Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2643-6744

Mini ReviewOpen Access

Green SCM in Indian Automobile Industry Volume 2 - Issue 2

Subhash Desai* and AV Nirmal

- Sabarmati University, Greenwood Resort, Near Vaishnodevi Circle, India

Received: January 11, 2022; Published: February 14, 2022

*Corresponding author:Subhash Desai, Sabarmati University, Greenwood Resort, Near Vaishnodevi Circle, India

DOI: 10.32474/CTCSA.2022.02.000135

Abstract

Unsustainable patterns of production and consumption particularly in industrial countries are identified as the major causes of the continued deterioration of the global environment. The automotive industry is one of the main producers of industrial wastes affecting the natural environment. Automotive companies are in a difficult position to implement green supply chain management (GSCM). The number one barrier in the automotive sector is “market competition and uncertainty”. The second problem is “Lack of Implementing Green Practices”. Like these two barriers, cost implications, unawareness of customers, lack of corporate social responsibility, lack of globalization, lack of technical assistance from government have been identified as top-level barriers and lack of the government’s willingness to invest, reduced involvement in environmentally related conferences are recognized as most important bottom level barriers. The elimination of these barriers will help to apply the GSCM in the Indian automobile industry. A major unresolved issue is the probable onset of rapid global warming caused by increased levels of greenhouse gases in the atmosphere. Whether the warming of the earth is cause by human activity, agricultural practices or cause by natural fluctuations in solar activity is a matter of scientific debate.

Introduction

Production organizations often upgrade their supply chain processes to green supply chain system for various operational synergies, but they certainly fail to implement such advanced systems because of barriers that are accountable for internal and external environments. Considering this, the study analyzes the automobile industry in India, both to explore the barriers of green supply chain and to classify them. The identified relationship between these barriers may help organizations overcome them in order to implement an effective and efficient green supply chain management (GSCM) system.

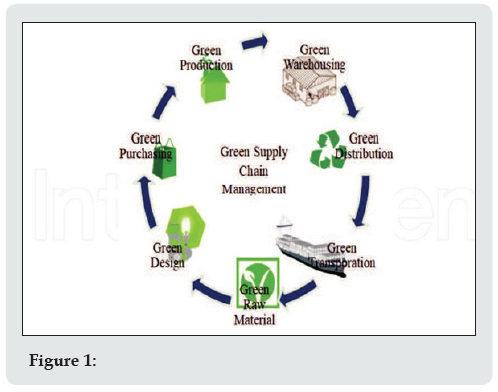

Recent literature focuses on supply chain management concerned with environmental issues through the emerging concept of green supply chain management (GSCM). The green supply chain means to eliminate or minimize waste of resources (energy and materials) and negative environmental impacts (air, water, and land pollution) through all phases of a product‘s life cycle from the extraction of raw materials up to the use of the product by consumers and its disposal at the end of the product‘s life cycle. GSCM has three approaches: environment, strategy and logistics. GSCM is a companywide harmonized effort and ensures that environmental performance is consistently developed at all management levels and on the floor of the workshop, rather than just taking the place of some green applications. The green supply chain as a managerial approach aimed at minimizing the environmental and social impacts of a product or service or footprint (Figure 1).

Figure 1: Centralized model: PKI-CA. User verifies there is a valid path of trust from a prespecified trust anchor to the destination they want to reach.

Increasing pressures and challenges to improve economic and environmental performance have caused developing countries in general and automobile manufacturing firms in particular to consider and start implementing green supply chain management. It is emerging as an important approach which not only reduces environmental issues but also brings economic benefit to manufacturers. Recently, there are intensive studies on the issues, which have been dealt with extensively by practitioners and academicians. However, studies on performance evaluations are few. In responses this study explores the criteria that influence the performance of the automobile manufacturing industry, using the fuzzy set theory and Decision Making Trial and Evaluation Laboratory. The hybrid method evaluates its performance to find key criteria in improving the manufacturers’ green performance. Findings show that the increase of cost for purchasing environmentally friendly material is the most influential and significant criterion, while the pollution control initiatives is the most effective criterion. Managerial implications are also discussed and concluding remarks are made.

Organizations of the present day have directed their work patterns by acquiring the approach of green supply chain management (GSCM), in order to combat harmful environmental concerns. The most prominent reason behind the adoption of green strategy is to reduce the burden of the polluted environment. It is a concept which identifies the relationship between the supply chain operations and the natural environment. It is revealed that most of the international markets prioritize the emission of gas, rather than focusing on implementing the green technologies in transportation. Slow steaming, voyage optimization, and efficiency in port operations are some of the major recent trends of green transportation identified in green supply chain management.

Green supply chain management has emerged as a proactive approach for improving environmental performance of processes and products in accordance with the requirements of environmental regulations. Various approaches for implementing green supply chain management practices has been proposed and recognized in previous literatures, yet no investigation has identified the reliability and validity of such approaches particularly in electronic industry. The fuzzy analytic hierarchy process method is applied to prioritize the relative importance of four dimensions and twenty approaches among nine enterprises in electronic industry. The findings indicate that these enterprises would emphasize on supplier management performance in the crucial role of implementing green supply chain management. Establishing an environmental database of products, asking for product testing report and top management support are among the most important approaches.

Relevant Review

The importance of environmental cooperation in the supply chain is increasing. The different literature has focused on analyzing green practices in different sectors. [1] Reviewed Taiwan’s motorcycle industries. Similarly, Mavani, P., & Pandya, A. R. analyzed the pharmaceutical supply chain in Gujarat in India. Chien and Shih [2] conducted an empirical study on the application of GSCM practices in the Taiwanese electrical and electronics industries. Chan et al. [6] observed risks related to the implementation of GSCM in the fashion industry. Indian researchers and practitioners analyzed GSCM because of pressure, pressure, barriers, drivers and performance from consumers and environmental regulations. An important part of the literature review deals with the manufacturing sector. However, there were some cases where the service sector or other sectors were analyzed as well.

Firm’s capacity constraints are a major obstacle to the implementation of the GSCM. The biggest challenge is facing small medium enterprises (SMEs) in significant upfront cost of green space. They have emphasized that managers of firms are unaware of existing advanced technologies and therefore are not in a position to adopt green practices. SMEs are faced with more difficulties during the adoption of GSCM than larger firms. The GSCM needs substantial funding to support infrastructure and human resource needs. The benefits of GSCM are not only practical in the long run. Therefore, SMEs do not have to make extra effort to adopt green practices. Several companies are eager to be more aware of common external environmental problems.

External factors include customer and market pressures. Government intervention is also an important factor in SMEs to adopt green practices. Sheu and Chen [2] analyzed the effects of government fiscal interventions on the adoption of GSCM. The government may also motivate a firm by providing technical assistance and incomplete information on green practices. The study also suggested that the size of the firms played an important role in determining the barriers to the implementation of the GSCM.

Standardization of industry processes is another important factor affecting SMEs’ decision to implement GSCM. Mudgal [3] analyzed the barriers to implement GSCM in the Indian automotive industry. Using Delphi technique, they found that reducing environmental hazards is a strong motivation for a firm to adopt GSCM. Moreover, their research supported the role of market image in the implementation of GSCM, while the findings of their research did not support the role of the government in motivating an industry to adopt GSCM. The automotive industry is the main industry in India with a support chain. More than 10% of the total work force is employed within this industry. Stakeholders and regulatory agencies are putting pressure on automotive industries to ensure sustainability due to increased concern about environmental pollution. Consequently, India is placing emphasis on the economic development and at the same time, it is trying to emphasize on environmental and social protection [4-13]. These forces created a balance of on the economic, environmental and social performance of companies. For this reason, green initiatives and policies should be developed for any company to overcome these challenges and ensure sustainability. Developing country like India is still seen as a major problem due to several barriers. It is imperative that managers must understand these barriers and try to minimize them and increase their competitive power. The second problem identified by the respondents is lack of implementing green practices. In order to overcome this obstacle, the Indian government may report some additional benefits to organizations that follow green practices. The application of government policies to green practices will generate greater governance. IT activation will reduce many paper jobs that will further reduce the need to cut trees. Support from top management is required. The activation of IT will also help in the fast and effective communication between the members of the supply chain to the authorized GSCM.

The third problem identified is cost implication. It is the government’s responsibility to reduce the costs of the disposal of hazardous solid waste, reuse and recycling of used materials. Also, government can reduce the cost by motivating the firms to introduce innovative green practices, encourage innovative design and initiate new market opportunities.

Conclusion

Fourteen barriers have been found in the implementation of GSCM in the Indian automobile industry. The ISM methodology has been applied for finding and developing the model. These barriers are:

a) Strong dependence power.

b) Commitment from top management.

c) Adoption of reverse logistics practices.

d) Strategic planning.

e) Integrated information system.

f) Environmental performance.

g) Support and guidance from regulatory authorities.

h) Linkage barriers.

i) Training and skill development programs.

j) Level of supply chain integration.

k) Resistance to change.

l) Adoption of innovation.

m) Eco literacy among supply chain partners.

n) Market demand (green product), financial constraints and global financial crises are the foot level barriers.

Elimination of these barriers will improve the performance of GSCM in the Indian automobile industry.

The model developed presents the interrelationship between the various barriers. There is no availability of sufficient data, particularly related to barriers and their effects on the automobile industry. Adoption is a limitation for the validation of the model. The model is used here as a primary tool and is based on the judgment of experts, but such models can also be developed using quantitative techniques such as structural equation modeling (SEM) or the linear structural relationship approach. The present model enhances the existing knowledge of GSCM. This model will provide the scope of identifying the relationship between the barriers for the implementation of GSCM. The same methods can also be applied in other important supply chains, such as, the process industry or the service industry. In conclusion, it can be suggested that regular training programs can be implemented to raise awareness of green practices that will help institutions to adopt and encourage. Likewise, the commitment of top management is required to encourage the implementation of current technological developments in green practices. The government should take the initiative to raise awareness about organic products and how they can help them. Special advertising campaigns and welfare programs can be carried out to increase the level of knowledge of the clients. Organizations can advertise green products to create awareness among customers. It is proposed a generic hierarchy model for assessing the relative importance of identified approaches that would affect the GSCM implementation and the development of GSCM strategy and practice. Different organizations can make use of the model in accordance with their specific situations and needs. In addition, the model also can help managers improve their understanding of GSCM practices and enables decision makers to assess the perception of GSCM in their organization. It is hoped that this proposed model can serve as a base for further research on exploring the implications of GSCM for different industry sectors and regions. The approaches for implementing GSCM in electronics industry should be transformed to accompany changes of environmental regulations and customers in future research. In addition, it is also worth mentioning that supplier management plays the crucial part of implementing GSCM, the buyer supplier relationships affect GSCM implementation to address the related issues. Furthermore, the application of analytical tool in determining weights for various approaches of GSCM practice is suggested to utilize analytic network process (ANP) in terms of feedback systematic and interdependencies property.

References

- Kuo T C, Hsu C W, Ku K C, Chen P S, Lin C H, et al. (2012) A collaborative model for controlling the green supply network in the motorcycle industry. Advanced Engineering Informatics 26(4): 941-

- Chien M K, Shih L H (2007) An empirical study of the implementation of green supply chain management practices in the electrical and electronic industry and their relation to organizational International Journal of Environmental Science and Technology 4(3): 383-394.

- Mudgal R K, Shankar R, Talib P, Raj T (2010) Modeling the barriers of green supply chain practices:an Indian International Journal of Logistics Systems and Management, 7(1): 81-107.

- Walker H, Sisto LD, McBain D (2008) Drivers and barriers to environmental supply chain management practices: Lessons from the public and private J Purch Supply Manag 14: 69–85.

- Abdallah T, Farhat A, Diabat A, Kennedy S (2012) Green supply chains with carbon trading and environmental sourcing: Formulation and life cycle Appl Math Model 36(9):4271–4285

- Davies J, Hochman (2007) The greening of the supply chain. Supply Chain Management Review 11(5): 13-14.

- Chan H K, Hongwei He, Wang W Y (2012) Green marketing and its impact on supply chain management in industrial markets, Industrial Marketing 41(4): 557-562.

- Diabat A, Govindan K (2011) An analysis of the drivers affecting the implementation of green supply chain Resources, Conservation and Recycling, 55(6): 659- 667.

- Testa F, Iraldo F (2010) Shadows and lights of GSCM (Green Supply Chain Management): determinants and effects of these practices based on a multi-national Journal of Cleaner Production, 18(10-11): 953-962.

- Sarkis J (1998) Evaluating environmentally conscious business European journal of operational research, 107(1): 159-174.

- Hervani A A, Helms M M, Sarkis J (2005) Performance measurement for green supply chain management. Benchmarking: An international journal, 12(4): 330-353.

- Lee S Y (2008) Drivers for the participation of small and medium- sized suppliers in green supply chain Supply Chain Management: An International Journal 13(3): 185-198.

- Vachon S, Klassen R D (2008) Environmental management and manufacturing performance: The role of collaboration in the supply International journal of production economics, 111(2): 299- 315.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...