Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2690-5752

Review Article(ISSN: 2690-5752)

Integrated Vibration Sensor Based Stethoscope Design Volume 5 - Issue 2

S Rajkumar1*, K Sathesh2 and Bayisa Taye Mulatu1

- 1Assistant Professor, Department of Electronics and Communication Engineering, School of Electrical Engineering and Computing, Adama Science and Technology University (ASTU), Ethiopia

- 2Associate Professor, Department of ECE, Madanapalle Institute of Technology & Science, India

Received:September 13, 2021 Published: September 22, 2021

Corresponding author: S Rajkumar, Assistant Professor, Department of Electronics and Communication Engineering, School of Electrical Engineering and Computing, Adama Science and Technology University (ASTU), Adama, Ethiopia

DOI: 10.32474/JAAS.2021.05.000208

Abstract

Stethoscope is an instrument that employs the technique of separation of two sound signals such as heart sound signals (HSS) and lung sound signals (LSS) by placing its flat sensor on the human body to receive and convey the sounds of internal organs to the diagnostician’s ears through its earphones. The conventional stethoscope contains a condenser microphone with preamplifier to obtain sound signals from the working human body organs. Observed sound signal is a mix of sounds from the heart, lungs, as well as some internal and external interference or background noise as usually happens in electronic devices during the sound signal observation. Recent technology in electronics has been implemented in various medical applications to help physicians. In this way the stethoscope was adapted by various techniques and its output computerized, but every system has some drawback in the distinctness and clarity of observed signals. In this work, piezoresistive and piezocapacitive pressure sensor is designed and implemented in Intellisuite software successfully paves the way for highly reliable stethoscope.

Keywords: Auscultation; Stethoscope; Comsol; Sensors

Introduction

In recent years, electronics play [1] a very big role in the healthcare system for early detection and diagnosis of disease. The internal parts of the body such as the heart and lungs repeat mechanical movements to produce vibration, and the vibration propagates the sound signal. Physicians listen to the sound signals through a stethoscope to observe the function of the heart and lungs. The stethoscope relays both sound signals but the heart produces high spectrum signals whereas the lungs produce low spectrum signals during inhalation and exhalation. In this research, we are focusing on the respiratory system to enable early detection and diagnosis of lung disease by isolating and enhancing lung sound signal transmission through a specially-designed stethoscope.

Lung auscultation [2] is a diagnostic method used for checking the integrity of lung function. In lung auscultation, physicians use a stethoscope to listen for changes in lung sounds to assess whether a patient has any obvious lung abnormalities. Selvin et al [3] have dealt new type of strain sensors can be employed practically through two main approaches. Zhou et al. [4,5] have dealt the common feature of these resistance-type nanocomposite sensors, which is of the most importance, is that as compared to conventional strain sensors, e.g., strain gauges, higher sensitivity has been observed in these novel sensors, at least at a macro-scale. Zhou et al. [4,5] discussed the research on carbon nanotubes (CNTs) for sensing application is a very promising direction for nanoscale devices due to CNTs’ excellent electrical and mechanical properties. Biological signals [6-9] may be defined as the vibration and/or mechanical movement from internal parts of the human body, and the signals which originate in a biological system. Kang et al [10] have dealt the bottom-up technique utilized catalytic particles directly patterned onto a substrate to control the position of CNTs, while the top down method focused on manipulation of the growth CNTs into their desired position. In the 1960s, Paul Forgacs [11] designed a simple model using microphones, amplifiers, oscilloscopes, and tape recorders to obtain the first detailed investigation of sound waves by systematic digital measurements of respiratory sound.

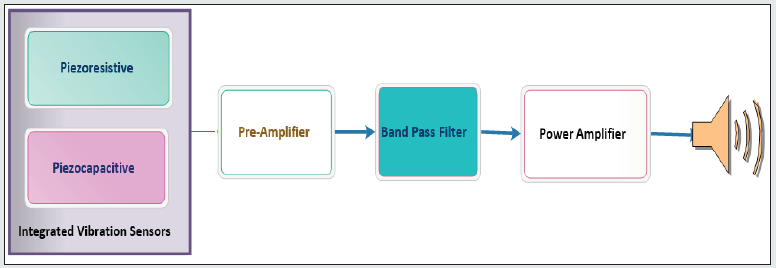

Proposed Sensor-Based Digital Stethoscope

The sophisticated advances in electronics [12,13] can be implemented to achieve the most favorable expected outcomes in biomedical systems. The conventional stethoscope uses a condenser microphone to observe the sound signal. One of the main objectives of this research is to replace the condenser microphone with vibration sensors to observe biomedical sound signals. The vibration sensors are classified into two types namely Piezoresistive and Piezocapacitive. Both sensor designs were implemented in MEMS INTELLISUTE 10.4 software and compared with traditional microphone based electronic stethoscope. The sensors convert the vibrations of human organs to sound waves. Both these sensors capture the vibrations and convert them to sound waves with respect to resistive and capacitive load, thus significantly reducing the noise level from the input signal and enabling early and reliable detection of disease.

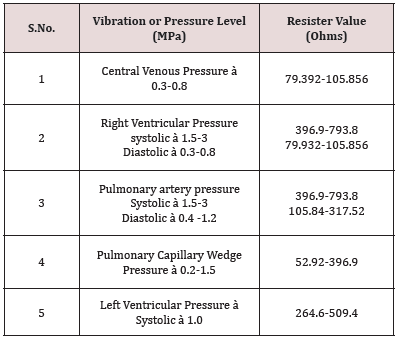

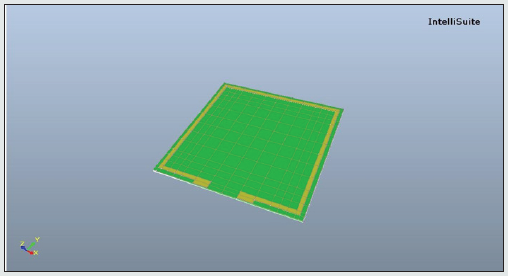

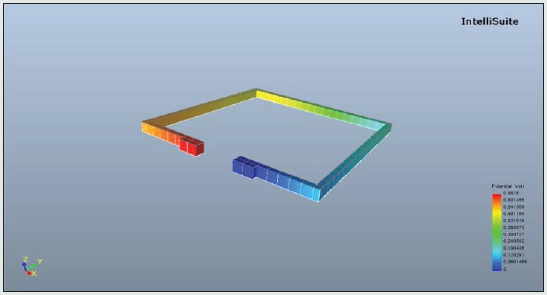

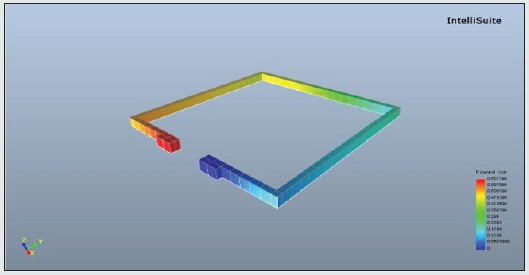

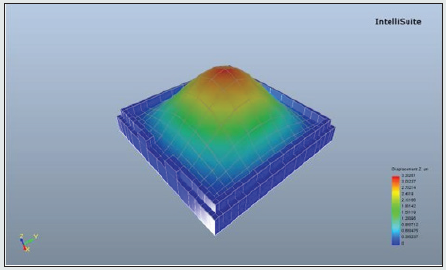

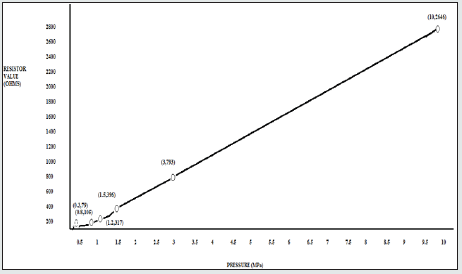

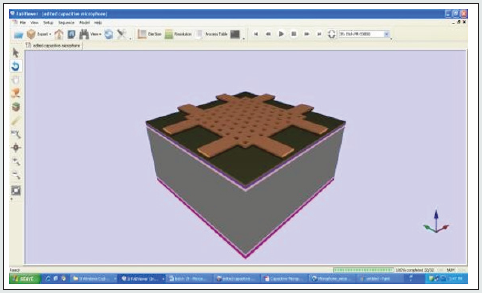

Micro-Electromechanical System (MEMS) is used to design both the vibration sensors and Intellisuite software is used to analyse their characteristics Figure 1. The sensors’ characteristics depend on the semiconductor material, and Intellisuite is the only software which offers the provision of changing the material according to the required characteristics and design of the sensors. Figure. 2 show the piezoresistive pressure sensor designed in Intellisuite software. Figure 3 shows the Electrical Potential for Input 0.6616 V and current 5 mA, this corresponds to a resistance of 132.32 Ohm. Figure 4 shows the Electrical Potential at the input is 0.6571 V and current was 5 mA, this corresponds to a resistance of 131.42 ohm. Figure 5 shows the displacement structure of Piezoresistive pressure sensor for 0.5 MPa Pressure applied to the design. The designed sensors operate at a voltage between 0.9 and 2V, and a frequency range between 0.3-2GHz to analyze the output characteristics with respect to varying position and pressure levels as shown in Table 1. Heart sound pressure level varies from 0.2 MPa-10 MPa by applying these level of pressure to piezoresistive pressure sensor the various sensitivity values obtained as shown in Table 1. From the table result we came to know that our sensor can be able to sense for various heart sounds by digital stethoscope. The graph between pressure vs resistance is shown in Figure 6 from that we understood that sound pressure increase as well as resistance also get increases. The Piezocapacitive MEMS microphone has high signal to noise performance (58dB). It is well suited for a wide range potential application. The capacitance value with respect to different pressure will be analyzed. The construction is analyzed by using TEM module. Figure 7 shows the Piezocapacitive pressure sensor designed in Intellisuite software.

The piezo capacitive pressure sensor design is obtained by using four software modules. First we have to construct the microphone structure in Blueprint module. Then the construction will be attached to the Intellifab module. In this module step by step processing steps will be included. Then we have to obtain a design by visualize in Fab viewer module. After getting the correct design, it will analyze by thermo electromechanical system module. In this module, the capacitance value with respect to different pressure will be analyzed. The sensitivity is the electrical signal at the microphone output to a given acoustic pressure as input. The reference of acoustic pressure is 1PA, and sensitivity is typically measured in Mv/Pa. first we compute the capacitance C0 between perforated plate and moving plate without acoustic pressure, and then compute a new the capacitance c1 by applying 1pa pressure on the moving plate (Vibrating Diaphragm).

Conclusion

This paper discussed about the basics of digital stethoscope in detail. Piezoresistive and Piezocapacitive pressure sensor is designed and implemented in Intellisuite software. This study opens several lines for future work. Analyzing the existing tradeoffs and implementation are some of the future works of this research. This work can be extended by following the same fashion for other signal analysis and may vary with different engineering applications.

Declarations

Funding

The author(s) received no specific funding for this work.

Conflict of interest

Authors declare that they have no conflict of interest.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Competing interest statement

The authors have declared that no competing interests exist. Author Contributions All Authors are equally contributed to the study conception and design and implementation of the research, analysis and interpretation of results, and manuscript preparation.

Availability of data and material

No data used to support the findings of this study.

References

- Klum M, Urban M, Tigges T, Alexandru Gabriel Pielmus, Aarne Feldheiser, et al (2020) Wearable Cardiorespiratory Monitoring Employing a Multimodal Digital Patch Stethoscope: Estimation of ECG, PEP, LVET and Respiration Using a 55 mm Single-Lead ECG and Phonocardiogram. Sensors (Basel) 20(7): 2033-2039.

- Araiza G D, Jordán Ríos A, Sierra Fernández C, Juárez Orozco L E (2020) On stethoscopes, patient records, artificial intelligence and zettabytes: a glimpse into the future of digital medicine in Mexico.Arch Cardiol Mex 90(2): 193-199.

- Selvin SA, Lovelin SA, Moorthy NB, Gupta A, Alagappan M, et al (2011) Design and Simulation of Carbon Nanotube based Piezoresistive Pressure sensor. Proceeding of the 2011 Comsol Conference pp. 1-5.

- Zhou C, Kong J, Dai H (2000) Electrical measurements of individual semiconducting single-walled carbon nanotubes of various diameters. Applied Physics Letters 76(12): 1597-1599.

- Zhou C, Kong J, Dai H (2000) Intrinsic electrical properties of individual single-walled carbon nanotubes with small band gaps. Physical Review Letters 84(24): 5604-5607.

- Swarup S, Makaryus AN (2018) Digital stethoscope: Technology update. Med Devices (Auckl) 11: 29-36.

- Landge K, Kidambi BR, Singhal A, Basha A (2018) Electronic stethoscopes: Brief review of clinical utility, evidence, and future implications. J Pract Cardiovasc Sci 4(2): 65-68.

- Yang X, Zhou Z, Wu Y, Xiao M, Luo Q, et al (2007) Measurement and simulation of carbon nanotube's piezoresistance property by a micro/nano combined structure. Indian journal of pure and applied physics 45(4): 282-286.

- Rajkumar S, Sathesh K, Goyal NK (2020) Neural network-based design and evaluation of performance metrics using adaptive line enhancer with adaptive algorithms for auscultation analysis. Neural Computing& Applications 32: 15131-15153.

- Kang SJ, Kocabas C, Ozel T, Shim M, Pimparkar N, et al (2007) High-performance electronics using dense, perfectly aligned arrays of single-walled carbon nanotubes. Nature Nanotechnology 2(4): 230-236.

- Forgacs P (1978) Lung sounds, Cassell and Coller MacMillan Publishers Ltd, London, UK.

- Ayub M, Zander AC, Howard CQ, Cazzolato BS, Shanov VS, et al (2014) Acoustic absorption behaviour of carbon nanotube arrays. Proceedings of the forty third International Congress on Noise Control Engineering pp. 1-10.

- Sathesh K (2016) On ways to improve lung sound diagnostics system using VLSI technology. PhD Thesis, Anna University, USA.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...