Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4749

Review Article(ISSN: 2637-4749)

An Overview of Special Harvesters for Harvesting Fine-Grain Products Volume 3 - Issue 4

Pourya Bazyar*

- Faculty of Agricultural Engineering and Technology, University of Tehran, Iran

Received: March 20, 2020; Published: March 31, 2020

Corresponding author: Pourya Bazyar, Faculty of Agricultural Engineering and Technology, University of Tehran, Iran

DOI: 10.32474/CDVS.2020.03.000170

Abstract

Fine-grained products are harvested in two manual and mechanized forms. Nowadays, common combine harvesters are used, but fine-grained products such as rapeseed, sesame and sorghum cannot be harvested with conventional heads of combine harvesters due to the excessive loss in the head of the combine harvester. Therefore, the necessity of design an d fabricating machines and heads of combine harvesters became the center of attention to researchers because fine-grain products have lots of nutritional and medicinal benefits. In this research, we are going to have an overview of the special headers and machines for harvesting fine-grain products.

Keywords: Machine, head of combine harvester, harvesting, fine-grained products

Introduction

The effort to achieve agricultural development depends on

concentration on mechanization. Fine-grained products such as

sesame, sorghum, and canola have been hand-picked in the past,

while nowadays the use of special machines and heads of combine

harvesters makes it easy to harvest them. To begin with, let’s take

a look at the physical and mechanical properties of these products.

Rapeseed (Brassica napus L.), also known as rape, oilseed rape,

rapa, rapeseed, and canola, is a bright yellow flowering member of

the Brassicaceae family (mustard or cabbage family). Rapeseed is

widely cultivated throughout the world for the production of animal

feed, vegetable fat for human consumption, and biodiesel. Leading

producers include the European Union, Canada, the United States,

Australia, China and India [1]. World production is growing rapidly,

As FAO reports say 48.97 million tons of rapeseed was produced [2].

Rapeseed grains are fine and round and the weight of one thousand

seeds is 3.5 to 7gram. Canola pigments are brown to black. Some

physical properties of rapeseed seed were measured and analyzed

(based on wet) by Calisir et al. At three levels of the moisture content

of 4.7, 14.13 and 23.96 percent [3]. Physical properties of rapeseed

oilseeds are essential for the design of the required devices or for

determining their motor behavior for displacement [4]. Sorghum

(Sorghum bicolor L. Moench) is an important crop species in the

United States and around the world. Because of its substantial heat

and drought tolerance, sorghum production is traditional in semiarid,

subtropical and tropical regions. In addition to abiotic stress

tolerance, sorghum is very responsive (in terms of productivity) to

more favorable conditions.

While primarily known as a cereal grain, sorghum is grown

throughout the world as a forage, syrup and more recently, energy

crop. In 2008, U.S. farmers harvested about 2.9 million hectares

of grain sorghum [5]. The sesame is thermophilic and basically,

a particular product for tropical and subtropical regions and is

sensitive to low temperatures, but by implementing a breeding

program, it is possible to extend its cultivation to temperate regions.

Sesame seed is from 40 degrees north latitude to 40 degrees south

latitude, it is usually cultivated at the height of 1200 meters above

sea level. This plant needs warm weather and an abundant amount

of light and shows sensitivity to low temperatures [6]. Sesame is

harvested when the seeds are ripe in the lower capsule. Capsules

usually come up from the bottom of the stem, and the left loss

begins, and while the capsules are still green, they must be removed

before they dry [7].

Sesame is a strategic product with high nutritional and medical

value, that the daily increase in the number of the lands under

cultivation due to sesames high consumption in the world and to

make some reductions in harmful effects of spraying to increase plant resistance to seed loss are the reasons which necessitate the

mechanized harvesting of this product [8]. As the cultivation area of

this product is increasing in the world, there are many industrial and

pharmaceutical properties for sesame. Nowadays, the consumption

of sesame oil in the world is increasing, but because of the high head

of combine loss in common combines, it is often taken manually in

some countries, which is, costly and time-consuming and in some

other countries it is carried out by combine harvesters which is a

special head of combine harvester for fine-grained products, In this

case, the losses rate is too high [9]. According to the research on the

physical and mechanical properties of some fine-grained products

and the need for the use of special heads of combine harvesters

and machines for their harvesting. In this research, the activities

carried out in the field of construction and design of these hedges

and harvest machines have been studied.

Sesame harvesters

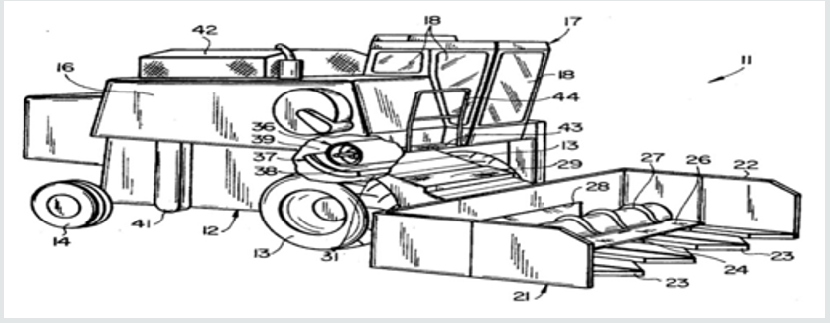

a. In 1981, Taylor et al. from the United States invented a special head of combine for harvesting sesame. This head of the combine harvester is used to harvest sesame seeds existing in plant’s capsules. The frame of this head of combine harvesting consists of two parts with a cylindrical structure and a concave structure. The cylinder structure has a rotary motion and a concave structure in a fixed position mounted on the frame. This head has an inlet area, outlet area, and separation area. The sesame plant enters by the feeder between the cylindrical and concave structures of the entrance area. Then the separator zone separates seeds from the pods, and the stems, straw, and the remaining straw are driven to the outlet area by the walker. The head of combine harvester designed for harvesting sesame seeds (Figure 1) by Taylor [10], which is used to harvest sesame seeds contained in the plant’s capsules. In this head of the combine harvester due to the flatness of the fingers, the seeds are spilled on the ground and there is no the system for transferring the collected seeds Due to the short height sides of the separators, the losing probability is high. Its advantages are also extremely low cutting force while cutting the product and connecting it to a combine harvester for harvesting sesame on large lands and high maneuverability [10].

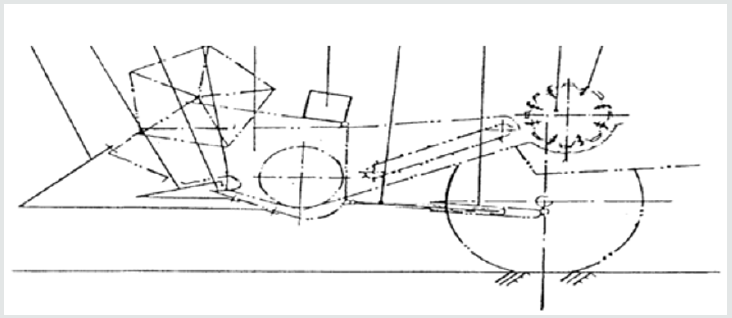

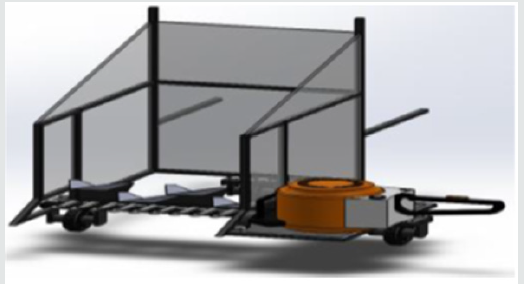

b. In 2015, Zhang Dawi [11] invented a large-scale sesame the harvesting machine. This harvesting machine includes a reaper at the front, and the reaper section passes through conveyors and connects to the Threshing Unit of the machine. The bottom of the threshing unit also passes through the product entry into the reaper and connects by the feeder. The cutting unit has a frame equipped with a back and forth blades in its front bottom. In the upper part of the cutting section, there is also a reel. The sloping conveyors are also connected to the threshing unit, on the other side, it is connected to the center of the back of the cutter section and is equipped with at least one helix for transferring the product, which completely separates the seeds of sesame in the threshing unit. This harvesting machine provides the advantage of creating the conditions for large-scale sesame harvesting with a simple structure and logical design. The sesame Harvesting Machine designed by Zhang Dawi for a large scale (Figure 2), has the advantages of having a complete system from harvesting to seed separation and utilization for harvesting sesame in large farms. Its disadvantage is the fact that the reel is not tall enough, while the sesame’s height is sometimes about two meters and also it lacks a system for collecting lost seeds in the part of the head of combine harvester [11].

In 2019, Bazyar [12] invented small-scale head of combine harvester for harvesting fine-grain products especially for sesame. The design of the machine was based on the reduction of grain loss. It should be noted that this machine needs manpower to move and advance. The main parts of the machine include the collection tank, product cutting unit, separator unit with high elevation and nylon coverage, the stair frame system. The bowls with the overlap between them first make the stem of the cereal crop pass through these fingers. The stem is then bent and directed to the incision of the head. The presence of long dividers in the head with highheight nylon cover eliminates the possibility of any grain shedding from the head. Any spillage is also poured into the bowl. Due to the sloping design of these fingers, the grains inside the bowl are directed to the grain collection reservoir. The result of this research demonstrates that its head loss is about 16% (less than the head loss of ordinary headers). However, this was constructed with the least cost [12].

Canola Harvesters

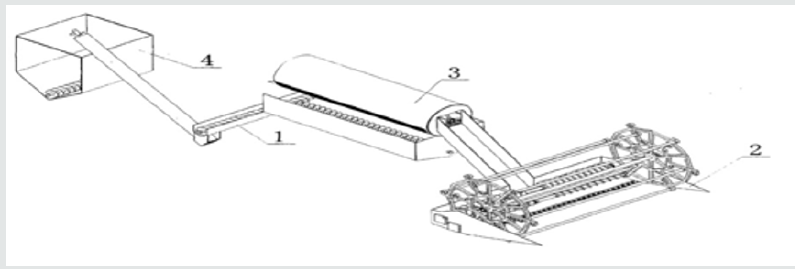

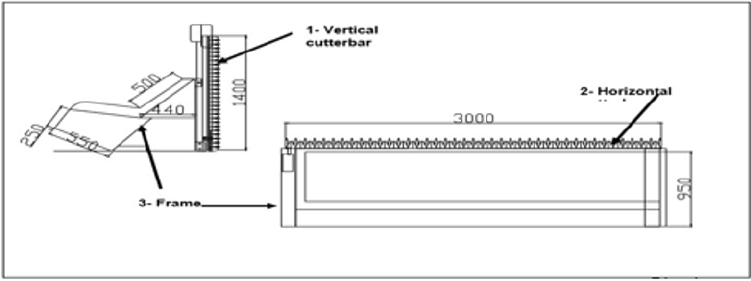

In 2008, Sharobeem from Egypt invented the first head of a combine for harvesting Canola oil plant which was made at Abokeer Company and evaluated on Nobaria farms. The work of the head of combine begins after the canola plant is ripe, the combined harvester pulleys cut the rapeseed stems before they touch the plants. The designed head of combine harvester mainly consists of three parts: a frame, two cutting sections (horizontal and vertical) and a power transmission system. A cutting mechanism that includes two cutting sections (horizontal and vertical) is used. The horizontal cut includes forty fixed knives (76.2 mm) and forty movable knives, eight knife holder that is fixed in the cutter holder. The speed of 1.5 m / s moves with a 76.2 mm knife. Horizontal cutting is attached to a special frame. The vertical shearing strip has two strips, each of them has twenty-eight knives (50 mm) as a double knife. Vertical cutting is designed based on a 12 V electric motor. This head of a combine harvester is perfectly suitable for harvesting this plant and significantly reduces the amount of canola loss in the head of the combine harvester. The first head of combine harvester designed for harvesting the canola oil seed by Sharobeem (Figure 3) has a cutting mechanism that consists of two cutting sections (horizontal and vertical) and a variablespeed system which is used for power transfer. Due to the high compression of rapeseed plants, and also the plant’s tallness, which causes the decumbency and intertwinement of them, the chance of grain loss during cutting is high because the friction between the plants is high. Therefore, using this mechanism reduces the loss of canola seed but increases its power consumption. Also, by using a variable-speed system for the cutting unit which fits the product’s feed power the cutting speed can be changed [13].

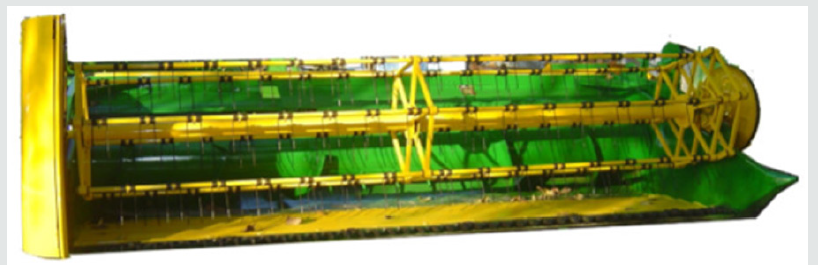

In 2013, Tabatabaekoloor [14] has evaluated a special head of combine harvester for harvesting rapeseed mounted on a grain’s combine. In this research, a canola head model RH-3600 attached to front a John Dear 1055 combines and evaluated in the field. The results showed that the combine farm capacity with a mean working width of 335 cm and a forward speed of 3.7 km/hr was 0.88 ha/hr and its field efficiency was 80%. The mortality rate of grain loss from head parts including a carousel and horizontal shoulder blades to an average of 0.18%. The special head of combine harvester designed for harvesting canola has been evaluated by Tabatabaekoloor mounted on grain’s combine. In this study, an Rh-3600 that is special head of combine harvester for harvesting rape (Figure 4) installed on the John deer 1055 combine with a high capacity of large lands, high efficiency, and maneuverability. The cutting unit of this head of a combine harvester, likewise the head designed by the Sharobeem, has two cutting sections (vertical and horizontal), which reduces the grain loss [14].

Sorghum Harvesters

In 1990, Zhang Min [15] invented to combine harvester for sorghum. The utility model has a technological improvement of grain combine harvesters, and the components are added to the combine to improve grain combine harvesters including an ejector pin, a divider, an extruder, and an ear blocking device. Threshing spike-teeth are fixed on the bottom of a web notch of a threshing cylinder by a connector, and a grain harvester is refitted to a combine harvester for picking sorghum. The utility model is adapted to various self-propelled and pull-type grain combine harvesters, has a simple structure, and convenient manufacture and installation, and is ideal harvesting machinery for reaping sorghum. The combine harvester to reap sorghum was invented by Zhang Min (Figure 5), has some advantages and disadvantages. Some advantages are an adaptation to various self-propelled and pull-type grain combines, simple structure and convenient manufacture and installation, easy operation, low cost, less failure, however it has some disadvantages such as high power consumption, lack of lost seed collecting system, short height separator and high possibility of throwing grains [15].

In 2008, Ghahraei [16] in Iran, invented a special head of combine for harvesting sorghum. The developed cutting mechanism in this research has a rotary disk with 50 cm diameter and four cutting blades that spin clockwise. The stalks are cut with impact and inertia forces at the linear velocity of 27 m/s, by cutting blades. This system has a simple bar mechanism guiding the wholestalk to one side. The cutting quality tests were achieved by two series of blades with 30° and 45° blade angles on the stalk. As the results showed the stalk cutting surface with a 30° blade angle was smooth, with no fracture. A head of combine harvester designed for harvesting sorghum (Figure 6) by Ghahraei whose cutting unit has a rotary disk and four cutter blades in the clockwise direction that cut the plant with impact and inertia by cutting blades. This head of a combine harvester has a system with a simple mechanism that directs all the stems to one side. Its advantages are simply the mechanism for cutting the product and cutting the product with a smooth cross-section and its disadvantage is the lack of a system for collecting lost grains in the state of vibration when cutting the plant stem [16] (Figure 7).

This research was designed to facilitate researchers’ access to study on special heads of combine harvesters and harvesting machines for fine-grained products and to get their advantages and disadvantages. In this part of the research each research to have detailed-knowledge about special harvesters for harvesting fine-grain products. Moreover, all of the designs are evaluated by considering their merits and demerits.

Result and Discussions

Due to the mentioned researches on special harvesters for

harvesting fine-grain products, the mentioned devices have been

analyzed from several points such as the rate of grain loss, collected

grain transfer mechanism, power consumption, maneuverability,

and farm capacity. Although each of fine-grain products has different

physical and mechanical properties, Most of these products have

a high head loss so there should be a mechanism for reducing it.

In the head, which was designed by Taylor [10], was used as a

mechanism to prevent the sesame seeds from falling on the ground.

In the other research, Bazyar [12] designed bowl fingers with

overlap and stair chassis to plunge the amount of head loss. This

research was constructed for harvesting but it revealed successful

results in harvesting canola. Therefore, in a special head made by

Sharobeem, as well as the head of combine harvester designed by

Tabatabaekoloor for rapeseed operates two cutting (vertical and

horizontal), and reduces the friction between the plants so the grain

loss reduces, but this head is specific to rapeseed and is not suitable

for other fine-grained grains. Considering the power consumption

of the head of combine harvester designed by Sharobeem and

the head of combine harvester made by Tabatabaekoloor due to

the usage of an additional vertical section and a head of combine

harvester designed by Bazyar due to the usage of a suction system

for transferring grain, they have the highest power consumption.

In terms of farm capacity and maneuvering ability, all of the

proposed projects have high maneuverability and farm capacity

because of the connection to the combine harvester. Considering

the results mentioned above, for harvesting rapeseed the head

designed by Sharobeem is suitable because of the use of a specific

mechanism for cutting rapeseed stems and it has high farm capacity

for this plant. The combine for reaping sorghum invented by Zhang

Min is specially used for sorghum and its disadvantages are greater

than its benefits, also it is not appropriate for harvesting finegrained

grains due to the lack of lost grained collecting system.

For other fine-grain, the use of a harvesting machine designed

by Zhang Dawi is the most suitable option because it has a complete

system from harvesting to separating the seed from pod, and it does

not need to be connected to the combine harvester. In this research,

all of the designs are weighed to choose the best harvester for

harvesting fine-grain products [17]. These designs are evaluated

by some parameters for example Energy consumption, Easy to maintain, Weight of the machine, Authenticity low number of

pieces, Cost of production, Convenience of shipping, Failure to lose

to either side, Transfer grain to a reservoir. In Table 1, inventions

(Taylor, Dawi, Bazyar, Sharobeem, Tabatabaekoloor, Min, Gahraei)

are named (A, B, C, D, E, F, G) respectively [18,19].

References

- Izli N, Unal H, Sincik M (2009) Physical and mechanical properties of rapeseed at different moisture content. International Agrophysics 23(2): 137-145.

- FAO (2006) Production, yield, harvested area values of rapeseed. Available from FAOSTAT (October 2008).

- Calisir S, Marakoglu T, Ogut H, Ozturk O (2005) Physical Properties of Rapeseed. Journal of Food Engineering 69: 61-66.

- Sahay KM, Singh KK (1994) Unit Operations in agricultural processing. Vikas, New Delhi, India.

- Rooney WL (2014) Sorghum. Cellulosic energy cropping systems. pp. 109-112.

- Najeeb U, Mirza MY, Jilani G, Mubashir AK, Zhou WJ (2012) Sesame. In Technological Innovations in Major World Oil Crops. Springer, New York, USA, 1: 131-145.

- Ishpekov S, Petrov P, Triffonov A, Dimitrov I., Mihaylova Z, et al.(2014) Investigation the Indices for Mechanized Picking Sesame Capsules. Bulgarian Journal of Agricultural Science, 18, 628-633.

- Grichar WJ, Rose JJ, Dotray PA, Baughman TA, Langham D, et al. (2018) A response of Sesame to Selected Herbicides Applied Early in the Growing Season. International Journal of Agronomy p. 11.

- Langham DR, Riney J, Smith G, Wiemers T (2008) Sesame harvest guide. American Sesame Growers Association.

- Taylor CL, Taylor Clyde L (1981) Sesame seed harvester. U.S. Patent 4: 266-393.

- Zhang D (2015) Large-scale harvester is used to sesame (patent). Application number: CN204860092U. p.1-2.

- Bazyar P, Jafari A, Alimardani R, Mohammadi V (2019) Small-scale head of combine for harvesting sesame. Agriculture Engineering 22(4): 02.

- Sharobeem YF (2008) Development of a Special Combine header for harvesting Canola, it is written for presentation at the 2008 ASABE Annual International Meeting Sponsored by ASABE Rhode Island Convention Center Providence, Rhode Island, pp. 083460.

- Tabatabaekoloor R (2013) Filed evaluation of canola special harvesting head used on cereal combine. The Eighth National Congress of Agricultural Machinery Engineering (Biosystem) and Mechanization, Ferdowsi University of Mashhad, Iran.

- Zhang Min (1990) Combine for reaping sorghum. Application number: CN2056807U. p.1-2.

- Ghahraei O, Khoshtaghaza MH, Desabin A (2008) Design and development of special cutting system for sweet sorghum harvester. Journal of Central European Agriculture 9(3): 469-474.

- Amir Fazli A (2001) Design methods in engineering. Publication of Sharif university. (First edn), Iran, p. 25-30.

- Gharibzahedi SMT, Mousavi SM, Razavi SH (2009) Evaluation of Physical, Mechanical and Nutritional Properties of Sesame Seed (Sesamum Indicum L.)in Different Moisture Contents for the Optimization of the Processing Operation, Electronic Journal of Food Processing and Maintenance.

- Izadinia Y, Asudar MA, Shafeinia AS (2005) Evaluation of rapeseed mortality in direct harvesting by three types of combine platforms. National Conference on Agricultural Waste Disposa p. 51-59.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...