Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4749

Research Article(ISSN: 2637-4749)

Protein Deterioration in Milk-Based Products by Maillard Reaction: Evaluation by Furosine Content Volume 5 - Issue 4

Baptista José1,2* and Paiva Lisete1,2

- 1Department of Physics, Chemistry and Engineering (DCFQE), Faculty of Science and Technology, University of Azores, 9500-321 Ponta Delgada, Azores, Portugal

- 2Institute of Agricultural and Environmental Research and Technology (IITAA), University of Azores, 9500-321 Ponta Delgada, Azores, Portugal

Received: April 25, 2023; Published: April 29, 2023

Corresponding author: Baptista José, Department of Physics, Chemistry and Engineering (DCFQE), Faculty of Science and Technology, University of Azores, Portugal, Institute of Agricultural and Environmental Research and Technology (IITAA), University of Azores, 9500-321 Ponta Delgada, Azores, Portugal

DOI: 10.32474/CDVS.2023.05.000220

Abstract

The determination of the Maillard reaction in raw, pasteurized, UHT cow milks and dietetic infant formula (DIF) was determined by high performance liquid chromatography (HPLC) with ultraviolet detection. During the heat treatment, drying and storage of milk and dairy products, different reactions involving the reducing sugars (lactose) and proteins, particularly lysine-rich protein in milk make it especially sensitive to these thermally induced non-enzymatic reactions (Maillard-reactions). The protein value can be affected by these reactions, causing losses in the food nutritional quality. Lysine having a ε-free amino group can be converted to a non-bioavailable N-substituted (blocked) lysine form. Knowledge of the Maillard reaction extent in milk-based products, and consequently the protein deterioration can be achieved by the indirect determination of furosine formed during the hydrolysis of the Amadori products.

This reaction is relatively slow in high moisture foods but is the predominant at room temperature of low moisture milkbased products, and can give rise to antinutritive and toxic compounds, changing the organoleptic and functional food properties. Furosine content is a good indicator to evaluate the extent of the Maillard reaction and can be used to calculate the decrease of bioavailable lysine, particularly in DIF that the protein reduction greatly reduces the beneficial effects as a dietary supplement. The objective of this study was the determination of furosine by HPLC methodology to evaluate the process severity by heat treatment or storage conditions and, together with protein, to estimate the quality of the protein.

Keywords: Milk protein; Maillard reaction; Reducing sugars; Furosine; HPLC/UV

Methodology, Results and Discussion

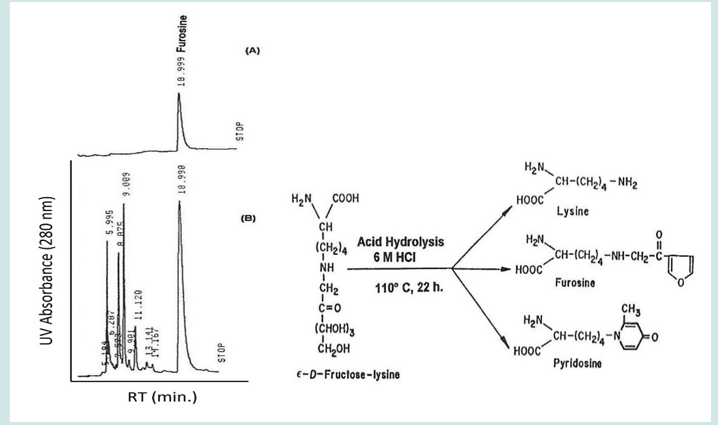

Pasteurized and UHT milks were obtained from local stores and fresh raw cow milk was donated by an Azorean herd. The samples were stored 1-3 days at 4°C before analysis. Dietetic infant formula (DIF) powders were kindly donated by the Azorean Pediatric Hospital. All the reagents were purchased from Sigma-Aldrich Chemical (USA) and Merck (Germany). Furosine standard was supplied by Neo system Laboratories (France). The methodology used was in accordance with Erbersdobler et al., [1] and Henle et al., [2] with some modifications. A weighted aliquot of raw and commercial cow milks corresponding to 30 mg of protein (by Kjeldahl methodology) or milk powder and DIF containing 0.1 g (10-30 mg of protein) were hydrolyzed with 6 N HCl at 110°C for 22 hrs. After hydrolysis the furosine was determined by HPLC in the following conditions: Column RP-C18 (250 x 4.6 mm i.d.), maintained at 35 °C, using 0.06 M sodium acetate at pH 4.3, with acetic acid, as the mobile phase. The elution was isocratic at a flow rate of 0.5mL/min and the detection at the wavelength of 280 nm (Figure 1).

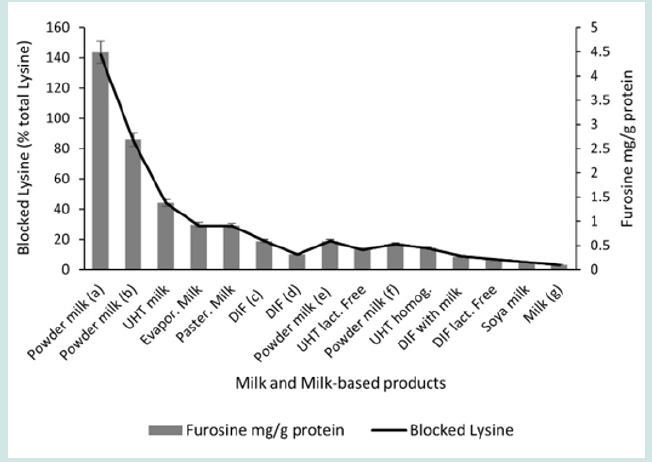

The results, performed in triplicate, show protein damage by measuring the furosine content, that revealed values ranging from 0.097 to 1.379 mg/g of protein in raw and UHT milks, respectively, and between 0.527 and 4.491 mg/g of protein for fresh commercial powder milk and for powder milk storage during two years at room temperature, respectively. DIF revealed levels of furosine ranged from 0.216 to 0.593 mg/g of protein, depending on protein source and DIF composition, however, the blocked lysine levels did not increase significantly in powder milk stored one year at 4°C. According to Bujard and Finot [3] the lysine units in milk-based products, which are in form of lactulosyl-lysine (blocked lysine) generated on acid hydrolysis under specified conditions, 40% lysine, 32% furosine and 28% pyridoxine (Figure 2). According to Finot et al., [4], from these values, lysine as lactulosyl-lysine was calculated as 3.125 x furosine content and reactive lysine may be calculated as total lysine minus 1.24 x furosine content.

Figure 1: HPLC chromatogram of a solution of standard furosine (A) and of a acid hydrolysed sample of dietetic infant formula- DIF (B). Figure 2: Maillard reaction and formation of an Amadori adduct to a protein amino group (lisine in this figure).

Figure 1 shows the HPLC chromatogram of a standard furosine (A) and an acid hydrolyzed sample of DIF (B). Figure 2 shows the first step of the Maillard reaction and formation of an Amadori adduct to a protein amino group (lysine in this figure). Figure 3 shows the amount of blocked lysine related to furosine con-tent in milk and milk-based products. Figure 3. Blocked lysine and relative furosine content in milk and milk-based products. Quantitative data obtained by Chem Station Agilent Software programed for area normalization method. Legend: (a) Powder milk kept 2 years at RT; (b) Powder milk kept 1 year at RT; (c) DIF with whey plus casein; (d) DIF with hydrolyzed whey; (e) Powder milk kept 1 year at 4°C; (f) Fresh powder milk; (g) Raw (whole) bovine milk. The Maillard-reaction is relatively slow in high-moisture foods but is the predominant reaction at room temperature of low moisture milk-based products [5].

The results of this study show that the reduction of bioavailable lysine cannot be totally avoided particularly during DIF production. DIF samples without lactose and samples with skimmed milk plus maltodextrin present low levels of furosine (7 and 9 of blocked lysine), respectively, and DIF with whey plus casein and hydrolyzed whey present higher values of furosine (18 and 10 of blocked lysine), respectively, (Figure 3). A reduction of about 30% of available lysine in milk-based food supplements could lead to an inadequate supply. On the other hand, higher amounts of reducing carbohydrates present in added products (juices, sucrose, glucose, honey, etc.) also increase the damage of the milk-based products. Some DIF which contained hydrolyzed whey proteins revealed much higher blocked lysine levels, results have also been reported by Evangelishi et al., [6]. According to Ferrer et al., [7], furosine can also be used to detect illegal addition of reconstituted whey and milk powders to milk-based products. Additionally, Maillard reaction may adversely impacted the digestibility of the protein fraction by modification of the protein structures induced by lactulosyl-lysine formation that makes hydrolysis of the peptide bound during digestion more difficult, probably through steric hindrance [7]. However, in both conditions during storage the protein fractions undergo chemical changes, and unfortunately some of these food products are often maintained on store shelves at ambient temperature [6].

Figure 2: Blocked lysine and relative furosine content in milk and milk-based products. Quantitative data obtained by ChemStation Agilent Software programed for area normalization method. Legend: (a) Powder milk kept 2 years at RT; (b) Powder milk kept 1 year at RT; (c) DIF with whey plus casein; (d) DIF with hydrolysed whey; (e) Powder milk kept 1 year at 4 °C; (f) Fresh powder milk; (g) Raw (whole) bovine milk.

Conclusion

This study shows the advantage of using furosine determination to evaluate the extent of the Maillard reaction and consequently to calculate the bioavailable lysine reduction in milk and milkbased products by a sensitive and fast HPLC method using a RPC18 column under isocratic conditions. Furosine was found in all samples DIF, and in some of the milk-based products. Dietetic Infant Formulas are advertised as “suitable for infant physical growing”, thus advertising it contributes to protein requirements for infant child. To support this fact, a correct amino acids balance should be safeguard for child food supplements. The present research findings show that milk-based products storage should be kept at as low temperature as possible and for long-term storage may be conserved either in dry powder or in liquid form. However, in both conditions during storage the protein fractions undergo chemical changes, and unfortunately some of these food products are often maintained on store shelves at ambient temperature.

References

- Erbersdobler HF, Dehn B, Nangpal A, Reuter H (1987) Determination of furosine in heated milk as a measure of heat intensity during processing. J Dairy Res 54: 147-151.

- Henle T, Walker H, Krause I, Klostermeyer H (1991) Efficient determination of individual Maillard compounds in heat-treated milk products by amino acid analysis. Int Dairy J 1(2): 125-135.

- Bujard E, Finot PA (1978) Determination of the available and blocked lysine in industrial milks. Ann Nutr Aliment 32(2-3): 291-305.

- Finot PA, Deutsch R, Bujard E (1981) The extent of the Maillard reaction during the processing of milk. Progr Food Nutr Sci 5: 345-355.

- Mauron J (1981) The Maillard reaction in food: a critical review from the nutritional standpoint. Progr Food Sci Nutr 5(1-6): 5-35.

- Evangelisti F, Calcagno C, Zunin P (1994) Relationship between blocked lysine and carbohydrate composition of infant formulas. J Food Sci 59(2): 335-337.

- Ferrer E, Alegria A, Courtaois G, Farre R (2000) High-performance liquid chromatography determination of Maillard compounds in store-brand and name-brand ultra-high-temperature –treated cow´s milk. J Chromatogr 881(1-2): 599-606.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...