Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4668

Research article(ISSN: 2637-4668)

REVERS-ABILITY. Towards Changeable Digital Light Timber Frame Constructions Volume 4 - Issue 2

Luigi Alini*, Miriam Pappalardo, Paolo Di Prima and Rossella Maria Carlotta Pisano

- Department of Civil Engineering and Architecture, University of Catania, Italy

Received:April 9, 2021 Published: April 22, 2021

Corresponding author:Luigi Alini, Department of Civil Engineering and Architecture, University of Catania, Italy

DOI: 10.32474/TCEIA.2021.04.000184

Abstract

The last twenty years have seen, especially for residential buildings, the development and prototyping of several digitally manufactured light timber frame construction systems, that take advantage of digital fabrication techniques for the entire construction process, from design to construction. Today, there is a pressing need to provide spatial configurations that let users modify the internal distribution according to the changing of their needs over time. Following this research path, the proposed work aims to verify the degree of changeability and reversibility of these systems. These systems are compared in relation to the specific construction solutions adopted, the fabrication and assembly process used, the amount and variety of variables that affect the project workflow and other parameters. The results converge in a table that highlights the advantageous and the negative aspects which facilitate or affect the assembly - disassembly process and the flexibility of the systems to meet the changing needs of users.

Keywords:Digital Fabrication; Plywood Constructions; Constructive Flexibility

Background

In the light of the environmental challenges that architecture is facing, wood is no longer considered antiquated and nostalgic, but increasingly recognized as one of the most promising building materials for the future (Menges et al., [1]). Current climate objectives tend to reduce the negative impact of buildings or at most aim for a “neutral” energy balance, but it is becoming clear that buildings must go beyond reducing environmental impact and have positive environmental effects (Naboni and Havinga, [2]).

Therefore, the urgency to reduce the waste of energy and resources in the world of AEC and to design buildings that become part of the solutions to climate change, has made the use of wood current again. The world architectural panorama is full of examples that show the potential of combining contemporary production processes with an ancient and traditional material such as wood. Is a fact that technologically advanced wood-based materials have amplified the spectrum of possible applications for timber constructions. (Hudert and Pfeiffer, 2019). Equally, fundamental contribution was given by digital design, simulation and fabrication. Digital fabrication (Dunn, [3]) is not a new phenomenon ,as CAD and CAM processes have been used in engineering and industrial sector since the second half of 20th century. What is recent is its application in architecture. The possibility of translating with fluidity from the design generation to the construction, through a continuous prototyping and fabrication, “has precipitated a transformation in design disciplines, as it allows the designer to engage with the entire process from concept to final product in an unprecedented manner” (ibidem, 2012).

As Iwamoto (2009) explains, “Architects have been drawing digitally for nearly thirty years. CAD programs have made two dimensional drawing efficient, easy to edit, and, with a little practice, simple to do. Yet for many years, as the process of making steadily shifted from being analog to digital, the design of buildings did not really reflect the change. CAD replaced drawing with a parallel rule and lead pointer, but buildings looked pretty much the same. This is perhaps not so surprising - one form of two-dimensional representation simply replaced another. It took three- dimensionalcomputer modelling and digital fabrication to energize design thinking and expand the boundaries of architectural form and construction.”

The work of leading European research groups,as the Gramazio Kohler Research, ETH Zürich, Switzerland, the IBOIS Laboratory for Timber Construction, EPFL, Switzerland and the Institute for Computational Design, University of Stuttgart, Germany, in computational design and digital fabrication has increasingly shifted the advancements of timber construction in architecture (Menges et al., [1]).

Digital Light Timber Frame Constructions Within this framework, since the beginning of 21st century, have been developed CNC-milled timber frame construction systems, especially for residential buildings. Using the technologies of industrial production has opened a new, increasingly widespread, “field of action” which also affects residential architecture. These innovative construction systems exploit the potential of engineered wood, especially thin-laminated panels, including plywood and LVL (Laminated Veneer Lumber), and the industrial processing to obtain building “products” quickly, efficiently and inexpensively, but with design and construction quality equal to more traditional systems.

The design outcomes and the constructive solutions adopted are various, as well as the motivations behind these experimentations and the objectives that each one has set. In the case of Wiki House project (Wiki House, 2021), literally an open- source building system, the concept of “personal fabrication” (Gershenfeld, [4]) is taken to extremes. Applying the open-source logic also to buildings, architecture becomes a resource accessible to a community that shares information and design solutions. Each user can customize the project in relation to his specific needs and conditions, even to being able to “self-produce” his own home (Parvin, [5]). The sharing community is the focus. As Parvin affirms (Zara [6]), “You design to solve the problem where you are and then share the solution. Share globally, build locally”. Besides, he explains (Parvin, [7]) “In the last two decades the web has transformed our economy and society. In the next it will also transform the way we produce and understand our built environment”, underling the transition from what is known as the Third Industrial Revolution (Naboni and Paoletti, [8]) to the fourth or “Industry 4.0”.From another point of view, Facit Homes project (Facit Homes, 2021) proposes a system that, unlike existing prefabricated housing models, allows each project to be entirely tailored to the end user, maintaining a more traditional client / architect relationship. The company represents the customer’s sole interlocutor, managing the entire design, production and construction process internally and bringing together all the skills. Each project is driven by site, environmental conditions and local planning requirements, rather than based on standard “types” or customizable templates. Parametric design, Building Information Modelling (BIM) and digital fabrication are some of the tools that allowed this tailored approach, the working methodology that Facit calls the „D-Process‟.(Bell and Simpkin, 2013).

One of the first experimentation, the Instant House project (Botha and Sass 2006) aims to create customized accommodations with a variety of design for communities in emergency, quickly produced with CNC machinesand a traditional construction material as wood (Sass and Botha, [9]). A different approach led to the development of Veneer Home (Veneer House, 2021). This project intends to provide an alternative and innovative way of rebuilding in the wake of natural disasters, with the facility of transportation of engineered wood products, the application of ancient knowledge in wood carpentry, and the advantages of digital fabrication (Kobayashi and O‟Keefe, [10]).

Materials and Methods

The digital prefabrication does not imply homogenization and standardization. As Boarin states, “Despite prefabrication principles, building design continues to be customized: structural components are prefabricated but the project does not become standardized” (Boarin et al., [11]). Furthermore, the digital processes allow to take into account and to control all those parameters that confer peculiarity and uniqueness to each project (Bell, Naboni and Paoletti, [8]). So key concepts in architecture come into play, such as adaptability and flexibility. According to Schneider and Till, flexibility “can be defined as housing that is designed for choice at the design stage (…) or designed for change over its lifetime. (…) The degree of flexibility is determined in two ways. First the inbuilt opportunity for adaptability, defined as „capable of different social uses‟, and second the opportunity for flexibility, defined as „capable of different physical arrangements‟” (Schneider and Till, 2005). This is related to the fact that today, there is a pressing need to provide spatial configurations that let users modify the internal distribution according to the changing of their needs over time: “If one considers the rapid changes happening in the world today in terms of lifestyles, housing forms, and demographics (…) then it is clear that inflexible housing layouts are not sustainable in the long term” (Drexler, [12]). On the other hand, adaptability refers to the concepts of personalization, that is a tailored project based on the user requirements, and of customization, if is the user to modify something to suit a particular need. The theme is not new, as the work of Walter Segal shows (Brome [13]; Schneider and Till, [14];Parvin [5]), however is back current (Drexler, 2019). Another important factor is the concept of assembly and disassembly, which impact the degree of flexibility of a construction system. As declared in the The DfMA Housing Manual, “Breaking the product into modular components (…) allows the work to be done in stages, with more complex, standardized, precise work done by machines and assembly teams in advance in factory conditions, where the product can be checked for quality. The parts can then be rapidly assembled” (Open System Lab [15]). The building is designed for assembly and disassembly.

Following the mentioned research path, the proposed work intends to evaluate the degree of changeability and reversibility of some digitally fabricated timber construction systems and to evaluate how much the systems mentioned above allow to modify the interior layout configurations, not only in the design phase, but also in the operational phase. A wide-ranging survey of the systems and prototypes developed by academic research centres, professional firms and non-profit R&D laboratories has been conducted. Is reported the cases of Instant House, one of the first systems, developed in 2005 by Marcel Botha, Lawrence D. Sass at the Department of Architecture, Massachusetts Institute of Technology (Sass and Botha, [9]). Among the other systems, are mentioned: Facit Home, by Facit Homes (2007, UK) and its danish version, by Een Til Een (2011, DK); Click-Raft, by CMA+U (2008, NZ); Wiki House, by Open Systems Lab (2011, UK); its branches developed in other countries, as Wiki House NZ (2012, NZ) and Wiki House NL (2011, NL); U-Build, by Studio Bark (2011, UK).

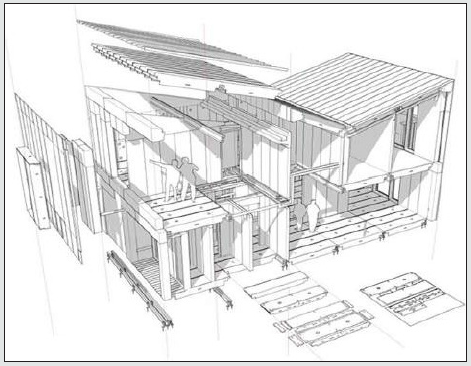

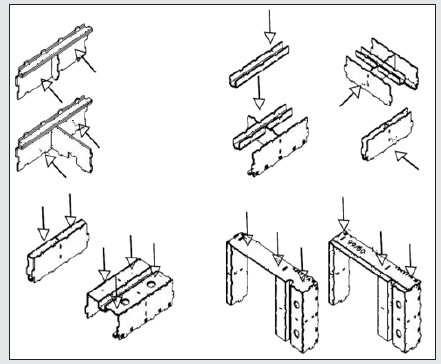

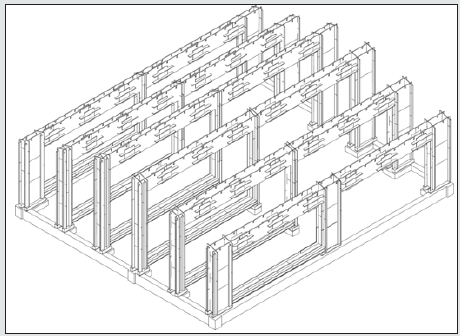

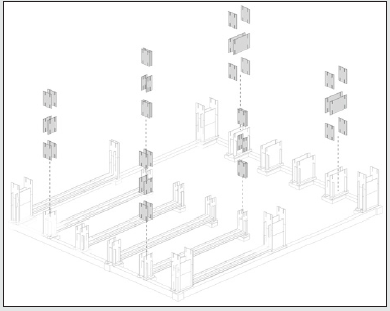

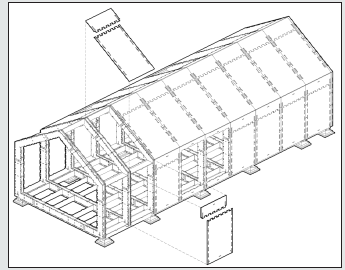

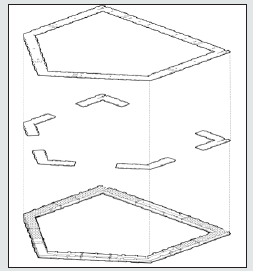

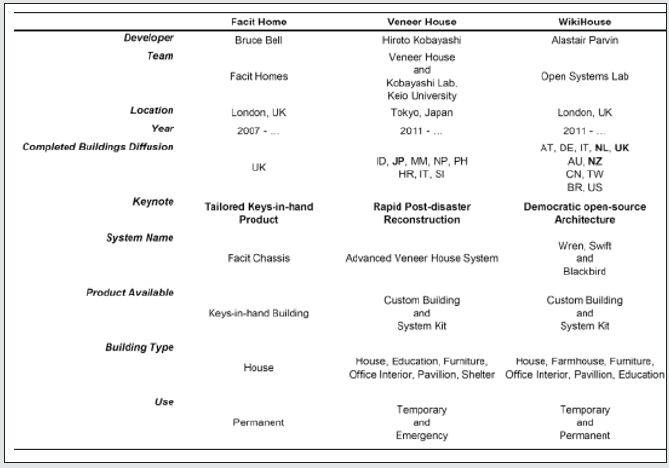

Then, three case studies are selected, for the different system typologies, contests and aims that they represent. They are, in alphabetical order: Facit Home, see Figures 1a - 1b, Veneer House ,see Figures 2a - 2b, and Wiki House, see Figures 3a - 3b. Comparison and assessment

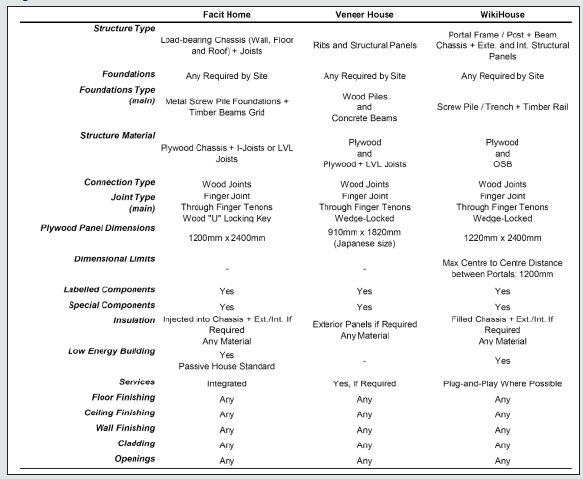

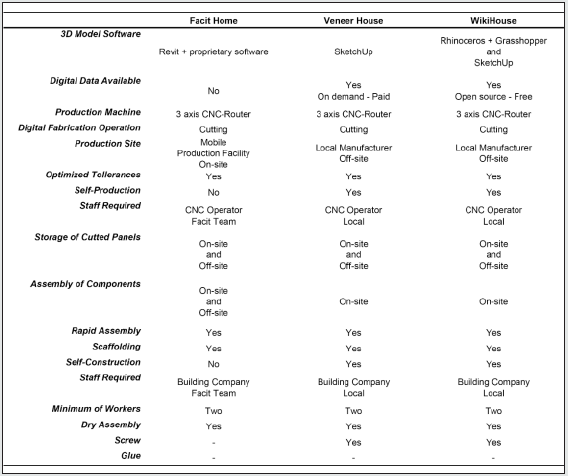

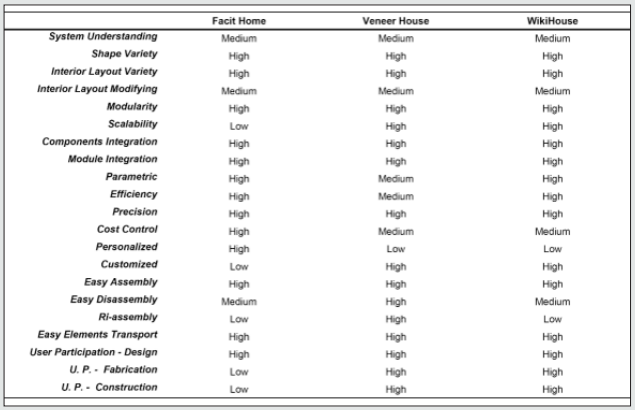

These systems are compared in relation to the specific construction solutions adopted, the fabrication and assembly process used, the amount and variety of variables that affect the project workflow and other parameters. Data are deduced from publications, company’s websites, interviews, architecture web journals, conference talks. At first, general data are given, in order to contextualize the systems, for team that designed them, location in which they are developed and countries where they are built. In addition, a keynote for each is underlined, as to rapidly understand the core of each, see Table 1. Subsequently, each construction system is deeply analyzed on the basis of technological and structural aspects, materials, type of connections and all those parameters that let understand the breakdown of each construction. Besides, are presented data referring to all kind of building components that are possible or not to implement with the structure, for comprehending which are the alternatives possible and what is the grade of integration and flexibility, see Table 2.

The further step is to compare the technologies from the point of view of the production and construction and for all those aspects related to the digital fabrication process: software and machine used, staff required for production and for assembly, storage of milled elements, fabrication and construction site. Besides, are considered those parameters that affects the assembly process, see Table 3. Finally, an assessment is presented for evaluating the grade of flexibility and adaptability of these innovative technologies: referring to the realized projects and reported cases, a greater or lesser degree is expressed according to the correspondence to a given property, see Table 4.

Results and Conclusion

The results converge in a table that highlights the advantageous and the negative aspects which facilitate or affect system disassembly, so that the individual construction elements can be moved or replaced locally without involving interventions on large portions of the building. A result that the analysis shows is that the Facit system is configured as the most personalized one, precisely because it is designed as a product of industrial craft, truly tailored to the user. It is efficient, sustainable; everything is controlled and integrated to contain costs, reduce time and avoid unexpected errors. On the other hand, being tailored to a specific user, it is not suited for changes in the long term. Another observation is that the more the system is complex, the more special pieces are needed; therefore, the greater the customization that determines this complexity, the less easy it will be to collect or replace the pieces after a possible disassembly (Kobayashi [16,10]. In closing, the case studies analyzed show a high degree of adaptability, which lies in their extreme ability to respond to multiple parameters, to the most various needs of users and to different site conditions: this adaptability must, however, be understood in the sense of “designed for choice at the design stage” (Schneider and Till, [14]). Reporting what Kobayashi claims, as this “technology continues to develop, the quantity and variety of its potential applications grows apace[17-25]. The agility of the technology helps it to adapt and grow along with the changing demand and conditions we have come to expect” (Kobayashi [10]).

References

- Menges A, Schwinn T and Krieg OD( 2016) ‟Advancing Wood Architecture: An introduction‟, in Menges A, Schwinn, T, Krieg OD (eds) (2016) Advancing Wood Architecture: A Computational Approach, Routledge pp. 1-10.

- Naboni E, Havinga L (2019) Regenerative design indigital practice. A handbook for the built environment, Eurac Research.

- Dunn N (2012) Digital Fabrication in Architecture, Laurence King Pub, London.

- Gershenfeld NA (2005) Fab: The Coming Revolution on Your Desktop–from Personal Computers to Personal Fabrication, Basic Books.

- Parvin A (2013) ‟Architecture (and the other 99%): Open-Source Architecture and Design Commons‟, Architectural Design 83(6): pp. 90-95.

- Zara J (2019) ‟Free: Download a Construction Kit to BuildYour Own “WikiHouse”‟, Architizer Journal, 1, p: 1.

- Parvin A, Reeve A (2016) Scaling the Citizen Sector. A White Paper on the role of digital innovation in tacklingthe UK housing crisis, Medium.

- Naboni R, Paoletti I (2015), Advanced Customizationin Architectural Design and Construction, Springer International Publishing.

- Sass L, Botha M (2006) ‟The Instant House: A Model of Design Production with Digital Fabrication‟, International Journal of Architectural Computing 4(4): pp.109-123.

- Kobayashi H and O‟Keefe D (2019), ‟Empathic Architecture: Digital Fabrication and Community Participation”, in Biancone, F and Filippucci, M (eds) 2019, Digital Wood Design: Innovative Techniques of Representation in Architectural Design, Springer International Publishing, Cham, pp. 1063-1086.

- Boarin, P, Calzolari, M and Davoli, P (2018) ‟Two timber construction models: tradition without innovationor innovation without tradition?‟, TECHNE - Journal of Technology for Architecture and Environment 16: pp. 68-78.

- Drexler H (2019) ‟Press-Fit Timber Building Systems: Developing a Construction System for Flexible Housing Solutions‟, in Hudert, M and Pfeiffer, S (eds) 2019, Rethinking wood: future dimensions of timber assembly, Birkhäuser, Basel: pp. 100-115.

- Brome J (1986) ‟The Segal Method‟, The Architects,183(Special Issue): pp.31-68.

- Schneider T, Till J (2005) ‟Flexible housing: opportunities and limits‟,arq: Architectural Research Quarterly,9(2), pp. 157-166.

- Open Systems Lab CC (2019) The DfMA Housing Manual, Open Systems Lab.

- Kobayashi H (2014) VENEER HOUSE EXPERIENCE, Keio University Graduate School of Media and Governance.

- Alini, L (2011) “Materialità Digitale‟, Costruire in Laterizio, 141, pp. XIX-XXII Bell, B and Simpkin, S 2013, ‟Domesticating ParametricDesign‟,Architectural Design 83(2): 88-91.

- Botha, M and Sass, L 2006 ‟THE INSTANT HOUSE: Design and digital fabrication of housing for developing environments‟,CAADRIA 2006 [Proceedings of the 11thInternational Conference on Computer Aided Architectural Design Research in Asia] Kumamoto (Japan): pp.209-216.

- Hudert, M and Pfeiffer, S (eds) (2019) Rethinking wood: future dimensions of timber assembly, Birkhäuser, Basel Iwamoto, L 2009, Digital Fabrications: Architectural and Material Techniques, Princeton Architectural Press, New York.

- Kobayashi H (2017) ‟The Veneer House Experience: The R ole of Architects in Recovering Community After Disaster‟, in Yan, W and Galloway, W (eds) 2017, Rethinking Resilience, Adaptation and Transformation in a Time of Change, Springer International Publishing, Cham, pp. 365-385.

- Open Systems Lab, CC (2016), Micro House Assembly Manual, Open Systems Lab.

- Open Systems Lab, CC (2016b), Wiki House Into Process, Open Systems Lab Open Systems Lab, CC 2018, Using Wiki House. A introductoryguide for your project, Open Systems Lab.

- Parvin A, Saxby, D, Cerulli, C, Schneider, T (2011) a Right to Build: The next mass-housebuilding industry, Architecture 00:/ and University of Sheffield School of Architecture.

- Ruggiero R (2019) ‟Executive design and digital construction processes. A constructive experimentation between Italy and Japan‟, TECHNE - Journal of Technology for Architecture and Environment, 18: pp. 300-308.

- Till J, Schneider T (2005) ‟Flexible housing: the meansto the end‟, arq: Architectural Research Quarterly 9(3-4): pp. 287-296.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...