Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2690-5752

Research Article(ISSN: 2690-5752)

Digitizing Supply Chain Management: Challenges and Opportunities in the Era of the Covid-19 Pandemic Volume 6 - Issue 1

Abdul Aziz*, Wahyu Purbo Santoso, Siti Nurhasanah and Ratih A Wilis

- Department of Management, Asia Cyber University, Indonesia

Received:November 23, 2021; Published: December 10, 2021

Corresponding author: Abdul Aziz, Department of Management, Asia Cyber University, Indonesia

DOI: 10.32474/JAAS.2021.06.000229

Abstract

Digitalization in supply chain management in the era of the Covid-19 pandemic is a necessity for producers. Efficiency and effectiveness in supply chain management, which was originally done through physical contact, is now very easy in the era of disruption that relies on engineering technology. Digitalization of supply chain governance is a challenge in this pandemic era as well as an open opportunity to achieve big profits, because of its efficiency and effectiveness in this activity directly between producers and consumers communicating with each other. No need to face to face physically, consumer ordering online is faster and companies in digital supply chain management are easy to respond to more quickly, optimally and variedly.

Introduction

The COVID-19 pandemic has had a global impact on all lines of life, both health, social life, economy, and the environment [1]. To prevent the transmission of the virus-19, various efforts have been made by all countries in the world, one of these efforts is the direct restriction of social activities [2-4]. Even though there are direct restrictions on social activities for this prevention, business activities must continue so that economic balance is maintained. Thus, supply chain governance must be digitally based [5]. Digitizing supply chains in business activities in the Covid-19 era is an effective effort in addition to avoiding face-to-face meetings, it is also more efficient in supplying goods and services from one place to another [6]. So, managers must carry out supply chain activities manually with digital technology is a necessity [7-9], supply chain management which is usually done physically must switch digitally [10]. Likewise, consumers are more flexible in ordering purchases of goods and services online. The supply chain digitization system makes it easier for producers and consumers in the era of physical restrictions due to the Covid-19 pandemic [11]. This is an opportunity for supply chain managers [12]. Therefore, the purpose of this paper is to explain how supply chains are managed digitally as a challenge and at the same time a great opportunity in the new normal era of the Covid-19 pandemic [13]. To support some of the theories above, and at the same time explain the unique characteristics of this paper, it is necessary to state the facts in the field.

Literature Review

The Covid-19 pandemic has changed the world’s paradigm, especially from offline activities and activities to online. Slowly but surely forcing changes in all business actions depending on the use of technology. According to [14] not only does this change enter the business sector, but this digital acceleration has become a trend in other sectors, such as

a) Social relations and labour,

b) Sales and marketing, and technology.

This close relationship does not only rely on the use of technology but also has an impact on the organization’s competitive advantage. In particular, [15] in their findings state that due to this digitalization, competitive advantage in organizations can improve supply chain management. This is considering that engineering technology which is the basic capital in its involvement in the advancement of various industries triggers SCM to be played optimally. [16] emphasize that a company’s competitive advantage that leads to decision-making involvement in digital supply chain transformation requires at least blockchain technology. This is done by business vendors, wherein pallet rental they rely on online. Their main reason said [17] is for efficiency in asset and supply chain management to occur. In the fast-food business and other products, according to [18], it is very possible in the Covid-19 era the supply chain uses blockchain technology. They proposed that Food SQR Block be widely used. [19] firmly recognize that digitalization must be utilized by supply chains. This is not only to streamline and improve planning but also supply chain management. Moreover, its use for the production and logistics sectors. Likewise [20] in their research note that digitalization in the supply chain is very significant for any industry. Even digital supply chains can help advance a sustainable economy. According to [21] global competition in the industry 4.0 and Society 5.0 era, which is marked by technological changes, forces supply chain management and logistics to be digitally based.

Moreover, this era relies on Big Data which all industrial companies must follow this change. So, it is impossible to use the old ways in meeting the needs of a large and broad market. [22-23] also recognize that supply chains that include product development, manufacturing, logistics and marketing in this era of disruption are impossible without technology. Therefore, digital-based supply chain management is needed for companies. This is because supply chain management for the industry is the acceleration and visibility to get to the customer immediately. According to [24] that what we think about the supply chain for large and small companies in this Big Data era needs two main aspects, namely sustainability and technology. Aspects of sustainability to improve the balance of economic growth on the one hand, and on the other hand technology as a tool to facilitate the acceleration of supply services from companies to customers.

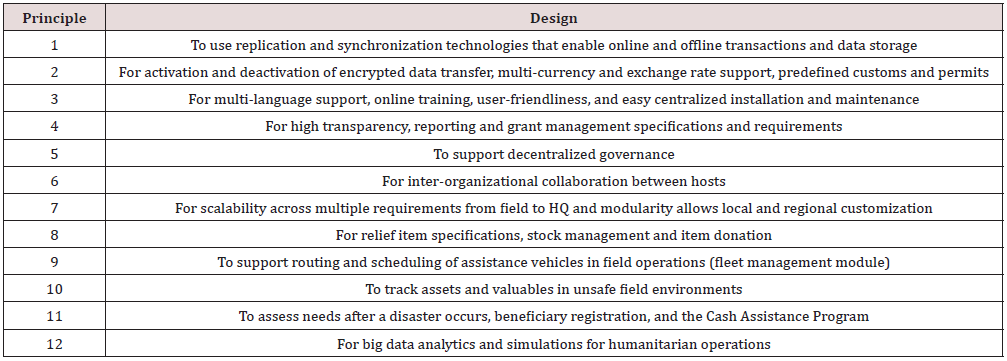

This is emphasized by [25] in their research that to plan superior, competitive and sustainable corporate resources (ERP) requires agile and adaptive supply chain management according to changing times. They offer 12 principles to industrial companies who want to plan superior, agile and adaptive supply chains as can be seen in the following table. The twelve principles offered by Sigala et al are very helpful in accelerating companies in the era of disruption (Industry 4.0 and Society 5.0), especially in increasing resources, as well as company competitiveness in facing global competition and improving its performance. In addition to the above principles, [26] also propose the Agile Supply Chain (ASC) principle in dealing with market competition pressures and their instability as well as strengthening the operational and organizational performance of technology-based global companies that must be adaptive and flexible. However, they admit that with this ASC, a company’s supply chain does not necessarily improve its performance effectively. According to [27] to improve these shortcomings, it is necessary to integrate digitalization technology devices through the Internet of things (IoT) with Blockchain with the principles mentioned above. The use of Blockchain in supply chain management for acceleration, security, and strengthening in an integrated manner throughout the supply chain. [28] also emphasized the advantages of blockchain-based technologies in supply chains. Where they explain that the supply chain can know four important components, such as techniques, knowledge, organization and products in detail. However, this model of using technology tools needs to be integrated with the use of other technologies in an integrated manner, such as IoT with ASC and the twelve principles mentioned above, Greenfield Analysis and Network Optimization, as applied to automotive companies in Mexico [29]. In the Covid-19 era, which has an impact on wide-scale restrictions, of course, it is very likely to optimize digital-based supply chains and use the Internet of things (IoT) as an adaptive solution to maximize supply chain management performance for large and small companies.

Method

This article aims to increase critical knowledge both inductively [30] as well as descriptive and in-depth which refers to various articles on digitalization of supply chain management in the Covid-19 pandemic era as a challenge as well as an opportunity in improving resource competence and supply chain performance. a company. Several conceptual models and literature in other papers that make important contributions from various sources (Scopus, Google Scholar, Google Science, Science direct, Elsevier, ProQuest, Nature, Springer, and so on) are used as main references in this study so that actual, comprehensive writing can be presented, and integrative through keywords, citations, and analysis [25-27,31,32].

Results and Discussion

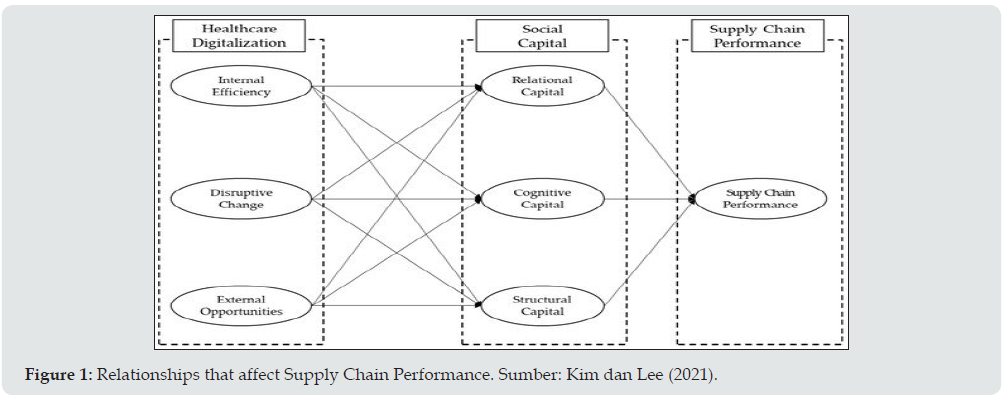

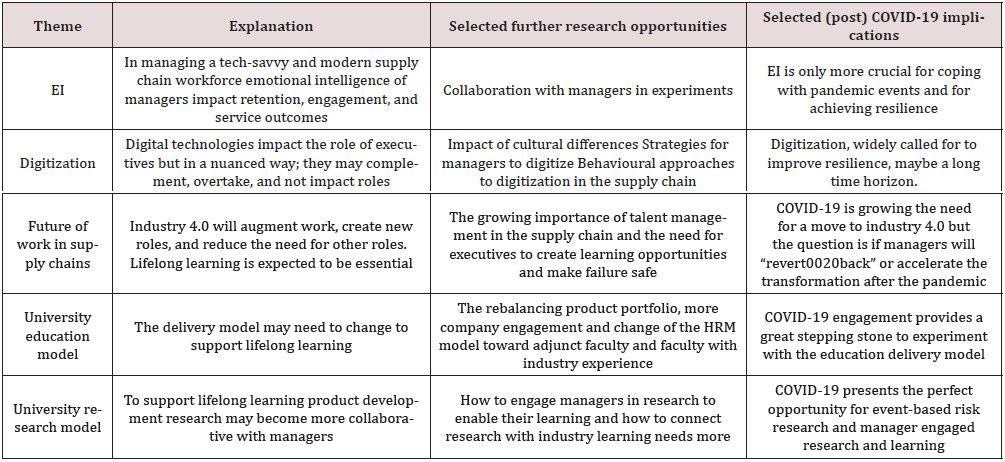

SCM in the Covid-19 pandemic era is very interesting to study compared to ordinary management studies, especially when it is connected to digital technology. [33] argue that this field of study is closely related to the skills and abilities of a team in a company so that its success cannot be denied. This statement is reinforced by his findings on the Deloitte Company, where less than 50% of respondents affected by Covid-19 stated that supply chain strategy was influenced by the skills and abilities of the team. Therefore, they divide research opportunities related to SCM into 5 important themes to make it easier for managers to focus on this area, as can be seen in Table 1 below. Table 1 above shows that the five themes that Hoek et al expect are at least an option for managers in increasing the competitiveness of supply chain companies. [34] emphasized that in the era of Covid-19, which is spreading very quickly in the world, managers need to accelerate the pace of supply chain usage with digital technology utilizing artificial intelligence (AI) and the Internet of Things (IoT) so that supply chains can be connected. quickly and precisely. Both of them in their research at a South Korean Manufacturing Company linking 2 factors that affect supply chain performance, including healthcare digitalization, and social capital with supply chain performance as can be seen in Figure 1 below:

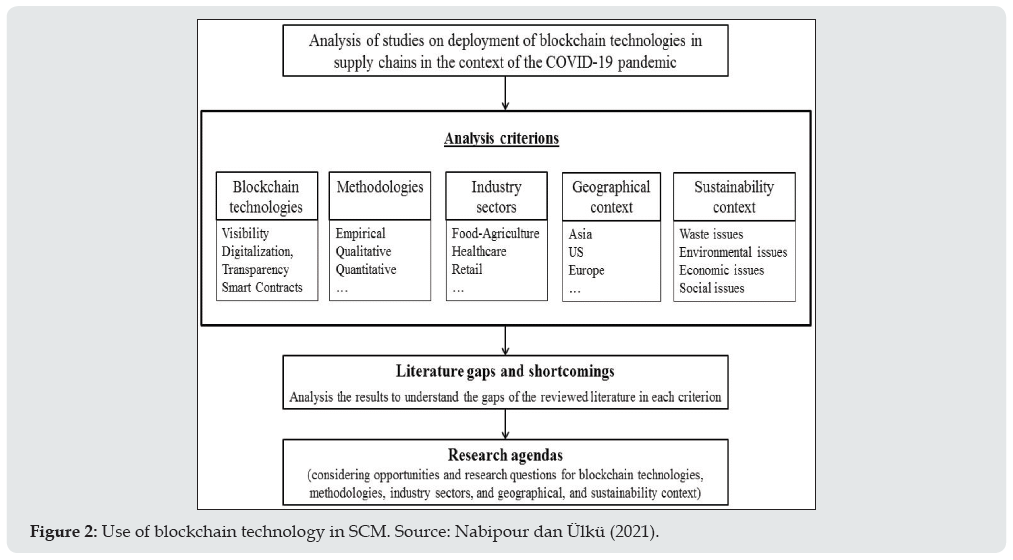

Figure 1 above makes it clear that the existence of SCP can be influenced directly or indirectly by digitalization and social capital as intermediate variables. Kim and Lee found that supply chain performance can be effectively influenced by digitalization which includes internal efficiency, disruption change, and external opportunities as well as social capital in terms of relationships, knowledge, and structural capital. This of course should be a reference for company managers in planning the production process and supply chain network for optimizing factory output. However, [32] see that the significance of digitization in SCM is not the same in all countries. This is influenced by the situation and conditions, especially in the geographical sector especially during the Covid-19 period, so it offers the need for further, more comprehensive research, especially regarding the digitization of SCM, as can be seen in Figure 2 below. Blockchain technology as one of the models recommended by researchers to accelerate SCM digital transformation in the Covid-19 era can be seen in Figure 3 above. Methodologically, both qualitative-empirical and quantitative are challenges as well as opportunities for companies, especially in the industrial sector, both food-agricultural products, health and retail in all countries in the world. According to [35] in addition to what was stated above, SCM in the era of the Covid-19 pandemic actually through utilizing digitalization-based technology can strengthen the sustainability of careful supply chain planning. Moreover, a mature SCM planning process with the involvement of productivity, disruption, and destruction can provide positive reinforcement (Table 2).

Table 2. Supply chain talent management research themes and opportunities and the impact of COVID-19. Source: van Hoek et al (2020).

So, the impact of the Covid-19 endemic on supply chain management in almost all countries is felt so that it needs adequate handling. [36] offer six keys to systematic handling so that SCM can compete quickly, responsively and precisely. Among them are adaptation, digitization, preparedness, recovery, ripple effects, and sustainability. These six measurable and systemic treatment perspectives have been partly described above. According to [37- 39] that the digital perspective in increasing opportunities and reducing risks in the SCM and logistics sector based on several researchers’ findings, such as the use of blockchain technology and the Internet of things (IoT) as the main drivers of change. Digital business models are very strategically applied to SCM in this era. On the other hand, SCM remains strong in the Covid-19 era if logistics service providers (LSP) are digital-based [40].

Conclusion

Two years of the Covid-19 pandemic, which has shattered the world’s challenges in all aspects of life, including the supply chain sector, global companies have seriously adapted from using computing technology to digitalization using the internet of things (IoT) as a reference. Key elements offered by [32-40] as mentioned above have significantly contributed to the resilience of SCM. Business digitalization by utilizing Big data and engineering technology with the Internet of Things (IoT) is a new direction in the new normal era of the Covid-19 pandemic, and the toughness of logistics service providers adds to the competitive advantage and competitiveness of SCM in facing the challenges of the times and opportunities in the future.

References

- Siriwardhana Y, Gür G, Ylianttila M, Liyanage M (2021) The role of 5G for digital health care against COVID-19pandemic: Opportunities and challenges. ICT Express 7(2): 244-252.

- Singer R, Crooks N, Johnson A K, Lutnick A, Matthews A (2020) COVID-19 prevention and protecting sex workers: a call to action. Archives of Sexual Behavior 49(8): 2739-2741.

- Király O, Potenza M N, Stein D J, King D L, Hodgins D C, et al (2020) Preventing problematic internet use during the COVID-19 pandemic: Consensus guidance. Comprehensive Psychiatry 100: 152180.

- Güner HR, Hasanoğlu İ, Aktaş F (2020) COVID-19: Prevention and control measures in the community. Turkish Journal of medical sciences 50(SI-1): 571-577.

- Frederico GF (2021) Towards a Supply Chain 4.0 on the post-COVID-19 pandemic: a conceptual and strategic discussion for more resilient supply chains. Rajagiri Management Journal 15(2): 94-104.

- Tasnim Z E R I N (2020) Disruption in global food supply chain (FSCs) due to COVID‐19 pandemic and impact of digitalization through blockchain technology in FSCs management. European Journal of Business and Management 12(17): 73-84.

- Kumar A, Luthra, S, Mangla S K, Kazançoğlu Y (2020) COVID-19 impact on sustainable production and operations management. Sustainable Operations and Computers 1: 1-7.

- Paul S K, Chowdhury P, Moktadir M A, Lau K H (2021) Supply chain recovery challenges in the wake of COVID-19 pandemic. Journal of business research 136: 316-329.

- Ivanov D, Dolgui A (2020) A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Production Planning & Control 32(9): 775-788.

- Quayson M, Bai C, Osei V (2020) Digital inclusion for resilient post-COVID-19supplychains: smallholder farmer perspectives. IEEE Engineering Management Review 48(3): 104-110.

- Končar J, Grubor A, Marić R, Vučenović S, Vukmirović G (2020) Setbacks to IoT implementation in the function of FMCG supply chain sustainability during COVID-19 pandemic. Sustainability 12(18): 7391.

- Burgos D, Ivanov D (2021) Food retail supply chain resilience and the COVID-19 pandemic: A digital twin-based impact analysis and improvement directions. Transportation Research Part E: Logistics and Transportation Review 152: 102412.

- Farooq M U, Hussain A, Masood T, Habib M S (2021) Supply chain operations management in pandemics: a state-of-the-art review inspired by COVID-19. Sustainability 13(5): 2504.

- Almeida F, Santos J D, Monteiro J A (2020) The challenges and opportunities in the digitalization of companies in a post-COVID-19 World. IEEE Engineering Management Review, 48(3): 97-103.

- Gupta H, Kumar S, Kusi Sarpong S, Jabbour C J C, Agyemang M (2020) Enablers to supply chain performance on the basis of digitization technologies. Industrial Management & Data Systems 121(9): 1915-1938.

- Scully P, Höbig M (2019) Exploring the impact of blockchain on digitized supply chain flows A literature review. In 2019 Sixth International Conference on Software Defined Systems (SDS) IEEE pp. 278-283.

- Pundir A K, Jagannath JD, Chakraborty M, Ganpathy L (2019) Technology integration for improved performance: A case study in digitization of supply chain with integration of internet of things and blockchain technology. In 2019 IEEE 9th Annual Computing and Communication Workshop and Conference (CCWC) IEEE pp. 170-176.

- Dey S, Saha S, Singh AK, McDonald Maier K (2021) FoodSQRBlock: Digitizing Food Production and the Supply Chain with Blockchain and QR Code in the Cloud. Sustainability 13(6): 3486.

- Daxböck C, Kröber J, Bergmann M (2019) Digitized performance management along the supply chain. In Performance Management in Retail and the Consumer Goods Industry pp. 405-423.

- Zhou Q, Wang S (2021) Study on the Relations of Supply Chain Digitization, Flexibility and Sustainable Development-A Moderated Multiple Mediation Model. Sustainability 13(18): 10043-10045.

- Marmolejo Saucedo J, Hartmann S (2020) Trends in digitization of the supply chain: A brief literature review. EAI Endorsed Transactions on Energy Web 7(29).

- Park S T, Kim T U, Kim M R (2020) Digitization of Supply Chain Management: Key Elements and Strategic Impacts. Journal of Digital Convergence 18(6): 109-120.

- Chauhan C, Singh A (2019) A review of Industry 4.0 in supply chain management studies. Journal of Manufacturing Technology Management.

- Sanders NR, Boone T, Ganeshan R, Wood J D (2019) Sustainable supply chains in the age of AI and digitization: research challenges and opportunities. Journal of Business Logistics 40(3): 229-240.

- Sigala IF, Kettinger WJ, Wakolbinger T (2020) Digitizing the field: designing ERP systems for Triple-A humanitarian supply chains. Journal of Humanitarian Logistics and Supply Chain Management 10(2): 231-260.

- Shashi Centobelli P, Cerchione R, Ertz M (2020) Agile supply chain management: where did it come from and where will it go in the era of digital transformation?. Industrial Marketing Management 90: 324-345.

- Bailur R P, Rao S, Iyengar D (2020) Use of Blockchain Partnerships to Enable Transparency in Supply Chain Digitization. In The Oxford Handbook of Supply Chain Management, USA.

- Köhler S, Pizzol M (2020) Technology assessment of blockchain-based technologies in the food supply chain. Journal of cleaner production 269: 122193.

- Marmolejo Saucedo J, Retana Blanco B, Rodriguez Aguilar R, Pedraza Arroyo E (2020) A proposal for the supply chain design: A digitization approach. EAI Endorsed Transactions on Energy Web 7(29).

- Ishfaq R, Davis Sramek B, Gibson B (2021) Digital supply chains in omnichannel retail: A conceptual framework. Journal of Business Logistics.

- Dhamija P, Bedi M, Gupta M L (2020) Industry 4.0 and supply chain management: A methodological review. International Journal of Business Analytics (IJBAN) 7(1): 1-23.

- Nabipour M, Ülkü M A (2021) On Deploying Blockchain Technologies in Supply Chain Strategies and the COVID-19 Pandemic: A Systematic Literature Review and Research Outlook. Sustainability 13(19): 10566.

- Van Hoek R, Gibson B, Johnson M (2020) Talent Management for a Post‐COVID‐19 Supply Chain-The Critical Role for Managers. Journal of Business Logistics 41(4): 334-336.

- Kim H K, Lee C W (2021) Relationships among healthcare digitalization, social capital, and supply chain performance in the healthcare manufacturing industry. International Journal of Environmental Research and Public Health 18(4): 1417.

- Kamal M M (2020) The triple-edged sword of COVID-19: understanding the use of digital technologies and the impact of productive, disruptive, and destructive nature of the pandemic. Information systems management 37(4): 310-317.

- Queiroz M M, Ivanov D, Dolgui A, Wamba S F (2020) Impacts of epidemic outbreaks on supply chains: mapping a research agenda amid the COVID-19 pandemic through a structured literature review. Annals of operations research p. 1-38.

- See B V, Grafe B, Lodemann S, Kersten W (2021) Digital Transformation of Logistics and SCM: The Long Way from Digitization to Digital Business Models. Digital Business Models in Industrial Ecosystems Springer Cham p. 3-21.

- Abdin MD, Joynal (2021) New Facets of SCM Ecosystem and Business Management.

- Kraus N, Kraus K (2021) Digitalization of business processes of enterprises of the ecosystem of Industry 4.0: virtual-real aspect of economic growth reserves. WSEAS Transactions on Business and Economics 18: 569-580.

- Herold DM, Nowicka K, Pluta Zaremba A, Kummer S (2021) COVID-19 and the pursuit of supply chain resilience: reactions and “lessons learned” from logistics service providers (LSPs). Supply Chain Management: An International Journal.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...