Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-6660

Short Communication(ISSN: 2637-6660)

Disclosure of the Generation and Accumulation of the Hydrogen in Steel and Graphite Irradiated by Neutrons in Inert Environment Volume 2 - Issue 2

Krasikov E*

- National Research Centre, Kurchatov Institute, Moscow, Russia

Received: November 6, 2019; Published: November 25, 2019

*Corresponding author: Krasikov E, National Research Centre, Kurchatov Institute, Moscow, Russia

DOI: 10.32474/ANOAJ.2019.02.000132

Keywords: Hydrogen; Generation; Accumulation; Steel; Graphite; Irradiation; Environment

Introduction

It is known that in traditional power engineering hydrogen may be one of the first primary source of equipment damage [1]. This problem has high actuality for both nuclear and thermonuclear power engineering [2]. Particularly reactor pressure vessels (RPV) of the WWER-440/230 project was manufactured without stainless cladding that were in contact with primary circuit water and accessible for hydrogen as a product of RPV wall corrosion. Analysis of the combined radiation-hydrogenation embrittlement of the 48TS type vessel steel was performed in [3] where at the mention of the American [4] and own data question concerning unknown source of hydrogen in metal that was irradiated in nuclear reactor in hermetic ampoules (was named as “irradiation-produced hydrogen” (IPH) was raised.

Materials and Methods

(Table 1) lists chemical composition of the RPV steel used (48TS type). A-543 type US steel takes for comparison.

4% solution of H2SO4 was used for additional electrolytic hydrogenation of the specimens (current density 0,1A/cm2). Hydrogen concentration was determined by thermal degassing method at temperatures up to 1000°C with gas chromatograph (thermal conductivity detector) registration of gas released.

Experimental Results and Discussion

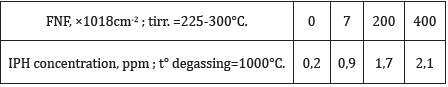

Determination of the hydrogen content in the irradiated steel fulfilled in the USA went to unexpected result: hydrogen content noticeably exceeded the quantity rated at (n, p) transmutation reaction: less than 0,1 ppm. Results of the IPH concentration in steel analysis carried out in the USA are shown in (Table 2) [4]. One can see that the greater the fast neutron fluence (FNF) the greater the hydrogen content. Ageing of the steel at 100-325°C during 48 hours revealed that IPH is not diffusible up to irradiation temperature that is IRH are in the irradiation produced traps. Inasmuch as IPH at temperatures of mechanical tests was immovable indicated values were subtracted from total quantity of hydrogen measured.

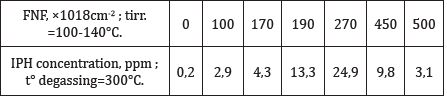

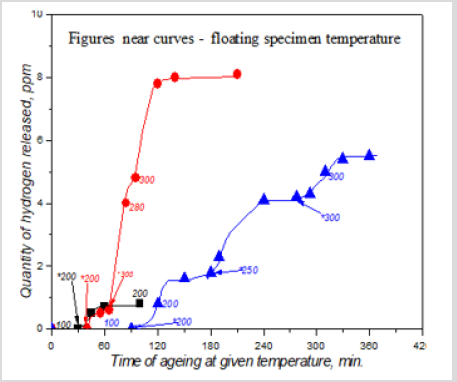

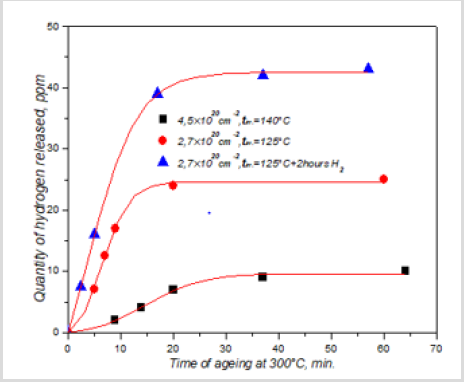

In I.V. Kurchatov Institute at several experiments was determined that steel specimens irradiated at relatively low (100- 140°C) temperatures in sealed Ar contained ampoules hydrogen content was many times higher relatively initial content but was independent on FNF (Table 3) [3]. Degassing kinetics are plotted in Figures 1&2. As one can see from Figure 1 that RIH discharge starts when heating temperature exceeds the irradiation temperature. It means that RIH is accumulated in radiation defects (traps). Rather later data appear on unexpectedly high hydrogen concentrations in stainless steels irradiated in BWR type reactors [5] and high generations of hydrogen and helium in nickel [6]. Surprisingly high hydrogen concentrations were revealed in irradiated graphite [7].

Conclusion

It is necessary to look for enigmatic source of hydrogen especially because in frame of inspections numerous flows were detected in the forged rings of the reactor pressure vessels in the Belgian nuclear power plants [8]. The owner Electrabel claimed that flaws were “most likely” hydrogen flakes. One of the unobvious but probable initial hypothesis on enigmatic source of the hydrogen in operating nuclear reactor is generation of protons as a product of beta-decay of free neutrons (lifetime ~15 min.) [9].

References

- Vainman A (1990) Hydrogen Embrittlement of the High-Pressure Vessels. Kiev Naukova Dumka.

- Nikolaev VA, Gorynin I, Alekseenko NN, Amaev AM (1997) Radiation Damage of Nuclear Power Plant Pressure Vessel Steels ANS pp. 282.

- Krasikov E (1974) Investigation of Hydrogen Embrittlement and Hydrogen Diffusion in Irradiated Steel. SciFed Materials Research Letters 1(1): 1-2.

- Brinkmann C (1970) Effects of Hydrogen on the Ductile Properties of Irradiated Pressure Vessel Steels. Report IN-1359, NRTS, Idaho Falls p.64.

- Jacobs AI (1987) Hydrogen Buildup in Irradiated Type-304 Stainless Steel. ASTM STP 956. Garner FA and Igata N (Eds.) ASTM Philadelphia pp. 239-244.

- Greenwood L, Garner F, Oliver D (2004) Surprisingly Large Generation and Retention of Helium and Hydrogen in Pure Nickel. Journal of ASTM International 1(4): 529-539.

- Biriukov A, Krasikov E (1998) Impact of Neutron Irradiation on Graphite Dehydrogenations. VANT ser. Thermonuclear Fusion 1(2): 3-8.

- Tweer I (2016) Flawed Reactor Pressure Vessels in the Belgian NPPS Doel 3 and Tihange 2, Comments on the FANC 2015 Final Evaluation Report 1-42.

- Mostoyoi Yu (1996) Neutron Yesterday, Today, Tomorrow. Successes of Physics (UFN).

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...