Lupine Publishers Group

Lupine Publishers

Menu

Review ArticleOpen Access

Application of Big Data Mining in the Expert System of Safety Warning in Coal Mining Face Volume 1 - Issue 3

Fanqiang Meng1,2*

- 1School of Economics and Management, USTB, Beijing100083, China

- 2Beijing Ccid Industry & Information Engineering Supervision Center Co., Ltd, Beijing 10048, China

Received: July 19,2021 Published: August 03,2021

Corresponding author: Fanqiang Meng, Beijing Ccid Industry & Information Engineering Supervision Center Co., Ltd, Beijing 10048, China

DOI: 10.32474/JBRS.2021.01.000115

Abstract

Coal mining face is the place where coal mine accidents occur frequently. In the process of coal mining safety monitoring and management has accumulated a large amount of data, to explore the value of potential data, improve the effectiveness of safety management, application of association rule data mining technology, to improve the traditional coal mining safety early-warning expert system knowledge acquisition, based on the mining face big data mining safety pre-warning management methods. Based on the multi-source big data of the working face, this method realizes the identification and early warning of the safety risks of the mining face by mining the correlation relation between the data, and takes the safety monitoring data of E3402 comprehensive mining face of a certain mine in Shandong province as an example for the application practice analysis.

Keywords: Security alert; Big data; Data mining; Association rules

Introduction

As the main production place of coal, the coal mining face is a complex social technology system with narrow space, complex environment, more equipment and concentrated workers [1]. There are many risk factors changing dynamically in the system, which increase the complexity of risk prevention and control in the work. Using the method of system engineering analysis, this paper comprehensively analyzes the risk factors influencing coal mining working face, establishes the expert system of safety early warning of coal mining working face, and carries out early warning of risks and adopts emergency plan. Knowledge acquisition is the core problem of building knowledge base of expert system, and also the bottleneck of building expert system, which determines the quality of expert system.

Data Mining (DM) extracts hidden valuable information from a large number of incomplete, vague and random Data. An important process is the process of Mining Knowledge from Data, also known as Knowledge Discovery in Database (KDD), which is the best way to discover patterns from Data [2]. Therefore, this paper mainly studies the problem of “bottleneck” of knowledge acquisition in the expert system of coal mining safety early warning by applying data mining technology to the expert system [3]. In order to better realize the safety early warning management of coal mining face.

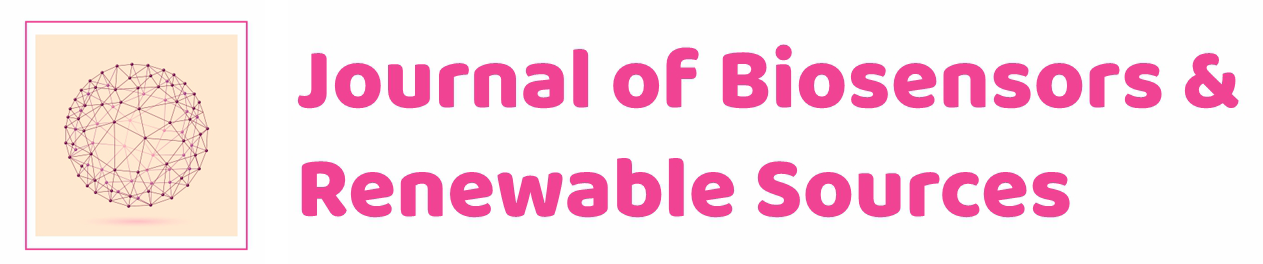

Expert System Of Coal Mining Face Safety Warning

The expert system of traditional coal mining face safety warning is composed of knowledge base, database, reasoning machine, interpreter, knowledge acquisition system and man-machine interface. As the core of the system, knowledge base and reasoning machine are used to store the expert experience knowledge, known facts and production rules of coal mining safety [4], the system structure is shown in (Figure 1).

The acquisition of knowledge is in accordance with the target requirements of the coal mining face safety warning system and the solution scope of the limited problems in the field. The expert knowledge is collected [2]. However, due to the limitations or subjective factors of domain expertise, or the limited skills of knowledge engineers, the acquired knowledge is incomplete, one-sided or inaccurate in the process of knowledge acquisition. Knowledge acquisition is the core of the construction of knowledge base, since there is a problem when knowledge acquisition, in the process of building a knowledge base, domain knowledge representation is not independence and uniqueness, sum up the knowledge of the yuan by the possibility of correlation, such uncertain reasoning machine application premise condition, leading to inaccurate inference conclusion [3]. In order to solve this problem, the knowledge base is constructed with the idea and method of data mining technology and experts in the field of coal mining safety.

Expert System Based On Big Data Mining

Multiple Data Sources for Coal Mining Face Safety Warning

The safety warning of coal mining face requires the selection and collection of measured parameters. The main sources of parameters are collected and transmitted through sensors. The parameters directly measured include the environmental parameters of working face, such as gas concentration, wind speed, air volume and carbon monoxide concentration [5,6]; Roof pressure parameters, such as front pressure and back pressure of hydraulic support column; Operating parameters of coal mining equipment, such as coal mining machine speed, cutter speed, motor temperature, etc. In addition, video, maintenance management and other large amount of unstructured data, the development trend of data conforms to the characteristics of large data capacity, fast processing speed, diversified types and large value [7]. Multiple data of coal mining face constitute a big data source of safety early warning database, mainly including

Initial Database

The initial database is mainly the data of design and construction stage of coal mining face, including all kinds of knowledge list, rules and regulations, data and documents of coal mining face. Knowledge list such as coal mining operation system knowledge, transportation system knowledge, ventilation system knowledge, power supply system knowledge, drainage system knowledge, auxiliary operating system knowledge; Roof management knowledge, gas and dust management knowledge, flood prevention knowledge, fire hazards knowledge, mechanical and electrical accident knowledge, transport accident knowledge and risk knowledge of blasting accident [5].

Run the Database

The operation database of coal mining face consists of the state information of coal mining face environment, equipment operation, roof pressure and so on. As mentioned earlier, this information is collected through automated monitoring sensors.

Manage the Database

The management database includes daily maintenance, maintenance and related maintenance equipment materials, accident handling and management personnel. Maintenance data usually refers to the daily maintenance records of the working team, reports of maintenance personnel handling events, material consumption and data of corresponding technical support. Maintenance data refers to the periodic maintenance records, equipment maintenance and replacement data of the working surface (mainly mechanical and electrical equipment, supporting materials, monitoring instruments, etc.). The management personnel data mainly include the maintenance personnel’s educational background, professional level, personal skills, working years, post responsibilities and so on.

Other related databases

The relevant database is related to the coal mining working face but cannot be confirmed, such as the influence of the roadway transportation system and the lifting system on the coal mining working face.

Data Mining Analysis of Safety Early Warning in Coal Mining Face

The application of big data technology of safety warning in coal mining face, data collection and mining analysis focused on.

Due to the complex structure of big data in security early warning, including structured, semi-structured and unstructured data, it is difficult for common information processing system to process data, so it is necessary to use big data processing technology to store and process it effectively.

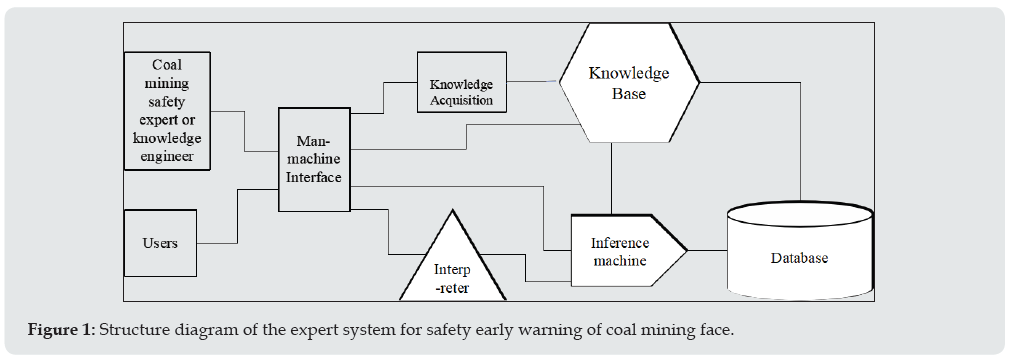

Hadoop, a big data processing architecture, is a computing platform capable of Distributed processing for a large number of data. It adopts two core technologies of Distributed storage and Distributed processing, among which Hadoop Distributed File System (HDFS) can process super-large data [8]. Mining analysis of big data solves the connection between data. The mining process adopts distributed parallelization technology and Hadoop’s MapReduce platform to complete a series of data processing processes including partitioning, mapping, sorting, merging and merging [9]. During the mining of large data of coal mining face safety warning, all data are extracted, converted and loaded through MapReduce platform and converted into identifiable status data. A large amount of data is accumulated continuously, which is aggregated into empirical big data of coal mine safety warning (Figure 2).

Expert system of coal face safety warning based on big data mining

Data mining is to use various technologies to find knowledge (rules) from the database into the knowledge base. The commonly used mining algorithms include association analysis, classification, clustering, visualization, decision tree, genetic algorithm, rough set theory, etc [10] The method of association rule analysis is adopted for the safety warning of coal mining face. Security early warning of big data mining technology route is to face all the data of deep mining, production safety in working face normal working mode corresponding data index and face the risks of the corresponding data index, compare the collected data, and to face security situation prediction of judgment.

Application Analysis Of The Expert System Of Safety Early Warning For Coal Mining Face Based On Big Data Mining

Data Preprocessing

The preprocessing of massive data is an important step for the safety warning of coal mining face. Especially when mining objects containing incomplete data and abnormal data, in order to improve the quality of data mining, data preprocessing is required, which generally includes structured processing, data cleaning and integration, selection and transformation [7,11,12].

Structured process

a) Working face daily maintenance, repair and maintenance of related equipment material, accident treatment and management data is stored in the form of text, more data mining model is hard to deal directly with the unstructured information, need for this structured text, and form a structured data, in order to meet the requirement of data mining.

b) Data cleaning and integration: there is usually a large amount of abnormal data in the collected original data, such as deviation expectations of key indicators, missing information of key attributes and data of error type, etc. If these data are not cleaned, the quality of information will be seriously affected. Smooth noise data, fill missing data, remove abnormal data, and standardize data structure to integrate different data into a collection.

c) Data selection and transformation: data selection and transformation: according to business requirements, data information is selected, then data formatting and processing is carried out, unified coding is conducted, and a security earlywarning database is formed for data mining.

Mining Association Rules of Risk Early Warning Information

The study of association rules is helpful to discover the potential association between different items in a data set, which is represented by rules, and its relationship model is obtained after reasoning and accumulating knowledge. Item sets I = {i1, i2,.. in}; TR is a collection of things; TR ⊂ I, and the TR is a collection of {0, 1} properties. If X is a set of items, and X ⊆ TR. The association rule is an implied expression of the form, where, and, X -- the condition of the rule (the former), Y -- the result of the rule (the latter) [13]. Association rules have two important attributes of support and confidence.

a) Support: the support of association rules for thing TR is defined as the ratio between the number of transactions containing object X and Y and all transactions, which is described as:

support(X ⇒Y) = P(X Y) (1)

It reflects the probability that X and Y occur at the same time in the set TR.

b) Confidence: the support (confidence) of association rules for things TR is defined as the ratio between the number of transactions containing X and Y and the number of transactions containing X, which is described as:

confidence(X ⇒Y) = P(X Y) (2)

It reflects the conditional probability of the occurrence of item set X in the data set and the occurrence of item set Y at the same time.

The support degree and confidence degree of association rules respectively reflect the usefulness and certainty of the discovered rules. General users can define two closed values, which are the minimum support threshold and the minimum confidence threshold respectively. When both the support and confidence of the mined association rules satisfy these two closed values, the rule can be considered valid or invalid [13]. The two thresholds are generally set by domain experts or users in advance.

Data mining association rules mainly include the following two steps:

Step-1: discover all frequent item sets, and the frequency of these item sets shall be at least equal to the minimum support frequency set in advance;

Step-2: according to the corresponding strong rules generated by the obtained frequent itemsets, these rules must meet the minimum confidence threshold.

Through the process described above, the information in the security early-warning database of the working face is transformed into different association rules. With these rules, the security manager can predict the possibility of other factors based on known factors and realize security early-warning [14].

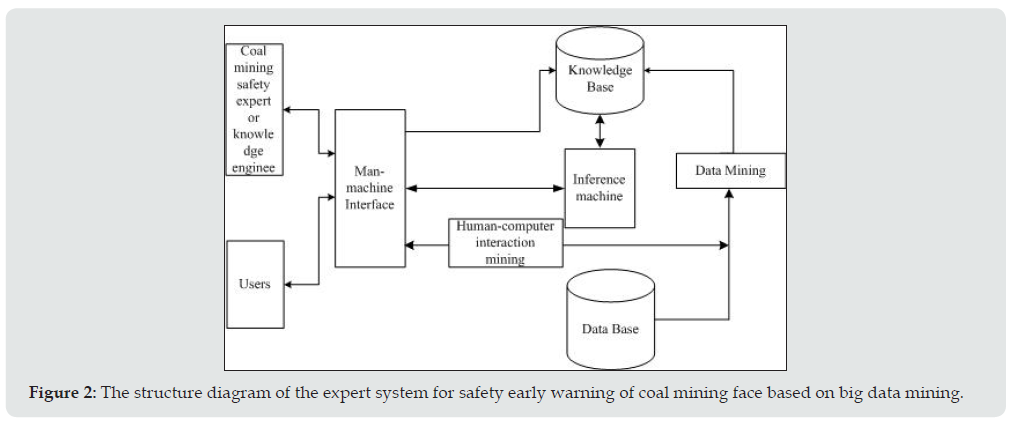

Visual Analysis

The visualization of security warning information can be expressed directly by different images. For example, nodes are used to represent different types of security related factors, and the higher frequency of factors, the larger the corresponding nodes. The visual image analysis provides the decision basis for the security manager.

Application Practice

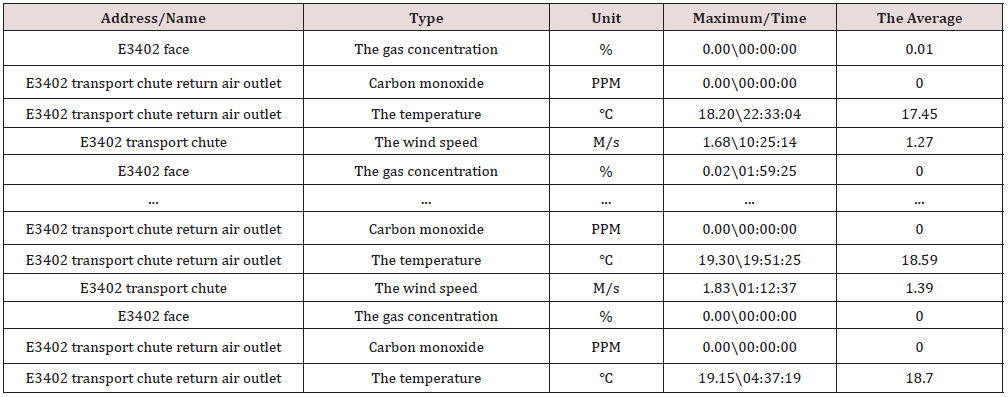

Taking the safety monitoring data of E3402 comprehensive mining face in a Shandong mine as an example, the application practice analysis is carried out. This case USES association rule mining technology to explore the correlation between different working hours and monitoring data. The E3402 comprehensive mining face safety warning system collects the working face gas, carbon monoxide, temperature, wind speed, roof pressure, coal mining machine, belt conveyor, ventilator, and other equipment on and off by the downhole monitoring system. According to the analysis of geological structure and occurrence conditions of the mine, the main factors influencing the safety warning of E3402 working face are gas, carbon monoxide, ventilation, and temperature. All security monitoring data and important operational event parameters are stored in the relational database. Intercept some data from January to April 2017, and the original data are as follows: The big data mining algorithm was applied to visualize the temperature association rules of gas, carbon monoxide and working face, as shown in (Figure 3): As can be seen from (Figure 3), during the period from 6:00am to 8:00 am, the working face has high temperature and low wind speed. Analysis of the reason this time of night shift, the early handover, night shift workers more tired, anxious to mine the early workers did not arrive, and the downhole shift leader, safety regulators did not reach the designated position, face no regulation, appear the phenomenon such as fans to stop or not close, lead to face ventilation is not good, this is likely to lead to the harmful gas such as gas concentration increases, increase the risk of accidents Table 1.

Conclusion

Coal mining face is the place where coal mine accidents occur frequently, accounting for about 40% of coal mine accidents. Roof, flood, fire, gas, dust and other disasters in the face of coal mining in a large proportion. Application technology of data mining in the mining face safety early-warning expert system, build the coalface security early warning method, based on the data mining safety monitoring, security management, through the relationship between mining data, realize the mining safety risk identification and early warning, to prevent the happening of the coal mine accidents.

References

- Zhang Zhijian (2014) Safety management and technical measures of coal mining face production [J]. Inner Mongolia coal economy (10): 73-73.

- Li Xiongfei, Dong Yuanfang, Li jun (2010) Data mining and knowledge discovery [M]. Higher education press.

- Xing ping, Shi Pengfei (1999) Data mining and its application in agricultural expert system [C]/ national academic conference on agricultural knowledge engineering 291pp.

- Wang Wenjie, Ye Shiwei (2004) Principles and applications of artificial intelligence [M]. People's post and telecommunications press.

- Andrew WH (2011) China law press. Coal mine safety regulations: the latest revision [M]. China law press 39(3): 424-439.

- Jiang Fuxing (2010) Roof control design of coal mining face and its expert system [M]. Coal industry press.

- Wang Xinhao, Luo Yun, Li Tong (2018) Research on macroscopic safety isk early warning methods for special equipment based on big data [J]. China safety production science and technology (4).

- Lin Ziyu (2015) Principles and applications of big data technology [M]. People's post and telecommunications press.

- Das T K, Kumar p (2013) BIG Data Analytics: A Framework for Unstructured Data Analysis[J]. International Journal of Engineering & Technology 5(1).

- Cheng xiang, Gan zheng (2016) Research on safety monitoring data analysis model technology based on big data mining [J]. Low-carbon world (28): 101-102.

- Guo yudong, Li shenglin (2016) Application of big data key technology in comprehensive management system of infrastructure barracks [J]. Logistics technology 35(5): 169-175.

- Bahn S (2013) Workplace hazard identification and management: The case of an underground mining operation[J]. Safety Science 57(8): 129-137.

- Zhou Bo, Tang Guibin, Sun Maocun (2013) Research on an object-oriented expert system for gas safety early warning [J]. Geographic information world (4): 78-81.

- Zhao Dan, Chen Shuai, Pan Jingtao (2015) Research on early warning system of mine monitoring and diagnosis [J]. Chinese journal of safety science 25(4): 63-69.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...