Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4749

Case Report(ISSN: 2637-4749)

Case Study: Quantitative Risk Assessment of Staphylococcus Aureus Enterotoxins in Artisan Fresh Cheese Volume 4 - Issue 4

Ailin Martínez Vasallo1*, Nivian Montes de Oca Martínez1, René Tejedor Arias2, Liesbeth Jacsens3 and Mieke Uyttendaele3

- 1National Center of Animal and Plant Health, Cuba

- 2Institute of Pharmacy and Foods, University of Havana, Cuba

- 3Faculty of Bioscience Engineering, Laboratory of Food Microbiology and Food Preservation, Belgium

Received: May 18, 2021; Published: June 23, 2021

Corresponding author: Ailin Martinez Vasallo, National Center of Animal and Plant Health, Cuba

DOI: 10.32474/CDVS.2021.04.000191

Abstract

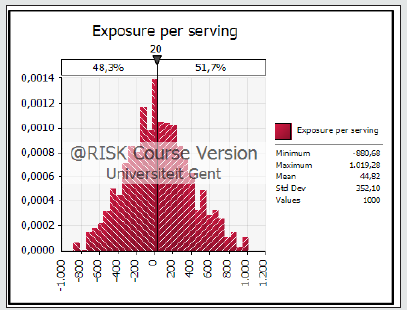

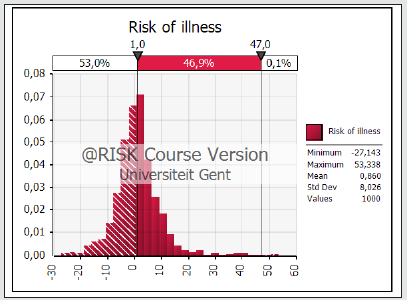

In Cuba, an important proportion of fresh cheese is made in artisan cheesemaking. Microbial hazards have been identified in artisan fresh cheese made from raw milk; different studies report contamination with S. aureus. The objective of this study was to do an exercise in risk assessment on enterotoxins of S. aureus for artisan fresh cheese in Cuba. A pathway was constructed as series of unit operations according to Quantitative Risk Assessment Model. The pathway comprises of initial contamination at cheesemaking, growth during sale in the informal market, growth during the storage and dose-response after consumption. The @Risk, version 7 (Palisade, USA) was used to run the simulations. Results showed that in the 51.7 % of population are at risk of exposure of enterotoxin dose of S.aureus between 0 to 1.0 μg/serving and 46.9 % of people will be at risk of getting ill for enterotoxins of S. aureus by artisan fresh cheese consumption. The risk assessment model developed provides valuable information for artisan cheesemakers to improve cheese production process. Subsequently, it also could provide valuable recommendations for sellers and consumers education on safe handling of cheese.

Keywords:Artisanal Fresh Cheeses; Staphylococcus Aureus; Enterotoxins; Quantitative Risk Assessment Model

Introduction

Cheeses are one of the most important dairy products. Around 21 million metric tons were produced in the year 2019 [1]. In several geographic regions such as Latin America and the Caribbean, Asia and others, the artisan fresh cheeses are foods preferred by the population due to factors like tradition, low prices and the relevant nutrient sources. Artisan fresh cheeses are those made out in the own dairy farms [2] under rustic conditions. The elaboration of these cheeses constitutes an old tradition in the countries of Latin America and is in the preference of the populations of this region [3]. These manufactures offer sustenance to many families and have an appreciable production volume. The production process of artisan fresh cheese in Cuba is carried out without compliance with Good Manufacturing Practices [4]. Staphylococcus aureus are considered one of the four pathogenic bacteria (Salmonella spp., Listeria monocytogenes, and Escherichia coli (STEC)) that constitute a risk to the safety of cheese production [5-8] showed that the source of S. aureus contamination could be multifactorial, such as raw materials, food handlers, or poor hygiene in food processing equipment.

Staphylococcal intoxication results from the ingestion of staphylococcal enterotoxins (SEs) produced during the growth of S. aureus in foods in amounts >105 CFU/g [6,9]. The SEs are potent gastrointestinal exotoxins synthesized by S. aureus throughout the logarithmic phase of growth or during the transition from the exponential to the stationary phase. They are active in high nanogram to low microgram quantities [10], and are resistant to conditions (freezing, drying, heat treatment, low pH) that easily destroy the bacteria that produce them, and to proteolytic enzymes, hence retaining their activity in the digestive tract after ingestion [11-13]. Symptoms of intoxication have a rapid onset (30 min-8 h), and include nausea, violent vomiting, abdominal cramping, with or without diarrhea [14]. Cuba artisan fresh cheese has high humidity (76.65 ± 5.7), a pH around of 5.25 ± 0.1, and a maximum shelf life of seven days under refrigeration [4]. Different studies in Cuba report data ranging from 3.0-6.8 log CFU/g in artisan fresh cheeses contaminated with S. aureus [4,15-17]. The main objective was to do an exercise in risk assessment on enterotoxins of S. aureus for artisan fresh cheese in Cuba.

Materials and Methods

General Description of the Risk Assessment Model

In this study, the hazard was identified as staphylococcal enterotoxins (SE). The toxin dose considered in this study was between 20-100 ng, according to the study of [18]. For toxigenic microorganism’s dose-response relations are that of a chemical toxin according to threshold model [19]. Threshold levels for enterotoxin of 20 or 100 ng per serving have been used; the levels are based on outbreak [17,20]. Threshold levels expressed as the number of S. aureus of 5 to 8 log CFU per g have been used [21]. Exposure assessment and risk characterization for this study were conducting using a modular process model. Initial contamination at cheesemaking process (Node 1), growth during the sale in the informal market (Node 2), growth during storage at home of consumers (Node 3) and the dose-response after consumption (Node 4) was assessed.

Exposure Assessment

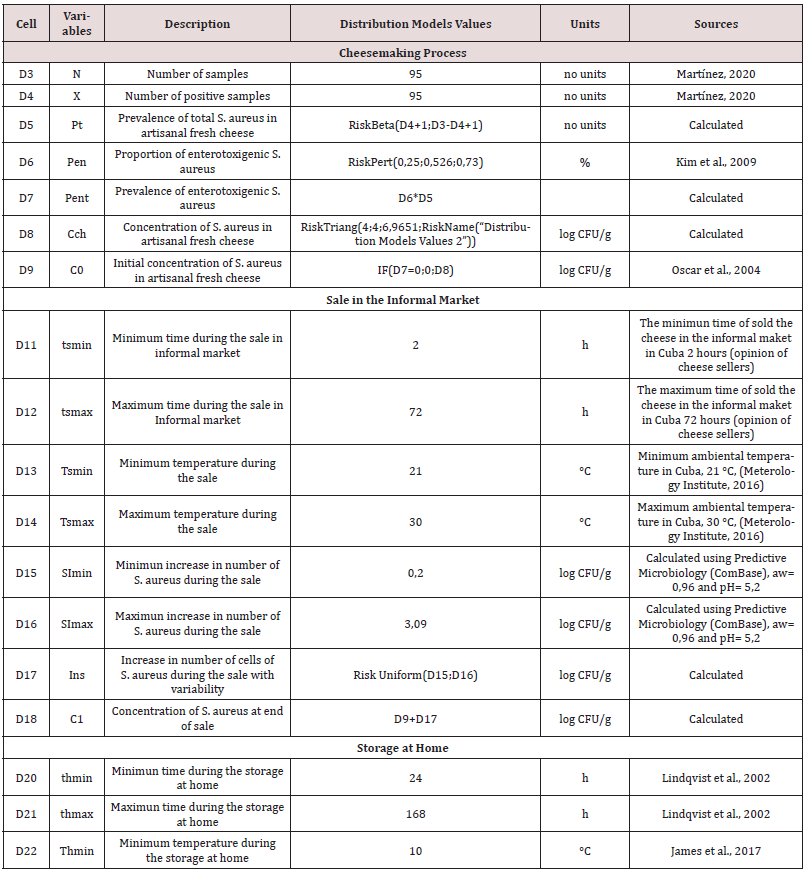

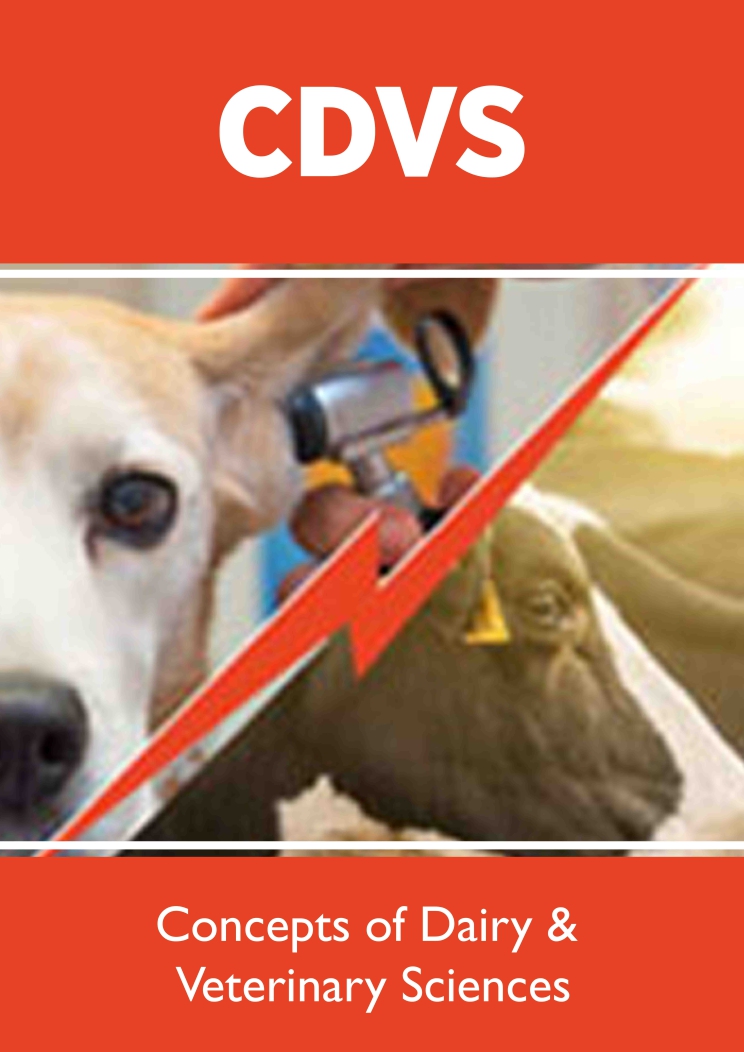

Prevalence and initial concentration of Staphylococcus aureus in Cuban artisanal fresh cheese (Node 1): The initial concentration at cheesemaking process are contributed by the level of Staphylococcus aureus contamination and it prevalence in artisanal fresh cheese. A specific study in 95 artisanal fresh cheese samples, reported the entire samples positive, above the theoretical detection limit of the analytical method, 100 CFU/g [17]. For this risk assessment, all the analysed (N=95) and of positive samples (X=95) were used in a Beta distribution to describe the uncertainty about the prevalence of S. aureus in artisanal fresh cheese (Table 1). The percentage of enterotoxigenic strains among the S. aureus isolated from food sample is variable, ranging from 8 to 73 %, and it is dependent on the food, geographical location and methodology for detection [11,22,23]. Proportion of enterotoxigenic Staphylococcus aureus was determined by Risk Perk distribution, using 25% as minimum, 52.6% as most likely and 73% as maximum according to. The prevalence of enterotoxigenic S. aureus was calculated (Table 1). Data from results of counts of Staphylococcus aureus in 95 samples of artisan fresh cheese were used for the best distribution fitting using @Risk software to estimate the concentration of S. aureus in artisan fresh cheese in Cuba (Figure 1).

Growth of Staphylococcus aureus during the sale in the informal market (Node 2)

The ambient temperature in Cuba was assumed to influence the growth of S. aureus during the sale of artisan fresh cheese in the informal market. Thus, the daily minimum and maximum temperatures in Cuba are 21 and 30⁰C, respectively [24]. The model used to predict the minimum and maximum increase in number of S. aureus during the sale as a function of temperature and time in artisanal fresh cheese was Combined Database for Predictive Microbiology (ComBase) [25], is managed by the Institute of Food Research in the United Kingdom, the USDA Agricultural Research Service in the United States, and the University of Tasmania Food Safety Centre in Australia [25]. The physiological state is a dimension less number between 0 and 1, expressing the physical suitability of the cells to their environment-when it is 0, growth will not occur (infinite lag-phase), when it is 1, growth will start immediately, without lag-phase. The lag-phase is the transition period during which microbial cells adjust to the environment before exponential growth starts [26]. The physiological state does not affect the growth rate, but affects the lag-phase time (in hours) [27].

The logarithmic concentration per hour was calculated using static conditions for minimum temperature (21°C) and minimum time (2h) and for maximum temperature (30⁰C) and maximum time (72h). The initial level was five, physiological state= 1.3x10- 2, aw= 0.96 and pH= 5.2. The minimum increase in number of S. aureus during the sale was 0.2 log CFU/g and the maximum 3.09 log CFU/g (Figure 1). The increase in number of cells of S. aureus during the sale with variability was calculated using a Risk Uniform distribution.

Figure 1: Fitting distribution for results of counts of Staphylococcus aureus in 95 samples of artisan fresh cheese.

Growth of Staphylococcus aureus during the storage at home (Node 3)

S. aureus growth was simulated at the point of storage (t) in a domestic refrigerator between 24 to 168 hours. For this risk assessment was assumed the daily minimum and maximum domestic refrigerator temperatures between 10 and 14°C [28]. As in the previous node, Combase was used to predict the logarithmic concentration per hour, using static conditions for minimum temperature (10 °C) and minimum time (24 h) and for maximum temperature (14 °C) and maximum time (168 h). The initial level was seven, physiological state= 1.3x10-2, aw = 0.96 and pH= 5.2. The minimum increase in number of S. aureus during the sale was 0.024 log CFU/g and the maximum 1.09 log CFU/g (Figure 2). The increase in number of cells of S. aureus during the sale with variability was calculated using a Risk Uniform distribution.

Figure 2: Fitting distribution for results of counts of Staphylococcus aureus in 95 samples of artisan fresh cheese.

Dose-response after consumption (Node 4)

The variable enterotoxin of S. aureus (SE) (Tox), as ng/g, is given by the equation:

Tox =10^Ptox*(0.9300751*cell number (log CFU/g)-6.662092) (1)

obtained [20] using a constant relation between toxin production and cell numbers (log CFU/ml) by the growth data reported [18] in milk products. This equation was applied to the model when the contamination level was > 5 log CFU/g, minimum bacterial concentration for enterotoxin production (FDA, 2012). Data of serving size was according to the Institute of Nutrition, Epidemiology and Microbiology in Cuba, (50 g as minimum, 100 as most likely and 150 as maximum), Risk Pert distribution was utilized. For this risk assessment uniform distribution was used for the dose-response assessment with a minimum value of 20 ng and a maximum value of 100 ng of SE, according to Soejima et al., [18]. The exposure per serving was calculated by multiplication between the doses of enterotoxins at the time of consumption per serving size. The risk of illness per serving was obtained by dividing the exposure per serving by the dose-response. Table 1 summarizes the formulas used to estimate the exposure and the risk with the variables and conditions assumed in this study.

Model Simulation

The information and assumptions were identified to be used in the input settings as described here. Probabilistic modeling describing increase of number of cell of growth of S. aureus and toxin production was used to estimate exposure to staphylococcal enterotoxin per serving. The model was constructed in an Excel spreadsheet and was simulated using @Risk, version 7 (Palisade, USA) running 1,000 iterations. The overview of the model and its assumptions used (i.e. the time and temperature) in this risk assessment are presented (Table 1)

Results and Discussion

Figure 2 shows the frequency distribution of enterotoxins of Staphylococcus aureus on artisan fresh cheese at the time of consumption. According to this risk assessment study, the simulation results showed that in 51.7 % the population would be exposed to a dose of 20 ng/serving or higher, with a mean value of 44.2 ng/serving and between 0 to 1.0 μg/serving. According to the Figure 2, below the P48% percentile, the population has no exposure to the minimum dose (20 ng/serving) of S. aureus enterotoxin by consumption of artisan fresh cheese. But, the rest of the population that is above the P48% percentile that is 52% are exposed to risky dose of S. aureus enterotoxins. The probability of risk of illness from an exposure to S. aureus enterotoxin resulted in approximately 52 000 illnesses out of 100 000 consumers arising from the consumption of artisan fresh cheese.

In this study, the risk of illness for consumption of enterotoxins of S. aureus will be greater than 1 (Figure 3). The model predicted that 46.9% of people will be at risk to the dose 20 ng, which is the minimal dose to cause illness. From the distribution of the risk, 5 % of people who not are at risk can be explained for their immunity system [29]. The risk of exposure to SE depends directly on the dose that is considered toxic, which is determined from clinical, epidemiological studies and may vary among population and age groups [10]. Nunez and Caldas (2017) [27], found the maximum probability of illness per person per day in the order of 10-4 and the exposure doses estimated by the models were probably affected by the initial concentration of S. aureus. The study of these authors indicated that the consumption of fresh cheese Minas by the Brazilian population is most likely safe. The results of risk characterization for S. aureus in natural and processed cheese obtained [30] in Korea showed that the mean values for the probability of illness per person per day were higher in processed cheese (7.97×10-6) than in natural cheese (2.32×10-6). The results indicate that the risk of S. aureus-related foodborne illness due to cheese consumption can be considered low under those conditions in Korea.

Figure 3: Frequency distribution of risk illness from enterotoxins of S. aureus on artisanal fresh cheese at the time of consumption (Values in X axis are in ng of enterotoxin per serving ).

For unripened raw milk cheese production [21] used predictive modeling and survey data in combination with probabilistic modeling to simulate the levels of S. aureus at the time of consumption. These authors found that the initial S. aureus population, pH, and storage time were the main risk factors. For on farm production of pasteurized drinking milk in the UK, [31] developed a probabilistic model for the representation of the risks that arise from the presence of SEs of S. aureus, during the entire production chain. The Bayesian model developed by these authors allowed the identification of the main hazard sources and introduced the concept of bio traceability. The results indicated pre-emptive action should be taken in the milk production process to increase its efficiency and safety [31].

Heidinger et al., [32] considered a staphylococcal enterotoxin A toxic dose of 94 ng, based on a large outbreak of staphylococcal food poisoning involving chocolate milk that occurred in the United States of America. These authors, using the ComBase and PMP models and @Risk, found that this dose may be exceeded at the 99.99 percentile after the consumption of raw milk by the American population, and concluded that raw milk servings do not represent a significant risk from SEA intoxication. One of the major components of risk assessment is the exposure assessment; the use of predictive models is an essential tool for estimating the spatiotemporal changes of S. aureus population in the food chain, the attainment of toxin producing levels in target foods, and the amounts of toxins present in foods at the time of consumption [33]. The predictive models such as Com Base are capable of simulating dynamics of S. aureus strains to temperature (7.5-30.0°C), pH (4.4- 7.0), and aw (0.907-1) in broth [34]. But, the Com Base models have limitations; do not consider the competitive microbiota and the level of lactic acid in bacterial growth) [27,35] refers with the Com Base program the growth rates were overestimated, which is nevertheless acceptable for conservative risk models.

During the QMRA of S. aureus enterotoxins in artisan fresh cheese, the contamination level of S. aureus has increased along the production chain. These could be due to growth, cross contamination from handlers or utensils. This result indicates the importance of Good Manufacturing Practices according to the Cuban reality and the ability to meet the raised measures, always ensuring the safety of milk. An approach to the implementation of Good Dairy Practices in the country is the Integral Program for the Improvement of Production and Milk Quality (PROCAL) [36- 37]. In this sense the producers of fresh artisan cheese need to receive basic food hygiene knowledge, technical skills on behavior of microbial growth and how to minimize and control it costeffectively. Trainings on document and record keeping can help to ensure continuous improvement.

Conclusion

This risk assessment shows that the risk of getting sick is around 46.9 % of Cuban consumers at home for artisan fresh cheese. This result confirms the importance of implementing the Good Manufacturing Practices along the production chain to ensure the safety of artisan fresh cheese.

References

- Shahbandeh M (2020) Global cheese production 2015-2020. Annual cheese production worldwide from 2015 to 2020.

- ACS (2009) American Cheese Society Definition of terms.

- Castañeda GM, Soto M, Chaidez C (2017) Detecting sources of Staphylococcus aureus in one small-scale cheese plant in northwestern Mexico. Journal of Food Safety 37: 1-8.

- Martinez A, Ribot A, Riverón Y, Remón D, Martínez Y, et al (2019) Staphylococcus aureus in the production chain of artisan fresh cheese. Journal of Animal Health 41(1).

- Kousta M, Mataragas M, Skandamis P, Drosinos EH (2010) Prevalence and sources of cheese contamination with pathogens at farm and processing levels. Food Control 21(6): 805-815.

- Fetsch A, Johler S (2018) Staphylococcus aureus as a foodborne pathogen. Curr Clin Microbiol 5: 88-96.

- Hennekinne J A, De Buyser M L & Dragacci S (2012) Staphylococcus aureus and its food poisoning toxins: characterization and outbreak investigation. FEMS Microbiol Rev 36(4): 815-836.

- Fisher E L, Otto M & Cheung G Y C (2018) Basis of virulence in enterotoxin-mediated staphylococcal food poisoning. Front Microbiol 9: 436.

- Kadariya J, SmithT C, & Thapaliya D (2014) Staphylococcus aureus and staphylococcal food-borne disease: an ongoing challenge in public health. BioMed Research International 2014: 1-9.

- Larkin EA, Carman RJ, Krakauer T, Stiles BG (2009) Staphylococcus aureus: The toxic presence of a pathogen extraordinaire. Current Medicinal Chemistry 16(30): 4003-4019.

- Le Loir Y, Baron F, Gautier M (2003) Staphylococcus aureus and food poisoning. Genetics and Molecular Research 2(1): 63-76.

- Presscott LM, Harley JP, Klein DA (2012) Text book of Microbiology. Brown Publishers. (5th edn), 441-442.

- Toubar SME, Elbialy AA, Zaky MMM, El-Shafey AA (2018) Prevalence of Staphylococcus aureus in Raw Milk and Some Dairy Products in Port Said Governorate. American Journal of Zoology 1(2): 40-46.

- Riva A, Borghi E, Cirasola D, Colmegna S, Borgo F, et al (2015) Methicillin-resistant Staphylococcus aureus in raw milk: Prevalence, SCC mec typing, enterotoxin characterization and antimicrobial resistance patterns. Journal of Food Protection 78(6): 1142-1146.

- Martínez A, Montes de Oca N, Villoch A (2016) Comunicación corta. Determinación de indicadores sanitarios en quesos artesanales. Rev Salud Anim 38(1): 64-66.

- Martínez A, Villoch A, Ribot A, Ponce P (2013) Evaluación de la calidad e inocuidad de quesos frescos artesanales de tres regiones de una provincia de Cuba. Rev Salud Anim 35(3): 210-213.

- Martínez A, Montes de Oca N, Armenteros M, Uffo O, Riverón Y, et al. (2020) Identification of bacterial hazards in the production of artisan fresh cheese in Cuba. Journal of Dairy Research 87(2): 263-265.

- Soejima T, Nagao E, Yano Y, Yamagata H, Kagi H, et al (2007) Risk evaluation for staphylococcal food poisoning in processed milk produced with skim milk powder. Int J Food Microbiol 115(1): 29-34.

- Buchanan RL, Smith JL, Long W (2000) Microbial risk assessment: dose-response relations and risk characterization. Int J Food Microbiol 58(3): 159-72.

- Kim HJ, Griffiths MW, Fazil AM, Lammerding AM (2009) Probabilistic risk model for staphylococcal intoxication from pork-based food dishes prepared in food service establishments in Korea. Journal of Food Protection 72(9):1897-1908.

- Lindqvist R, Sylvén S, Vågsholm I (2002) Quantitative microbial risk assessment exemplified by Staphylococcus aureus in unripened cheese made from raw milk. Int J Food Microbiol 78(1–2): 155-170.

- Oh S K, Lee N, Cho YS, Shin D B, Choi S, Koo M (2007) Occurrence of toxigenic Staphylococcus aureus in ready-to-eat food in Korea. J Food Prot 70: 1153-1158.

- EFSA (2017) The European Union summary report on trends and sources of zoonoses, zoonotic agents and food-borne outbreaks in 2016. EFSA J 15: 5077.

- (2016) Meteorology Institute of Cuba.

- Com Base (2016) A combined database for predictive microbiology.

- Swinnen IA, Bernaerts K, Dens EJ , Geeraerd AH, Van Impe JF (2004) Predictive modelling of the microbial lag phase: Areview. International Journal of Food Microbiology 94(2): 137-159.

- Nunez M & Calda E (2017) Preliminary Quantitative Microbial Risk Assessment for Staphylococcus enterotoxins in fresh Minas cheese, a popular food in Brazil. Food Control 73: 524-531.

- James C, Bukola, A, & Stephen J (2017) Refrigerators: A Review The use and Performance of Household. Food Science and Food Safety 16(1): 160-179.

- Karauzum H, Datta S K (2017) Adaptive immunity against Staphylococcus aureus. Curr Top Microbiol Immunol 409: 419-439.

- Lee H, Kim K, Choi KH, Yoon Y (2015) Quantitative microbial risk assessment for Staphylococcus aureus innatural and processed cheese in Korea. Journal of Dairy Science 98: 5931-5945.

- Barker GC, Goméz Tomé N (2013) A risk assessment model for enterotoxigenic Staphylococcus aureus in pasteurized milk: A potential route to source-level inference. Risk Anal 33(2): 249-269.

- Heidinger JC, Winter CK, Cullor JS (2009) Quantitative microbial risk assessment for Staphylococcus aureus and Staphylococcus enteroxon A in raw milk. J Food Prot 72(8): 1641-1653.

- Zeaki N, Johler S, Skandamis PN, Schelin J (2019) The Role of Regulatory Mechanisms and Environmental Parameters in Staphylococcal Food Poisoning and Resulting Challenges to Risk Assessment. Front Microbiol 10: 1307.

- Rosengren A, Lindblad M, Lindqvist R (2013) The effect of undissociated lactic acid on Staphylococcus aureus growth and enterotoxin A production. Int J Food Microbiol 162(2): 159-166.

- Ponce P, Capdevila J, Zaldivar V, Armenteros M, Hernandez R, et al (2004) Comprehensive program for improving the production and quality of milk. Legal Certification of Registration in CENDA. Registry Number 363-2004.

- Oscar TP (2004) A quantitative risk assessment model for Salmonella and whole chickens. International Journal of Food Microbiology 93(2): 231-247.

- INHEM(2016) Institute of Nutrition, Epidemiology and Microbiology, Annual report 100, Cuba.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...