.

- M Senthilkumar (2005) Elastic knitted fabrics for tight fit sportswear.

- https://www.researchgate.net/publication/242385487_Geometrical_and_Dimensional_Properties_of_Plain_Knitted_Fabrics_Made_from_Glass_Fiber_Yarns_for_Composite_ReinforcementDL Munden (2007) The geometry and dimensional properties of plain-knit fabrics. Journal of Industrial Textiles 37(2): 139-149.

- https://www.theguardian.com/lifeandstyle/2017/jun/19/under-pressure-do-compression-sports-clothes-really-improve-performance

- https://www.livestrong.com/article/438174-why-is-stretching-painful/

- Senthil Kumar M, Anbumani N, Hayavadana J (2011) Elastane fabrics-A tool for stretch applications in sports. Indian Journal of Fibre & Textile Research 36(1): 300-307.

- Watkins P (2011) Designing with stretch fabrics.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...