Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4609

Research Article(ISSN: 2637-4609)

Dyed Silicone Pressure-Sensitive Adhesives Volume 4 - Issue 3

Adrian Krzysztof Antosik1* and Nataniel Adrian Antosik2

- 1Institute of Organic Chemical Technology, West Pomeranian University of Technology Szczecin, Poland

- 2IT Institute, West Pomeranian University of Technology Szczecin, Poland

Received: September 26, 2019; Published: October 10, 2019

*Corresponding author: Adrian Krzysztof Antosik, Institute of Organic Chemical Technology, West Pomeranian University of Technology Szczecin, Poland

DOI: 10.32474/AOICS.2019.04.000186

Abstract

The paper presents the results of research on the impact of the amount of dye on selected commercially silicone pressuresensitive adhesives. The effect of dye addition of 0.5-3.0% wt. on useful properties of adhesives was investigated. Increasing the dye concentration caused a decrease in cohesion, stickiness and adhesion, and an increase in viscosity over time. Investigating the effect of the dye was caused by frequent requirements in industry, where it is required to improve the visibility of joints. It is used, for example, for bonding adhesive materials with low surface energy.

Keywords: Silicone pressure-sensitive adhesives; Dye; Adhesion; Cohesion

Introduction

In comparison with non-cross-linked pressure-sensitive adhesives (PSA), cross-linked adhesives have greater cohesion while reducing adhesion and tack (tack). Physico-mechanical and mechanical properties such as stickiness, cohesion and adhesion of PSA depend largely on the type and concentration of the crosslinking compound used [1-3].

PSAs are used to bond hard-to-stick materials such as glass, plastic, wood, metal, paper or leather. They are characterized by excellent resistance to aging, both at room and elevated temperature, and a constant level of peeling and sticking forces (adhesion). PSAs show excellent resistance to the damaging effects of oxygen, moisture and light. They have found use in industry as removable labels, self-adhesive office cards, tapes and dressings used in medicine, protective films, masking tapes and decorative films [4-8].

Silicones PSA (Si-PSA) are characterized by chemical inertness and weather resistance. They show excellent adhesion to adhesive materials with low surface energy and good mechanical properties at elevated temperatures. They have found application in the production of specialized adhesive tapes. Si-PSA has excellent ion barrier properties. They are characterized by low glass transition temperature, high flexibility (through connections Si–O–Si in backbone), excellent elasticity properties and impermeable to water, low intermolecular interactions, low surface tension, excellent thermal stability and high UV transparency. Si-PSAs have great application potential in the aviation, medicine and electrical industries. Excellent properties mean that they are often used in cases where due to environmental conditions (e.g. high temperature amplitude, humidity, sunlight) where tapes based on carbon polymers are not sufficient [9-12].

In this paper influence of addition dye on self-adhesives properties of commercial silicone adhesives were presented. To compared impact on silicone pressure-sensitive adhesives two different commercial dye was chosen. Due to the frequent use of Si-PSA-based tapes in medicine, the requirement is staining (improving visibility), which makes research into the effect of colouring additives used compositions a necessary requirement.

Materials and Methods

To measurement influence dye on self-adhesives properties of Si-PSA comercial silicone adhesive was used (acronym: 280 A), which was product of Dow Corning (USA). Dichlorobenzoyl peroxide (DClBPO) was used as a crosslinking agent (product of Peroxid-Chemie, Germany). Luconyl green 9360 and TC - Green 8730 products of BASF (Germany) was used as a green dye.

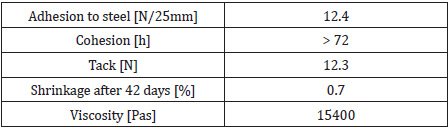

The selected adhesive composition exhibiting very good performance properties containing 1% wt. DClBPO (Table 1) [9] was added depending on the composition 0.5, 1, 1.5, 2, 2.5 and 3% wt. dye and then mixed to obtain a homogeneous consistency. Subsequently, composition was coated with coat speed of 5cm/s on polyester film and dried for 10min at 110 °C in drying canal. Thus, obtained adhesive film was protected with fluoro-siliconized film. That prepared self-adhesives tapes were used for further tests, i.e. adhesion, tack and cohesion measured. Based properties of silicone pressure-sensitive adhesives as peel cohesion, adhesion, and tack was measured by using machine designed at the Laboratory for Adhesives and Self-Adhesive Materials of the West Pomeranian University of Technology Szczecin and Zwick-Roell Z1 machine (Germany) according to international standard Federation Internationale des Fabricants et Transformateurs dadhesifs et thermocollants sur papiers et autres support (FINAT) respectively FTM 8, FTM 1 and FTM 9.

Viscosity of silicone pressures-sensitive adhesives composition was determined with a RM 180 rotational viscometer from Rheometric Scientific, with spindle No 3 at temperature room. Noncrosslinked adhesive compositions were tested at an interval 90 days from receipt of the composition. The value of shrinkage was measured using the cross-method according to BASF standards. The PVC or PET foil was coated with a Si-PSA layer and cross-linked. Then it was applicated on a degreased metal plate and two cuts were made at the right angle. The width of the cuts was measured. The second measurement was made after storage of the plate for 8 weeks at 70 °C. The shrinkage is the percentage value of the ratio of width of the cuts. Shrinkage greater than 0.5 % is not allowed.

Results and Discussion

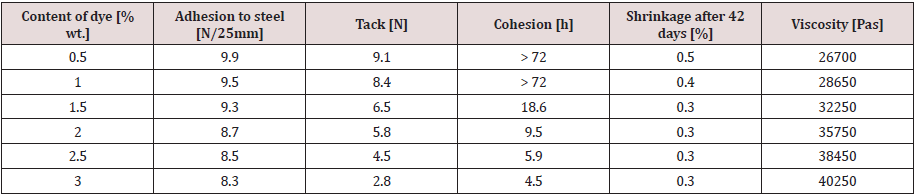

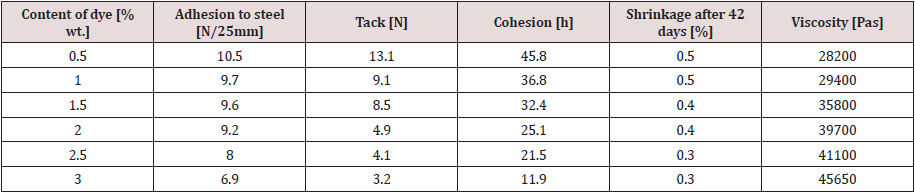

The results of the effluent tests for addition Luconyl green 9360 and TC - Green 8730 are collected in Tables 2 & 3. For all tested dye concentrations in pressure-sensitive adhesive 280A crosslinked DClBPO with a concentration of 1% wt. an increase in viscosity was noted during storage of the adhesive. The adhesive’s viscosity increased with increasing dye concentration. The highest viscosity was obtained by the adhesive containing 3% wt. dye. Along with the increase in the dye content in the adhesive, the adhesion of the tested adhesive samples to the steel substrate deteriorated (testing on a steel plate) as opposed to the adhesion on silicone paper, which improved with increasing dye concentration. The addition of dye adversely affected the cohesion of pressure-sensitive adhesives. This effect was particularly visible when the dye content exceeded 1% wt. for Luconyl green 9360, for TC - Green 8730 0.5 % wt. greatly reduces cohesion. Increasing the dye content causes thermal stabilization of the crosslinked adhesive film. This effect can be observed by reducing shrinkage as the amount of dye in the adhesive increases.

Conclusion

Dyes change color silicone pressure-sensitive adhesives composition relatively easily, already small amounts (0.5% wt.) allow you to get a visible effect. The colored Si-PSA adhesive tapes have been obtained. Generally, with the addition of dye to the composition, the adhesion, tack and cohesion values of the adhesive compositions slowly decrease. In addition, the viscosity of the composition increases after 90 days, which is an undesirable effect that prevents the storage of ready-to-coat compositions, no dye sedimentation has been observed. The thermal stability of the powder is improved at elevated temperature, which can be seen after the shrinkage decreases with the amount of dye added. Best balance between basic properties of adhesives and property color exhibit composition with 1.0% wt. Luconyl green 9360 and 0.5% wt. TC - Green 8730. It is generally accepted that one-sided adhesive tape must meet the basic properties (adhesion >10N/25mm; tack >8 N/25mm; cohesion >72 hours) [12] therefore, it is generally accepted in the industry to use as little dye as possible.

References

- Zosel A (1998) The effect of fibrillation on the tack of pressure sensitive adhesives. International Journal of Adhesion and Adhesives 18: 265-271.

- Czech Z (2002) Sieciowanie samoprzylepnych poliakrylanowych wodnych klejów dyspersyjnych. Polimery 47: 234-241.

- Czech Z, Butwin A (2009) Poliakrylanowe kleje samoprzylepne sieciowane dualnie. Wiadomości Chemiczne 63: 269-284.

- Czech Z (2003) Crosslinking of pressure sensitive adhesives on water-born acrylate. Polymer International 52(3): 347-357.

- Tolia G, Li SK (2012) Study of drug release and tablet characteristics of silicone adhesive matrix tablets. European Journal of Pharmaceutics and Biopharmaceutics 82(3): 518-525.

- Czech Z, Kowalczyk A, Shao S, Cheng XQ, Quan S, et al. (2013) Novel acrylic pressure-sensitive adhesive (PSA) containing silver particles. Journal of Adhesion Science and Technology 27(13): 1446-1454.

- Tan HS, Pfister WR (1999) Pressure-sensitive adhesives for transdermal drug delivery systems. Pharmaceutical Science & Technology Today 2(2): 60-69.

- Pang B, Ryu CM, Kim HII (2012) Improvement in wettability of pressure-sensitive adhesive on silicon wafer using crosslinking agent with siloxane groups. Journal of Applied Polymer Science 129(1): 276-281.

- Antosik AK, Ragańska P, Czech Z (2014) Termiczne sieciowanie samoprzylepnych klejów silikonowych nadtelenkami organicznymi. Polimery 59: 792-797.

- Antosik AK, Czech Z (2018) Si-PSA tape with the addition of dolomite. Archives of Organic and Inorganic Chemical Sciences 5: 1-3.

- Antosik AK, Czech Z (2017) Acrylic-silicone pressure-sensitive adhesives. Organic and Medicinal Chemistry 4 :1-3.

- Antosik AK, Bednarczyk P, Czech Z (2015) Jednostronnie klejące taśmy na bazie samoprzylepnych klejów silikonowych- dobór najlepszej kompozycji. Chemik 69: 95-97.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...