Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-6660

Review Article(ISSN: 2637-6660)

Impact of Nanotechnology in the Agro-Food sector Volume 2 - Issue 1

Waleed Fouad Abobatta*

- Department of Citrus, Horticulture Research Institute, Egypt

Received: August 16, 2019; Published:August 26, 2019

*Corresponding author:Waleed Fouad Abobatta,Department of Citrus, Horticulture Research Institute, Egypt

DOI: 10.32474/ANOAJ.2019.02.000130

Abstract

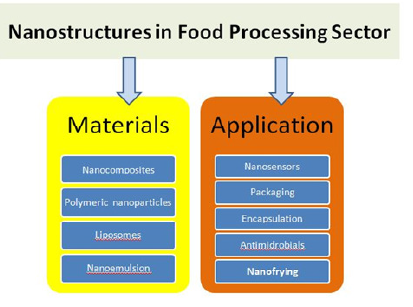

Nanotechnology provides a new challenge in the agri-food sector to use new management systems has capable of treated with any risks. Nanomaterials have unique properties due to wide surface area per each mass unit, so it offers several applications to make the food safety diagnostics field easier, there are various Nanostructures in agro-food sector include materials like (Nanocomposites, Polymeric nanoparticles, Liposomes, and Nanoemulsion), also, there are different application of nanostructures include Nanosensor, smart Package, Nanocoatings, Encapsulation, and Nanofrying. There is a vital role for nanosensor in protecting food products during the whole steps of the food chain. Different applications of nanomaterials in the agro-food sector like (Nanoscale fillers, smart Package, Nanocoatings, Encapsulation, and Nanofrying) aim to enhance food quality. Nanostructured materials considered the novel application of nanotechnology and it is being used to produce the Nanofoods, moreover, there are nanomaterials used for coating the inner surface in different devices like refrigerators and dairy processing pipes, and tanks to avoid microbial infection, provide a hygiene environment and reduce cost.

Keywords: Agri-Food Sector; Nanocomposites; Nanosensor; Nanocoatings; Encapsulation; Smart Package

Abbreviation: European Food Safety Authority: (EFSA); Foodborne disease: (FBD); Nanostructure materials: (NSMs); Engineered nanomaterials: (ENMs); Food contact materials: (FCMs); Nanofiltration: (NF)

Introduction

Nanotechnology opens a new opportunity for the food industry and food products to use new management systems has capable of treated with any risks associated with nanofoods as well as the use of nanotechnology at food industry. Nanomaterials have a wide surface area per each mass unit, they are expected to be more biologically active than larger-sized particles of the same chemical composition, which offer numerous perspectives for functional food applications [1]. Nanotechnology has the potential to address many of the food industry requirements, and it is expected that nanotechnology-derived food products will be increasingly available to consumers worldwide in the coming future. According to the European Food Safety Authority (EFSA) Nanomaterials is “any form of a material that has one or more dimensions in the nanoscale”, however, nanoparticle is “a discrete entity that has all three dimensions in the nanoscale” [2]. Food safety is a prime concern of human life, it is a serious and persistent public health issue, there is further intensified by inappropriate hygiene, wrong food handling practices, and contaminated food supplies, leading to a financial burden of foodborne disease (FBD). Increase global food companies lead to more attention to food quality during various stages of the agri-food supply chain. Nanotechnology plays a main role in all steps of the food production chain, from the field until the end-user to achieve enhanced functionality, there are various benefits for nanotechnology in food industries like increase agricultural production, improve food quality through proper management of handing out and packaging in food production facilities, enhancing functional of various additive like food ingredients as an encapsulated nanomaterials, nanotechnology could reduce contaminants and pathogens and detecting change in food by Nanosensor, also, there is important role of nanotechnology in the food-packaging sector which has great potential in the application of nanomaterials to decrease food contamination, reduce food spoilage and other issues during food processing by using various segments of nanotechnology, in general, this work concerns the use of nanotechnology in the food processing sector

Nanotechnology and Food Processing

Nanotechnology made the food safety diagnostics field easier, now there are possibilities to enhance the resolution of sample preparation and downstream by using nanomaterials with unique properties. Nanotechnology has a wide range of food-related applications, some of these applications used to integrate a specific type of nanomaterials like food ingredients into the food product to develop certain desired properties of food products. Various reports confirm that these nanomaterials can effectively enhance food safety by improving the efficacy of food packaging, extend shelf-life, and nutritional value as additives without altering the taste or physical properties of food products [3]. There are different applications of nanomaterials in agro-food sector aim to enhancing food quality including:

I. Detection of crop pesticides (Nanosensor).

II. Reduce the quantity of traditional fertilizers (Nano fertilizers).

III. Reduce microbial pathogens or allergens contamination (Nano pesticide).

IV. Minimize food spoilage.

V. Extend food shelf life.

VI. Food packaging (nanoscale fillers).

Currently, there are different commercially Nanotechnologybased food and health food products, and food packaging materials available in the global market particularly in USA, EU Japan, and China. Nanofood: According to Tiju and Morrison (2009) [4] nano food is that food, processed, formed or packaged by using any nanotechnology techniques or tools. In addition, Nanostructure materials (NSMs) are being applied in the food industry as a nanosensor, nano ingredients, new packaging material, and encapsulated food component.

Nanotechnologies in the Food Industry

There are various nanomaterials and applications of nanotechnologies in agro-food sector (Figure 1), it increases food safety, enhances ingredients delivery and increase food life shelf, some of this application explains below:

a. Using Nanosized and Nano-encapsulated additives.

b. Food ingredients have been processed or formulated to form nanostructures

c. Engineered nanomaterials (ENMs) defined as “any material that is intentionally produced in the nanoscale to have specific properties or a specific composition” have been incorporated to develop improved, active, or intelligent materials for food packaging or in food contact materials (FCMs) or surfaces

d. Nanotechnology-based devices and materials have been used, e.g., for Nanofiltration (NF) and water treatment

e. Nano biosensors have been used for food safety and traceability and contaminant detection.

f. Applications of ENMs have been suggested for pesticides, veterinary drugs, and other agrochemicals to improve food production systems [5,6].

Nanosensor

Nanosensor is any sensor lesser than 100 nm, Nanosensors offer several and speedy analysis that is vital for the detection of contaminants in food products, particularly in perishable commodities, Nanosensors provide advanced solution to detect food contaminants addressing a critical component of a complex public health issue of food safety due to their accuracy and size which considered the main advantage of nanosensor compare to traditional ways. There is a great potential for using Nanosensor in the food industry which can play a vital role to maintain food chain from the field to table. In the farm, the nanosensor used to notice drought and nutrient deficiency in the soil, and the excessive use of fertilizers to reduce residual materials in food and decrease the environmental pollution. Nanosensor divided to Chemical sensors and biosensors [7], chemical sensor uses chemical or bacterial detector (reagents) on the probe to targeted chemical element; however, biological sensor targeted microorganisms like bacteria causes a change on the nanosensor [8]. There are different forms of nanosensor used for detecting food spoilage like electronic nose or electronic tongue, these sensors used for detecting chemicals released during spoilage of food, these nanosensor are placed in direct contact with the packaging materials to detect changes in food color or smell, also, nanosensor could use to indicate the weather or the improper storage condition. There are different benefits for the usage of Nanosensors in food processing like improve food properties, extend shelf life, and preserve freshness and quality, and regulating the path of releasing gases and moisture through the packaging material.

Nanosensors and Food Processing

There is different usage for nanosensor in food processing, it is work in external conditions and internal conditions as follow:

a. Detection of gasses change around the food package (external conditions)

b. Measuring the change in the inner atmosphere of the package (internal condition) like Detection of high oxygen levels in the package which could strap or breaking the whole package.

c. Detecting microorganisms activates and bacterial infection inside the package (internal condition).

d. Enhance food safety and extend food products shelf life by detection of chemical change in food (internal condition).

Food-Packaging Sector

Nanotechnology has a crucial role in this sector, nanoparticles improve mechanical properties of package materials, therefore, there are many changes in the food-packaging sector, such as usage of nanoscale fillers which extend food shelf life and preservation freshness and quality through reducing accelerating of different spoilage factors. Smart packaging considered a practical application for nanotechnology in the food processing sector, this packaging containing nanosensor that detects contamination and spoilage by reacting with the physical or chemical change in food in the packaging. There are more than 400–500 nanofood packaging applications available in the global market [6].

Nanomaterials for Packaging

There is different materials use during smart packaging production by using various nanocomposites materials comprising polymers nano polymer reinforced in the nanofillers (Nanoclays, Nanonylons, Nano Carbon Tubes,, and cellulose microfibrils) [9] this composite contain at least one dimension in nanosize (less than 100nm) [10], also, some nanomaterials like (chitosan, cellulose, and carrageenan) placed into the internal wall of packaging to increase mechanical stability of the package and reduce reaction of the package material with food product. In addition, other nanoparticles as Nano Silver, Nano Zinc oxide, NanoTitanium oxide, and Nano Silver oxide can be added to this material to implement the package antibacterial characteristics [11] as follow:

a. Nano silver: which inhibit the growth of aerobic psychrotrophic, yeasts, and molds; also, has an antimicrobial effect against Escherichia coli and Staphylococcus aureus, Nano silver used in the package of Asparagus, Orange juice, Poultry meat, Fresh-cut melon, Beef meat [12] .

b. Nano Silver oxide: used for Retarding microbial spoilage in Apple [13].

c. Nano Zinc oxide: used to keep quality characters of Orange juice by decrease activity of Lactobacillus plantarum, Salmonella, and yeast [14].

d. Nano Titanium oxide: delay ripening, senescence, and decay of Chinese jujube, Strawberry [15].

Some application of Nanotechnologies in Food processing

There are various applications of nanomaterials in the food processing sector, including nanosensors, packaging materials, and encapsulated food components. However, Nanostructured systems in food processing comprising polymeric nanoparticles, liposomes, nanoemulsions, and microemulsions. These applications of nanotechnology improve solubility, enhance the bioavailability, facilitate controlled release, and protect bioactive components during produce and storage of food products.

Nanosensors

Nanosensors offer numerous and prompt analysis that is essential for the detection of contaminants in food products, mainly in fresh products, there are Chemical sensors and biosensors, also, there are various forms of nanosensor such as electronic nose or electronic tongue, Nanosensors provide different benefits in food processing (e.g. enhance food properties, extend shelf life, and conserve freshness and quality of perishable products).

Smart Package

Usage of nanosensors in food packaging will result in so-called “smart materials”. This kind of food package could detect unsafe bacteria in the product (e.g. salmonella) and change the color of a package (marking that the food product in question is not safe for consumption). Detection of a chemical element within the package is also possible, so in that way it is possible to detect a high concentration of oxygen which is the cause of package strapping or breaking Production of nano polymer plastics which are very thick on the nano-scale is developing today [16,17].

Nanofrying

There is a new catalytic device for frying oil for use in restaurant deep-frying machines, this product decrease quantity of oil use by half approximately, because of its wide surface area [4], as well, this device preserves oil fresh for a longer time than traditional frying machine, in the same time, in addition, the fried food with this device enhancing food taste, reduce costs and improve profits, also, various health benefits besides protecting the environment [18].

Edible Nanocoatings

These nanocoating used in encapsulating different hydrophilic or amphiphilic materials, the nanolaminate consists of two or more layers of nanomaterial (usually 5nm) bonded to each other physically or chemically.

Nanoencapsulation of Edible Supplements

Nanoencapsulation is the produce coating materials at nanoscale, it provides final product functionality that comprises controlled release of the core. There are numerous advantages of encapsulated forms of ingredients, which include extending shelf life, better stability, regular delivery of multiple active ingredients, and pH-triggered controlled release [19].

Food Processing Equipment

According to (Baruah and Dutta 2009 & Pehanich, 2006) [20,21] there is a new nanoinsulate PT for coating dairy processing pipes and tanks for decrease operation cost and extend shelf life, also, Nanosilver has been used as coating for the inner surface in refrigerators to avoid microbial infection and provide hygienic environment into the fridge.

Conclusion

Nanotechnology opens more challenges for the agro-food sector to use new systems has able of treated with different hazards due to unique properties of Nanomaterials, which present numerous perspectives for functional food applications to make the food safety diagnostics field easier, there are different Nanostructures in Food Processing Sector comprise materials (e.g. Nanocomposites, Polymeric nanoparticles, Liposomes, and Nanoemulsion), as well, there are various application of nanostructures include Nanosensor, smart Package, Nanocoatings, Encapsulation, and Nanofrying. Nanosensor could play important role in food processing, it is work both in external and internal conditions. Different applications of nanomaterials in agro-food sector (like Nanoscale fillers, smart Package, Nanocoatings, Encapsulation, and Nanofrying) aim to improving food quality, moreover, there are nanomaterials used for coating the inner surface in different devices to avoiding microbial infection and improving hygienic environment and decrease the cost.

References

- Waleed Fouad Abobatta WF (2018) Nanotechnology Application in Agriculture. Acta Scientific Agriculture 2(6): 99-102.

- (2010) FAO/WHO Meeting report.

- Liu S, Yuan L, Yue X, Zheng Z, Zhiyong T (2008) Recent Advances in Nanosensors for Organophosphate Pesticide Detection. Advanced Powder Technology 19(5): 419-441.

- Tiju J, Morrison M (2006) Nanotechnology in Agriculture and Food 2006, Nanoforum report.

- Chaudhry Q, Scotter J, Blackburn M, Ross B, Boxall A, et al. (2008) Applications and implications of nanotechnologies for the food sector. Food Addit Contam 25(3): 241-258.

- Momin JK, Jayakumar C, Prajapati JB (2013) Potential of nanotechnology in functional foods. Emirates J Food Agricult 25(1): 10-19.

- Kampers F (2008) Nanotechnologies for Food, Proceedings of the Nanotech Northern Europe 2008 conference, Copenhagen, Danmark.

- Cullum BM, Vo Dinh T (2000) The Development of Optical Nanosensors for Biological Measurements. Trends in Biotechnology 18(9): 388-393.

- Rao J, McClements DJ (2011) Formation of flavor oil microemulsions, nanoemulsions and emulsions: influence of composition and preparation method. J Agric Food Chem 59(9): 5026-5035.

- Bastarrachea L, Dhawan S, Sablani SS (2011) Engineering properties of polymeric-based antimicrobial films for food packaging: a review. Food Eng Rev 3(2): 79-93.

- Bajpai VK, Kamle M, Shukla S, Mahato DK, Chandra P, et al. (2018) Prospects of using nanotechnology for food preservation, safety, and security. Journal of food and drug analysis 26(4): 1201- 1214.

- Fernandez A, Picouet P, Lioret E (2010) Cellulose-silver nanoparticle hybrid materials to control spoilage-related microflora in absorbent pads located in trays of fresh-cut melon. Int J Food Microbiol 142(1- 2): 222-228.

- Zhou L, Lv S, He G, He Q, Shi BI (2011) Effect of PE/AG2O nanopackaging on the quality of apple slices. J Food Qual 34(3): 171-176.

- Emamifar A, Kadivar M, Shahedi M, Soleimanian-Zad S (2011) Effect of nanocomposite packaging containing Ag and ZnO on inactivation of Lactobacillus plantarum in orange juice. Food Control 22(3-4): 408- 413.

- Li H, Li F, Wang L, Sheng J, Xin Z, et al. (2009) Effect of nano-packing on preservation quality of Chinese jujube (Ziziphus jujuba Mill. var. inermis (Bunge) Rehd). Food Chem 114(2): 547-552.

- He X, Hwang HM (2016) Nanotechnology in food science: functionality, applicability, and safety assessment. J Food Drug Anal 24(4): 671-681.

- De Azeredo HMC (2009) Nanocomposites for Food Packaging Applications. Food Research International 42(9): 1240-1253.

- (2006) Nanotechnology powered Oil Fresh entering Restaurant & Foodservice Industry. Sonny Oh, CEO, Oilfresh Corporation, Sunnyvale, CA, USA.

- Surassmo S, Min SG, Bejrapha P, Choi MJ (2010) Effects of surfactants on the physical properties of capsicum-oleoresin loaded nanocapsules formulated through the emulsion-diffusion method. Food Research Int 43(1): 8-17.

- Baurah S, Dutta J (2009) Nanotechnology applications in pollution sensing and degradation in agriculture: a review. Environ Chem Lett 7: 191-204.

- Pehanich M (2006) Small gains in processing, packaging. Food Processing, p. 46-48.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...